light ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 269 of 6020

3B-8 POWER-ASSISTED STEERING SYSTEM

6. Fully close the shutoff valve. Record the highest

pressures.

・ If the pressure recorded is within 9800-10300 kPa

(100-105 kg/cm

2/1422-1493psi), the pump is

functioning within its specifications.

・ If the pressure recorded is higher than 10300 kPa

(105 kg/cm

2/1493psi), the valve in the pump is

defective.

・ If the pressure recorded is lower than 9800 kPa

(100 kg/cm

2/1422psi), the valve or the rotating

assembly in the pump is defective.

7. If the pump pressures are within specifications, leave the valve open and turn (or have someone

else turn) the steering wheel fully in both directions.

Record the highest pressures and compare with the

maximum pump pressure recorded in step 6. If this

pressure cannot be built up at either side of the

power steering unit, the power steering unit is

leaking internally and must be replaced.

8. Shut the engine off, remove the testing gauge.

9. Reconnect the pressure hose, check the fluid level and make the needed repairs.

10. If the problem still exists, the steering and front suspension must be thoroughly examined.

Maintenance

The hydraulic system should be kept clean, the fluid

level in the reservoir should be checked at regula

r

intervals and fluid added when required. Refer to

Recommended Fluids and Lubricants in General

Information section for the type of fluid to be used and

the intervals for filling.

If the system contains some dirt, flush it as described in

this section. If it is exceptionally dirty, the pump must be

completely disassembled before further usage. (The

steering unit cannot be disassembled.)

All tubes, hoses, and fittings should be inspected for

leakage at regular intervals. Fittings must be tight. Make

sure the clips, clamps and supporting tubes and hoses

are in place and properly secured.

Power steering hoses and lines must not be twisted,

kinked or tightly bent. Air in the system will cause

spongy action and noisy operation. W hen a hose is

disconnected or when fluid is lost, for any reason, the

system must be bled after refilling. Refer to Bleeding the

Power Steering System in this section.

・ Inspect gear for looseness or damage.

・ Inspect hoses to insure they are not touching an

y

other parts of the vehicle.

・ Inspect fluid level and fill to the proper level.

Fluid Level

1. Run the engine until the power steering fluid

reaches normal operating temperature, about 55 °

C (130 °F), then shut the engine off.

2. Check the level of fluid in the reservoir.

3. If the fluid level is low, add power steering fluid as

specified in General Information to the proper level

and install the receiver cap.

4. W hen checking the fluid level after the steering system has been serviced, air must be bled from

the system. Refer to Bleeding the Power Steering

System in this section.

Bleeding the Power Steering System

W hen a power steering pump or unit has been installed,

or an oil line has been disconnected, the air that has

entered the system must be bled out before the vehicle

is operated. If air is allowed to remain in the powe

r

steering fluid system, noisy and unsatisfactory operation

of the system may result.

Bleeding Procedure

W hen bleeding the system, and any time fluid is added

to the power steering system, be sure to use only powe

r

steering fluid as specified in General Information.

1. Fill the pump fluid reservoir to the proper level and let the fluid settle for at least two minutes.

2. Start the engine and let it run for a few seconds. Do not turn the steering wheel. Then turn the engine

off.

3. Add fluid if necessary.

4. Repeat the above procedure until the fluid level remains constant after running the engine.

5. Raise and support the front end of the vehicle so that the wheels are off the ground.

6. Start the engine. Slowly turn the steering wheel right and left, lightly contacting the wheel stops.

7. Add power steering fluid if necessary.

8. Lower the vehicle, set the steering wheel at the straight forward position after turning it to its full

steer positions 2 or 3 times, and stop the engine.

9. Check the fluid level and refill as required.

10. If the fluid is extremely foamy, allow the vehicle to settle for a few minutes, then repeat the above

procedure.

Flushing the Power Steering System

1. Raise and support the front end of the vehicle off

the ground until the wheels are free to turn.

2. Remove the fluid return line at the pump inlet connector and plug the connector port on the pump.

Direct the line toward a large container to catch the

draining fluid.

3. W hile running the engine at idle, fill the reservoi

r

with new power steering fluid. Turn the steering

wheel in both directions. Do not contact or hold the

steering wheel to the wheel stops. This will cause

the pump to go to pressure relief mode, which ma

y

cause a sudden fluid overflow at the reservoir.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 293 of 6020

3B-32 POWER-ASSISTED STEERING SYSTEM

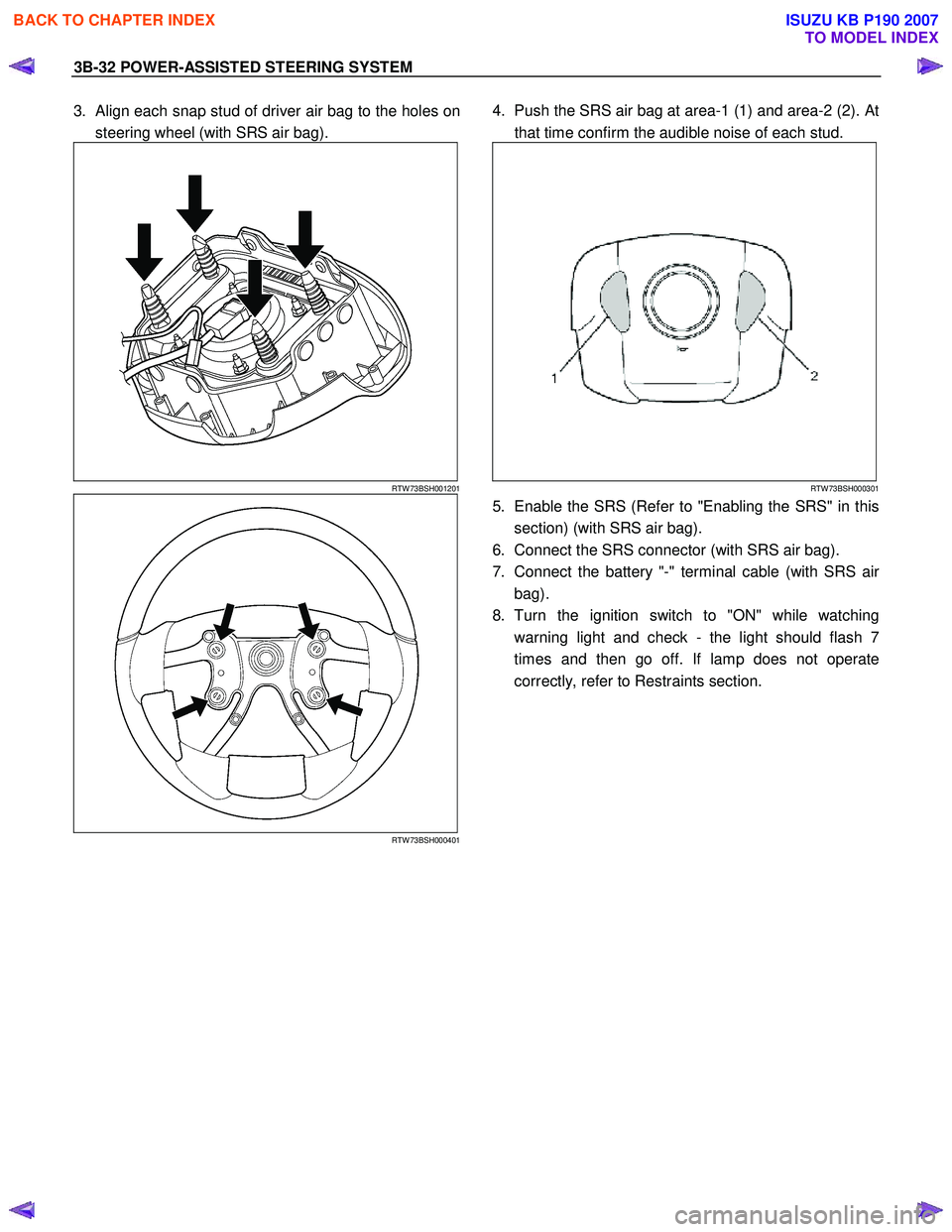

3. Align each snap stud of driver air bag to the holes on

steering wheel (with SRS air bag).

RTW 73BSH001201

RTW 73BSH000401

4. Push the SRS air bag at area-1 (1) and area-2 (2). At

that time confirm the audible noise of each stud.

RTW 73BSH000301

5. Enable the SRS (Refer to "Enabling the SRS" in this

section) (with SRS air bag).

6. Connect the SRS connector (with SRS air bag).

7. Connect the battery "-" terminal cable (with SRS ai

r

bag).

8. Turn the ignition switch to "ON" while watching warning light and check - the light should flash 7

times and then go off. If lamp does not operate

correctly, refer to Restraints section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 298 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-37

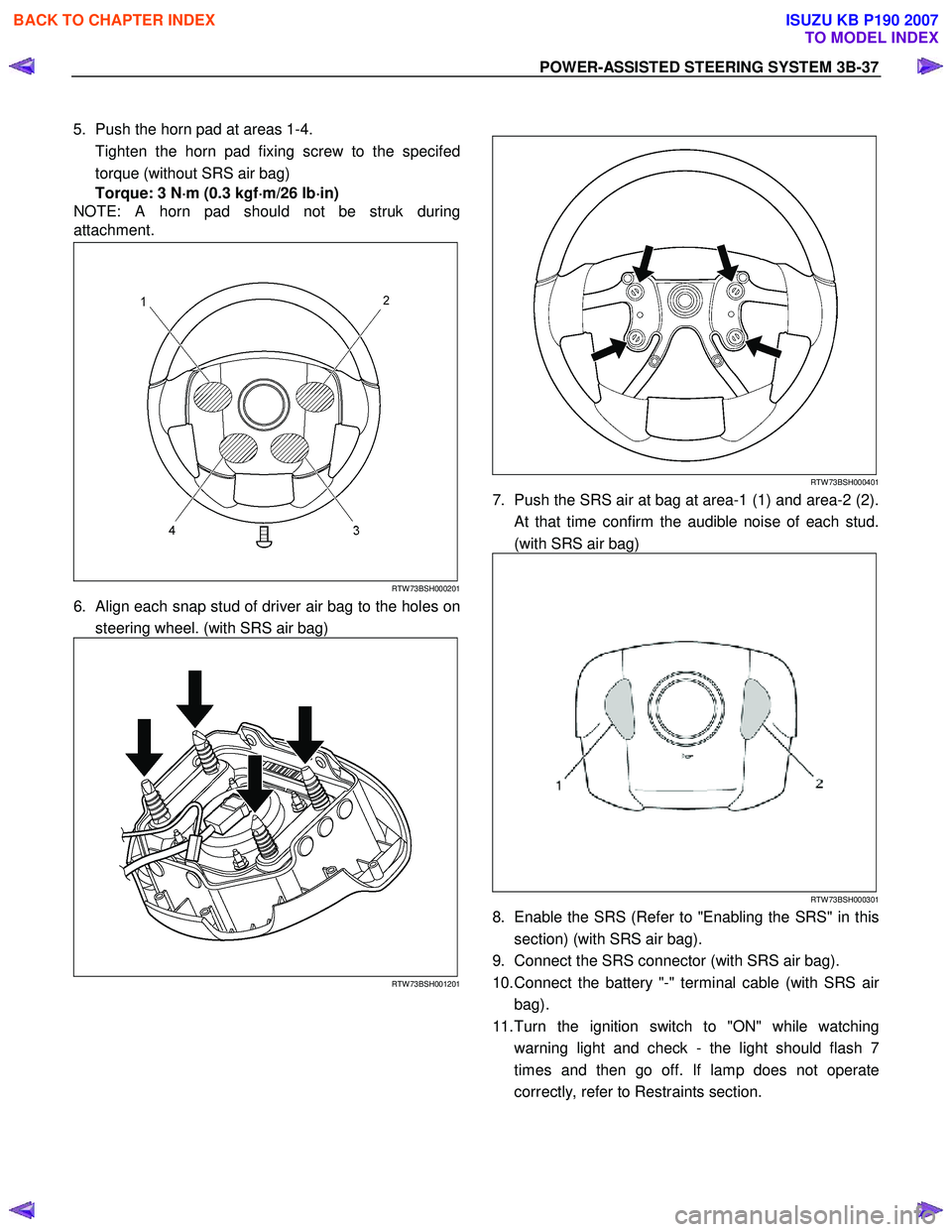

5. Push the horn pad at areas 1-4.

Tighten the horn pad fixing screw to the specifed torque (without SRS air bag)

Torque: 3 N ⋅

⋅⋅

⋅

m (0.3 kgf ⋅

⋅⋅

⋅

m/26 lb ⋅

⋅⋅

⋅

in)

NOTE: A horn pad should not be struk during

attachment.

RTW 73BSH000201

6. Align each snap stud of driver air bag to the holes on

steering wheel. (with SRS air bag)

RTW 73BSH001201

RTW 73BSH000401

7. Push the SRS air at bag at area-1 (1) and area-2 (2).

At that time confirm the audible noise of each stud.

(with SRS air bag)

RTW 73BSH000301

8. Enable the SRS (Refer to "Enabling the SRS" in this section) (with SRS air bag).

9. Connect the SRS connector (with SRS air bag).

10. Connect the battery "-" terminal cable (with SRS ai

r

bag).

11. Turn the ignition switch to "ON" while watching warning light and check - the light should flash 7

times and then go off. If lamp does not operate

correctly, refer to Restraints section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 305 of 6020

3B-44 POWER-ASSISTED STEERING SYSTEM

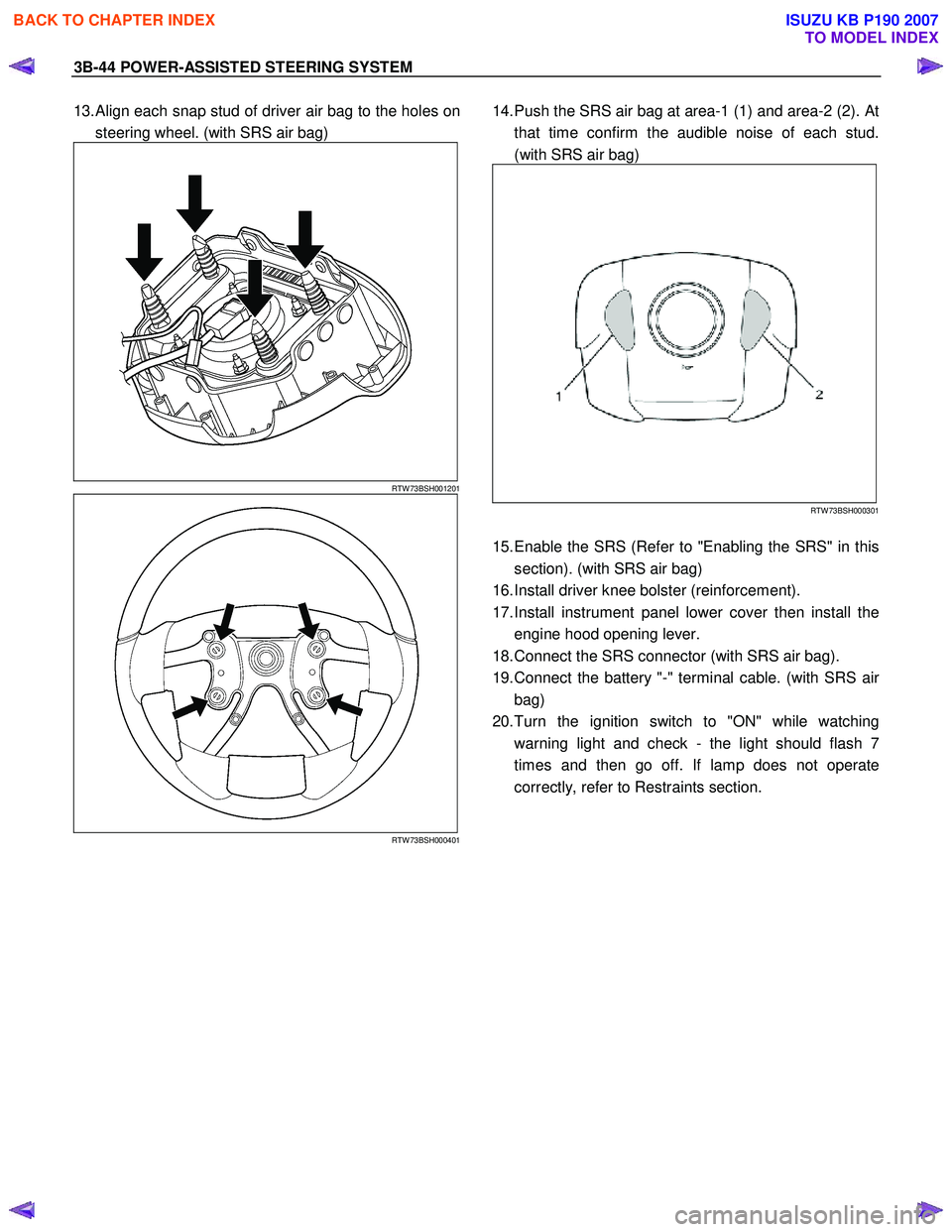

13. Align each snap stud of driver air bag to the holes on

steering wheel. (with SRS air bag)

RTW 73BSH001201

RTW 73BSH000401

14. Push the SRS air bag at area-1 (1) and area-2 (2). At

that time confirm the audible noise of each stud.

(with SRS air bag)

RTW 73BSH000301

15. Enable the SRS (Refer to "Enabling the SRS" in this

section). (with SRS air bag)

16. Install driver knee bolster (reinforcement).

17. Install instrument panel lower cover then install the engine hood opening lever.

18. Connect the SRS connector (with SRS air bag).

19. Connect the battery "-" terminal cable. (with SRS ai

r

bag)

20. Turn the ignition switch to "ON" while watching warning light and check - the light should flash 7

times and then go off. If lamp does not operate

correctly, refer to Restraints section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 311 of 6020

3B-50 POWER-ASSISTED STEERING SYSTEM

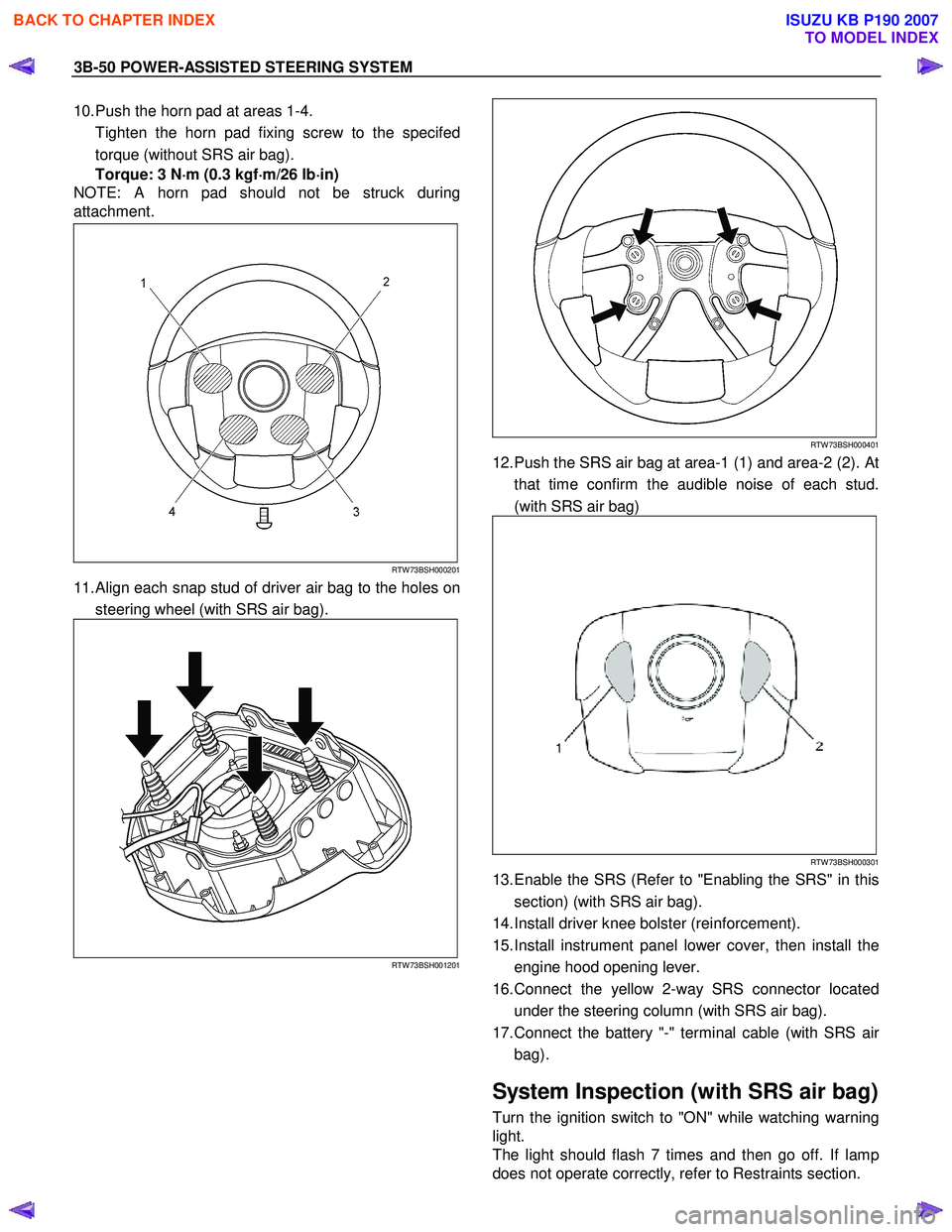

10. Push the horn pad at areas 1-4.

Tighten the horn pad fixing screw to the specifed torque (without SRS air bag).

Torque: 3 N ⋅

⋅⋅

⋅

m (0.3 kgf ⋅

⋅⋅

⋅

m/26 lb ⋅

⋅⋅

⋅

in)

NOTE: A horn pad should not be struck during

attachment.

RTW 73BSH000201

11. Align each snap stud of driver air bag to the holes on

steering wheel (with SRS air bag).

RTW 73BSH001201

RTW 73BSH000401

12. Push the SRS air bag at area-1 (1) and area-2 (2). At that time confirm the audible noise of each stud.

(with SRS air bag)

RTW 73BSH000301

13. Enable the SRS (Refer to "Enabling the SRS" in this section) (with SRS air bag).

14. Install driver knee bolster (reinforcement).

15. Install instrument panel lower cover, then install the engine hood opening lever.

16. Connect the yellow 2-way SRS connector located under the steering column (with SRS air bag).

17. Connect the battery "-" terminal cable (with SRS ai

r

bag).

System Inspection (with SRS air bag)

Turn the ignition switch to "ON" while watching warning

light.

The light should flash 7 times and then go off. If lamp

does not operate correctly, refer to Restraints section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 318 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-57

System Inspection (with SRS air bag)

Turn the ignition switch to "ON" while watching warning

light.

The light should flash 7 times and then go off. If lamp

does not operate correctly, refer to Restraints section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 433 of 6020

PROPELLER SHAFT 4A-17

401RS011

Universal Joint Reassembly

1. Set the propeller shafts.

• Be sure to set the propeller shaft yoke by aligning the

setting marks made during disassembly.

2. Spider

• Be sure to install the spider by aligning the setting marks

made during disassembly.

3. Needle Roller Bearing

1) Apply a molybdenum-disulfide grease or a multi-purpose. type grease NLGI No.2 to inside of the bearing cap. Grease Amount g(oz)

Approx. 1.2 (0.042)

401RS012

2) Using either a mallet (or copper hammer) or a press, install

the needle roller bearing into the yoke so that snap ring can

be installed in its groove.

CAUTION: •

••

•

The needle roller bearing cannot be installed smoothly

if it is set at an incorrect angle with the flange.

•

••

•

Excessive hammering will damage the needle rolle

r

bearing.

401R300003

3) Align setting marks and join the yokes.

NOTE:

Assemble the spider and spline yoke so that their grease

fittings are arranged on the same side.(4 ×4)

4. Snap ring

NOTE:

Discard used snap rings and install new ones.

W hen the bearing cap is in position, select and attach a snap

ring of suitable thickness so that the end play of the spider pin

is held within 0.1mm (0.004in).

mm(in)

Snap ring thickness Identification color

1.50 (0.059) Light Blue

1.53 (0.060) W hite

1.56 (0.061) Pink

1.59 (0.063) Yellow

1.62 (0.064) Green

1.65 (0.065) Brown

1.68 (0.066) Not colored

NOTE:

Be sure to use snap rings of the same thickness on both sides.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 443 of 6020

PROPELLER SHAFT 4A-27

401RS012

3. Using either a mallet (or copper hammer) or a press, install

the needle roller bearing into the yoke so that the snap ring

can be installed in its groove.

CAUTION:

The needle roller bearing cannot be installed smoothly if it

is set at an incorrect angle with the flange and excessive

hammering will damage the needle roller bearing.

401RS028

4. Align setting marks (1) and join the yokes.

5. Install snap ring.

NOTE:

Discard used snap rings and install new ones.

W hen the bearing cap is in position, select and attach a snap

ring of suitable thickness so that the end play of the spider pin

is held within 0.1 mm (0.004 in).

Snap ring thickness and Identification color

1.50 mm (0.059 in); Light Blue

1.53 mm (0.060 in); White

1.56 mm (0.061 in); Pink

1.59 mm (0.063 in); Yellow

1.62 mm (0.064 in); Green

1.65 mm (0.065 in); Brown

1.68 mm (0.066 in); Not colored

NOTE:

Be sure to use snap rings of the same thickness

on both sides.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 458 of 6020

4B-14 REAR AXLE

Inspection and Repair

Make all necessary adjustments, repairs, and part

replacements if wear, damage, or other problems are

discovered during inspections.

Visual Check

Inspect the following parts for wear, damage or other

abnormal conditions.

• Axle Shaft

Axle Shaft

W hen checking the axle shaft, pay special attention to

the splined portions and replace the shaft if distortion

or step wear is noticeable. Correct slight step wea

r

with a pencil grinder.

420RS008

Axle Shaft Run-Out

Check the shafts for bending with the use of a dial

indicator in contact with the shaft. Rotate the shaft

slowly and observe the dial indicator.

Limit mm (in

)

1.0 (0.039)

Note :

Never use heat to correct bending.

RTW 74BSH000101

Legend

a. 350 mm (13.8 in)

Axle Shaft Flange Run-Out

Check the axle shaft flange for run-out. Hold the

probe of a dial indicator in contact with the flange.

Rotate the shaft slowly and observe the dial.

Limit mm (in

)

0.08 (0.003)

RTW 74BSH000201

Legend

b. 160 mm (6.3 in)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 480 of 6020

4B-36 REAR AXLE

425R300010

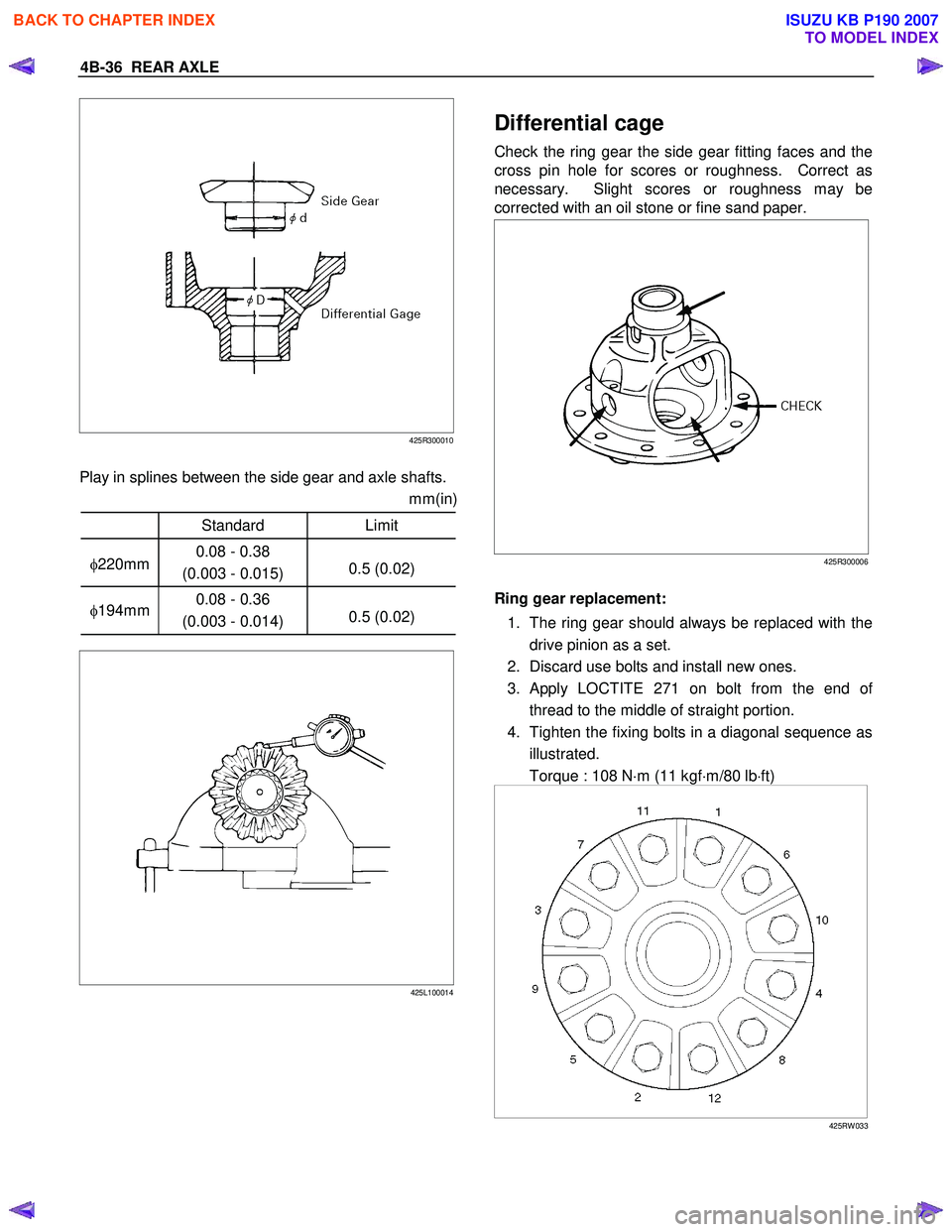

Play in splines between the side gear and axle shafts. mm(in)

Standard Limit

φ220mm 0.08 - 0.38

(0.003 - 0.015) 0.5 (0.02)

φ

194mm 0.08 - 0.36

(0.003 - 0.014) 0.5 (0.02)

425L100014

Differential cage

Check the ring gear the side gear fitting faces and the

cross pin hole for scores or roughness. Correct as

necessary. Slight scores or roughness may be

corrected with an oil stone or fine sand paper.

425R300006

Ring gear replacement:

1. The ring gear should always be replaced with the drive pinion as a set.

2. Discard use bolts and install new ones.

3.

Apply LOCTITE 271 on bolt from the end of

thread to the middle of straight portion.

4. Tighten the fixing bolts in a diagonal sequence as illustrated.

Torque : 108 N ⋅m (11 kgf ⋅m/80 lb ⋅ft)

425RW 033

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007