brake ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 391 of 6020

REAR SUSPENSION 3D-7

F03L100003

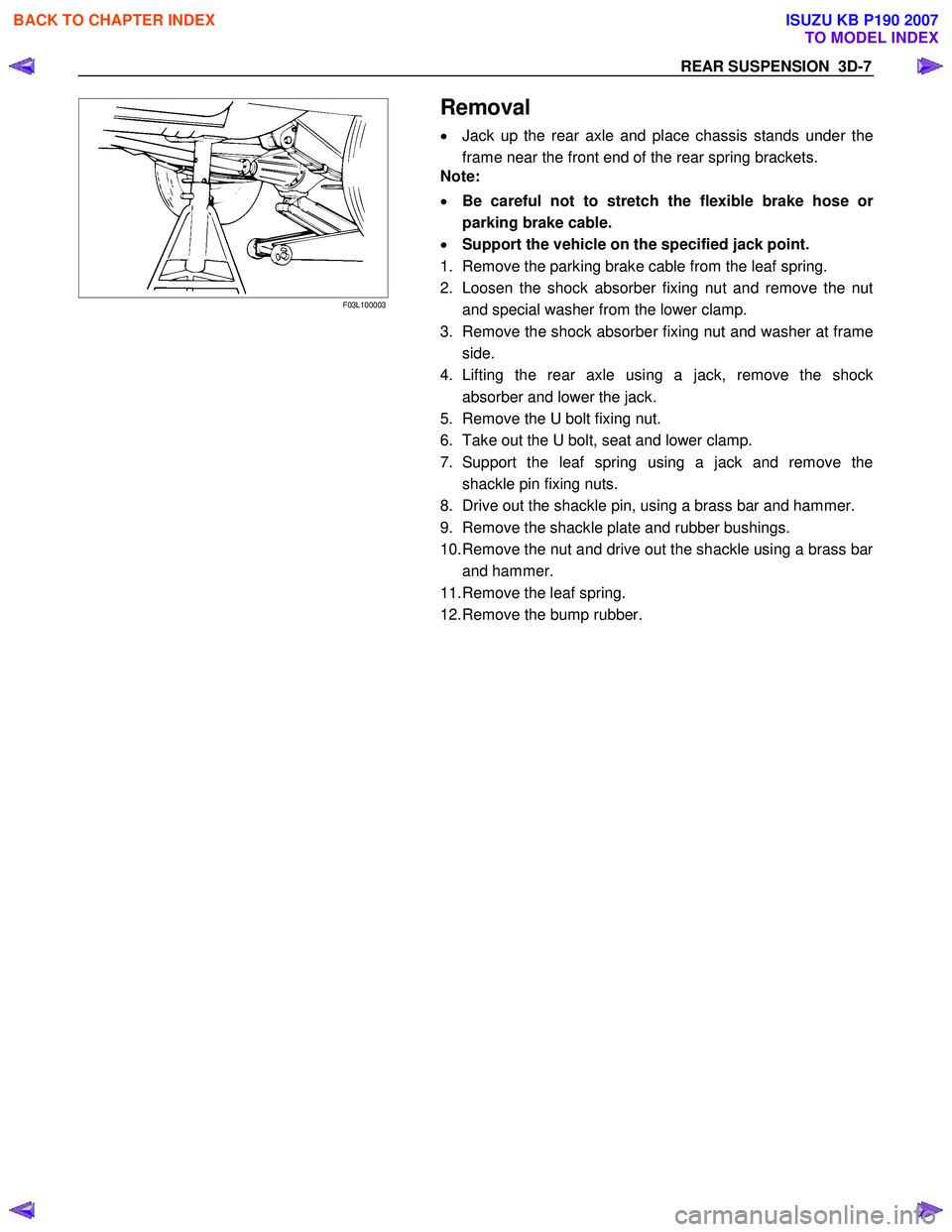

Removal

• Jack up the rear axle and place chassis stands under the

frame near the front end of the rear spring brackets.

Note:

• Be careful not to stretch the flexible brake hose o

r

parking brake cable.

• Support the vehicle on the specified jack point.

1. Remove the parking brake cable from the leaf spring.

2. Loosen the shock absorber fixing nut and remove the nut and special washer from the lower clamp.

3. Remove the shock absorber fixing nut and washer at frame

side.

4. Lifting the rear axle using a jack, remove the shock

absorber and lower the jack.

5. Remove the U bolt fixing nut.

6. Take out the U bolt, seat and lower clamp.

7. Support the leaf spring using a jack and remove the shackle pin fixing nuts.

8. Drive out the shackle pin, using a brass bar and hammer.

9. Remove the shackle plate and rubber bushings.

10. Remove the nut and drive out the shackle using a brass bar and hammer.

11. Remove the leaf spring.

12. Remove the bump rubber.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 394 of 6020

3D-10 REAR SUSPENSION

9. Install the parking brake cable on the leaf spring and

tighten the nut at its bracket.

Torque N ⋅m (kgf ⋅m/lb ⋅in)

7 (0.7/61)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 426 of 6020

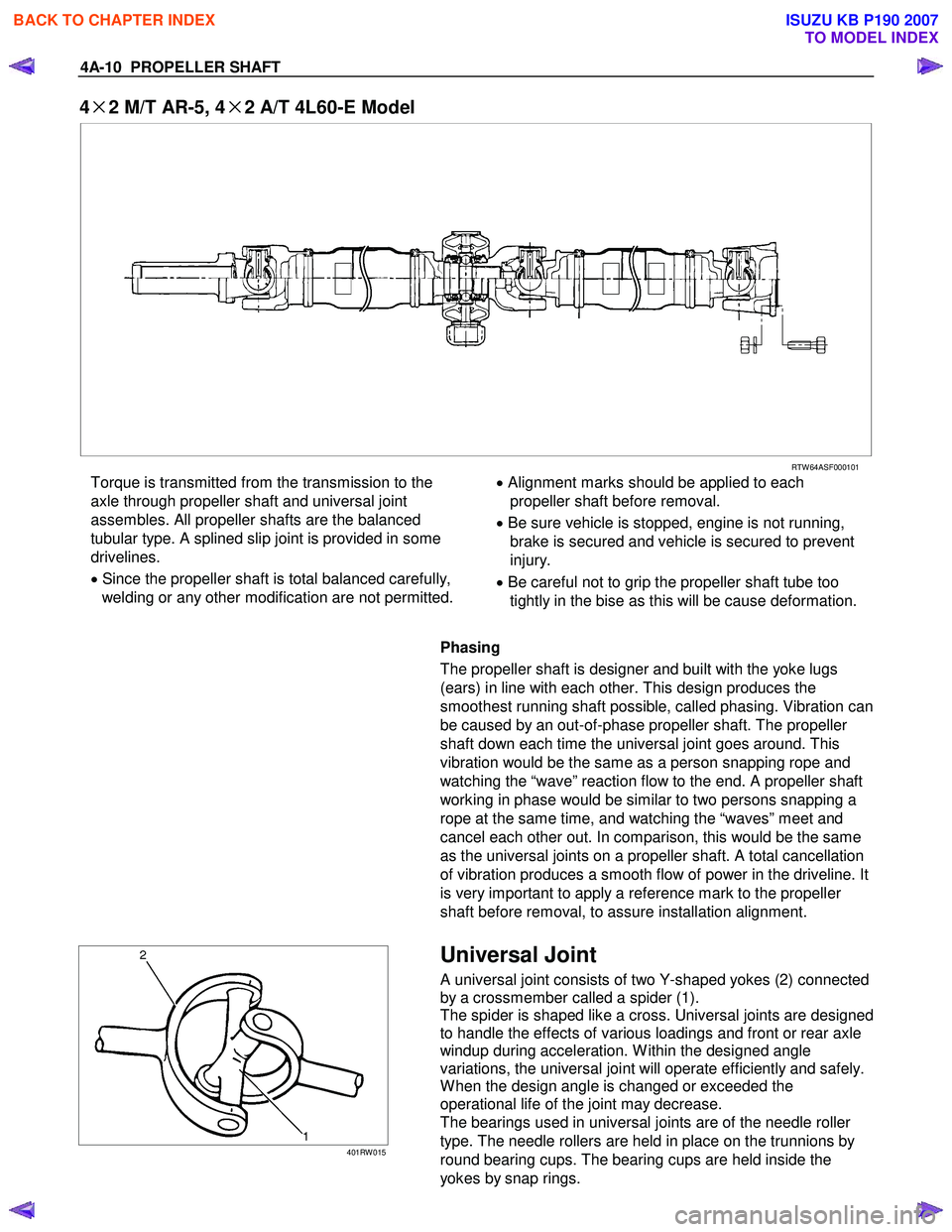

4A-10 PROPELLER SHAFT

4×

××

×

2 M/T AR-5, 4 ×

××

×

2 A/T 4L60-E Model

RTW 64ASF000101

Torque is transmitted from the transmission to the

axle through propeller shaft and universal joint

assembles. All propeller shafts are the balanced

tubular type. A splined slip joint is provided in some

drivelines.

• Since the propeller shaft is total balanced carefully,

welding or any other modification are not permitted.

•

Alignment marks should be applied to each

propeller shaft before removal.

• Be sure vehicle is stopped, engine is not running,

brake is secured and vehicle is secured to prevent

injury.

• Be careful not to grip the propeller shaft tube too

tightly in the bise as this will be cause deformation.

Phasing

The propeller shaft is designer and built with the yoke lugs

(ears) in line with each other. This design produces the

smoothest running shaft possible, called phasing. Vibration can

be caused by an out-of-phase propeller shaft. The propeller

shaft down each time the universal joint goes around. This

vibration would be the same as a person snapping rope and

watching the “wave” reaction flow to the end. A propeller shaft

working in phase would be similar to two persons snapping a

rope at the same time, and watching the “waves” meet and

cancel each other out. In comparison, this would be the same

as the universal joints on a propeller shaft. A total cancellation

of vibration produces a smooth flow of power in the driveline. It

is very important to apply a reference mark to the propeller

shaft before removal, to assure installation alignment.

401RW 015

Universal Joint

A universal joint consists of two Y-shaped yokes (2) connected

by a crossmember called a spider (1).

The spider is shaped like a cross. Universal joints are designed

to handle the effects of various loadings and front or rear axle

windup during acceleration. W ithin the designed angle

variations, the universal joint will operate efficiently and safely.

W hen the design angle is changed or exceeded the

operational life of the joint may decrease.

The bearings used in universal joints are of the needle roller

type. The needle rollers are held in place on the trunnions by

round bearing cups. The bearing cups are held inside the

yokes by snap rings.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 436 of 6020

4A-20 PROPELLER SHAFT

Front Propeller Shaft

Removal and Installation

RUW 54AMF000201

Legend

1. Bolt, Nut and W asher (Front Axle Side)

2. Front Propeller Shaft

3. Nut and W asher (Transfer Side)

401RS020

Removal

1. Jack up the vehicle and support it on the chassis stands.

2. Gear shift lever should be placed in neutral position and parking brake released.

3. Remove the exhaust and transfer protectors.

NOTE:

Apply alignment marks on the flange at the front propeller shaft

both front and rear side.

4. Remove bolt, nut and washer (Front axle side).

5. Remove bolt, nut and washer (Transfer side).

6. Remove front propeller shaft.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 452 of 6020

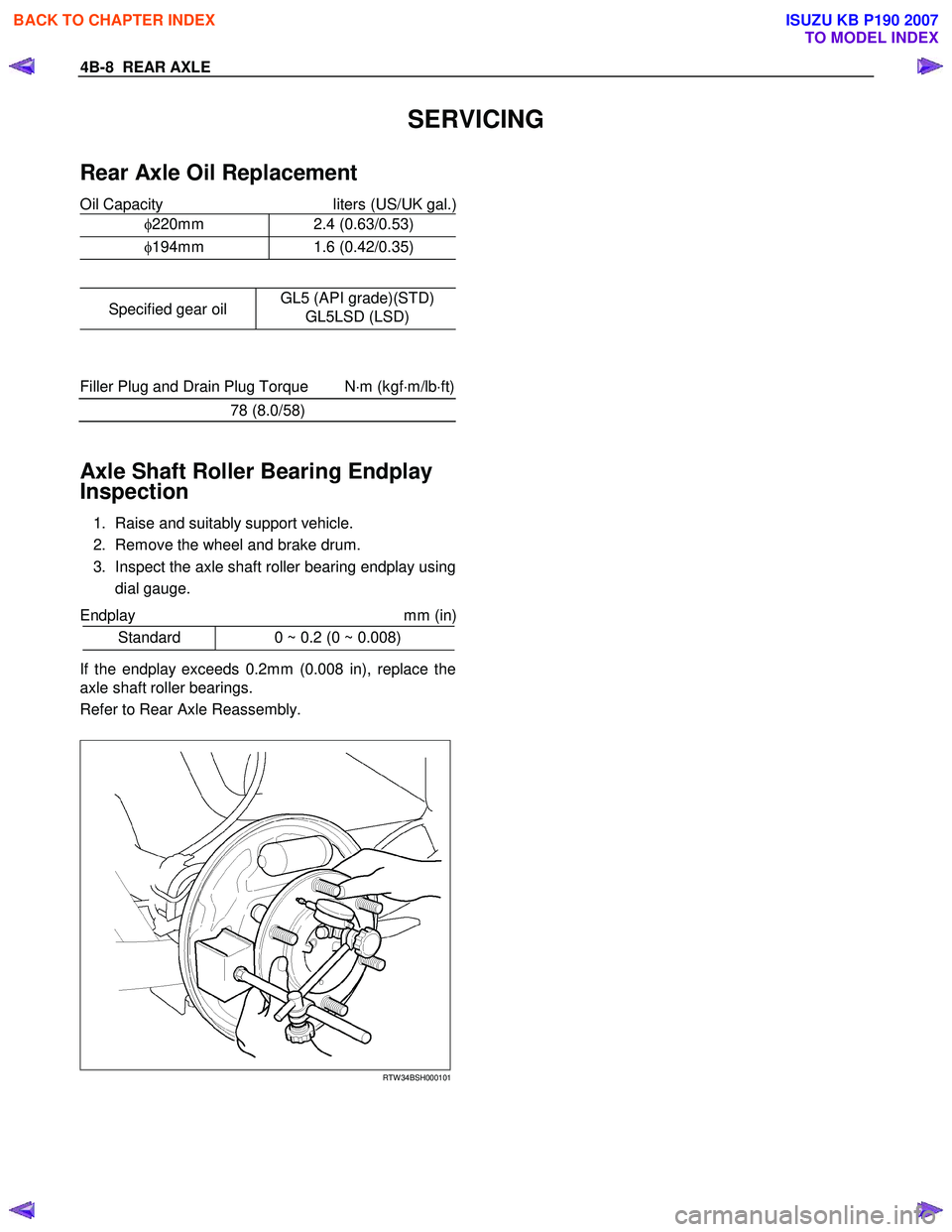

4B-8 REAR AXLE

SERVICING

Rear Axle Oil Replacement

Oil Capacity liters (US/UK gal.)

Specified gear oil GL5 (API grade)(STD)

GL5LSD (LSD)

φ220mm 2.4 (0.63/0.53)

φ194mm 1.6 (0.42/0.35)

Filler Plug and Drain Plug Torque N ⋅m (kgf ⋅m/lb ⋅ft)

78 (8.0/58)

Axle Shaft Roller Bearing Endplay

Inspection

1. Raise and suitably support vehicle.

2. Remove the wheel and brake drum.

3. Inspect the axle shaft roller bearing endplay using dial gauge.

Endplay mm (in

)

Standard 0 ~ 0.2 (0 ~ 0.008)

If the endplay exceeds 0.2mm (0.008 in), replace the

axle shaft roller bearings.

Refer to Rear Axle Reassembly.

RTW 34BSH000101

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 453 of 6020

REAR AXLE 4B-9

REAR AXLE

1. Refer to Section 3E “W HEELS and TIRES” for

road wheel Disassembly procedure.

2. Refer to Section 5 “BRAKE” for rear brake removal procedure.

RTW 54BLF000401

Legend

1. Brake Drum

2. Bolt and Nut

3. Axle Shaft Assembly with Brake

4. Shim

5. Snap Ring

6. Axle Shaft

7. Retainer (with ABS)

Retainer (without ABS)

8. Double Taper Roller Bearing

9. Oil Seal

10. Bearing Holder

11. Rear Brake

12. Bolt and Nut

13. Differential Assembly

14. Rear Axle Case Assembly

15. W heel Pin

16. Axle Case Oil Seal

17. Front

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 454 of 6020

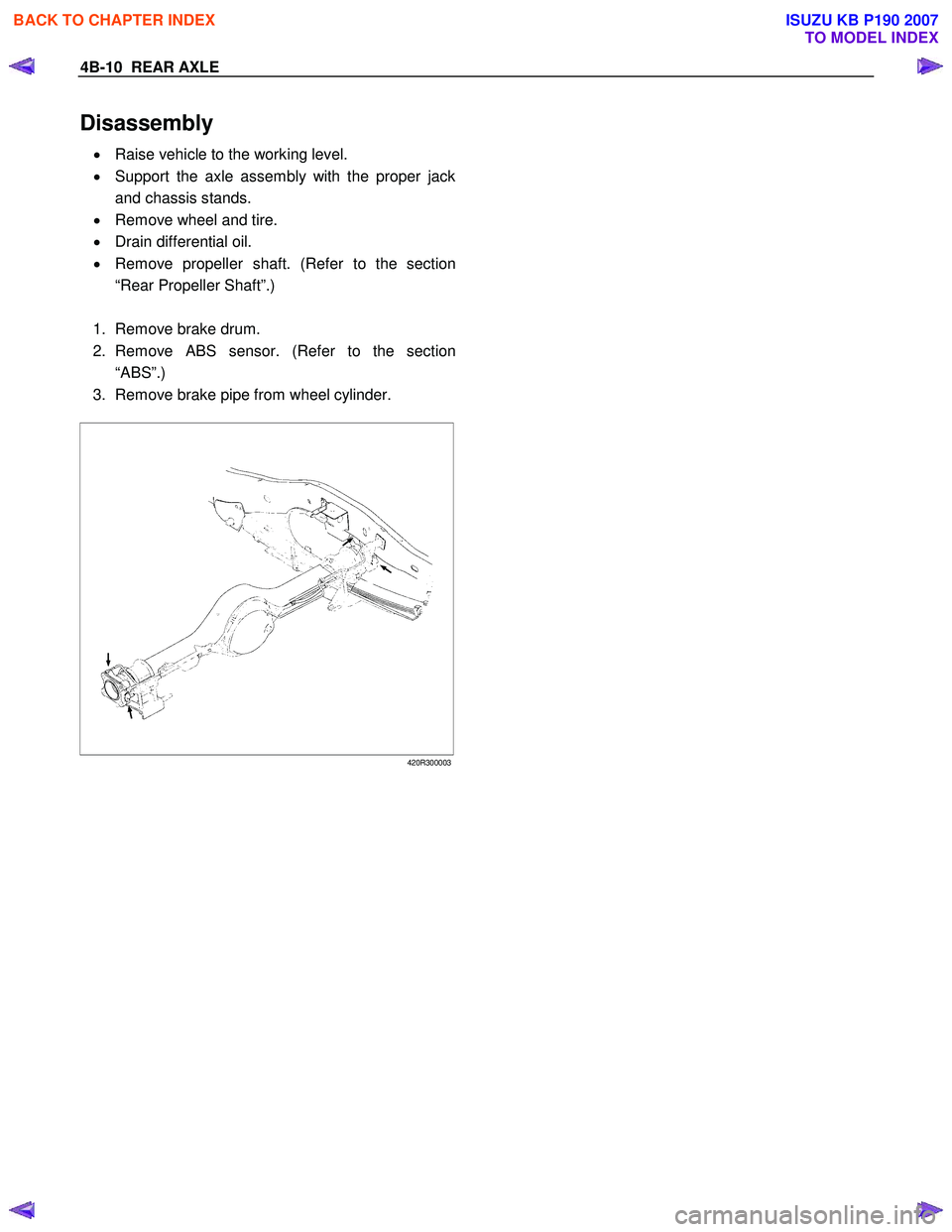

4B-10 REAR AXLE

Disassembly

• Raise vehicle to the working level.

• Support the axle assembly with the proper jack

and chassis stands.

• Remove wheel and tire.

• Drain differential oil.

• Remove propeller shaft. (Refer to the section

“Rear Propeller Shaft”.)

1. Remove brake drum.

2. Remove ABS sensor. (Refer to the section “ABS”.)

3. Remove brake pipe from wheel cylinder.

420R300003

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 455 of 6020

REAR AXLE 4B-11

305R30000

Legend

1. Tension Pin

2. Shoe Clamp Spring

3. Return Spring

4. Shoe Assembly with Parking Brake Lever

5. Shoe Assembly with Adjuster Lever

6. Spring

7. Parking Brake Cable

8. Adjuster

9. Parking Brake Lever

10. Adjuster Spring

11. Adjuster Lever

12. W heel Cylinder

13. Back plate

4. Remove tension pin and shoe clamp spring.

5. Remove return spring.

6. Remove shoe assembly with parking brake lever.

7. Remove shoe assembly with adjuster lever and spring.

8. Remove parking brake inner cable from parking

brake lever.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 456 of 6020

4B-12 REAR AXLE

9. Use offset box wrench to compress locking lugs

on the cable, then remove parking brake oute

r

cable from back plate.

311RS012

Legend

1. Offset Box W rench

10. Remove wheel cylinder.

11. Remove bearing holder fixing nuts.

12. Take out axle shaft assembly with back plate and

set it on a bench press as following illustration.

W hen axle shaft is extracted, since axle case oil

seal is damaged, replace the axle case oil seal.

13. Remove snap ring. Use snap ring pliers to

remove. Snap ring is prohibition of reuse.

14. Remove shim (If so equipped)

15. Grind the retainer surfaces using a grinder, then chisel them out with a chisel.

16. Position remover 5-8840-2831-0 on the bearing

holder with 4 nuts.

RTW 54BSH000801

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 461 of 6020

REAR AXLE 4B-17

8. Certainly install new snap ring, use snap ring

pliers. W hen transform or damage, replace ne

w

one.

RTW 34BMH000101

Legend

1. Snap ring

2. Crevice

3. Retainer (with ABS)

Retainer (without ABS)

9. Insert a shim of sufficient thickness between

snap ring and end of retainer.

Standard 0 − 0.2 mm (0 − 0.008 in)

Crevice is measured using thickness gauge, and

when crevice exceeds 0.2 mm (0.008 in), it

adjusts so that is may become 0.2 mm (0.008 in)

or less using shim.

Shim Pats No. Thickness

1 9-41519110- ∗ 0.18 mm (0.0071 in)

2 8-97130387- ∗ 0.50 mm (0.0197 in)

Crevice No. of shim Total

mm (in)

1 2 mm (in)

1.0(0.0394) 2 1.00(0.0394)

0.9(0.0354) 2 1 0.86(0.0339)

0.8(0.0315) 1 1 0.68(0.0268)

0.7(0.0276) 1 1 0.68(0.0268)

0.6(0.0236) 1 0.50(0.0197)

0.5(0.0197) 1 0.50(0.0197)

0.4(0.0157) 2 0.36(0.0142)

0.3(0.0118) 1 0.18(0.0071)

0.2(0.0079) 1 0.18(0.0071)

10. Install axle shaft assembly in rear axle case

assembly.

a. Clean the mating surface of axle case and bearing holder.

b. Apply Three Bond 1215 (TB1215) o

r

equivalent on the surface of axle case

assembly.

Note:

When inserting an axle shaft, it inserts so that an

oil seal may not be damaged.

11. Install and tighten bearing holder fixing nut to the specified torque.

Torque : 84 N ⋅m (8.6 kgf ⋅m/62 lb ⋅ft)

12. Install wheel cylinder and tighten the bolt to the specified torque.

Torque : 9 N ⋅m (0.9 kgf ⋅m/78 lb ⋅in)

13. Install parking brake outer cable in back plate and inner cable in parking brake lever.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007