ignition ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1650 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-33

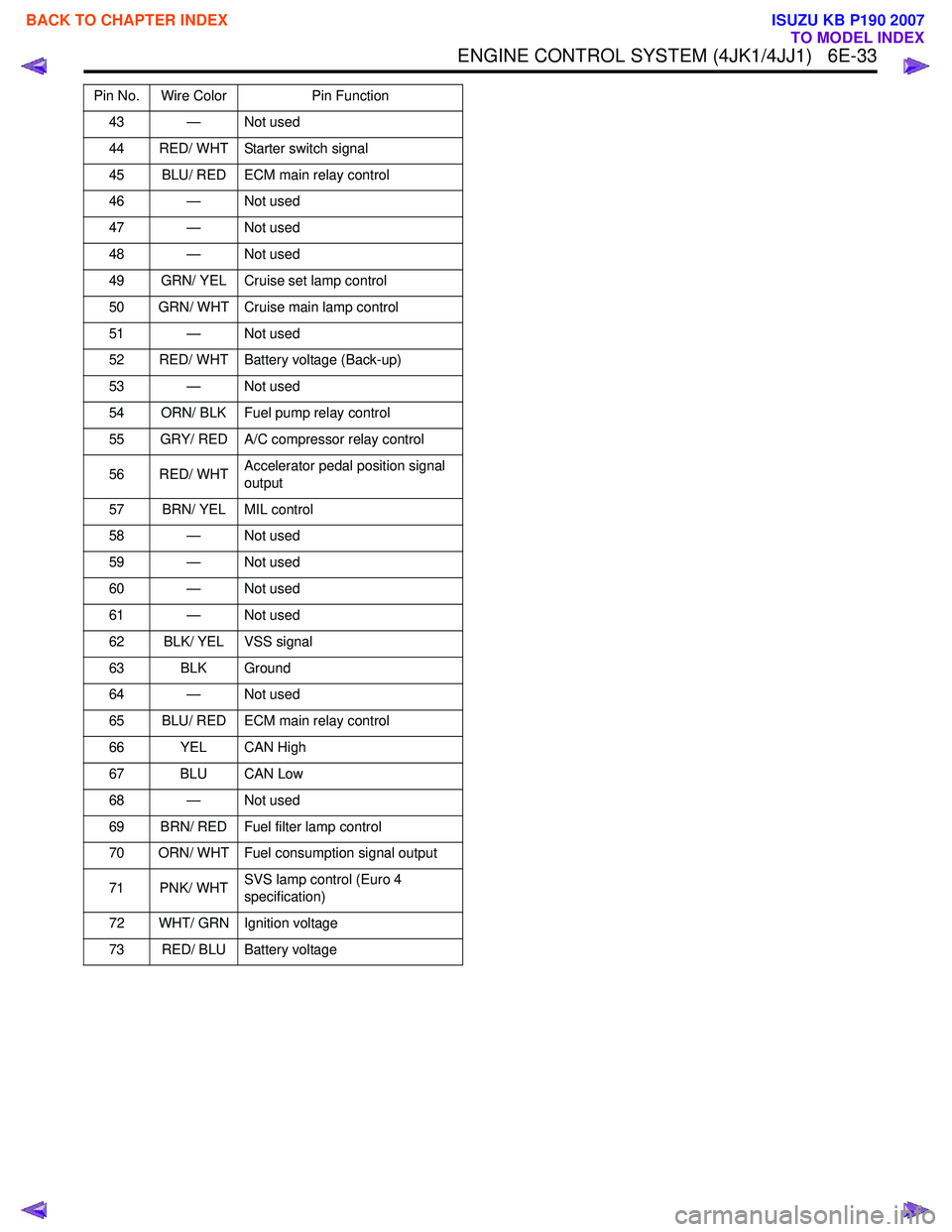

Pin No. Wire ColorPin Function

43 — Not used

44 RED/ WHT Starter switch signal

45 BLU/ RED ECM main relay control

46 — Not used

47 — Not used

48 — Not used

49 GRN/ YEL Cruise set lamp control

50 GRN/ WHT Cruise main lamp control

51 — Not used

52 RED/ WHT Battery voltage (Back-up)

53 — Not used

54 ORN/ BLK Fuel pump relay control

55 GRY/ RED A/C compressor relay control

56 RED/ WHT Accelerator pedal position signal

output

57 BRN/ YEL MIL control

58 — Not used

59 — Not used

60 — Not used

61 — Not used

62 BLK/ YEL VSS signal

63 BLK Ground

64 — Not used

65 BLU/ RED ECM main relay control

66 YEL CAN High

67 BLU CAN Low

68 — Not used

69 BRN/ RED Fuel filter lamp control

70 ORN/ WHT Fuel consumption signal output

71 PNK/ WHT SVS lamp control (Euro 4

specification)

72 WHT/ GRN Ignition voltage

73 RED/ BLU Battery voltage

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1652 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-35

Brake SwitchClutch Switch

Camshaft Position (CMP) Sensor

Connector No.

E-107

Connector Color Black

Test Adapter No. J-35616-64A

Pin No. Wire Color Pin Function

1 YEL Sensor signal

2 BLU Sensor low reference

3 GRN Sensor 5V reference

Connector No. C-44

Connector Color White

Test Adapter No. J-35616-40 (Pin1-2)

J-35616-2A (Pin3-4)

Pin No. Wire Color Pin Function

1GRN Switch 1 (stop lamp switch)

battery voltage feed

2 RED Switch 1 (stop lamp switch) signal

3 ORN Switch 2 signal

4WHT/ GRN Brake switch 2 ignition voltage

feed

RTW76ESH000801

12

34Connector No. C-77

Connector Color White

Test Adapter No. J-35616-42

Pin No. Wire Color Pin Function

1 WHT/ GRN Ignition voltage feed

2 YEL Switch signal

LNW46ESH000801

1

2

RTW76ESH000701

123

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1653 of 6020

6E-36 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

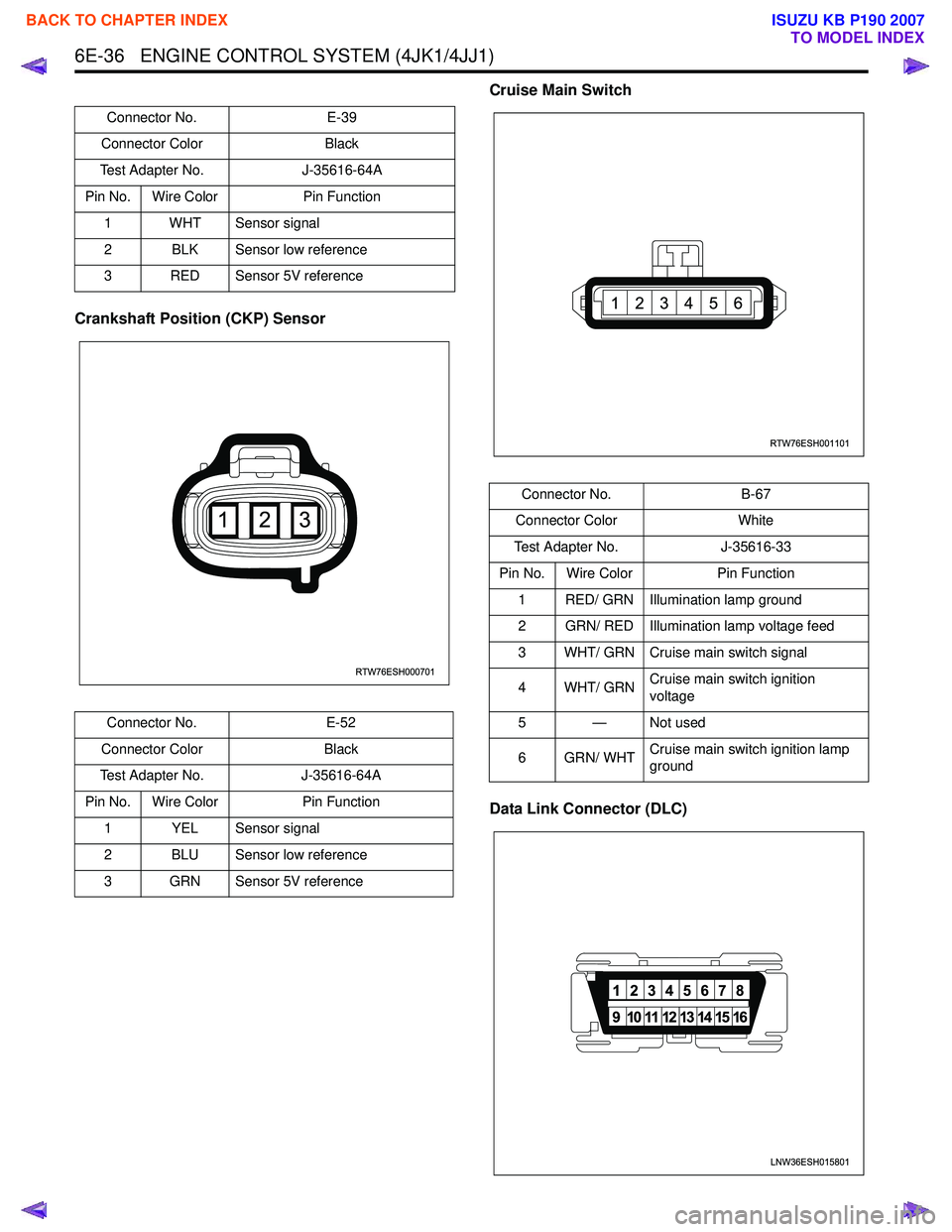

Crankshaft Position (CKP) SensorCruise Main Switch

Data Link Connector (DLC)

Connector No.

E-39

Connector Color Black

Test Adapter No. J-35616-64A

Pin No. Wire Color Pin Function

1 WHT Sensor signal

2 BLK Sensor low reference

3 RED Sensor 5V reference

Connector No. E-52

Connector Color Black

Test Adapter No. J-35616-64A

Pin No. Wire Color Pin Function

1 YEL Sensor signal

2 BLU Sensor low reference

3 GRN Sensor 5V reference

RTW76ESH000701

123

Connector No. B-67

Connector Color White

Test Adapter No. J-35616-33

Pin No. Wire Color Pin Function

1 RED/ GRN Illumination lamp ground

2 GRN/ RED Illumination lamp voltage feed

3 WHT/ GRN Cruise main switch signal

4WHT/ GRN Cruise main switch ignition

voltage

5 — Not used

6 GRN/ WHT Cruise main switch ignition lamp

ground

RTW76ESH001101

123456

LNW36ESH015801

87654321

16151413121110

9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1658 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-41

Intake Throttle ValveSwirl Control Solenoid Valve

Turbocharger Nozzle Control Solenoid Valve

Connector No. E-47

Connector Color Black

Test Adapter No. J-35616-64A

Pin No. Wire Color Pin Function

1 RED/ BLU MAF sensor ignition voltage feed

2 WHT/ BLU MAF sensor low reference

3 ORN/ BLU MAF sensor signal

4 BLU/ RED IAT sensor signal

5 BLU/ GRN IAT sensor low reference

Connector No. E-38

Connector Color Black

Test Adapter No. J-35616-64A

Pin No. Wire Color Pin Function

1 RED Solenoid control low side (PWM)

2 WHT Solenoid drive voltage

3 BLU Position sensor low reference

4 — Not used

5 ORN Position sensor signal

6 GRY Position sensor 5V reference

RTW76ESH000401

456

123

Connector No. E-67

Connector Color Brown

Test Adapter No. J-35616-64A

Pin No. Wire Color Pin Function 1 YEL Solenoid valve control

2 RED/ BLU Ignition voltage feed

RTW76ESH000201

12

RTW76ESH000101

21

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1659 of 6020

6E-42 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Vehicle Speed Sensor (VSS)

Connector No.E-106

Connector Color Brown

Test Adapter No. J-35616-64A

Pin No. Wire Color Pin Function

1 YEL/ BLK Solenoid valve control (PWM)

2 RED/ BLU Ignition voltage feed

Connector No. E-44

Connector Color Gray

Test Adapter No. J-35616-64A

Pin No. Wire Color Pin Function

1 YEL Ignition voltage feed

2 GRN/ WHT Sensor low reference

3 BLK/ YEL Sensor signal

LNW46ESH001401

12 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1661 of 6020

6E-44 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

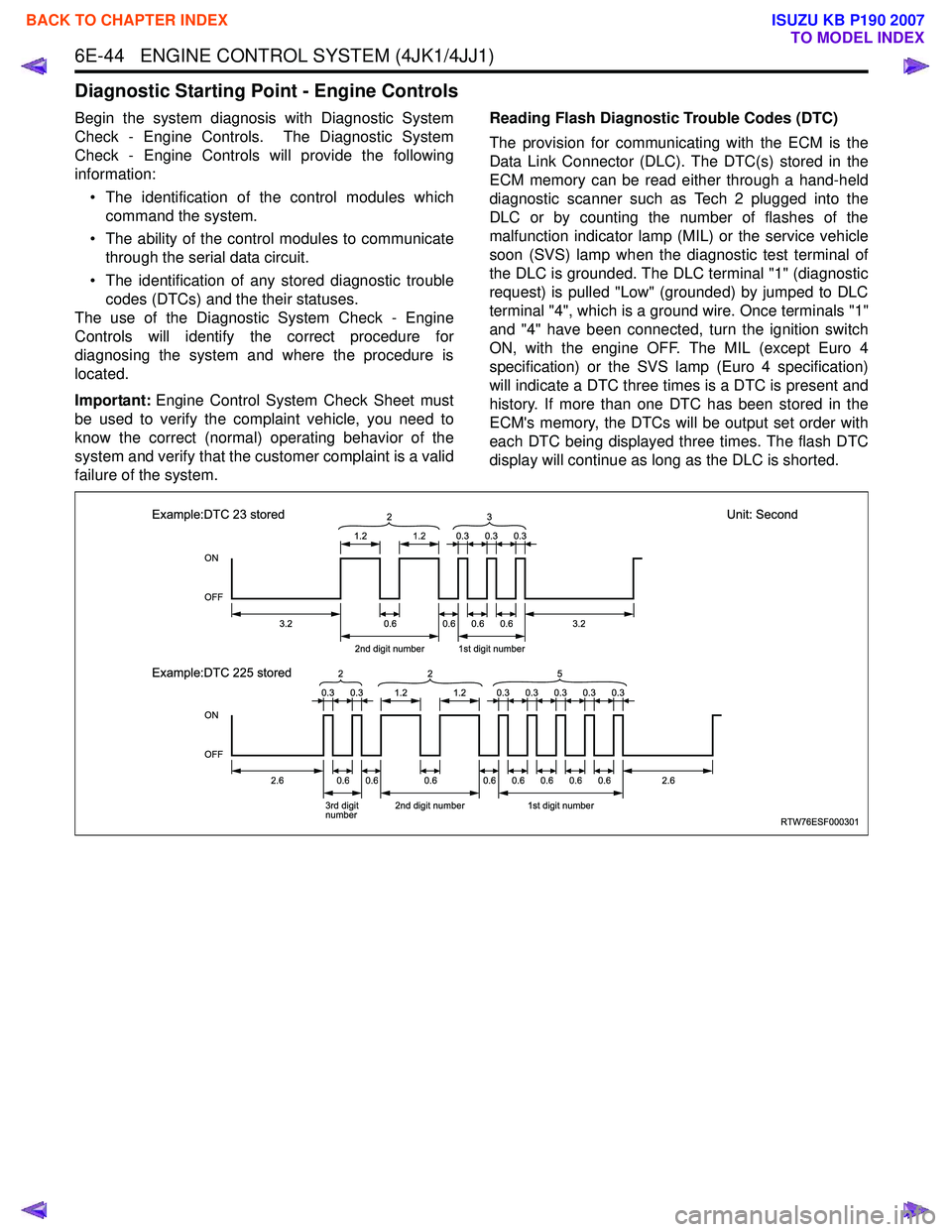

Diagnostic Starting Point - Engine Controls

Begin the system diagnosis with Diagnostic System

Check - Engine Controls. The Diagnostic System

Check - Engine Controls will provide the following

information:

• The identification of the control modules which command the system.

• The ability of the control modules to communicate through the serial data circuit.

• The identification of any stored diagnostic trouble codes (DTCs) and the their statuses.

The use of the Diagnostic System Check - Engine

Controls will identify the correct procedure for

diagnosing the system and where the procedure is

located.

Important: Engine Control System Check Sheet must

be used to verify the complaint vehicle, you need to

know the correct (normal) operating behavior of the

system and verify that the customer complaint is a valid

failure of the system. Reading Flash Diagnostic Trouble Codes (DTC)

The provision for communicating with the ECM is the

Data Link Connector (DLC). The DTC(s) stored in the

ECM memory can be read either through a hand-held

diagnostic scanner such as Tech 2 plugged into the

DLC or by counting the number of flashes of the

malfunction indicator lamp (MIL) or the service vehicle

soon (SVS) lamp when the diagnostic test terminal of

the DLC is grounded. The DLC terminal "1" (diagnostic

request) is pulled "Low" (grounded) by jumped to DLC

terminal "4", which is a ground wire. Once terminals "1"

and "4" have been connected, turn the ignition switch

ON, with the engine OFF. The MIL (except Euro 4

specification) or the SVS lamp (Euro 4 specification)

will indicate a DTC three times is a DTC is present and

history. If more than one DTC has been stored in the

ECM's memory, the DTCs will be output set order with

each DTC being displayed three times. The flash DTC

display will continue as long as the DLC is shorted.

RTW76ESF000301

ON

OFF

ON

OFF

1.2

3.2

2.62.6

2nd digit number1st digit number

3.20.6 2

1.2

0.60.60.6

0.30.30.3

0.30.30.30.30.3

Example:DTC 23 stored

Unit: Second

Example:DTC 225 stored

3rd digit

number 2nd digit number1st digit number

0.60.60.60.60.60.60.60.6

3

0.30.31.21.2

2

25

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1662 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-45

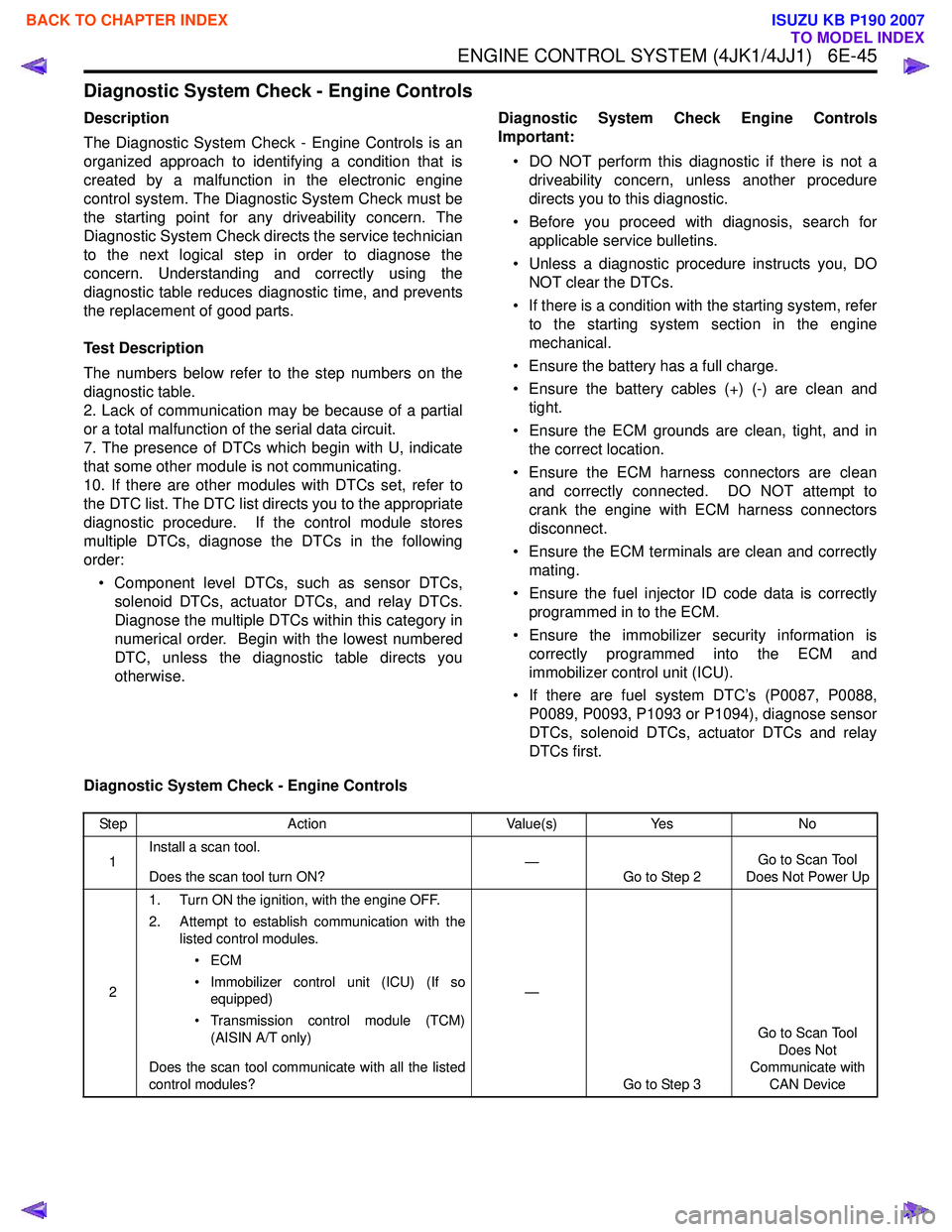

Diagnostic System Check - Engine Controls

Description

The Diagnostic System Check - Engine Controls is an

organized approach to identifying a condition that is

created by a malfunction in the electronic engine

control system. The Diagnostic System Check must be

the starting point for any driveability concern. The

Diagnostic System Check directs the service technician

to the next logical step in order to diagnose the

concern. Understanding and correctly using the

diagnostic table reduces diagnostic time, and prevents

the replacement of good parts.

Test Description

The numbers below refer to the step numbers on the

diagnostic table.

2. Lack of communication may be because of a partial

or a total malfunction of the serial data circuit.

7. The presence of DTCs which begin with U, indicate

that some other module is not communicating.

10. If there are other modules with DTCs set, refer to

the DTC list. The DTC list directs you to the appropriate

diagnostic procedure. If the control module stores

multiple DTCs, diagnose the DTCs in the following

order:

• Component level DTCs, such as sensor DTCs, solenoid DTCs, actuator DTCs, and relay DTCs.

Diagnose the multiple DTCs within this category in

numerical order. Begin with the lowest numbered

DTC, unless the diagnostic table directs you

otherwise. Diagnostic System Check Engine Controls

Important:

• DO NOT perform this diagnostic if there is not a driveability concern, unless another procedure

directs you to this diagnostic.

• Before you proceed with diagnosis, search for applicable service bulletins.

• Unless a diagnostic procedure instructs you, DO NOT clear the DTCs.

• If there is a condition with the starting system, refer to the starting system section in the engine

mechanical.

• Ensure the battery has a full charge.

• Ensure the battery cables (+) (-) are clean and tight.

• Ensure the ECM grounds are clean, tight, and in the correct location.

• Ensure the ECM harness connectors are clean and correctly connected. DO NOT attempt to

crank the engine with ECM harness connectors

disconnect.

• Ensure the ECM terminals are clean and correctly mating.

• Ensure the fuel injector ID code data is correctly programmed in to the ECM.

• Ensure the immobilizer security information is correctly programmed into the ECM and

immobilizer control unit (ICU).

• If there are fuel system DTC’s (P0087, P0088, P0089, P0093, P1093 or P1094), diagnose sensor

DTCs, solenoid DTCs, actuator DTCs and relay

DTCs first.

Diagnostic System Check - Engine Controls

Step Action Value(s)Yes No

1 Install a scan tool.

Does the scan tool turn ON? —

Go to Step 2 Go to Scan Tool

Does Not Power Up

2 1. Turn ON the ignition, with the engine OFF.

2. Attempt to establish communication with the listed control modules.

•ECM

• Immobilizer control unit (ICU) (If so equipped)

• Transmission control module (TCM) (AISIN A/T only)

Does the scan tool communicate with all the listed

control modules? —

Go to Step 3 Go to Scan Tool

Does Not

Communicate with CAN Device

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1665 of 6020

6E-48 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Fuel Rail Pressure SensorVolts1.4 to 1.5 volts More than 2.1 volts (4JJ1 Euro 4

specification)

More than 1.8 volts (4JJ1 except Euro 4 specification)

More than 1.9 volts (4JK1)

FRP Regulator Command (Fuel Rail Pressure) %

35 to 50 % 35 to 45 %

FRP Regulator Commanded Fuel Flow mm

3/sec More than 1,000 mm3/sec More than 2,000 mm3/sec

FRP Regulator Feedback (Fuel Rail Pressure) mA

1,600 to 2,000 mA 1,500 to 1,800 mA

Accelerator Pedal Position %0% 10 to 25 %

APP Sensor 1 (Accelerator Pedal Position) Volts

0.2 to 1.0 volts 1.0 to 1.7 volts

APP Sensor 2 (Accelerator Pedal Position) Volts

3.8 to 4.6 volts 3.3 to 3.9 volts

APP Sensor 3 (Accelerator Pedal Position) Volts

3.8 to 4.6 volts 3.7 to 4.0 volts

EGR Solenoid Command %Less than 30 % Less than 30 %

Desired EGR Position %Less than 70 % Less than 80 %

EGR Position %Less than 70 % Less than 80 %

EGR Position Sensor VoltsLess than 2.9 volts Less than 3.1 volts

Intake Throttle Solenoid Command %

Less than 30 % Less than 40 %

Desired Intake Throttle Position %Less than 30 % Less than 80 %

Intake Throttle Position %Less than 30 % Less than 80 %

Intake Throttle Position Sensor Volts Less than 1.6 voltsLess than 3.3 volts

Desired Injection Quantity mm

37 to 12 mm37 to 12 mm3

Main Injection Quantitymm33 to 8 mm35 to 10 mm3

Main Injection Timing°CA 2 to 12 °CA 0 to 10 °CA

Main Injection On Time ms600 to 800 ms 400 to 550 ms

Pre Injection Quantity mm

31 to 4 mm32 to 4 mm3

Pre Injection Interval°CA 3 to 20 °CA 10 to 30 °CA

Fuel Compensation Cyl. 1 mm

3-5.0 to 5.0 mm3 (varies)0.0 mm3

Fuel Compensation Cyl. 2 mm3-5.0 to 5.0 mm3 (varies)0.0 mm3

Fuel Compensation Cyl. 3 mm3-5.0 to 5.0 mm3 (varies)0.0 mm3

Fuel Compensation Cyl. 4 mm3-5.0 to 5.0 mm3 (varies)0.0 mm3

Cylinder Balancing Update Enabled/ Disabled EnabledDisabled

Fuel Supply Pump Status Not Learn/ Learning/ LearnedLearning or Learned

Learning or Learned

Rail Pressure Feedback Mode Wait Mode/ Feedback Mode/ Shutoff Mode Feedback Mode

Feedback Mode

Engine Running Status Off/ Ignition On/ Cranking/ Running Running

Running

Scan Tool Parameter Units Displayed Typical Data Value at Engine Idle Typical Data Value at 2000RPM

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1666 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-49

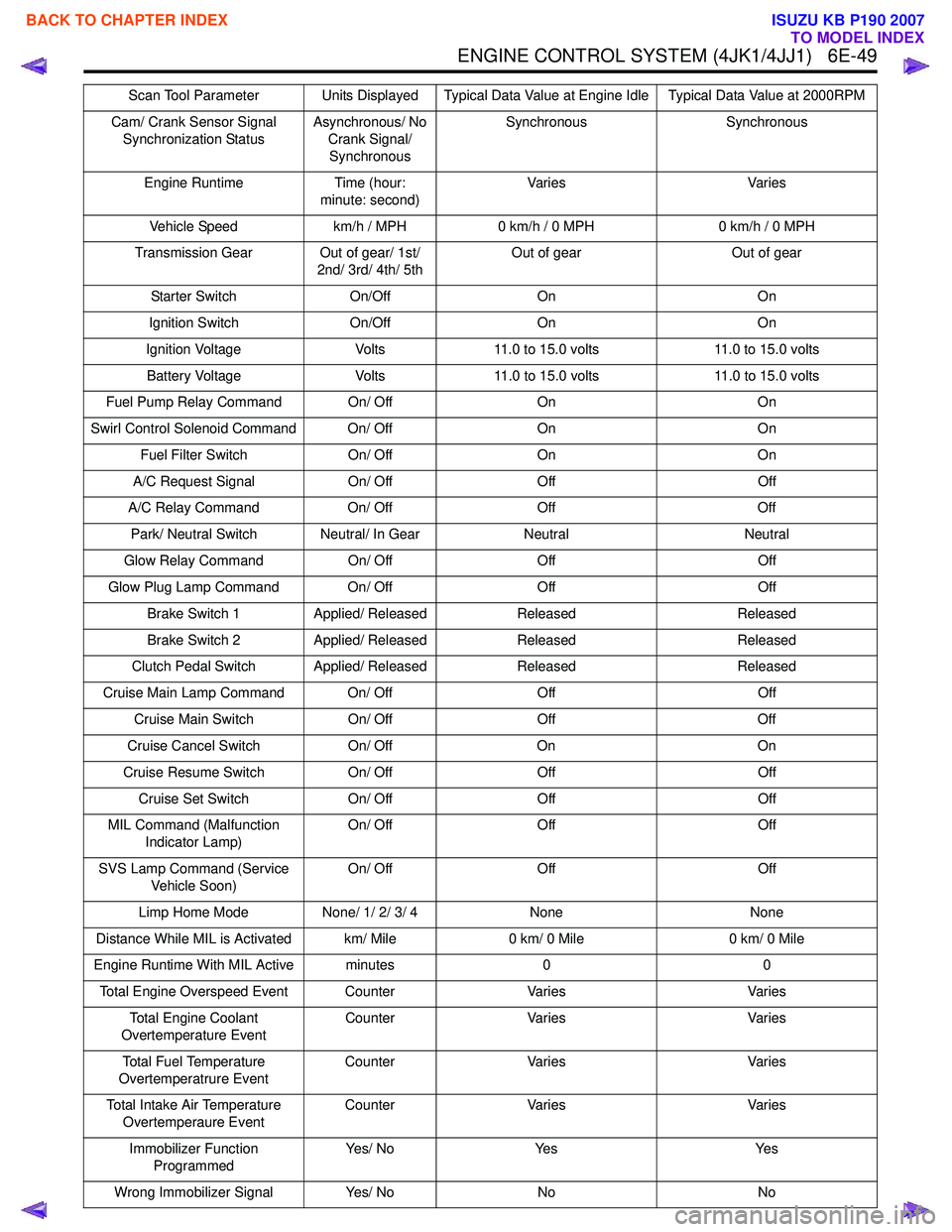

Cam/ Crank Sensor Signal Synchronization Status Asynchronous/ No

Crank Signal/ Synchronous Synchronous Synchronous

Engine Runtime Time (hour: minute: second) Va r i e s

Va r i e s

Vehicle Speed km/h / MPH0 km/h / 0 MPH 0 km/h / 0 MPH

Transmission Gear Out of gear/ 1st/ 2nd/ 3rd/ 4th/ 5th Out of gear

Out of gear

Starter Switch On/OffOn On

Ignition Switch On/OffOn On

Ignition Voltage Volts11.0 to 15.0 volts 11.0 to 15.0 volts

Battery Voltage Volts11.0 to 15.0 volts 11.0 to 15.0 volts

Fuel Pump Relay Command On/ Off OnOn

Swirl Control Solenoid Command On/ Off OnOn

Fuel Filter Switch On/ OffOn On

A/C Request Signal On/ OffOff Off

A/C Relay Command On/ OffOff Off

Park/ Neutral Switch Neutral/ In Gear NeutralNeutral

Glow Relay Command On/ OffOff Off

Glow Plug Lamp Command On/ Off OffOff

Brake Switch 1 Applied/ Released Released Released

Brake Switch 2 Applied/ Released Released Released

Clutch Pedal Switch Applied/ Released ReleasedReleased

Cruise Main Lamp Command On/ Off OffOff

Cruise Main Switch On/ OffOff Off

Cruise Cancel Switch On/ OffOn On

Cruise Resume Switch On/ OffOff Off

Cruise Set Switch On/ OffOff Off

MIL Command (Malfunction Indicator Lamp) On/ Off

Off Off

SVS Lamp Command (Service Vehicle Soon) On/ Off

Off Off

Limp Home Mode None/ 1/ 2/ 3/ 4 None None

Distance While MIL is Activated km/ Mile 0 km/ 0 Mile0 km/ 0 Mile

Engine Runtime With MIL Active minutes 00

Total Engine Overspeed Event Counter VariesVaries

Total Engine Coolant

Overtemperature Event Counter

Varies Varies

Total Fuel Temperature

Overtemperatrure Event Counter

Varies Varies

Total Intake Air Temperature Overtemperaure Event Counter

Varies Varies

Immobilizer Function Programmed Ye s / N o

Ye s Ye s

Wrong Immobilizer Signal Yes/ NoNo No

Scan Tool Parameter Units Displayed Typical Data Value at Engine Idle Typical Data Value at 2000RPM

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1669 of 6020

6E-52 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Desired EGR Position

This parameter displays EGR position desired by the

ECM based on current driving conditions. This can be

compared to the actual EGR position to determine

sensor accuracy or EGR control problems.

EGR Position

This parameter displays the EGR valve position

calculated by the ECM using the signal from EGR

position sensor. The scan tool will display a low

percentage when the EGR valve is closed, and a high

percentage when the ERG valve is opened.

EGR Position Sensor

This parameter displays the voltage signal sent to the

ECM from the EGR position sensor. EGR position

sensor is a range of value indicating a low voltage

when the EGR valve is closed, and a high voltage when

the EGR valve is opened.

Intake Throttle Solenoid Command

This parameter displays the intake throttle solenoid

valve control duty ratio based on inputs to the ECM

from various engine sensors. The scan tool will display

a lower percentage when the intake throttle solenoid

valve is controlled to open. The scan tool will display a

higher percentage when the intake throttle solenoid

valve is controlled to close.

Desired Intake Throttle Position

This parameter displays intake throttle position desired

by the ECM based on current driving conditions. This

can be compared to the actual intake throttle position to

determine sensor accuracy or intake throttle control

problems.

Intake Throttle Position

This parameter displays the intake throttle valve

position calculated by the ECM using the signal from

intake throttle position sensor. The scan tool will display

a low percentage when the intake throttle valve is

closed, and a high percentage when the intake throttle

valve is opened. Note that the intake throttle position

indicates over 100% if the solenoid is commanded

OFF.

Intake Throttle Position Sensor

This parameter displays the voltage signal sent to the

ECM from the intake throttle position sensor. Intake

throttle position sensor is a range of value indicating a

low voltage when the intake throttle valve is closed to a

high voltage when the intake throttle valve is opened.

Desired Injection Quantity

This parameter displays a total injection quantity (main

injection quantity + pre injection quantity) desired by

the ECM based on current driving conditions.

Main Injection Quantity

This parameter displays a main injection quantity

desired by the ECM based on current driving

conditions. Main Injection Timing

This parameter displays a main injection timing desired

by the ECM based on current driving conditions.

Main Injection On Time

This parameter displays the time the ECM turns ON the

fuel injectors. The scan tool will display a higher value

with a longer pulse width, or a lower value with a

shorter pulse width.

Pre Injection Quantity

This parameter displays a pilot injection quantity

desired by the ECM based on current driving

conditions.

Pre Injection Interval

This parameter displays a injection interval between

end of pilot injection and start of main injection desired

by the ECM based on current driving condition.

Fuel Compensation Cyl. 1 to 4

This parameter displays the adjustment of fuel volume

for each cylinder at low engine speed area as

calculated by the ECM. The scan tool will display a

negative value if the fuel volume is lowered. The scan

tool will display a positive value if the fuel volume is

increased. If there is a cylinder that is excessively high

or low value, it may indicate faulty fuel injector, weak or

slightly seized cylinder or an incorrectly programmed

fuel injector ID code.

Cylinder Balancing Update

This parameter displays the state of the fuel

compensation for each cylinder. Enabled indicates the

adjustment of fuel volume for each cylinder is being

executed by the ECM when the engine is idle speed,

the engine coolant temperature sensor, the intake air

temperature sensor, barometric pressure sensor and

the vehicle speed sensor inputs are normal state.

Fuel Supply Pump Status

This parameter displays the learning state of the fuel

supply pump. Not Learn indicates initialized state that is

replaced to a new ECM or adjustment value is reset.

After engine is warm upped, leaning will start at idle

speed. Learning indicates learning state. Learned

indicates learning process is completed state.

Rail Pressure Feedback Mode

This parameter displays the state of the fuel rail

pressure feedback to the ECM. Wait Mode indicates

the ignition switch is turned ON position. Feedback

Mode indicates the engine is during crank or run.

Shutoff Mode indicates the ignition switch is turned

OFF position.

Engine Mode

This parameter displays the state of engine. Ignition On

indicates the ignition switch is turned ON position.

Cranking indicates the engine is during crank. Running

indicates the engine is run. Off indicates the ignition

switch is tuned OFF position.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007