fuses ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 129 of 6020

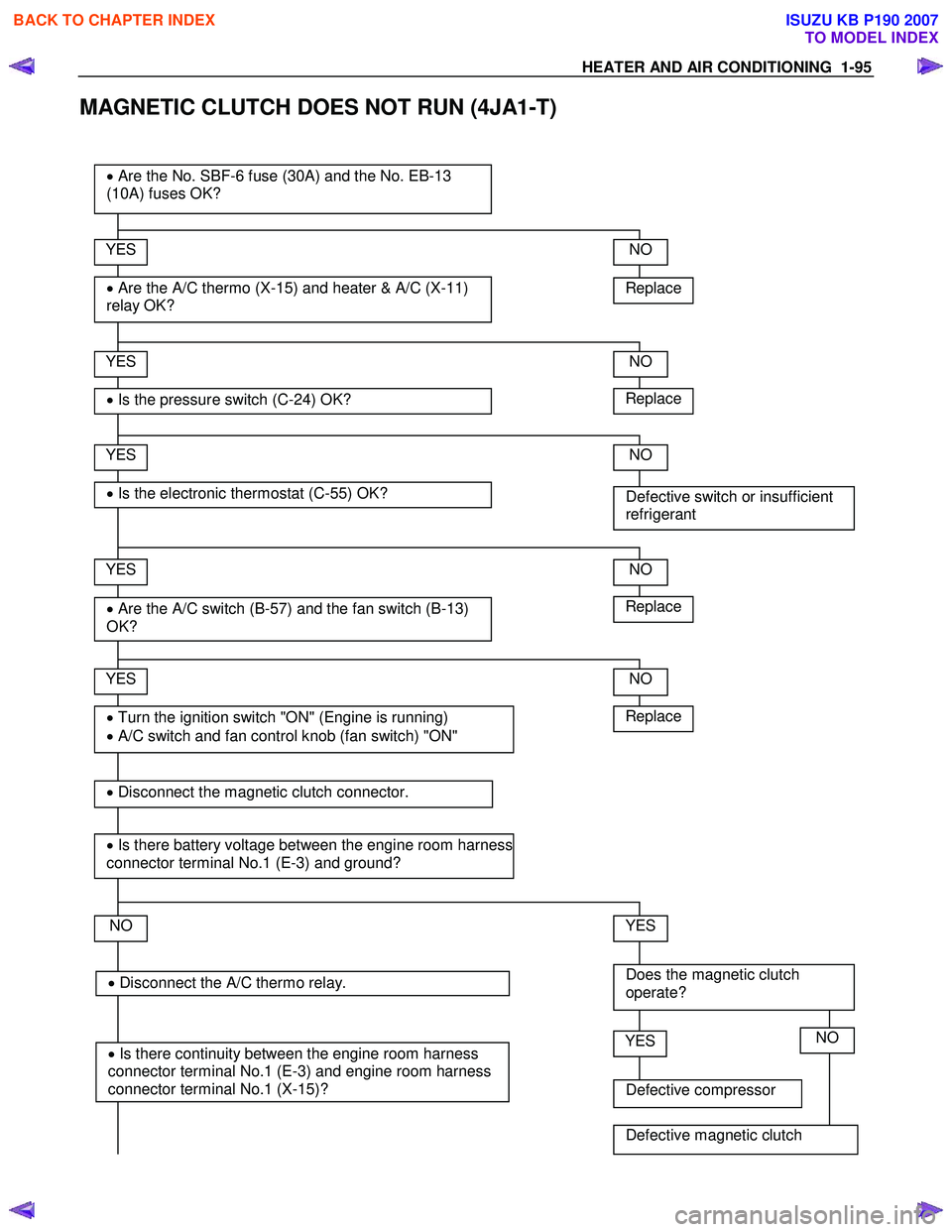

HEATER AND AIR CONDITIONING 1-95

MAGNETIC CLUTCH DOES NOT RUN (4JA1-T)

Replace

YES

• Are the A/C thermo (X-15) and heater & A/C (X-11)

relay OK?

• Are the No. SBF-6 fuse (30A) and the No. EB-13

(10A) fuses OK?

YES

• Is the pressure switch (C-24) OK?

YES

• Are the A/C switch (B-57) and the fan switch (B-13)

OK?

NO

YES

• Turn the ignition switch "ON" (Engine is running)

• A/C switch and fan control knob (fan switch) "ON"

NO

Replace

NO

Defective switch or insufficient

refrigerant

NO

NO

Does the magnetic clutch

operate?

YES

Replace

• Disconnect the magnetic clutch connector.

• Is there battery voltage between the engine room harness

connector terminal No.1 (E-3) and ground?

Defective compressor

YESNO

Defective magnetic clutch

• Is the electronic thermostat (C-55) OK?

YES

Replace

NO

• Disconnect the A/C thermo relay.

• Is there continuity between the engine room harness

connector terminal No.1 (E-3) and engine room harness

connector terminal No.1 (X-15)?

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 134 of 6020

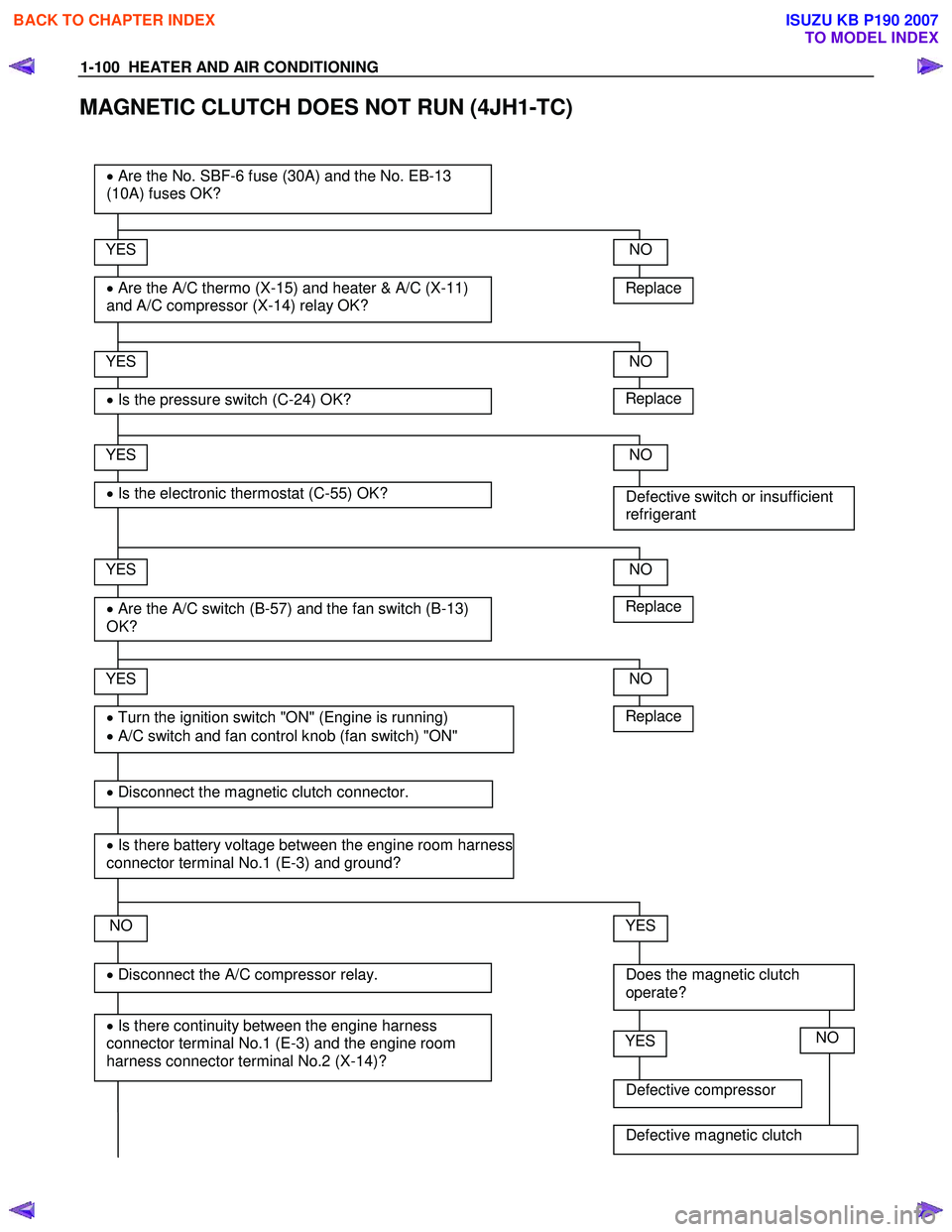

1-100 HEATER AND AIR CONDITIONING

MAGNETIC CLUTCH DOES NOT RUN (4JH1-TC)

Replace

YES

• Are the A/C thermo (X-15) and heater & A/C (X-11)

and A/C compressor (X-14) relay OK?

• Are the No. SBF-6 fuse (30A) and the No. EB-13

(10A) fuses OK?

YES

• Is the pressure switch (C-24) OK?

YES

• Are the A/C switch (B-57) and the fan switch (B-13)

OK?

NO

YES

• Is there continuity between the engine harness

connector terminal No.1 (E-3) and the engine room

harness connector terminal No.2 (X-14)?

• Disconnect the A/C compressor relay.

• Turn the ignition switch "ON" (Engine is running)

• A/C switch and fan control knob (fan switch) "ON"

NO

Replace

NO

Defective switch or insufficient

refrigerant

NO

NO

Does the magnetic clutch

operate?

YES

Replace

• Disconnect the magnetic clutch connector.

• Is there battery voltage between the engine room harness

connector terminal No.1 (E-3) and ground?

Defective compressor

YESNO

Defective magnetic clutch

• Is the electronic thermostat (C-55) OK?

YES

Replace

NO

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 139 of 6020

HEATER AND AIR CONDITIONING 1-105

MAGNETIC CLUTCH DOES NOT RUN (4JJ1-TC Standard Output, 4JJ1-TC

High Output, 4JK1-TC High Output RHD MODEL)

Replace

YES

• Are the A/C thermo (X-15), heater & A/C (X-11) and

A/C compressor (X-14) relay OK?

• Are the No. SBF-6 fuse (30A) and the No. EB-13

(10A) fuses OK?

YES

• Is the pressure switch (C-24) OK?

YES

• Are the A/C switch (B-57) and the fan switch (B-13)

OK?

NO

YES

• Is there continuity between the engine harness

connector terminal No.1 (E-3) and the engine room

harness connector terminal No.2 (X-14)?

• Disconnect the A/C compressor relay.

• Turn the ignition switch "ON" (Engine is running)

• A/C switch and fan control knob (fan switch) "ON"

NO

Replace

NO

Defective switch or insufficient

refrigerant

NO

NO

Does the magnetic clutch

operate?

YES

Replace

• Disconnect the magnetic clutch connector.

• Is there battery voltage between the engine room

harness connector terminal No.1 (E-3) and ground?

Defective compressor

YESNO

Defective magnetic clutch

• Is the electronic thermostat (C-55) OK?

YES

Replace

NO

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 144 of 6020

1-110 HEATER AND AIR CONDITIONING

MAGNETIC CLUTCH DOES NOT RUN (4JJ1-TC Standard Output, 4JJ1-TC

High Output, 4JK1-TC High Output LHD MODEL)

Replace

YES

• Are the A/C thermo (X-15), heater & A/C (X-11) and

A/C compressor (X-14) relay OK?

• Are the No. SBF-6 fuse (30A) and the No. EB-13

(10A) fuses OK?

YES

• Is the pressure switch (C-24) OK?

YES

• Are the A/C switch (B-57) and the fan switch (B-13)

OK?

NO

YES

• Is there continuity between the engine harness

connector terminal No.1 (E-3) and the engine room

harness connector terminal No.2 (X-14)?

• Disconnect the A/C compressor relay.

• Turn the ignition switch "ON" (Engine is running)

• A/C switch and fan control knob (fan switch) "ON"

NO

Replace

NO

Defective switch or insufficient

refrigerant

NO

NO

Does the magnetic clutch

operate?

YES

Replace

• Disconnect the magnetic clutch connector.

• Is there battery voltage between the engine room

harness connector terminal No.1 (E-3) and ground?

Defective compressor

YESNO

Defective magnetic clutch

• Is the electronic thermostat (C-55) OK?

YES

Replace

NO

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 149 of 6020

HEATER AND AIR CONDITIONING 1-115

MAGNETIC CLUTCH DOES NOT RUN (C24SE)

Replace

YES

• Are the A/C thermo (X-15), heater & A/C (X-11)

and A/C compressor (X-14) relay OK?

• Are the No. SBF 8 fuse (30A) and the No. EB-13

(10A) fuses OK?

YES

• Is the pressure switch (C-24) OK?

YES

• Are the A/C switch (B-57) and the fan switch (B-13)

OK?

NO

YES

• Is there continuity between the engine harness

connector terminal No.1 (E-2) and the engine room

harness connector terminal No.2 (X-14)?

• Disconnect the A/C compressor relay.

• Turn the ignition switch "ON" (Engine is running)

• A/C switch and fan control knob (fan switch "ON")

NO

Replace

NO

Defective switch or insufficient

refrigerant

NO

NO

Does the magnetic clutch

operate?

YES

Replace

• Disconnect the magnetic clutch connector.

• Is there battery voltage between the engine room

harness connector terminal No.1 (E-2) and ground?

Defective compressor

YESNO

Defective magnetic clutch

• Is the electronic thermostat (C-55) OK?

Replace

NOYES

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 617 of 6020

5A-24 BRAKE CONTROL SYSTEM

Computer System Service Precautions

The Anti-lock Brake System and Electronic Brake-force

Distribution interfaces directly with the Electronic

Hydraulic Control Unit (EHCU) which is a control

computer that is similar in some regards to the Engine

Control Module. These modules are designed to

withstand normal current draws associated with vehicle

operation. However, care must be taken to avoid

overloading any of the EHCU circuits. In testing for

opens or shorts, do not ground or apply voltage to any

of the circuits unless instructed to do so by the

appropriate diagnostic procedure. These circuits should

only be tested with a high impedance multimeter

5-8840-0366-0 or special tools as described in this

section. Power should never be removed or applied to

any control module with the ignition in the “ON” position.

Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the “OFF”

position.

General Service Precautions

The following are general precautions which should be

observed when servicing and diagnosing the Anti-lock

Brake System and/or other vehicle systems. Failure to

observe these precautions may result in Anti-lock Brake

System and Electronic Brake-force Distribution

damage.

• If welding work is to be performed on the vehicle using an electric arc welder, the EHCU and valve

block connectors should be disconnected before the

welding operation begins.

• The EHCU and valve block connectors should never be connected or disconnected with the

ignition “ON”.

Note:

• If only rear wheels are rotated using jacks or drum tester, the system will diagnose a speed sensor

malfunction and the “ABS and Brake” warning lamp

will illuminate. But actually no trouble exists. W hen

the DTC is not detected and the ABS and BRAKE

warning lamp is on, “How to erase code” is

performed and an ABS and BRAKE warning lamp

are off.

If the battery has been discharged

The engine may stall if the battery has been completely

discharged and the engine is started via jumper cables.

This is because the Anti-lock Brake System (ABS) and

Electronic Brake-force Distribution (EBD) System

requires a large quantity of electricity. In this case, wait

until the battery is recharged, or set the ABS and EBD

to a non-operative state by removing the fuse for the

ABS. After the battery has been recharged, stop the

engine and install the ABS fuse. Start the engine again,

and confirm that the ABS warning Lamp does not light.

Note on Intermittents

As with virtually any electronic system, it is difficult to

identify an intermittent failure. In such a case duplicating

the system malfunction during a test drive or a good

description of vehicle behavior from the customer may

be helpful in locating a “most likely” failed component or

circuit. The symptom diagnosis chart may also be

useful in isolating the failure. Most intermittent

problems are caused by faulty electrical connections or

wiring. W hen an intermittent failure is encountered,

check suspect circuits for:

• Suspected harness damage.

• Poor mating of connector halves or terminals not fully seated in the connector body (backed out).

• Improperly formed or damaged terminals.

Test Driving ABS Complaint Vehicles

If there has been an abnormality in the lighting pattern

of the “ABS” warning lamp, the fault can be located in

accordance with the “DIAGNOSIS BY “ABS” W ARNING

LAMP ILLUMINATION PATTERN”. Although such

problems can be detected by the driver as a vehicle

symptom, it is still necessary to perform a test drive

following the test procedure mentioned below, in order

to reproduce the symptom for problem diagnosis on a

symptom basis:

1. Start the engine and make sure that the “ABS” W /L

goes OFF. If the W /L remains ON, it means that

the Diagnostic Trouble Code (DTC) is stored.

Therefore, read the code and locate the fault.

Note: The DTC cannot be cleared if the vehicle speed

does not exceed about 10km/h (6mph) at DTC, even

though the repair operation is completed.

2. Start the vehicle and accelerate to about 30 km/h (19 mph) or more.

3. Slowly brake and stop the vehicle completely.

4. Then restart the vehicle and accelerate to about 40 km/h (25 mph) or more.

5. Brake at a time so as to actuate the ABS and stop the vehicle.

6. Be cautious of abnormality during the test. If the W /L is actuated while driving, read the DTC and

locate the fault.

7. If the abnormality is not reproduced by the test, make best efforts to reproduce the situation

reported by the customer.

8. If the abnormality has been detected, repair in accordance with the “SYMPTOM DIAGNOSIS”.

Note:

• Be sure to perform a test drive on a wide, even road

with light traffic.

• If an abnormality is detected, be sure to suspend the test and start trouble diagnosis at once.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1034 of 6020

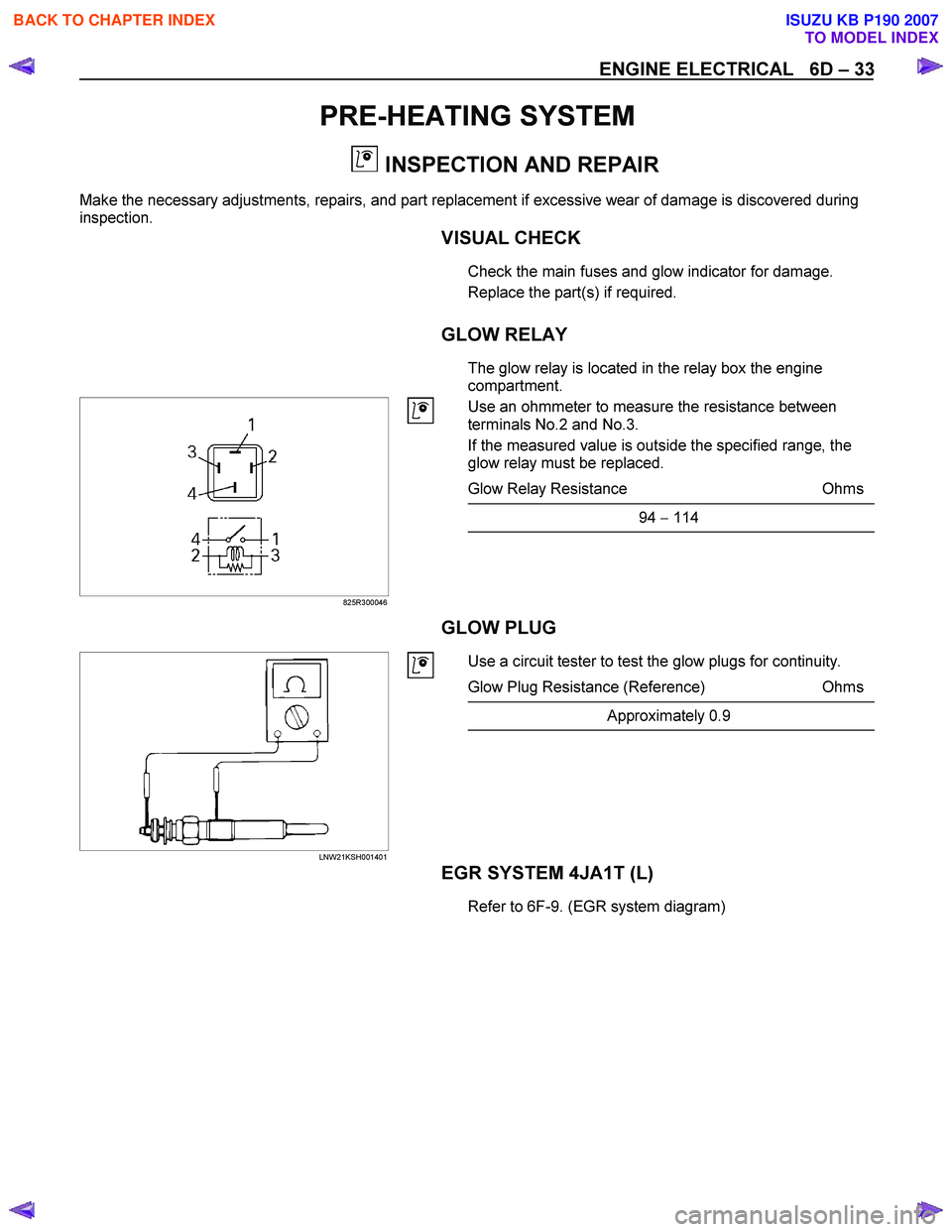

ENGINE ELECTRICAL 6D – 33

PRE-HEATING SYSTEM

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacement if excessive wear of damage is discovered during

inspection.

VISUAL CHECK

Check the main fuses and glow indicator for damage.

Replace the part(s) if required.

GLOW RELAY

The glow relay is located in the relay box the engine

compartment.

825R300046

Use an ohmmeter to measure the resistance between

terminals No.2 and No.3.

If the measured value is outside the specified range, the

glow relay must be replaced.

Glow Relay Resistance Ohms

94 − 114

GLOW PLUG

LNW21KSH001401

Use a circuit tester to test the glow plugs for continuity.

Glow Plug Resistance (Reference) Ohms

Approximately 0.9

EGR SYSTEM 4JA1T (L)

Refer to 6F-9. (EGR system diagram)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1291 of 6020

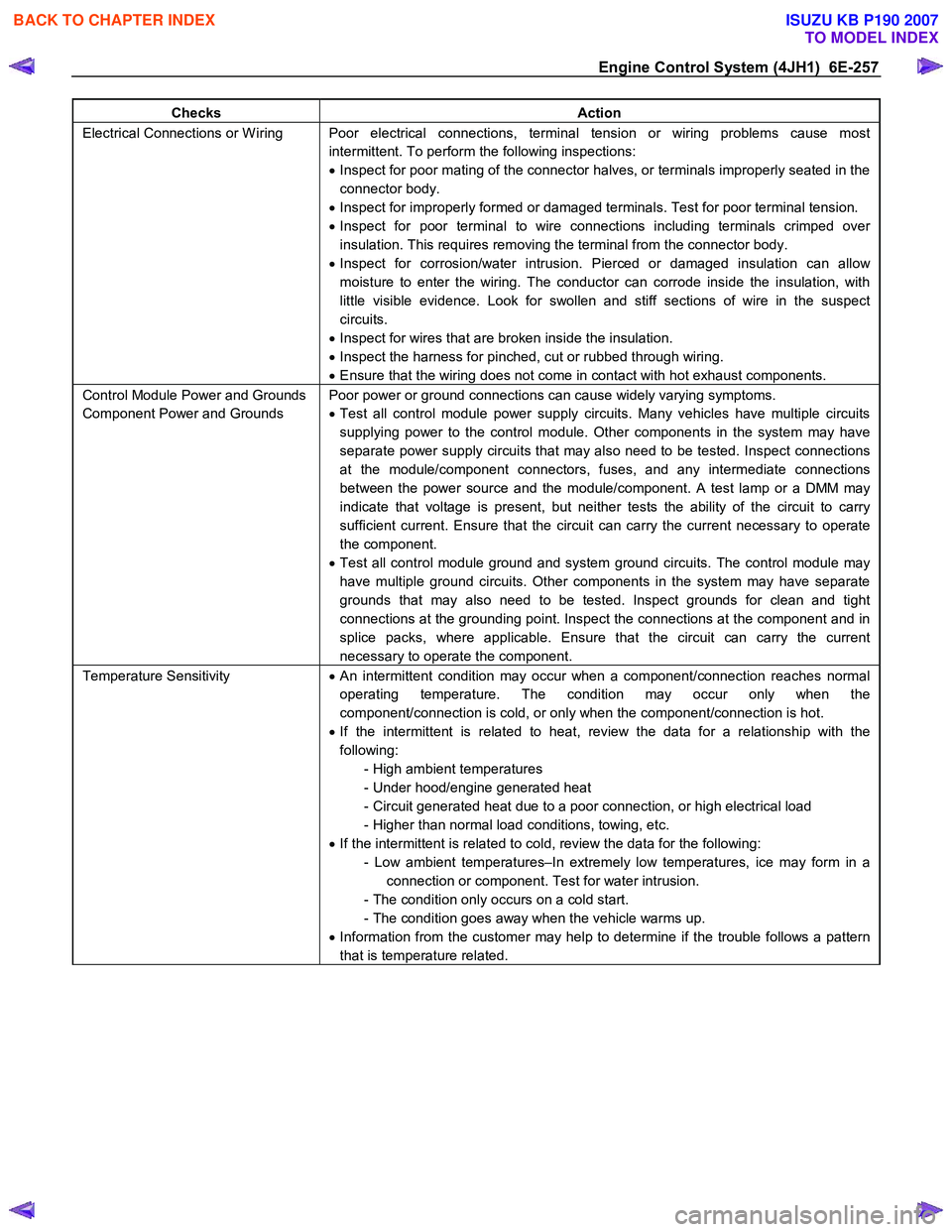

Engine Control System (4JH1) 6E-257

Checks Action

Electrical Connections or W iring Poor electrical connections, terminal tension or wiring problems cause most intermittent. To perform the following inspections:

• Inspect for poor mating of the connector halves, or terminals improperly seated in the

connector body.

• Inspect for improperly formed or damaged terminals. Test for poor terminal tension.

• Inspect for poor terminal to wire connections including terminals crimped over

insulation. This requires removing the terminal from the connector body.

• Inspect for corrosion/water intrusion. Pierced or damaged insulation can allow

moisture to enter the wiring. The conductor can corrode inside the insulation, with

little visible evidence. Look for swollen and stiff sections of wire in the suspect

circuits.

• Inspect for wires that are broken inside the insulation.

• Inspect the harness for pinched, cut or rubbed through wiring.

• Ensure that the wiring does not come in contact with hot exhaust components.

Control Module Power and Grounds

Component Power and Grounds Poor power or ground connections can cause widely varying symptoms.

• Test all control module power supply circuits. Many vehicles have multiple circuits

supplying power to the control module. Other components in the system may have

separate power supply circuits that may also need to be tested. Inspect connections

at the module/component connectors, fuses, and any intermediate connections

between the power source and the module/component. A test lamp or a DMM may

indicate that voltage is present, but neither tests the ability of the circuit to carry

sufficient current. Ensure that the circuit can carry the current necessary to operate

the component.

• Test all control module ground and system ground circuits. The control module may

have multiple ground circuits. Other components in the system may have separate

grounds that may also need to be tested. Inspect grounds for clean and tight

connections at the grounding point. Inspect the connections at the component and in

splice packs, where applicable. Ensure that the circuit can carry the current

necessary to operate the component.

Temperature Sensitivity • An intermittent condition may occur when a component/connection reaches normal

operating temperature. The condition may occur only when the

component/connection is cold, or only when the component/connection is hot.

• If the intermittent is related to heat, review the data for a relationship with the

following: - High ambient temperatures

- Under hood/engine generated heat

- Circuit generated heat due to a poor connection, or high electrical load

- Higher than normal load conditions, towing, etc.

• If the intermittent is related to cold, review the data for the following:

- Low ambient temperatures–In extremely low temperatures, ice may form in a connection or component. Test for water intrusion.

- The condition only occurs on a cold start.

- The condition goes away when the vehicle warms up.

• Information from the customer may help to determine if the trouble follows a pattern

that is temperature related.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1617 of 6020

ENGINE ELECTRICAL (4JK1/4JJ1) 6D-29

Pre-Heating System

Inspection and Repair

Make the necessary adjustments, repairs, and part

replacement if excessive wear of damage is discovered

during inspection.

Visual Check

Check the main fuses and glow indicator for damage.

Replace the part(s) if required.

Glow Relay

The glow relay is located in the relay box the engine

compartment.

Use an ohmmeter to measure the resistance between

terminals No.2 and No.3.

If the measured value is outside the specified range, the

glow relay must be replaced.

Glow Relay Resistance Ohms

94 - 114

825R300046

Glow Plug

Use a circuit tester to test the glow plugs for continuity.

Glow Plug Resistance (Reference) Ohms

Approximately 0.9

LNW 21KSH001401

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1942 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-325

Intermittent Conditions

ChecksAction

Definition:

The problem is not currently present but is indicated in DTC History.

OR

There is a customer complaint, but the symptom cannot currently be duplicated, if the problem is not DTC related.

Preliminary Checks • Refer to Symptoms - Engine Controls before starting.

Harness/ Connector Many intermittent open or shorted circuits are affected by harness/ connector

movement that is caused by vibration, engine torque, bumps/ rough pavement, etc.

Test for this type of condition by performing the applicable procedure from the following

list:

• Move related connectors and wiring while monitoring the appropriate scan tool data.

• Move related connectors and wiring with the component commanded ON, and OFF, with the scan tool. Observe the component operation.

• With the engine running, move related connectors and wiring while monitoring engine operation.

If harness or connector movement affects the data displayed, component/ system

operation, or engine operation, inspect and repair the harness/ connections as

necessary.

Electrical Connections or Wiring Poor electrical connections, terminal tension or wiring problems cause most intermittent. To perform the following inspections:

• Poor mating of the connector halves, or terminals improperly seated in the connector body.

• Improperly formed or damaged terminals. Test for poor terminal tension.

• Poor terminal to wire connections including terminals crimped over insulation. This requires removing the terminal from the connector body.

• Corrosion/ water intrusion. Pierced or damaged insulation can allow moisture to enter the wiring. The conductor can corrode inside the insulation, with little visible

evidence. Look for swollen and stiff sections of wire in the suspect circuits.

• Wires that are broken inside the insulation.

• Harness for pinched, cut or rubbed through wiring.

• Ensure that the wiring does not come in contact with hot exhaust components.

Control Module Power and Grounds

Component Power and Grounds Poor power or ground connections can cause widely varying symptoms.

• Test all control module power supply circuits. Many vehicles have multiple circuits supplying power to the control module. Other components in the system may have

separate power supply circuits that may also need to be tested. Inspect connections

at the module/ component connectors, fuses, and any intermediate connections

between the power source and the module/ component. A test lamp or a DMM may

indicate that voltage is present, but neither tests the ability of the circuit to carry

sufficient current. Ensure that the circuit can carry the current necessary to operate

the component.

• Test all control module ground and system ground circuits. The control module may have multiple ground circuits. Other components in the system may have separate

grounds that may also need to be tested. Inspect grounds for clean and tight

connections at the grounding point. Inspect the connections at the component and

in splice packs, where applicable. Ensure that the circuit can carry the current

necessary to operate the component.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007