fuse ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 152 of 6020

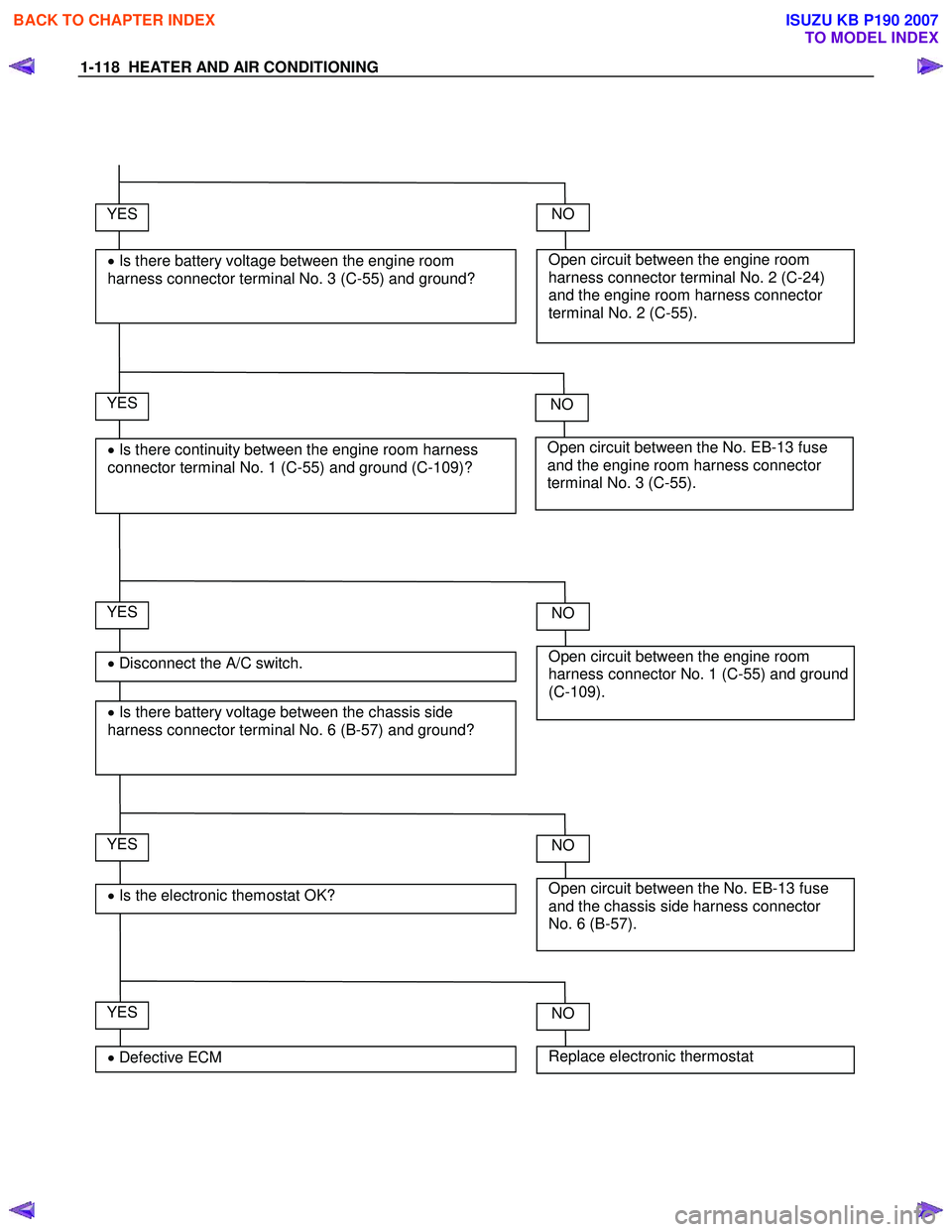

1-118 HEATER AND AIR CONDITIONING

YES

• Disconnect the A/C switch.

• Is there battery voltage between the chassis side

harness connector terminal No. 6 (B-57) and ground?

Open circuit between the engine room

harness connector terminal No. 2 (C-24)

and the engine room harness connector

terminal No. 2 (C-55).

NO YES

• Is there battery voltage between the engine room

harness connector terminal No. 3 (C-55) and ground?

Open circuit between the No. EB-13 fuse

and the engine room harness connector

terminal No. 3 (C-55).

NO YES

• Is there continuity between the engine room harness

connector terminal No. 1 (C-55) and ground (C-109)?

Open circuit between the engine room

harness connector No. 1 (C-55) and ground

(C-109).

NO

YES

• Is the electronic themostat OK? Open circuit between the No. EB-13 fuse

and the chassis side harness connector

No. 6 (B-57).

NO

YES

• Defective ECM Replace electronic thermostat

NO

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 608 of 6020

BRAKE CONTROL SYSTEM 5A-15

No. Connector face No. Connector face

H-6

White

Engine room ~ INST P-7

Battery (ALT)

H-7

White

Engine room ~ INST P-10

SilverEngine ground

H-9

White

Engine room ~ Chassis P-11

SilverFuse & relay box

H-15

White

Engine room ~ Chassis

H-18

White

Engine room ~ INST

H-48

White

Engine room ~ INST

P-1

Silver

Battery (+)

P-2

Silver

Relay & Fuse box

P-5

Silver

Battery (-)

P-6

Silver

Body ground

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 617 of 6020

5A-24 BRAKE CONTROL SYSTEM

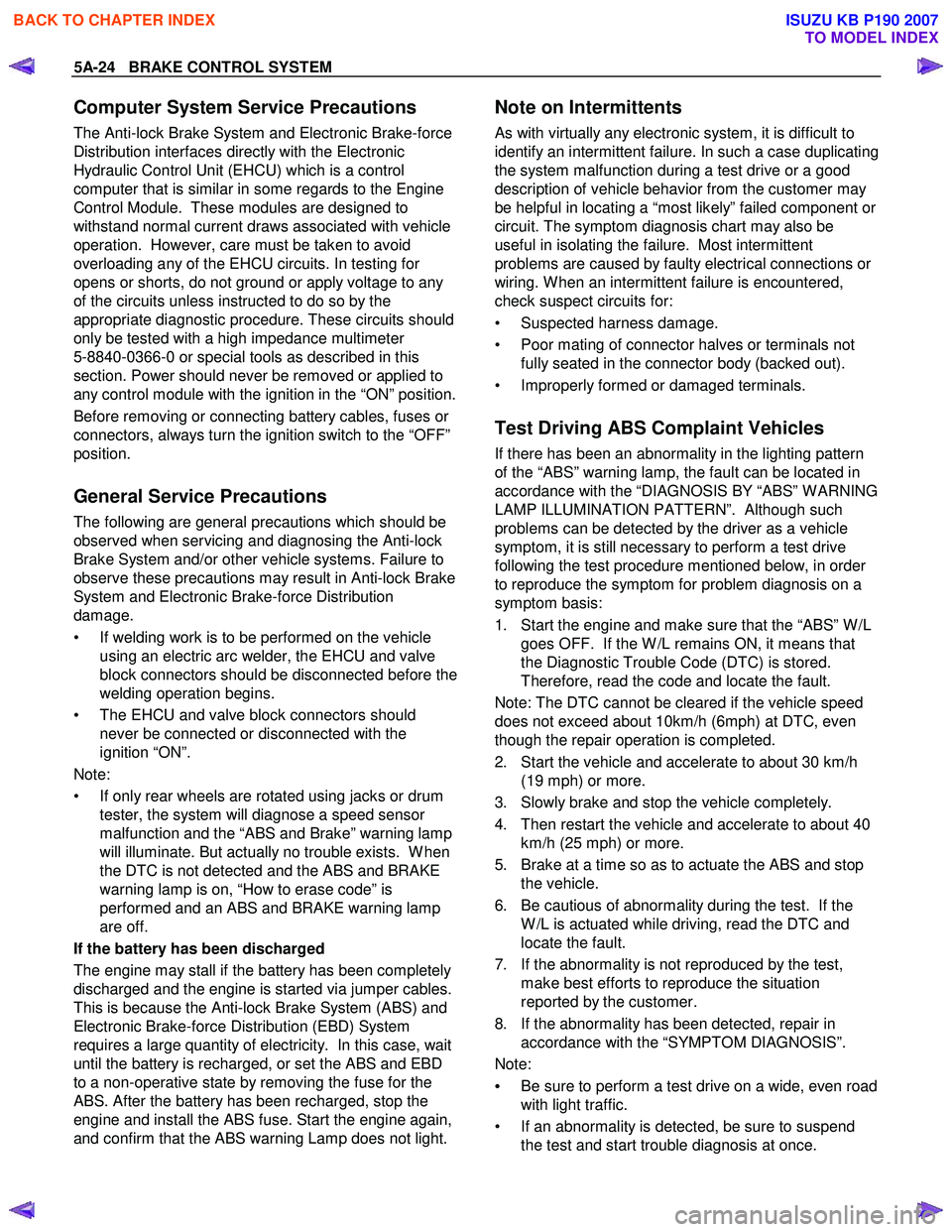

Computer System Service Precautions

The Anti-lock Brake System and Electronic Brake-force

Distribution interfaces directly with the Electronic

Hydraulic Control Unit (EHCU) which is a control

computer that is similar in some regards to the Engine

Control Module. These modules are designed to

withstand normal current draws associated with vehicle

operation. However, care must be taken to avoid

overloading any of the EHCU circuits. In testing for

opens or shorts, do not ground or apply voltage to any

of the circuits unless instructed to do so by the

appropriate diagnostic procedure. These circuits should

only be tested with a high impedance multimeter

5-8840-0366-0 or special tools as described in this

section. Power should never be removed or applied to

any control module with the ignition in the “ON” position.

Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the “OFF”

position.

General Service Precautions

The following are general precautions which should be

observed when servicing and diagnosing the Anti-lock

Brake System and/or other vehicle systems. Failure to

observe these precautions may result in Anti-lock Brake

System and Electronic Brake-force Distribution

damage.

• If welding work is to be performed on the vehicle using an electric arc welder, the EHCU and valve

block connectors should be disconnected before the

welding operation begins.

• The EHCU and valve block connectors should never be connected or disconnected with the

ignition “ON”.

Note:

• If only rear wheels are rotated using jacks or drum tester, the system will diagnose a speed sensor

malfunction and the “ABS and Brake” warning lamp

will illuminate. But actually no trouble exists. W hen

the DTC is not detected and the ABS and BRAKE

warning lamp is on, “How to erase code” is

performed and an ABS and BRAKE warning lamp

are off.

If the battery has been discharged

The engine may stall if the battery has been completely

discharged and the engine is started via jumper cables.

This is because the Anti-lock Brake System (ABS) and

Electronic Brake-force Distribution (EBD) System

requires a large quantity of electricity. In this case, wait

until the battery is recharged, or set the ABS and EBD

to a non-operative state by removing the fuse for the

ABS. After the battery has been recharged, stop the

engine and install the ABS fuse. Start the engine again,

and confirm that the ABS warning Lamp does not light.

Note on Intermittents

As with virtually any electronic system, it is difficult to

identify an intermittent failure. In such a case duplicating

the system malfunction during a test drive or a good

description of vehicle behavior from the customer may

be helpful in locating a “most likely” failed component or

circuit. The symptom diagnosis chart may also be

useful in isolating the failure. Most intermittent

problems are caused by faulty electrical connections or

wiring. W hen an intermittent failure is encountered,

check suspect circuits for:

• Suspected harness damage.

• Poor mating of connector halves or terminals not fully seated in the connector body (backed out).

• Improperly formed or damaged terminals.

Test Driving ABS Complaint Vehicles

If there has been an abnormality in the lighting pattern

of the “ABS” warning lamp, the fault can be located in

accordance with the “DIAGNOSIS BY “ABS” W ARNING

LAMP ILLUMINATION PATTERN”. Although such

problems can be detected by the driver as a vehicle

symptom, it is still necessary to perform a test drive

following the test procedure mentioned below, in order

to reproduce the symptom for problem diagnosis on a

symptom basis:

1. Start the engine and make sure that the “ABS” W /L

goes OFF. If the W /L remains ON, it means that

the Diagnostic Trouble Code (DTC) is stored.

Therefore, read the code and locate the fault.

Note: The DTC cannot be cleared if the vehicle speed

does not exceed about 10km/h (6mph) at DTC, even

though the repair operation is completed.

2. Start the vehicle and accelerate to about 30 km/h (19 mph) or more.

3. Slowly brake and stop the vehicle completely.

4. Then restart the vehicle and accelerate to about 40 km/h (25 mph) or more.

5. Brake at a time so as to actuate the ABS and stop the vehicle.

6. Be cautious of abnormality during the test. If the W /L is actuated while driving, read the DTC and

locate the fault.

7. If the abnormality is not reproduced by the test, make best efforts to reproduce the situation

reported by the customer.

8. If the abnormality has been detected, repair in accordance with the “SYMPTOM DIAGNOSIS”.

Note:

• Be sure to perform a test drive on a wide, even road

with light traffic.

• If an abnormality is detected, be sure to suspend the test and start trouble diagnosis at once.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 637 of 6020

5A-44 BRAKE CONTROL SYSTEM

Brake Pedal Feed Is Abnormal

Step Action Value(s) Yes No

1 Is the stop light actuated when the brake pedal is

depressed? - Go to Step 2 Go to Step 3

2 1. Turn the ignition switch off.

2. Disconnect EHCU connector. Is the check voltage for EHCU connector terminals

when brake pedal is depressed than battery voltage? - Go to Step 4 Harness NG

between stop light SW and EHCU.

Go to Step 6

3 Is stop light fuse normal?

- Go to Step 5 Replace stop

light fuse.

Go to Step 6

4 Is the check continuity between EHCU connector to body grounded?

- Go to Step 6 Repair body

grounded harness.

Go to Step 6

5 Is stop light switch operation normal?

- Repair stop

light harness.

Go to Step 6 Replace stop

light switch.

Go to Step 6

6 Reconnect all components, ensure all components are properly mounted.

Is this step finished? - Repeat the

“Basic

diagnostic

flow chart” Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 639 of 6020

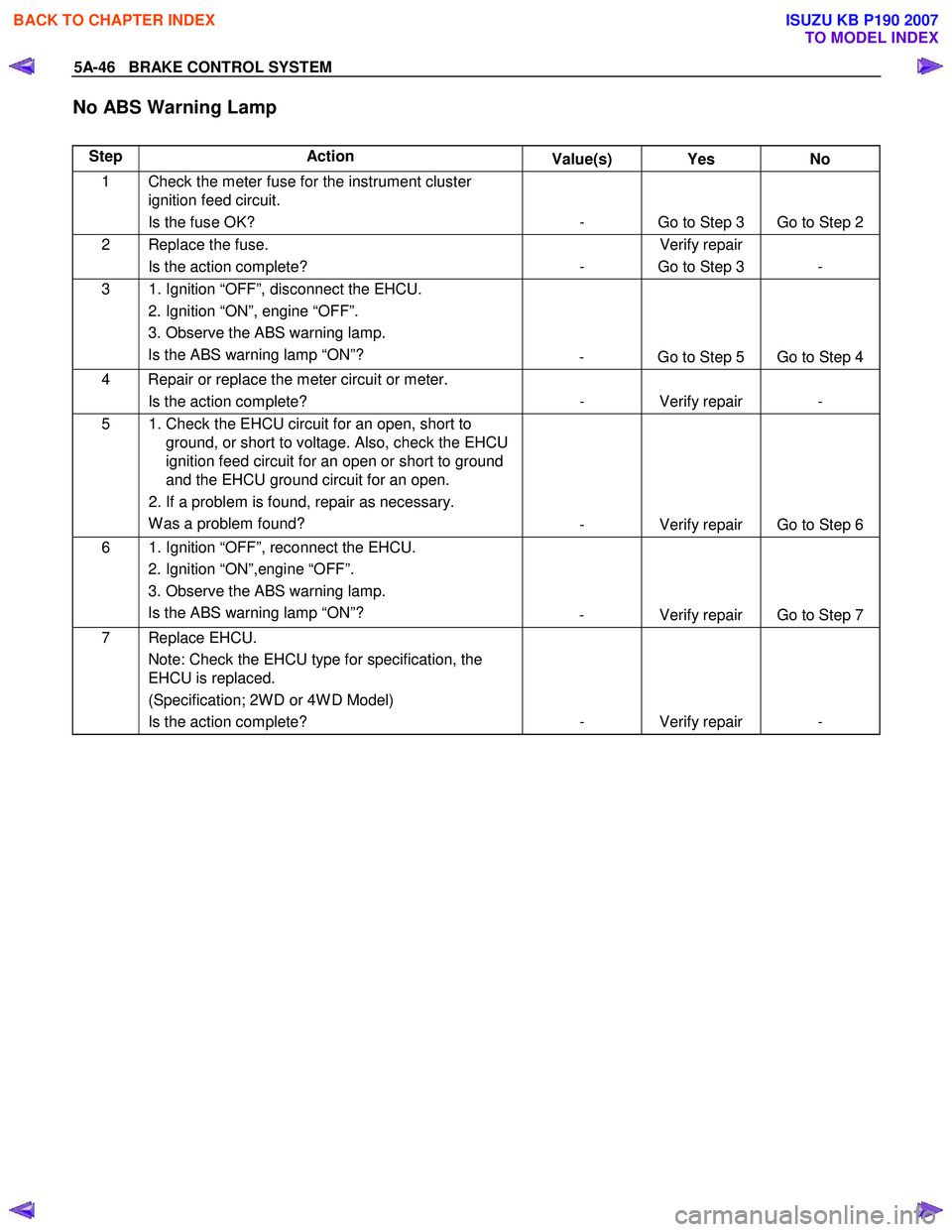

5A-46 BRAKE CONTROL SYSTEM

No ABS Warning Lamp

Step Action Value(s) Yes No

1 Check the meter fuse for the instrument cluster

ignition feed circuit.

Is the fuse OK? - Go to Step 3 Go to Step 2

2 Replace the fuse. Is the action complete? - Verify repair

Go to Step 3 -

3 1. Ignition “OFF”, disconnect the EHCU. 2. Ignition “ON”, engine “OFF”.

3. Observe the ABS warning lamp. Is the ABS warning lamp “ON”? - Go to Step 5 Go to Step 4

4 Repair or replace the meter circuit or meter.

Is the action complete? - Verify repair -

5 1. Check the EHCU circuit for an open, short to

ground, or short to voltage. Also, check the EHCU

ignition feed circuit for an open or short to ground

and the EHCU ground circuit for an open.

2. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 6

6 1. Ignition “OFF”, reconnect the EHCU.

2. Ignition “ON”,engine “OFF”.

3. Observe the ABS warning lamp. Is the ABS warning lamp “ON”? - Verify repair Go to Step 7

7 Replace EHCU.

Note: Check the EHCU type for specification, the

EHCU is replaced.

(Specification; 2W D or 4W D Model)

Is the action complete? - Verify repair -

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 788 of 6020

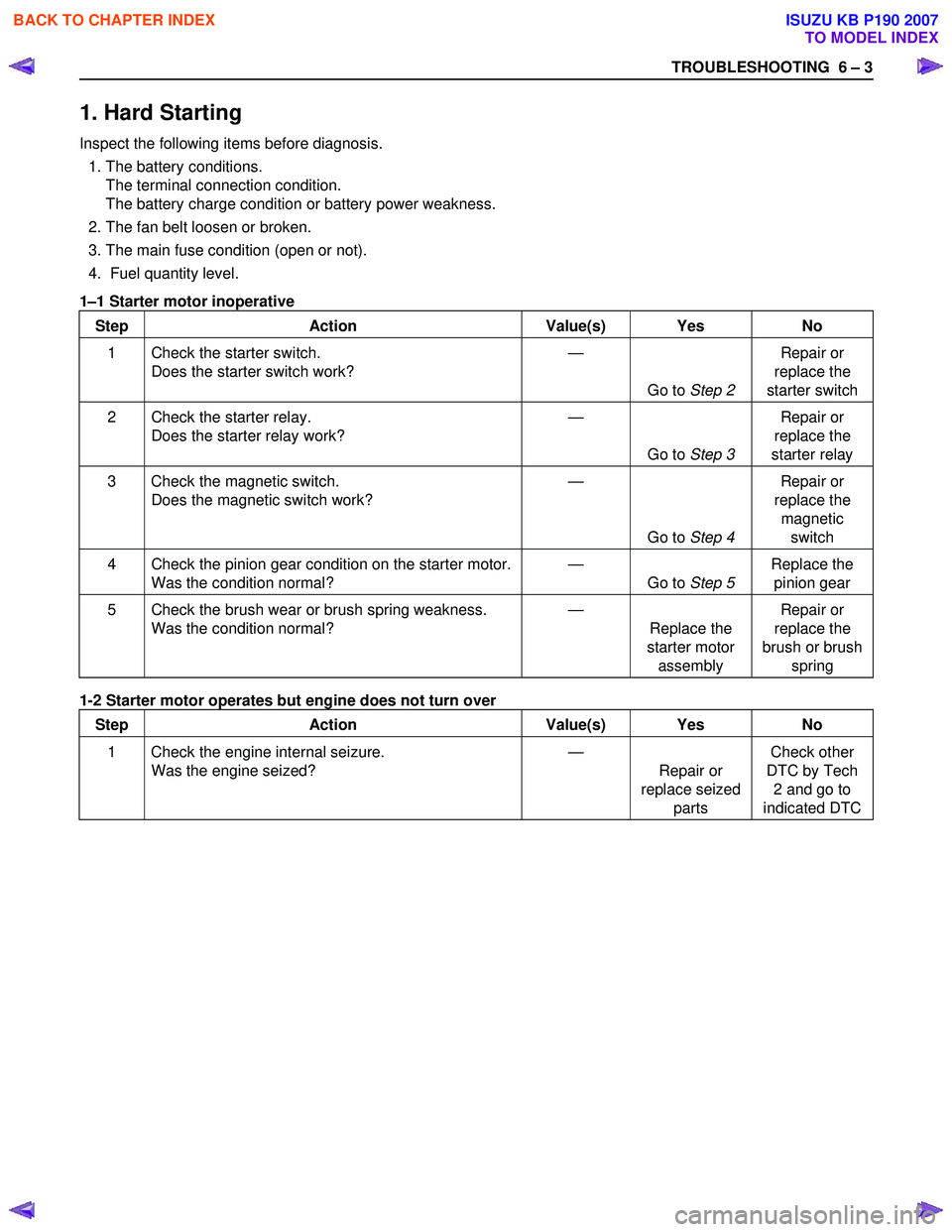

TROUBLESHOOTING 6 – 3

1. Hard Starting

Inspect the following items before diagnosis.

1. The battery conditions. The terminal connection condition.

The battery charge condition or battery power weakness.

2. The fan belt loosen or broken.

3. The main fuse condition (open or not).

4. Fuel quantity level.

1 –1 Starter motor inoperative

Step Action Value(s) Yes No

1 Check the starter switch. Does the starter switch work? —

Go to Step 2 Repair or

replace the

starter switch

2 Check the starter relay. Does the starter relay work? —

Go to Step 3 Repair or

replace the

starter relay

3 Check the magnetic switch. Does the magnetic switch work? —

Go to Step 4 Repair or

replace the magnetic switch

4 Check the pinion gear condition on the starter motor. Was the condition normal? —

Go to Step 5 Replace the

pinion gear

5 Check the brush wear or brush spring weakness. Was the condition normal? —

Replace the

starter motor assembly Repair or

replace the

brush or brush spring

1-2 Starter motor operates but engine does not turn over

Step Action Value(s) Yes No

1 Check the engine internal seizure. Was the engine seized? —

Repair or

replace seized parts Check other

DTC by Tech 2 and go to

indicated DTC

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1034 of 6020

ENGINE ELECTRICAL 6D – 33

PRE-HEATING SYSTEM

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacement if excessive wear of damage is discovered during

inspection.

VISUAL CHECK

Check the main fuses and glow indicator for damage.

Replace the part(s) if required.

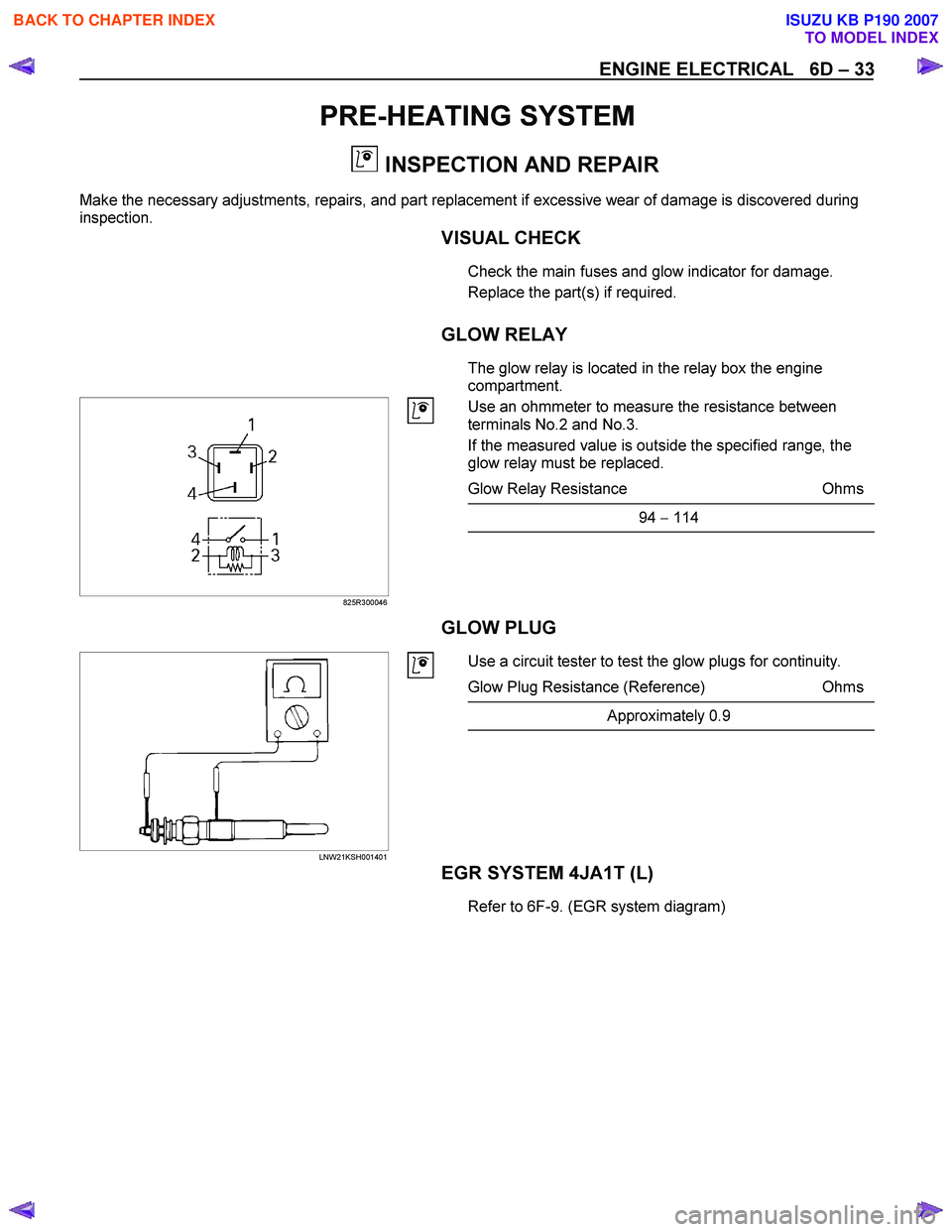

GLOW RELAY

The glow relay is located in the relay box the engine

compartment.

825R300046

Use an ohmmeter to measure the resistance between

terminals No.2 and No.3.

If the measured value is outside the specified range, the

glow relay must be replaced.

Glow Relay Resistance Ohms

94 − 114

GLOW PLUG

LNW21KSH001401

Use a circuit tester to test the glow plugs for continuity.

Glow Plug Resistance (Reference) Ohms

Approximately 0.9

EGR SYSTEM 4JA1T (L)

Refer to 6F-9. (EGR system diagram)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1052 of 6020

6E-18 Engine Control System (4JH1)

Component Locator

Engine Controls Component Views

3

4

1 2

6

45

Legend

1. Mass Air Flow (MAF) & Intake Air Temperature (IAT) Sensor Assembly

2. Throttle Cable

3. Air Cleaner Case

4. Battery

5. Relay & Fuse Box

6. EGR Cooler (Euro3) / EGR Pipe (Except Euro3)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1056 of 6020

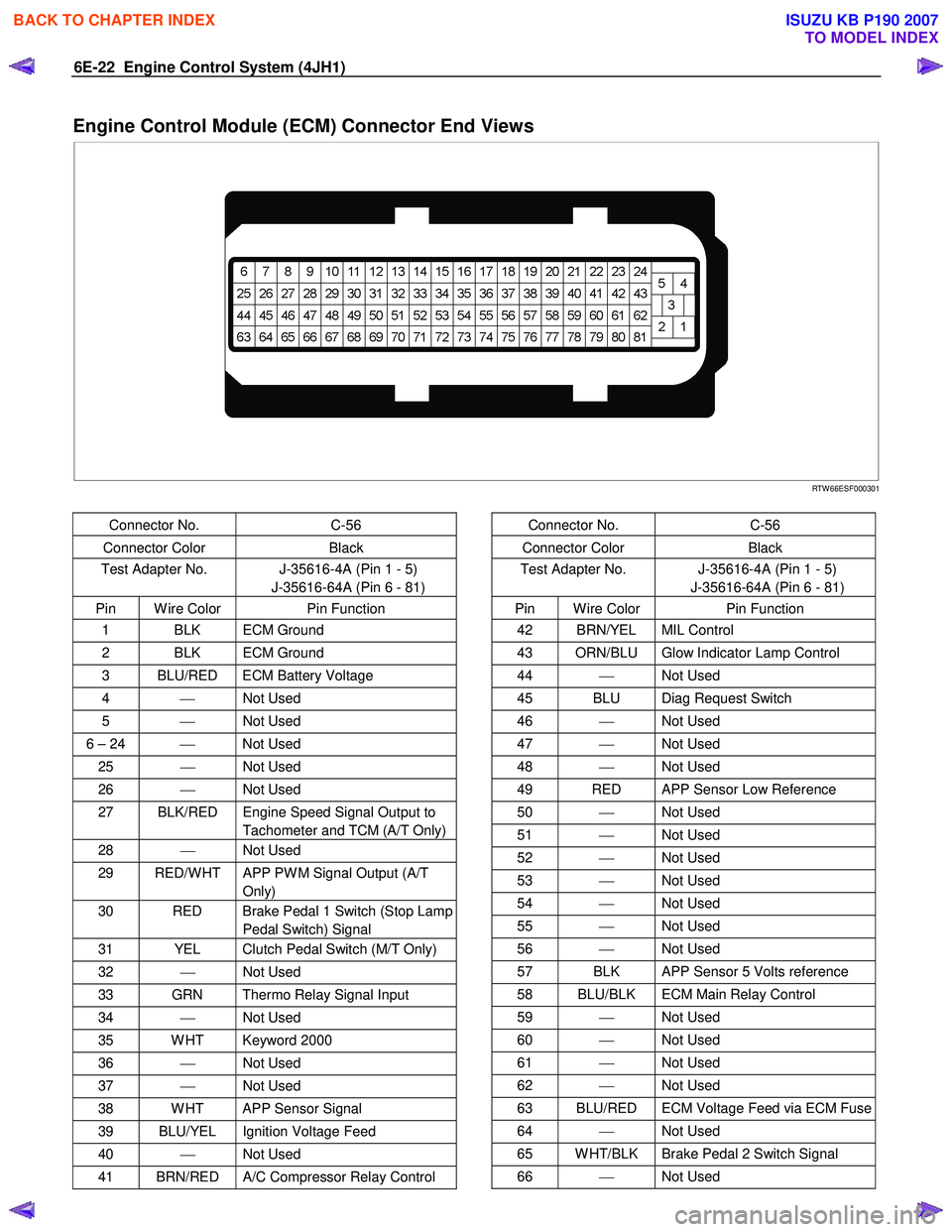

6E-22 Engine Control System (4JH1)

Engine Control Module (ECM) Connector End Views

RTW 66ESF000301

Connector No. C-56

Connector Color Black

Test Adapter No. J-35616-4A (Pin 1 - 5)

J-35616-64A (Pin 6 - 81)

Pin W ire Color Pin Function

1 BLK ECM Ground

2 BLK ECM Ground

3 BLU/RED ECM Battery Voltage

4 Not Used

5 Not Used

6 – 24 Not Used

25 Not Used

26 Not Used

27 BLK/RED Engine Speed Signal Output to

Tachometer and TCM (A/T Only)

28 Not Used

29 RED/W HT APP PW M Signal Output (A/T

Only)

30 RED Brake Pedal 1 Switch (Stop Lamp Pedal Switch) Signal

31 YEL Clutch Pedal Switch (M/T Only)

32 Not Used

33 GRN Thermo Relay Signal Input

34 Not Used

35 W HT Keyword 2000

36 Not Used

37 Not Used

38 W HT APP Sensor Signal

39 BLU/YEL Ignition Voltage Feed

40 Not Used

41 BRN/RED A/C Compressor Relay Control

Connector No. C-56

Connector Color Black

Test Adapter No. J-35616-4A (Pin 1 - 5)

J-35616-64A (Pin 6 - 81)

Pin W ire Color Pin Function

42 BRN/YEL MIL Control

43 ORN/BLU Glow Indicator Lamp Control

44 Not Used

45 BLU Diag Request Switch

46 Not Used

47 Not Used

48 Not Used

49 RED APP Sensor Low Reference

50 Not Used

51 Not Used

52 Not Used

53 Not Used

54 Not Used

55 Not Used

56 Not Used

57 BLK APP Sensor 5 Volts reference

58 BLU/BLK ECM Main Relay Control

59 Not Used

60 Not Used

61 Not Used

62 Not Used

63 BLU/RED ECM Voltage Feed via ECM Fuse

64 Not Used

65 W HT/BLK Brake Pedal 2 Switch Signal

66 Not Used

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1075 of 6020

Engine Control System (4JH1) 6E-41

Scan Tool Does Not Power Up

Circuit Description

The data link connector (DLC) is a standardized 16-

cavity connector. Connector design and location is

dictated by an industry wide standard, and is required to

provide the following:

• Scan tool power battery positive voltage at terminal

16.

• Scan tool power ground at terminal 4.

•

Common signal ground at terminal 5.

The scan tool will power up with the ignition OFF. Some

modules however, will not communicate unless the

ignition is ON.

Scan tool Does Not Power Up

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views

Step Action Value(s) Yes No

1 Important: Make sure the scan tool works properly

on another vehicle before using this chart.

1. Turn OFF the ignition.

2. Inspect the Meter (+B) (10A) fuse (C-19) in the cabin fuse box.

Is the Meter (+B) (10A) fuse (C-19) open?

Go to Step 2 Go to Step 3

2 Replace the Meter (+B) (10A) fuse (C-19). If the fuse continues to open, repair the short to ground on one

of the circuits that is fed by the Meter (+B) (10A) fuse

(C-19) or replace the shorted attached component

fed by the Meter (+B) (10A) fuse (C-19).

Did you complete the repair?

Go to Step 7

3 1. Check each circuit at the data link connector

(DLC) (B-58 connector) for a backed out, spread

or missing terminal.

2. Repair the terminal as necessary.

Did you find and complete the repair?

Go to Step 7 Go to Step 4

4 Connect a test lamp between the B+ circuit (pin 16 of B-58 connector) at the DLC and a known ground.

Does the test lamp illuminate?

Go to Step 6 Go to Step 5

5 Repair the open in the battery voltage circuit to the DLC.

Did you complete the repair?

Go to Step 7

6 1. Test each ground circuit at the DLC (pins 4 and 5

of B-58 connector) for an open circuit or high

resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 7 Go to Intermittent

Conditions

7 1. Connect the scan tool to the DLC. 2. Attempt to turn ON the scan tool.

Does the scan tool ON?

System OK Go to Step 1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007