height ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 200 of 6020

SHEET METAL 2B-3

RUW 52BSH002501

Important Operations - Removal

1. Washer Nozzle Tube

1) Open the hood.

2) Support the hood.

3) Remove the windshield washer nozzle tube.

RUW 52BSH002601

2. Hood Hinge Bolt

• Before removing the hinges from the engine hood, scribe a

mark showing location of the hinges to facilitate installation in

the original position.

RTW 72BSH000501

Important Operations - Installation

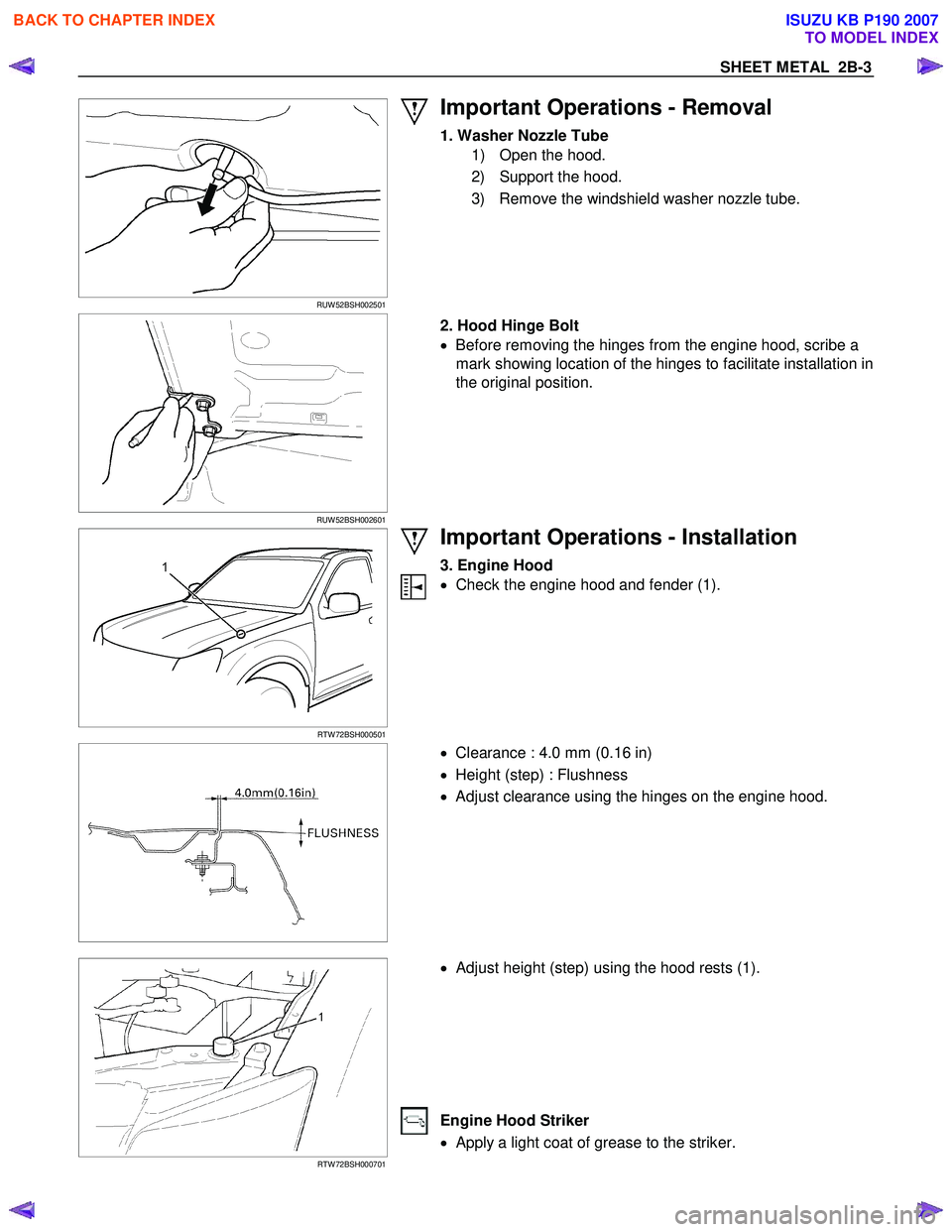

3. Engine Hood

• Check the engine hood and fender (1).

• Clearance : 4.0 mm (0.16 in)

• Height (step) : Flushness

• Adjust clearance using the hinges on the engine hood.

RTW 72BSH000701

• Adjust height (step) using the hood rests (1).

Engine Hood Striker

• Apply a light coat of grease to the striker.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 204 of 6020

SHEET METAL 2B-7

• Clearance : 4.0 mm (0.16 in)

• Height (step) : Flushness

• Adjust clearance using the hinges on the engine hood.

RTW 72BSH000701

• Adjust height (step) using the hood rests (1).

Engine Hood Striker

• Apply a light coat of grease to the striker.

4. Hood Hinge Bolt

• Tighten the engine hood hinge fixing bolts to the specified

torque.

Torque N ⋅m(kgf ⋅m/lb ⋅in)

10 (1.0 / 87)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 206 of 6020

SHEET METAL 2B-9

RUW 52BSH002501

Important Operations - Removal

1. Washer Nozzle Tube

4) Open the hood.

5) Support the hood.

6) Remove the windshield washer nozzle tube.

RUW 52BSH002601

2. Hood Hinge Bolts

• Before removing the hinges from the engine hood, scribe a

mark showing location of the hinges to facilitate installation in

the original position.

RTW 72BSH001101

Important Operations - Installation

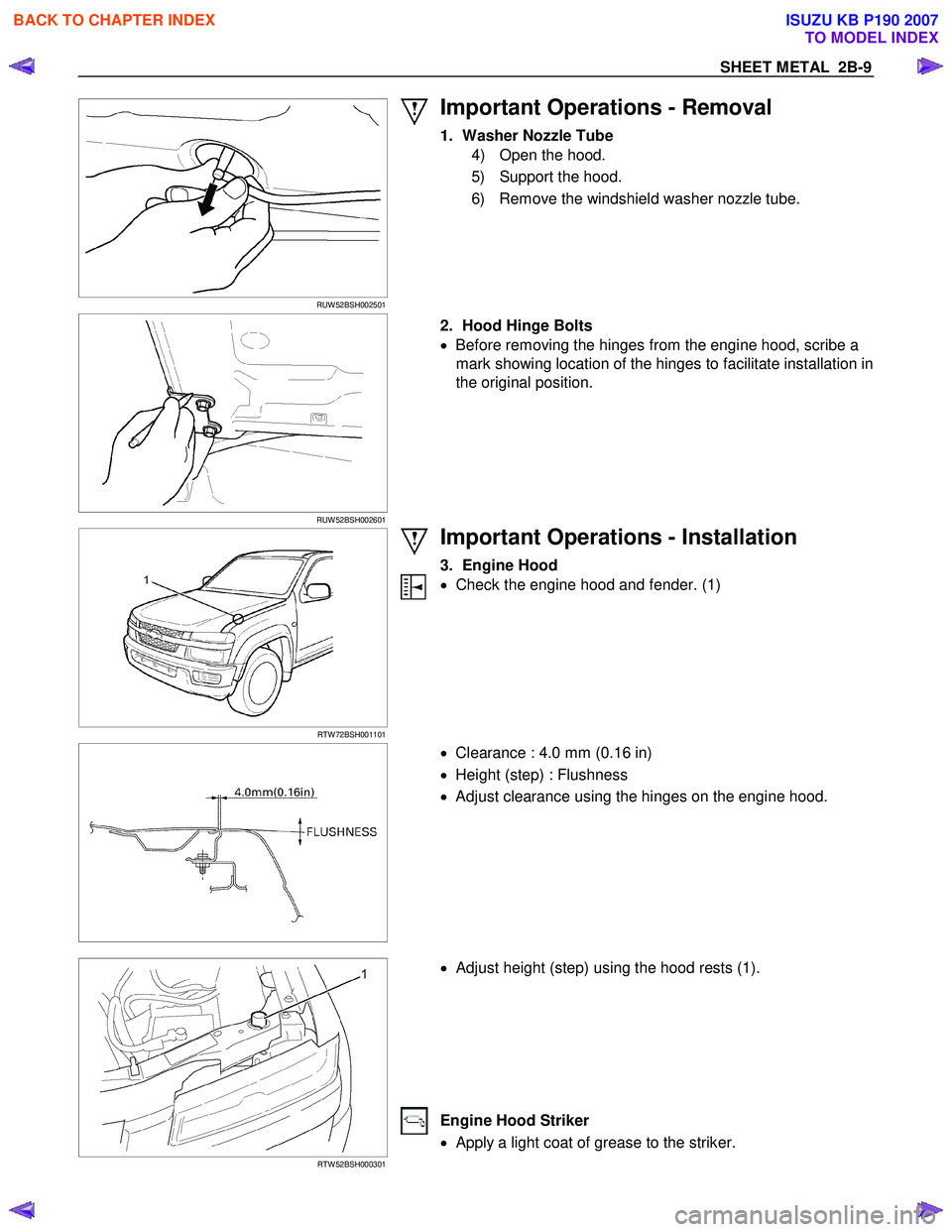

3. Engine Hood

• Check the engine hood and fender. (1)

• Clearance : 4.0 mm (0.16 in)

• Height (step) : Flushness

• Adjust clearance using the hinges on the engine hood.

RTW 52BSH000301

• Adjust height (step) using the hood rests (1).

Engine Hood Striker

• Apply a light coat of grease to the striker.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 214 of 6020

SHEET METAL 2B-17

RTW 72BSH000601

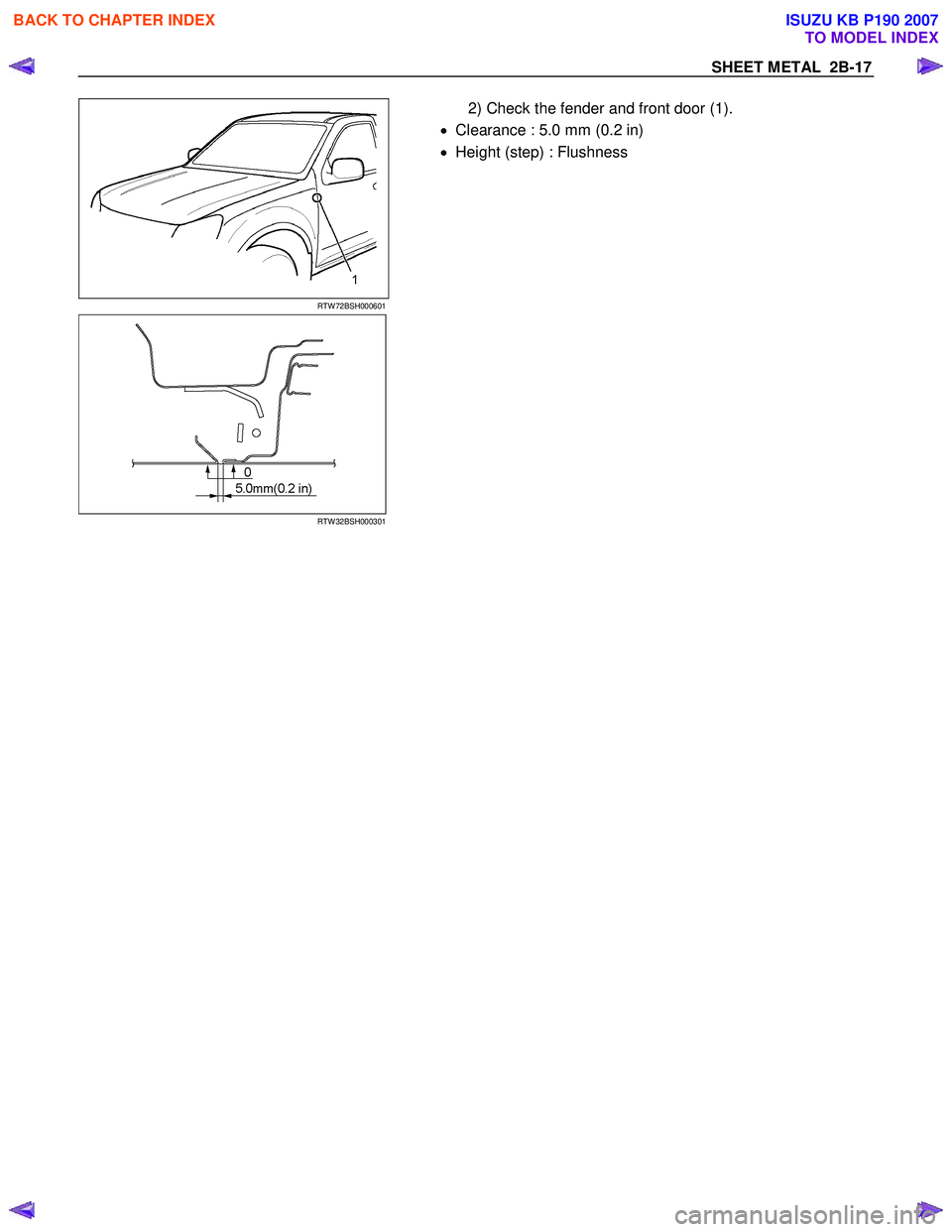

2) Check the fender and front door (1).

• Clearance : 5.0 mm (0.2 in)

• Height (step) : Flushness

RTW 32BSH000301

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 217 of 6020

2B-20 SHEET METAL

RTW 72BSH001201

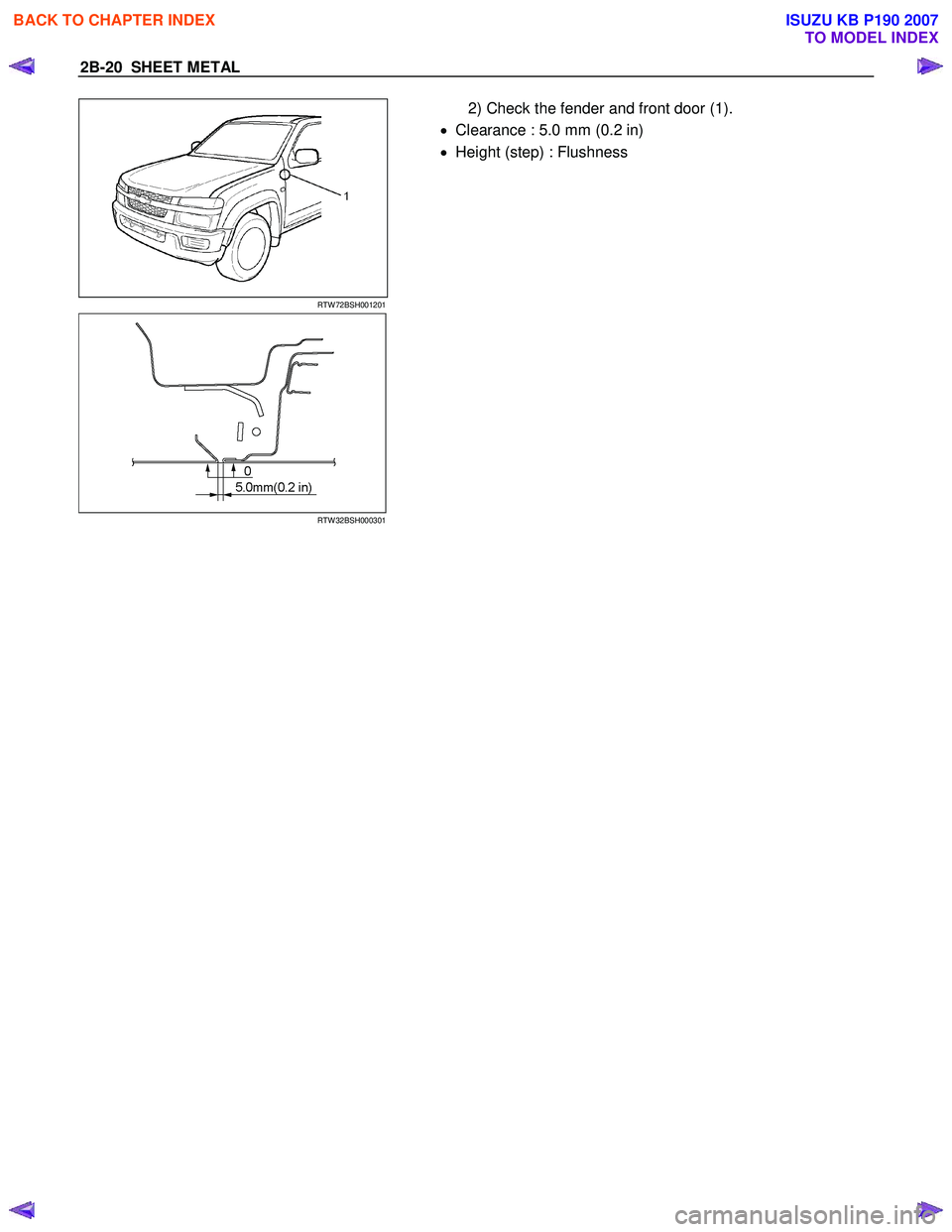

2) Check the fender and front door (1).

• Clearance : 5.0 mm (0.2 in)

• Height (step) : Flushness

RTW 32BSH000301

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 251 of 6020

FRONT ALIGNMENT 3A-3

Inspection

Before making any adjustments affecting caster, camber or

toe-in, the following front end inspection should be made.

1. Inspect the tires for proper inflation pressure. Refer to

Main Data and Specifications in W heel and Tire System section.

2. Make sure that the vehicle is in an unladen condition (W ith no passengers or loading).

3. Make sure that the spare tire is installed at the normal position.

4. Inspect the front wheel bearings for proper adjustment. Refer to Front Hub and Disc Overhaul in Suspension

section.

5. Inspect the ball joints and tie rod ends. If excessive looseness is noted, correct before adjusting. Refer to

Steering Linkage in this section.

6. Inspect the wheel and tires for run-out. Refer to W heel Replacement in W heel and Tire System section.

7. Inspect the trim height. If not within specifications, the correction must be made before adjusting caster.

8. Inspect the steering unit for looseness at the frame.

9. Inspect shock absorbers for leaks or any noticeable noise. Refer to Shock Absorber in Suspension section.

10. Inspect the control arms or stabilizer bar attachment fo

r

looseness. Refer to Suspension section.

11. Inspect the front end alignment using alignment equipment. Follow the manufacturer’s instructions.

12. Park the vehicle on a level surface.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 256 of 6020

3A-8 FRONT ALIGNMENT

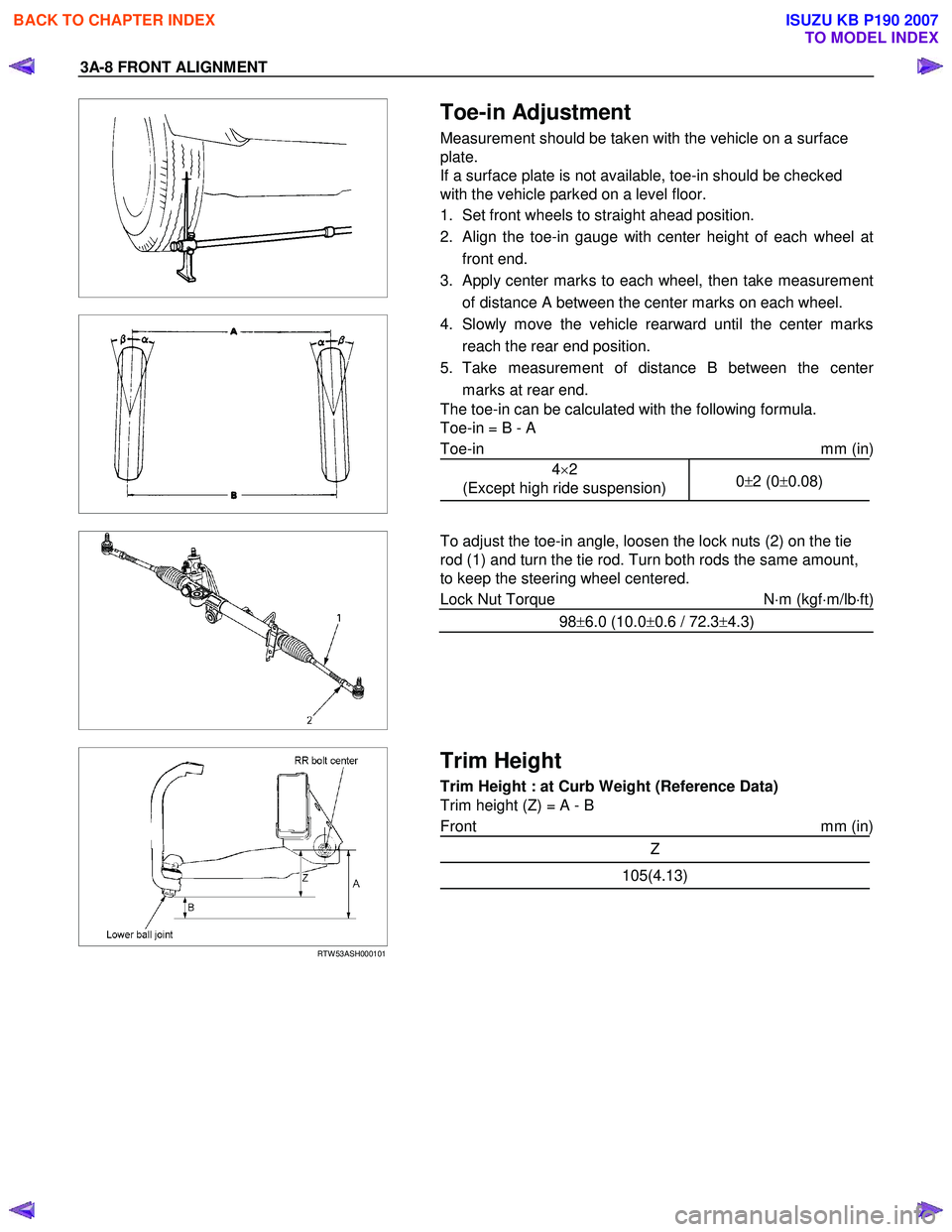

Toe-in Adjustment

Measurement should be taken with the vehicle on a surface

plate.

If a surface plate is not available, toe-in should be checked

with the vehicle parked on a level floor.

1. Set front wheels to straight ahead position.

2. Align the toe-in gauge with center height of each wheel at front end.

3.

Apply center marks to each wheel, then take measurement

of distance A between the center marks on each wheel.

4. Slowly move the vehicle rearward until the center marks reach the rear end position.

5. Take measurement of distance B between the cente

r

marks at rear end.

The toe-in can be calculated with the following formula.

Toe-in = B - A

Toe-in mm (in)

4×2

(Except high ride suspension) 0

±2 (0 ±0.08)

To adjust the toe-in angle, loosen the lock nuts (2) on the tie

rod (1) and turn the tie rod. Turn both rods the same amount,

to keep the steering wheel centered.

Lock Nut Torque N⋅m (kgf ⋅m/lb ⋅ft)

98 ±6.0 (10.0 ±0.6 / 72.3 ±4.3)

RTW 53ASH000101

Trim Height

Trim Height : at Curb Weight (Reference Data)

Trim height (Z) = A - B

Front mm (in)

Z

105(4.13)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 260 of 6020

3A-12 FRONT ALIGNMENT

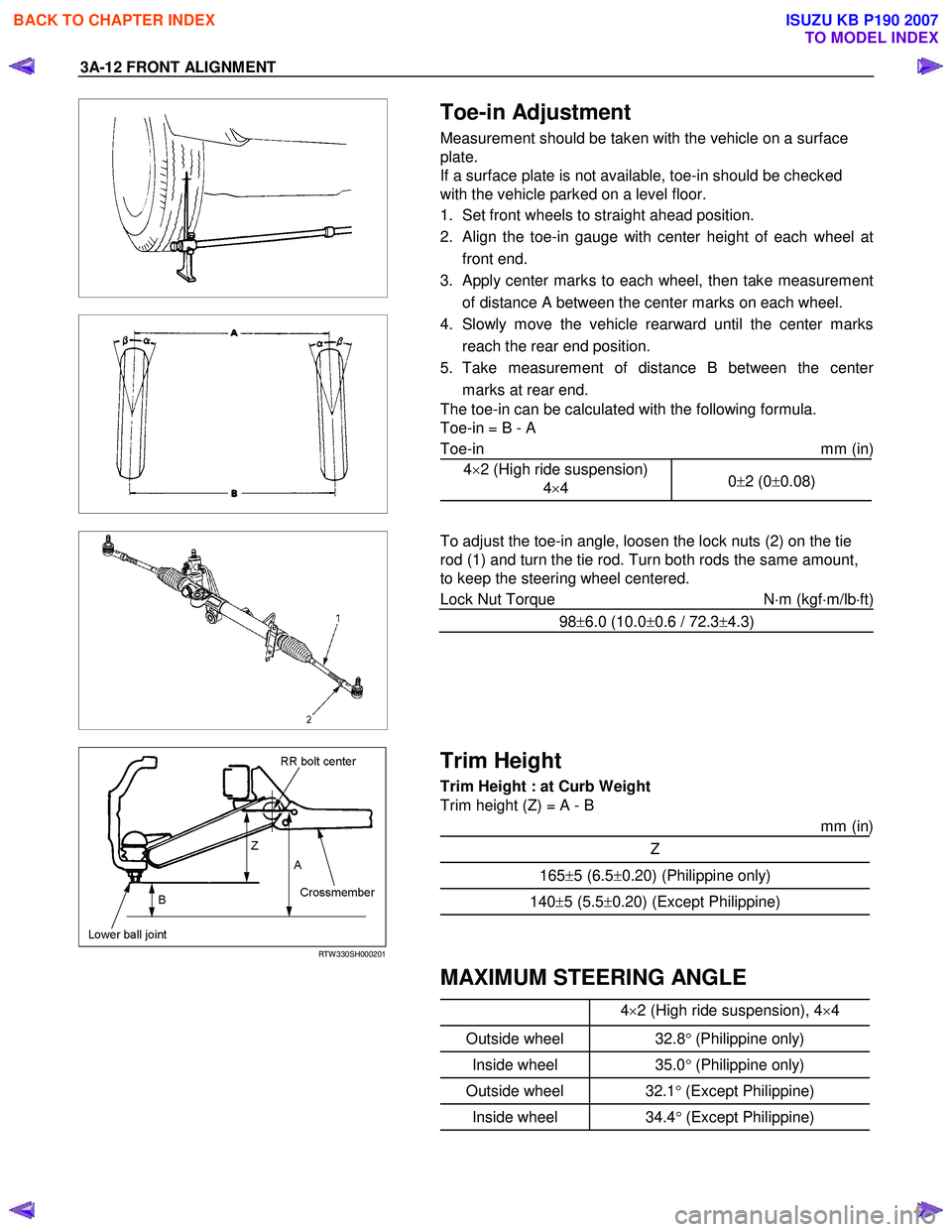

Toe-in Adjustment

Measurement should be taken with the vehicle on a surface

plate.

If a surface plate is not available, toe-in should be checked

with the vehicle parked on a level floor.

1. Set front wheels to straight ahead position.

2. Align the toe-in gauge with center height of each wheel at front end.

3.

Apply center marks to each wheel, then take measurement

of distance A between the center marks on each wheel.

4. Slowly move the vehicle rearward until the center marks reach the rear end position.

5. Take measurement of distance B between the cente

r

marks at rear end.

The toe-in can be calculated with the following formula.

Toe-in = B - A

Toe-in mm (in)

4×2 (High ride suspension)

4×4 0

±2 (0 ±0.08)

To adjust the toe-in angle, loosen the lock nuts (2) on the tie

rod (1) and turn the tie rod. Turn both rods the same amount,

to keep the steering wheel centered.

Lock Nut Torque N⋅m (kgf ⋅m/lb ⋅ft)

98 ±6.0 (10.0 ±0.6 / 72.3 ±4.3)

RTW 330SH000201

Trim Height

Trim Height : at Curb Weight

Trim height (Z) = A - B

mm (in)

Z

165±5 (6.5 ±0.20) (Philippine only)

140 ±5 (5.5 ±0.20) (Except Philippine)

MAXIMUM STEERING ANGLE

4

×2 (High ride suspension), 4 ×4

Outside wheel 32.8° (Philippine only)

Inside wheel 35.0° (Philippine only)

Outside wheel 32.1° (Except Philippine)

Inside wheel 34.4° (Except Philippine)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 261 of 6020

FRONT ALIGNMENT 3A-13

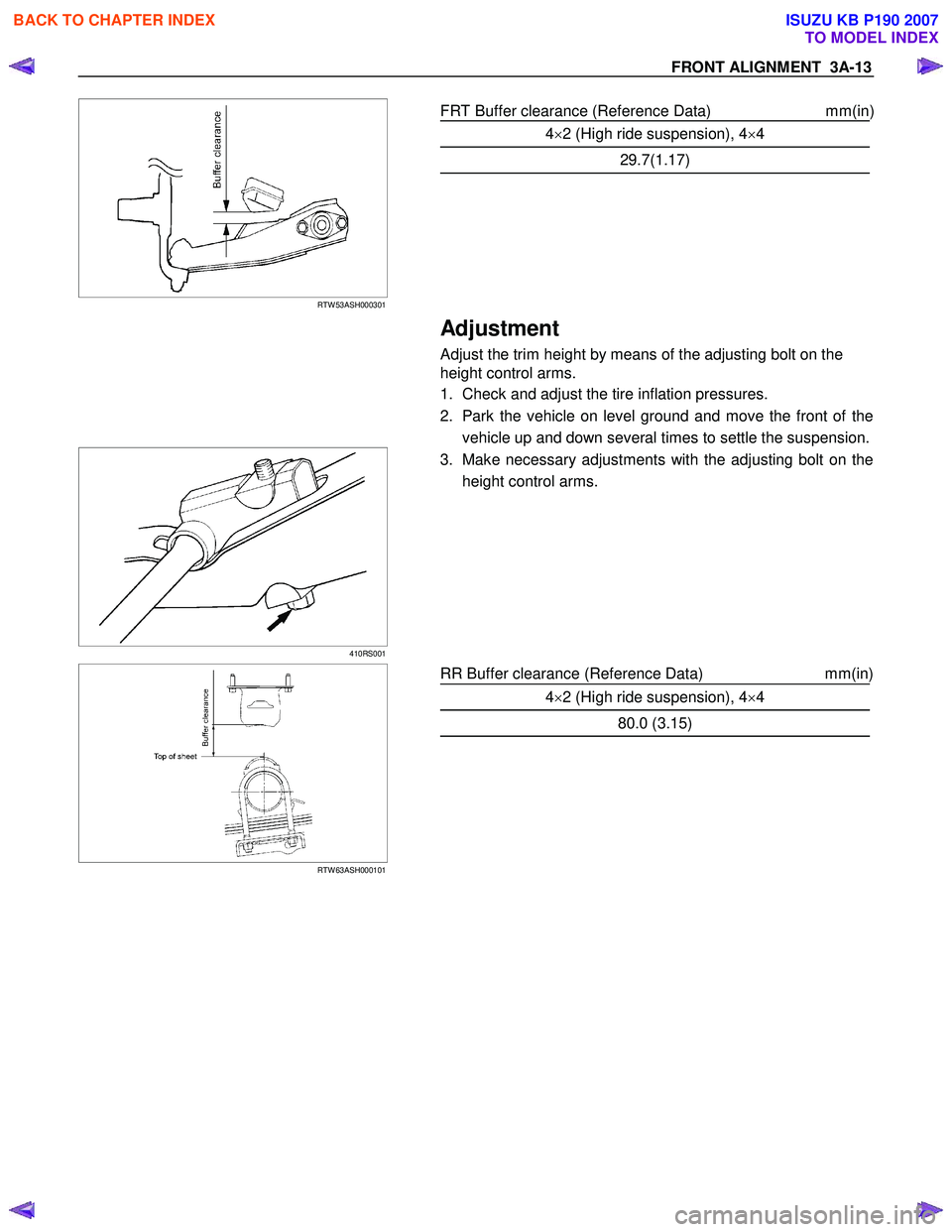

RTW 53ASH000301

FRT Buffer clearance (Reference Data) mm(in)

4×2 (High ride suspension), 4 ×4

29.7(1.17)

Adjustment

Adjust the trim height by means of the adjusting bolt on the

height control arms.

1. Check and adjust the tire inflation pressures.

2. Park the vehicle on level ground and move the front of the vehicle up and down several times to settle the suspension.

410RS001

3. Make necessary adjustments with the adjusting bolt on the

height control arms.

RTW 63ASH000101

RR Buffer clearance (Reference Data)

mm(in)

4×2 (High ride suspension), 4 ×4

80.0 (3.15)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 326 of 6020

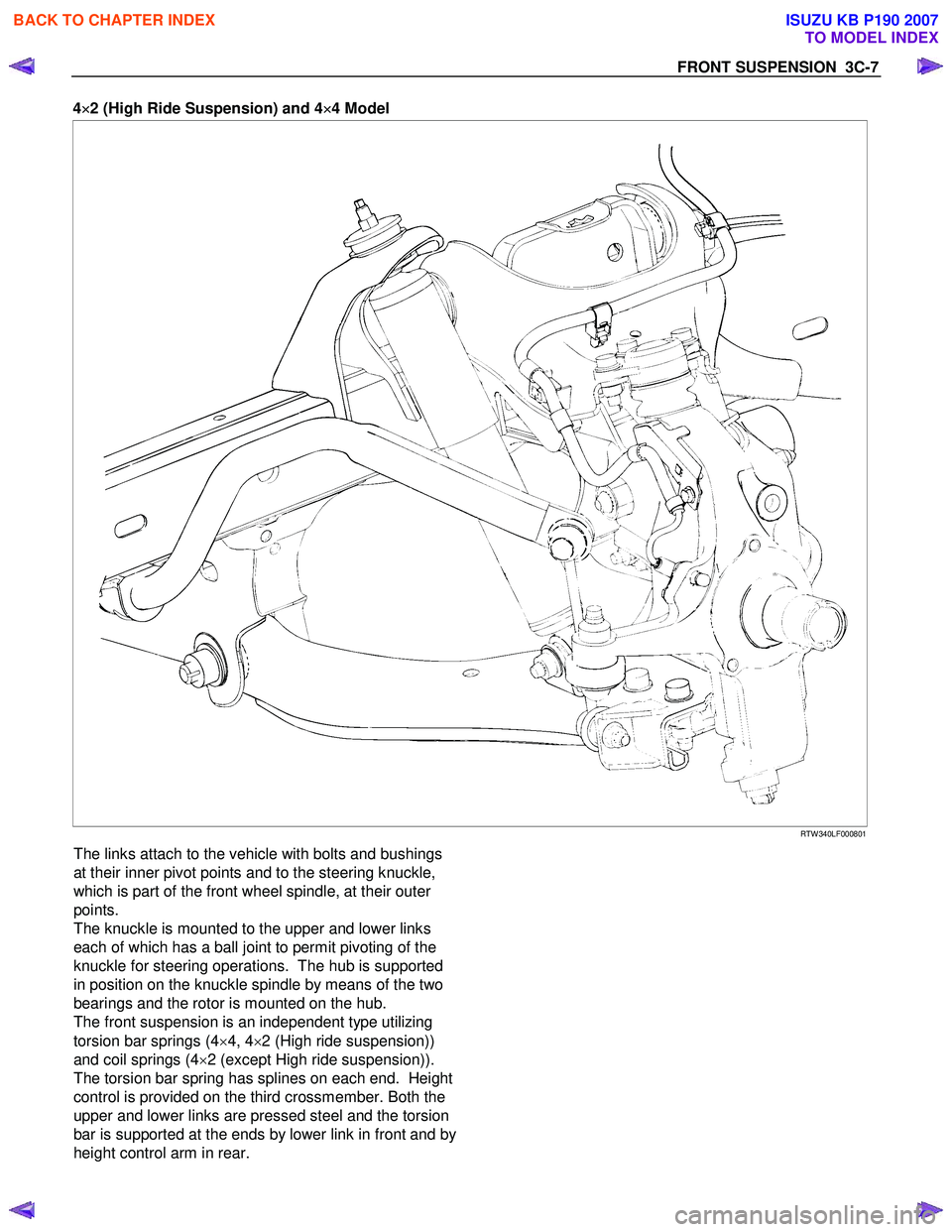

FRONT SUSPENSION 3C-7

4×

××

×

2 (High Ride Suspension) and 4 ×

××

×

4 Model

RTW 340LF000801

The links attach to the vehicle with bolts and bushings

at their inner pivot points and to the steering knuckle,

which is part of the front wheel spindle, at their outer

points.

The knuckle is mounted to the upper and lower links

each of which has a ball joint to permit pivoting of the

knuckle for steering operations. The hub is supported

in position on the knuckle spindle by means of the two

bearings and the rotor is mounted on the hub.

The front suspension is an independent type utilizing

torsion bar springs (4 ×4, 4 ×2 (High ride suspension))

and coil springs (4 ×2 (except High ride suspension)).

The torsion bar spring has splines on each end. Height

control is provided on the third crossmember. Both the

upper and lower links are pressed steel and the torsion

bar is supported at the ends by lower link in front and by

height control arm in rear.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007