phone ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3691 of 6020

Powertrain Interface Module – V6 Page 6E1–30

Checks Actions

Temperature Related The Tech 2 Freeze Frame / Failure Records or Snapshot data may be used if applicable

to the fault condition. Refer to 4.1 Diagnostic General Descriptions for information on

Tech 2 ECU diagnostic tests.

• If the intermittent fault is heat related, review the Tech 2 data in relationship to the

following:

• high ambient temperature,

• underhood / engine generated heat,

• circuit generated heat due to a poor electrical connection or high electrical

load, and

• higher than normal load conditions (towing, etc.).

• If the intermittent fault is related to cold ambient or engine temperature, review the

Tech 2 data in relationship to the following:

• low ambient temperature, and

• the fault condition that occurs only on a cold start situation.

Additional Tests

• Check for incorrect installation of aftermarket electrical equipment such as the

following:

• mobile phones,

• theft deterrent alarms,

• lights, or

• radio equipment.

• Check for electromagnetic Interference (EMI) caused by a faulty relay, ECM

controlled solenoid or switch. The fault is triggered when the relay or solenoid is

activated.

• Check the A/C compressor clutch and some relays that contain a clamping diode

or resistor for an open circuit.

• Check the generator for a faulty rectifier bridge that may allow A/C noise into the

PIM electrical circuit.

When all diagnosis and repairs are completed, check the engine management system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3780 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–20

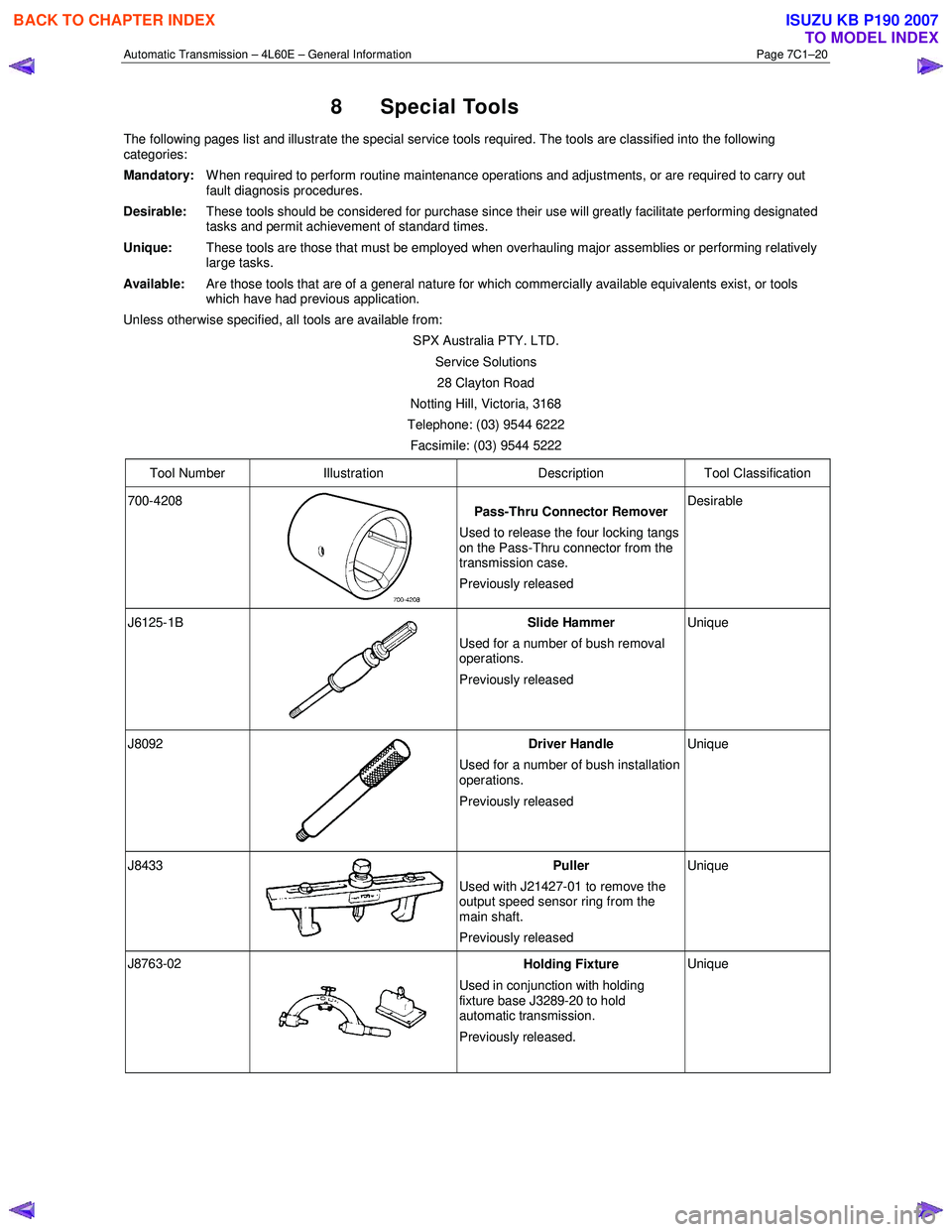

8 Special Tools

The following pages list and illustrate the special service tools required. The tools are classified into the following

categories:

Mandatory:

W hen required to perform routine maintenance operations and adjustments, or are required to carry out

fault diagnosis procedures.

Desirable:

These tools should be considered for purchase since their use will greatly facilitate performing designated

tasks and permit achievement of standard times.

Unique: These tools are those that must be employed when overhauling major assemblies or performing relatively

large tasks.

Available: Are those tools that are of a general nature for which commercially available equivalents exist, or tools

which have had previous application.

Unless otherwise specified, all tools are available from:

SPX Australia PTY. LTD. Service Solutions 28 Clayton Road

Notting Hill, Victoria, 3168

Telephone: (03) 9544 6222

Facsimile: (03) 9544 5222

Tool Number Illustration Description Tool Classification

700-4208

Pass-Thru Connector Remover

Used to release the four locking tangs

on the Pass-Thru connector from the

transmission case.

Previously released Desirable

J6125-1B

Slide Hammer

Used for a number of bush removal

operations.

Previously released Unique

J8092

Driver Handle

Used for a number of bush installation

operations.

Previously released Unique

J8433 Puller

Used with J21427-01 to remove the

output speed sensor ring from the

main shaft.

Previously released Unique

J8763-02 Holding Fixture

Used in conjunction with holding

fixture base J3289-20 to hold

automatic transmission.

Previously released. Unique

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3814 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–28

7 Ensure that all wiring harness connectors are fitted correctly and secure.

8 W hen steam or pressure cleaning vehicle components, such as engines, transmissions, etc., do not direct the cleaning nozzle at any system electrical wiring harness connectors or components.

9 Do not clear any DTCs unless instructed.

10 The fault must be present when using the Diagnostic Trouble Code (DTC) Diagnostic Tables. Otherwise, misdiagnosis or replacement of good parts may occur.

11 Do not touch any electronic control module connector pins or soldered components on the circuit board. This is required to avoid the possibility of electrostatic discharge damage.

12 Use only the test equipment specified in the diagnostic tables, as other test equipment may give incorrect results or damage good components.

13 Electronic control modules are designed to withstand normal current draws associated with vehicle operation. However, the following fault conditions or incorrect test procedure may overload internal control module circuits and

irreparably damage the control module:

• A short to voltage fault condition in any of the control module low reference circuits may cause internal and/or

sensor damage. Therefore, any short to voltage fault condition in the control module low reference circuits

must be rectified before replacing a faulty component.

• A short to ground fault condition in any of the control module 5 volts reference circuits may cause internal

control module and/or sensor damage. Therefore, any short to ground fault condition in the control module 5

volt reference circuits must be rectified before replacing a faulty component.

• W hen using a test light to test an electrical circuit, do not use any of the control module low reference circuits

or 5 volts reference circuits as a reference point. Otherwise, excessive current draw from the test light may

damage the control module.

14 Disregard DTCs that set while performing the following diagnostic Steps:

• Using the Tech 2 output control function, or

• Disconnecting a control module system sensor connector then switching the ignition ON.

15 After completing the required diagnostics and service operations, road test the vehicle to ensure correct system operation.

4.4 Preliminary Checks

The Preliminary Checks is a set of visual and physical checks or inspections that may quickly identify a control module

system fault condition:

1 Refer to relevant Service Techlines for information regarding the fault condition.

2 Ensure that the battery is fully charged.

3 Inspect the battery connections for corrosion or a loose terminal.

4 Ensure that all relevant control module system related fuses are serviceable.

5 Inspect for incorrect aftermarket theft deterrent devices, lights or mobile phone installation.

6 Ensure that there is no speaker magnet positioned too close to any electronic module that contains relays.

7 Inspect the system wiring harness for proper connections, pinches or cuts.

8 Ensure that all control module related electrical wiring connectors are fitted correctly.

9 Inspect the control module ground connections for corrosion, loose terminal or incorrect position.

10 Ensure that the resistance between the control module housing and the battery ground cable is less than 0.5 ohms.

11 Check that the control module and its mounting bracket is secure.

12 Check all control module related components for correct installation.

13 Check the control module and related wiring harness routing to ensure that no rubbing or cutting of the wiring harness by sharp body components can occur.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4376 of 6020

7A2-92 TRANSMISSION CONTROL SYSTEM (JR405E)

Symptoms - Transmission Controls

Symptoms - Transmission Controls

Important Preliminary Inspections Before Starting

Perform Diagnostic System Check - Transmission

Controls before using the symptom tables, and verify

that all of the following are true:

• The TCM and check trans lamp is operating correctly.

• The scan tool data is within the normal operating range. Refer to Scan Tool Data List in this section.

• Verify the customer concern and locate the correct symptom in the table of contents. Inspect the items

indicated under that symptom.

Visual and Physical Inspection

Several of the symptom procedures ask for careful

visual and physical inspection. This step is extremely

important. The visual and physical inspection can lead

to correcting a problem without further inspections, and

can save valuable time. Ensure that:

• The TCM grounds are clean, tight, and in their proper location.

• The transmission harness wiring and terminals are properly connected and are not pinched or cut.

Intermittent

Important: Inspect for improper installation of electrical

components if an intermittent condition exists. Inspect

for aftermarket add-on electrical equipment devices,

lights, and cellular phones. Verify that no aftermarket

equipment is connected to the serial data circuit.

Important: The problem may or may not turn ON the

check trans lamp or store a DTC. Faulty electrical

connections or wiring cause most intermittent

problems.

Perform a careful visual and physical inspection of the

suspect connectors for the following conditions:

• Improperly mated connector halves

• Terminals that are not seated

• Terminals that are damaged or improperly formed

Reform or replace connector terminals in the problem

circuit in order to ensure proper contact tension.

Remove the terminal from the connector body in order

to inspect for poor terminal wire connection.

Road test the vehicle with the DMM connected to the

suspected circuit. An abnormal reading that occurs

when the malfunction occurs is a good indication that

there is a malfunction in the circuit being monitored.

Use the scan tool in order to help detect intermittent

conditions. Useful features of the Tech 2 includes the

following: • Trigger the Snapshot feature in order to capture

and store transmission parameters when the

malfunction occurs. Review this stored information

in order to see the specific running conditions that

caused the malfunction.

• Use the Plot Function on the scan tool in order to plot selected data parameters. Review this stored

information to aid in locating an intermittent

problem. Refer to the scan tool Users Guide for

more information.

Important: If the intermittent condition exists as a start

and then stall, test for DTCs relating to the vehicle theft

deterrent system. Test for improper installation of

electrical options such as lights, cellular phones, etc.

Any of the following may cause an intermittent check

trans lamp with no stored DTC:

• The TCM grounds are loose or dirty. Refer to Transmission Controls Schematics.

• The check trans lamp circuit intermittently shorted to ground

• Electrical system interference caused by a malfunctioning relay, TCM driven solenoid, or

switch. The electrical component can cause a

sharp electrical surge. Normally, the problem will

occur when the malfunctioning component is

operating.

• There are any open diodes.

Important: The following symptom tables contain

groups of possible causes for each symptom. The

order of these procedures is not important. If the scan

tool readings do not indicate the problems, then

proceed in a logical order, easiest to check or most

likely to cause first. In order to determine if a specific

vehicle is using a particular system or component, refer

to Transmission Controls Schematics for an

application.

Use the following tables when diagnosing a symptom

complaint:

• Intermittent Conditions

• Vehicle Does Not Run

• Trouble at Starting

• Faulty Gearshift

• Faulty Shift Pattern

• No or Error Gearshift

• Faulty Operation During Running

• Faulty Operation in Stopping

• Faulty Lock Up

• No Lock Up

• Transmission Fluid Leak

•Others

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4378 of 6020

7A2-94 TRANSMISSION CONTROL SYSTEM (JR405E)

Temperature Sensitivity• An intermittent condition may occur when a component/ connection reaches

normal operating temperature. The condition may occur only when the

component/ connection is cold, or only when the component/ connection is hot.

• If the intermittent is related to heat, review the data for a relationship with the following:

- High ambient temperatures.

- Underhood/ engine generated heat.

- Circuit generated heat due to a poor connection, or high electrical load.

- Higher than normal load conditions, towing, etc.

• If the intermittent is related to cold, review the data for the following: - Low ambient temperatures-In extremely low temperatures, ice may form in a connection or component. Test for water intrusion.

- The condition only occurs on a cold start.

- The condition goes away when the vehicle warms up.

• Information from the customer may help to determine if the trouble follows a pattern that is temperature related.

Electromagnetic Interference (EMI) and

Electrical Noise Some electrical components/ circuits are sensitive to EMI or other types of electrical

noise. Inspect the following conditions:

• A misrouted harness that is too close to high voltage/ high current devices such as injection components, motors, generator etc. These components may

induce electrical noise on a circuit that could interfere with normal circuit

operation.

• Electrical system interference caused by a malfunctioning relay, or the TCM driven solenoid or switch. These conditions can cause a sharp electrical surge.

Normally, the problem will occur when the malfunctioning component is

operating.

• Improper installation of non-factory or aftermarket add on accessories such as lights, 2-way radios, amplifiers, electric motors, remote starters, alarm systems,

cell phones, etc. These accessories may lead to an emission related failure

while in use, but do not fail when the accessories are not in use.

• Test for any open diodes. Some relays may contain a clamping diode.

• Test the generator for a bad rectifier bridge that may be allowing AC noise into the electrical system.

Incorrect TCM Programming • There are only a few situations where reprogramming a TCM is appropriate:

- An ECM from another vehicle is installed.

- Revised software/ calibration files have been released for this vehicle.

Important: DO NOT reprogram the TCM with the SAME software/ calibration files

that are already present in the TCM. This is not an effective repair for any type of

driveability problem.

• Verify that the TCM contains the correct software/ calibration. If incorrect programming is found, reprogram the TCM with the most current software/

calibration.

Duplicating Failure Conditions • If none of the previous tests are successful, attempt to duplicate and/ or capture

the failure conditions.

• An alternate method is to drive the vehicle with the DMM connected to a suspected circuit. An abnormal reading on the DMM when the problem occurs,

may help you locate the problem.

Scan Tool Snapshot The scan tool can be set up to take a Snapshot of the parameters available via serial

data. The Snapshot function records live data over a period of time. The recorded

data can be played back and analyzed. The scan tool can also graph parameters

singly or in combinations of parameters for comparison. The Snapshot can be

triggered manually at the time the symptom is noticed, or set up in advance to trigger

when a DTC sets.

An abnormal value captured in the recorded data may point to a system or

component that needs to be investigated further.

Refer to the scan tool Users Guide for more information.

Checks

Action

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5887 of 6020

11A-36 IMMOBILIZER CONTROL SYSTEM (4JK1/4JJ1/HFV6)

Resetting and Programming

Resetting and Programming Guidelines

Notice:The security information must be programmed

when the ICU, ECM, PIM or transponder key(s) is

replaced, or transponder key(s) is added.

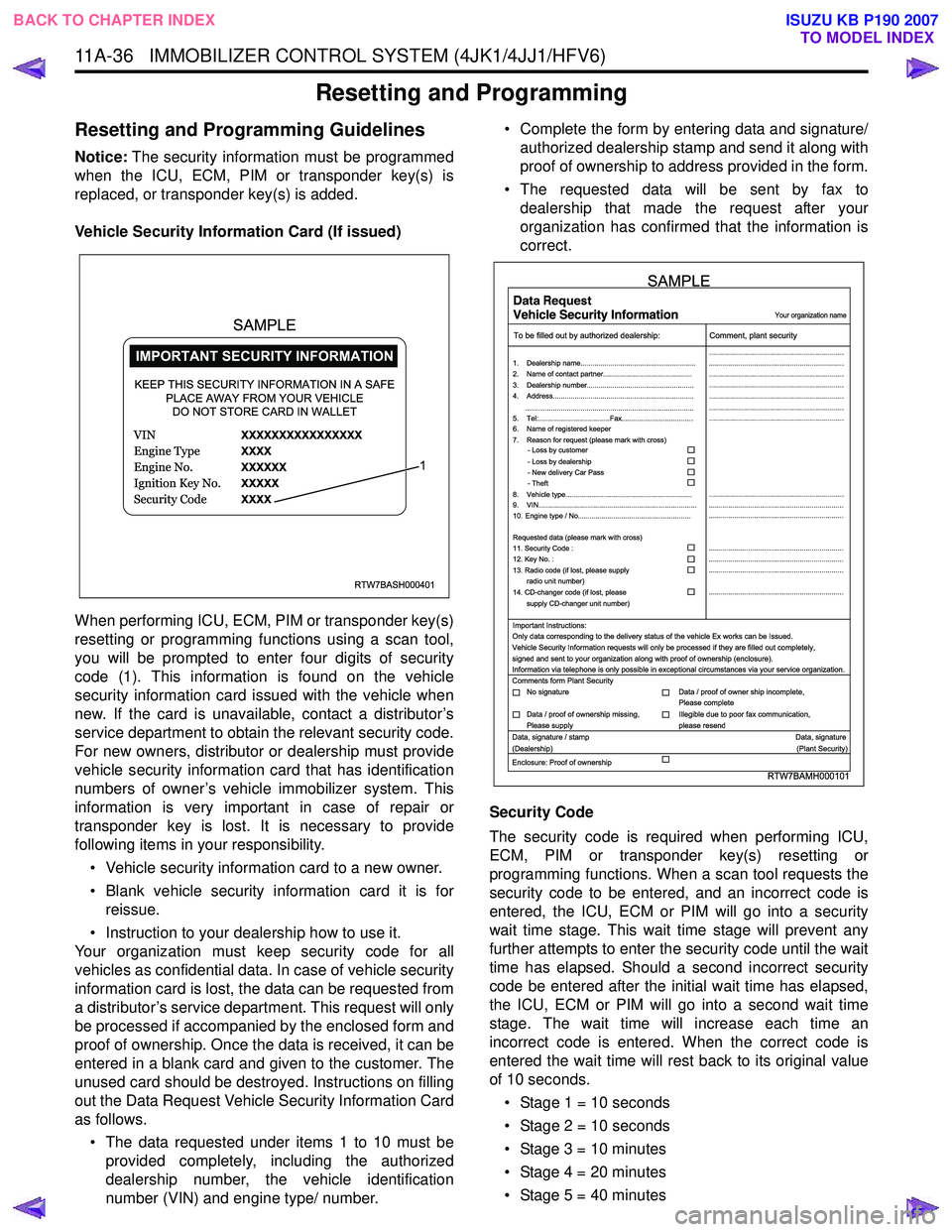

Vehicle Security Information Card (If issued)

When performing ICU, ECM, PIM or transponder key(s)

resetting or programming functions using a scan tool,

you will be prompted to enter four digits of security

code (1). This information is found on the vehicle

security information card issued with the vehicle when

new. If the card is unavailable, contact a distributor’s

service department to obtain the relevant security code.

For new owners, distributor or dealership must provide

vehicle security information card that has identification

numbers of owner’s vehicle immobilizer system. This

information is very important in case of repair or

transponder key is lost. It is necessary to provide

following items in your responsibility.

• Vehicle security information card to a new owner.

• Blank vehicle security information card it is for reissue.

• Instruction to your dealership how to use it.

Your organization must keep security code for all

vehicles as confidential data. In case of vehicle security

information card is lost, the data can be requested from

a distributor’s service department. This request will only

be processed if accompanied by the enclosed form and

proof of ownership. Once the data is received, it can be

entered in a blank card and given to the customer. The

unused card should be destroyed. Instructions on filling

out the Data Request Vehicle Security Information Card

as follows.

• The data requested under items 1 to 10 must be provided completely, including the authorized

dealership number, the vehicle identification

number (VIN) and engine type/ number. • Complete the form by entering data and signature/

authorized dealership stamp and send it along with

proof of ownership to address provided in the form.

• The requested data will be sent by fax to dealership that made the request after your

organization has confirmed that the information is

correct.

Security Code

The security code is required when performing ICU,

ECM, PIM or transponder key(s) resetting or

programming functions. When a scan tool requests the

security code to be entered, and an incorrect code is

entered, the ICU, ECM or PIM will go into a security

wait time stage. This wait time stage will prevent any

further attempts to enter the security code until the wait

time has elapsed. Should a second incorrect security

code be entered after the initial wait time has elapsed,

the ICU, ECM or PIM will go into a second wait time

stage. The wait time will increase each time an

incorrect code is entered. When the correct code is

entered the wait time will rest back to its original value

of 10 seconds.

• Stage 1 = 10 seconds

• Stage 2 = 10 seconds

• Stage 3 = 10 minutes

• Stage 4 = 20 minutes

• Stage 5 = 40 minutes

RTW7BASH000401

KEEP THIS SECURITY INFORMATION IN A SAFE PLACE AWAY FROM YOUR VEHICLEDO NOT STORE CARD IN WALLET

1

SAMPLE

RTW7BAMH000101

Your organization name

To be filled out by authorized dealership: Comment, plant security

1. Dealership name.......................................................... ....................................................................

....................................................................

....................................................................

....................................................................

....................................................................

....................................................................

....................................................................

....................................................................

.................................................................... ....................................................................

....................................................................

....................................................................

....................................................................

....................................................................

2. Name of contact partner.............................................

6. Name of registered keeper

7. Reason for request (please mark with cross)

3. Dealership number......................................................

4. Address.......................................................................

8. Vehicle type................................................................

9. VIN................................................................................

10. Engine type / No.........................................................

11. Security Code :

12. Key No. :

13. Radio code (if lost, please supply radio unit number)

14. CD-changer code (if lost, please

supply CD-changer unit number)

Requested data (please mark with cross)

5. Tel:....................................Fax....................................

.....................................................................................

- Loss by customer

- Loss by dealership

- New delivery Car Pass

- Theft

Important Instructions:

Comments form Plant Security

Data, signature / stamp Data, signature

(Dealership) (Plant Security)

Enclosure: Proof of ownership Only data corresponding to the delivery status of the vehicle Ex works can be Issued.

Vehicle Security Information requests will only be processed if they are filled out completely,

signed and sent to your organization along with proof of ownership (enclosure).

Information via telephone is only possible in exceptional circumstances via your service organization.

No signature Data / proof of owner ship incomplete,

Please complete

Data / proof of ownership missing,

Please supply Illegible due to poor fax communication,

please resend

SAMPLE

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5913 of 6020

IMMOBILIZER SYSTEM (C24SE, 4JA1-T) 11A-15

Important Instructions

Only data corresponding to the delivery status of the

vehicle can be issued. Car pass data requests will onl

y

be processed if the first column is filled out completely.

Signed and sent to your organization along with proof of

ownership.

Information via telephone is only possible in exceptional

circumstances via your service organization.

As for the delivery of new vehicles, the customer must

be informed about all features of the car pass that are

relevant to vehicle security, for example, that the ca

r

pass card should be kept in a safe place(not in the

vehicle) and should be presented when an authorized

your organization name workshop is visited, The exact

phrasing can be found in the relevant Owner's Manual.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007