ECO mode ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4 of 6020

0A-2 GENERAL INFORMATION

GENERAL REPAIR INSTRUCTIONS

1. Park the vehicle on level ground and chock the front or rear wheels before lifting the vehicle.

2. Raise the vehicle with a jack set against the axle or the frame.

3. Support the vehicle on chassis stands.

4. Use covers on the vehicle body, seats, and floor to prevent damage and/or contamination.

5. Disconnect the grounding cable from the battery before performing service operations.

This will prevent cable damage or burning due to short circuiting.

6. Handle brake fluid and antifreeze solution with great care.

Spilling these liquids on painted surfaces will damage the paint.

7. The use of the proper tool(s) and special tool(s) where specified is essential to efficient, reliable, and safe

service operations.

8. Always use genuine ISUZU replacement parts.

9. Discard used cotter pins, gaskets, O-rings, oil seals, lock washers, and self-locking nuts at disassembly.

Normal function of these parts cannot be guaranteed if they are reused.

10. Prepare new cotter pins, gaskets, O-rings, oil seals, lock washers, and self-locking nuts for installation.

11. Keep the disassembled parts neatly in groups. This will facilitate smooth and correct reassembly.

12. Keep fixing nuts and bolts separate. Fixing nuts and bolts vary in hardness and design according to installation position.

13. Clean all parts before inspection or reassembly.

14. Clean the oil ports and other openings with compressed air to make certain that they are free from dirt and obstructions.

15. Lubricate the rotating and sliding faces of all moving parts with oil or grease before installation.

16. Use the recommended liquid gasket to prevent leakage.

17. Carefully observe all nut and bolt torque specifications.

18. W hen removing or replacing parts that require refrigerant to the discharged from the air conditioning system, be sure to use the Vehicle Refrigerant Recovery and Recycling Equipment (VRRRE) to recover and recycle R134a,

to promote the aim of the protection of the ozone layer covering the earth.

19. Check and recheck your work. No service operation is complete until you have done this.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5 of 6020

GENERAL INFORMATION 0A-3

NOTES ON THE FORMAT OF THIS MANUAL

1. Find the applicable section by referring to the index at the front of the W orkshop Manual binder.

2. The following technical service information is included in this Section: • Identification

• Maintenance schedules

• Recommended Iubricants

• Recommended fuels

• Oil viscosity charts

3. Individual sections of this W orkshop Manual are divided into the following categories: • Main data and specifications

• Torque specifications

• Recommended liquid gasket

• Loctite application procedure

• Servicing

• Removal and installation

• Disassembly

• Inspection and repair

• Reassembly

• Troubleshooting

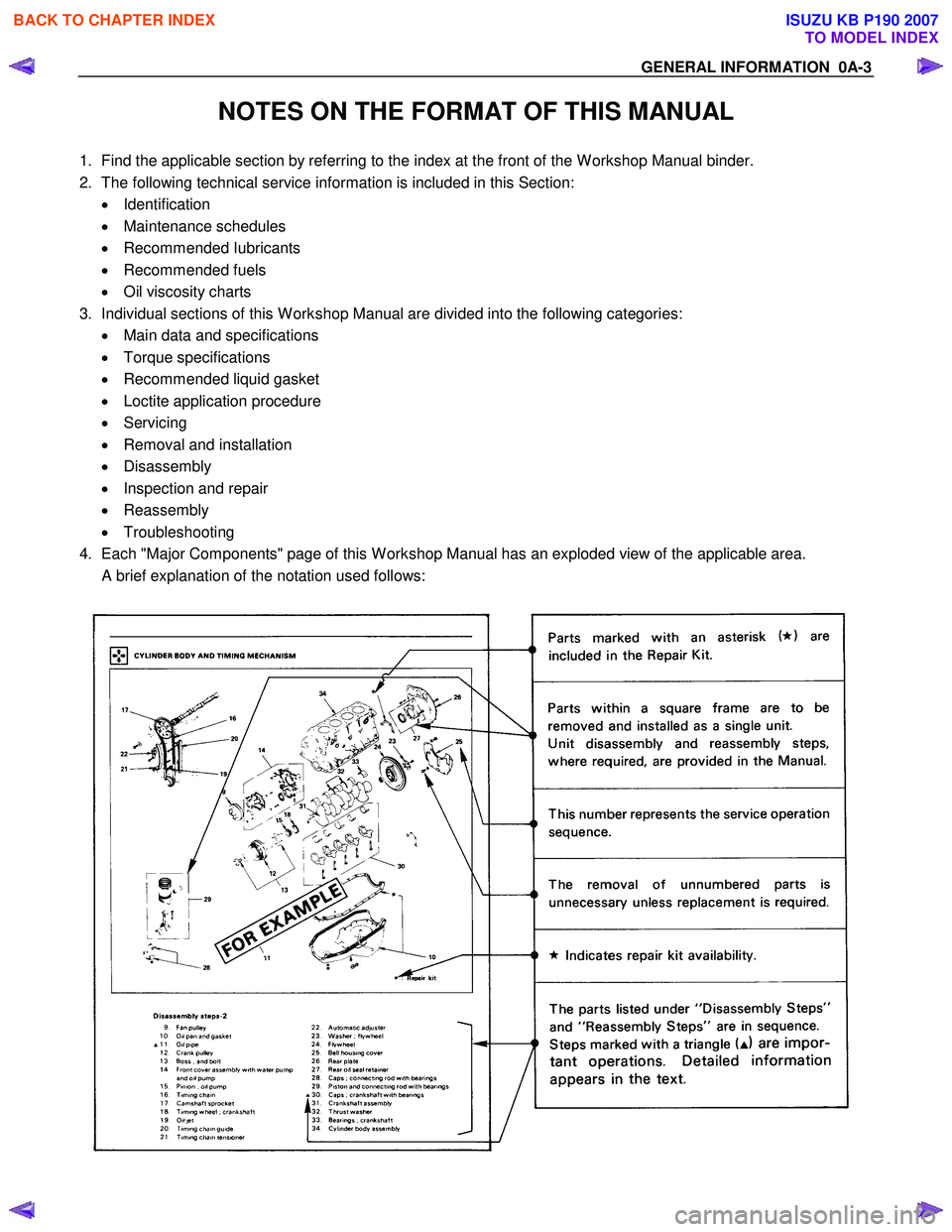

4. Each "Major Components" page of this W orkshop Manual has an exploded view of the applicable area.

A brief explanation of the notation used follows:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 6 of 6020

0A-4 GENERAL INFORMATION

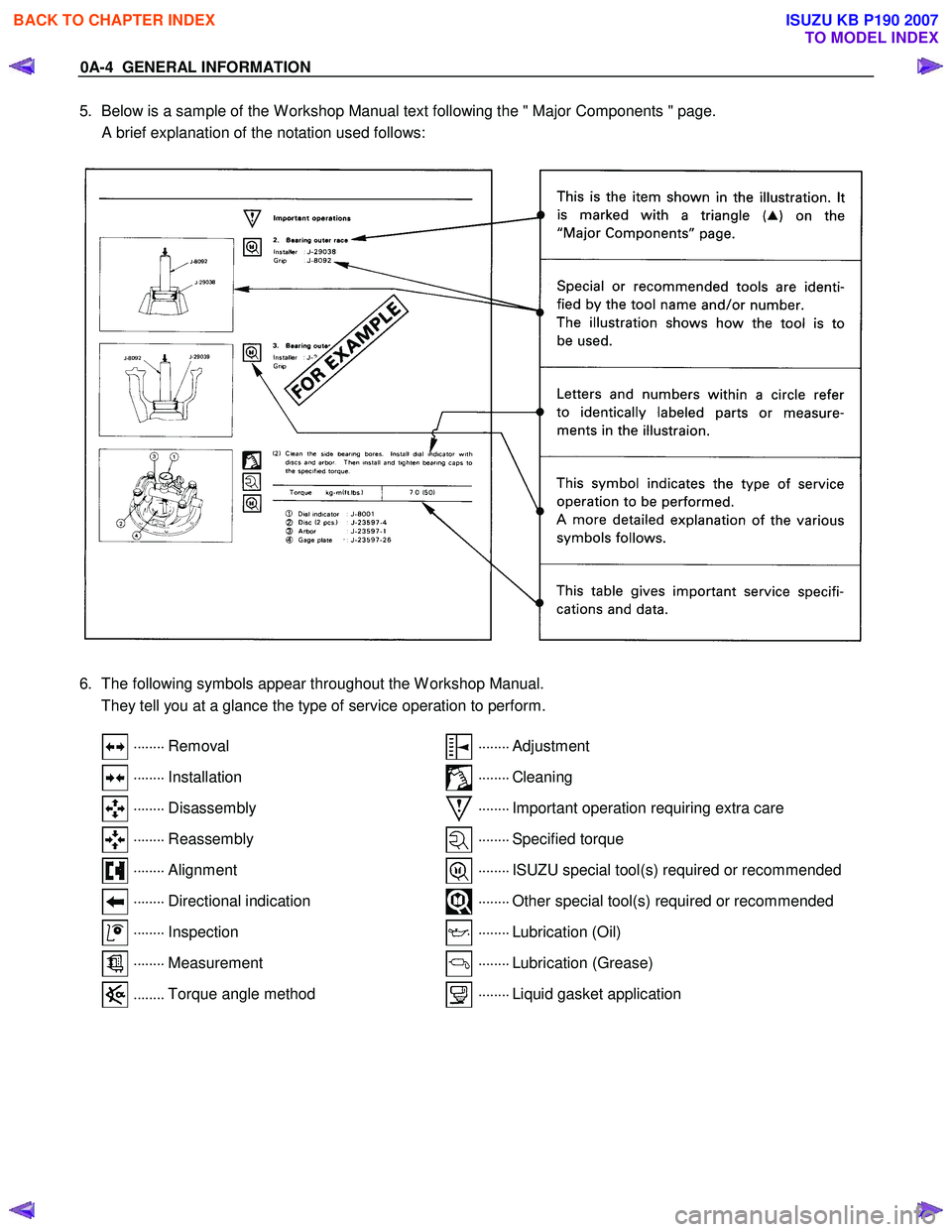

5. Below is a sample of the W orkshop Manual text following the " Major Components " page.

A brief explanation of the notation used follows:

6. The following symbols appear throughout the W orkshop Manual.

They tell you at a glance the type of service operation to perform.

........

Removal ........

Adjustment

........

Installation ........

Cleaning

........

Disassembly ........

Important operation requiring extra care

........

Reassembly ........

Specified torque

........

Alignment ........

ISUZU special tool(s) required or recommended

........

Directional indication ........

Other special tool(s) required or recommended

........

Inspection ........

Lubrication (Oil)

........

Measurement ........

Lubrication (Grease)

........

Torque angle method ........

Liquid gasket application

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 19 of 6020

MAINTENANCE AND LUBRICATION 0B-1

SECTION 0B

MAINTENANCE AND LUBRICATION

TABLE OF CONTENTS

PAGE

Maintenance Schedule (For GENERAL EXPORT)......................................................... 0B- 2

Maintenance Schedule (For EUROPE)........................................................................... 0B- 5

Severe Conditions Maintenance Schedule (For GENERAL EXPORT) ........................ 0B- 9

Severe Conditions Maintenance Schedule (For EUROPE) .......................................... 0B-10

Recommended Fluids and Lubricants (For GENERAL EXPORT) ............................... 0B-11

Recommended Fluids and Lubricants (For EUROPE) ................................................. 0B-13

Oil Viscosity Chart........................................................................................................... 0B-14

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 29 of 6020

MAINTENANCE AND LUBRICATION 0B-11

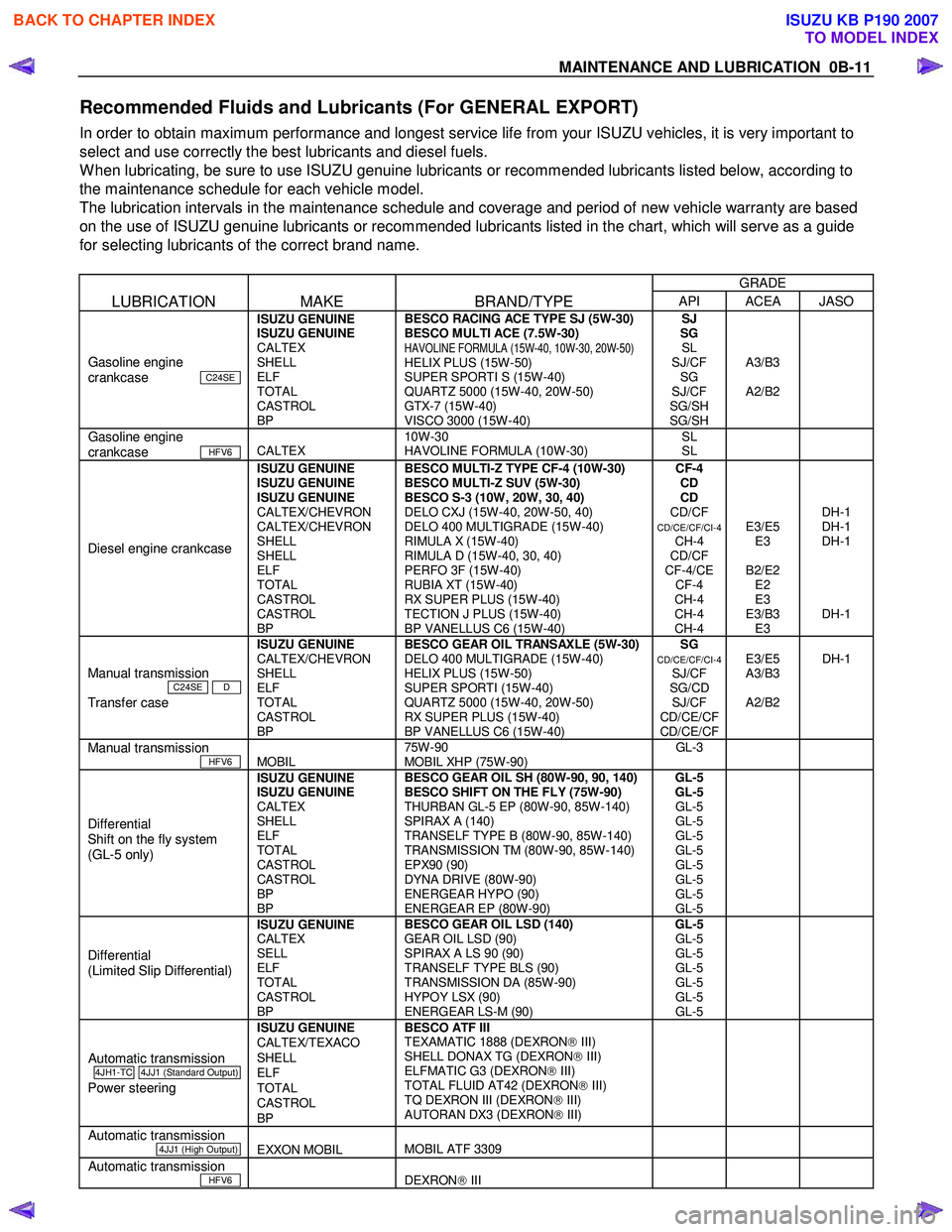

Recommended Fluids and Lubricants (For GENERAL EXPORT)

In order to obtain maximum performance and longest service life from your ISUZU vehicles, it is very important to

select and use correctly the best lubricants and diesel fuels.

W hen lubricating, be sure to use ISUZU genuine lubricants or recommended lubricants listed below, according to

the maintenance schedule for each vehicle model.

The lubrication intervals in the maintenance schedule and coverage and period of new vehicle warranty are based

on the use of ISUZU genuine lubricants or recommended lubricants listed in the chart, which will serve as a guide

for selecting lubricants of the correct brand name.

GRADE

LUBRICATION MAKE BRAND/TYPE API ACEA JASO

Gasoline engine

crankcase C24SE

ISUZU GENUINE

ISUZU GENUINE

CALTEX

SHELL

ELF

TOTAL

CASTROL

BP BESCO RACING ACE TYPE SJ (5W-30)

BESCO MULTI ACE (7.5W-30)

HAVOLINE FORMULA (15W-40, 10W-30, 20W-50) HELIX PLUS (15W-50)

SUPER SPORTI S (15W-40)

QUARTZ 5000 (15W-40, 20W-50)

GTX-7 (15W-40)

VISCO 3000 (15W-40) SJ

SG SL

SJ/CF SG

SJ/CF

SG/SH

SG/SH

A3/B3

A2/B2

Gasoline engine

crankcase HFV6

CALTEX 10W-30

HAVOLINE FORMULA (10W-30) SL

SL

Diesel engine crankcase

ISUZU GENUINE

ISUZU GENUINE

ISUZU GENUINE

CALTEX/CHEVRON

CALTEX/CHEVRON

SHELL

SHELL

ELF

TOTAL

CASTROL

CASTROL

BP BESCO MULTI-Z TYPE CF-4 (10W-30)

BESCO MULTI-Z SUV (5W-30)

BESCO S-3 (10W, 20W, 30, 40)

DELO CXJ (15W-40, 20W-50, 40)

DELO 400 MULTIGRADE (15W-40)

RIMULA X (15W-40)

RIMULA D (15W-40, 30, 40)

PERFO 3F (15W-40)

RUBIA XT (15W-40)

RX SUPER PLUS (15W-40)

TECTION J PLUS (15W-40)

BP VANELLUS C6 (15W-40) CF-4

CD

CD

CD/CF

CD/CE/CF/CI-4 CH-4

CD/CF

CF-4/CE CF-4

CH-4

CH-4

CH-4

E3/E5 E3

B2/E2 E2

E3

E3/B3 E3

DH-1

DH-1

DH-1

DH-1

Manual transmission

C24SE D

Transfer case

ISUZU GENUINE

CALTEX/CHEVRON

SHELL

ELF

TOTAL

CASTROL

BP

BESCO GEAR OIL TRANSAXLE (5W-30)

DELO 400 MULTIGRADE (15W-40)

HELIX PLUS (15W-50)

SUPER SPORTI (15W-40)

QUARTZ 5000 (15W-40, 20W-50)

RX SUPER PLUS (15W-40)

BP VANELLUS C6 (15W-40)

SG CD/CE/CF/CI-4 SJ/CF

SG/CD SJ/CF

CD/CE/CF

CD/CE/CF

E3/E5

A3/B3

A2/B2

DH-1

Manual transmission

HFV6

MOBIL 75W-90

MOBIL XHP (75W-90) GL-3

Differential

Shift on the fly system

(GL-5 only) ISUZU GENUINE

ISUZU GENUINE

CALTEX

SHELL

ELF

TOTAL

CASTROL

CASTROL

BP

BP BESCO GEAR OIL SH (80W-90, 90, 140)

BESCO SHIFT ON THE FLY (75W-90)

THURBAN GL-5 EP (80W-90, 85W-140)

SPIRAX A (140)

TRANSELF TYPE B (80W-90, 85W-140)

TRANSMISSION TM (80W-90, 85W-140)

EPX90 (90)

DYNA DRIVE (80W-90)

ENERGEAR HYPO (90)

ENERGEAR EP (80W-90) GL-5

GL-5 GL-5

GL-5

GL-5

GL-5

GL-5

GL-5

GL-5

GL-5

Differential

(Limited Slip Differential) ISUZU GENUINE

CALTEX

SELL

ELF

TOTAL

CASTROL

BP BESCO GEAR OIL LSD (140)

GEAR OIL LSD (90)

SPIRAX A LS 90 (90)

TRANSELF TYPE BLS (90)

TRANSMISSION DA (85W-90)

HYPOY LSX (90)

ENERGEAR LS-M (90) GL-5

GL-5

GL-5

GL-5

GL-5

GL-5

GL-5

Automatic transmission

4JH1-TC 4JJ1 (Standard Output)

Power steering

ISUZU GENUINE

CALTEX/TEXACO

SHELL

ELF

TOTAL

CASTROL

BP BESCO ATF III

TEXAMATIC 1888 (DEXRON III)

SHELL DONAX TG (DEXRON III)

ELFMATIC G3 (DEXRON III)

TOTAL FLUID AT42 (DEXRON III)

TQ DEXRON III (DEXRON III)

AUTORAN DX3 (DEXRON III)

Automatic transmission

4JJ1 (High Output)

EXXON MOBIL

MOBIL ATF 3309

Automatic transmission

HFV6

DEXRON III

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 31 of 6020

MAINTENANCE AND LUBRICATION 0B-13

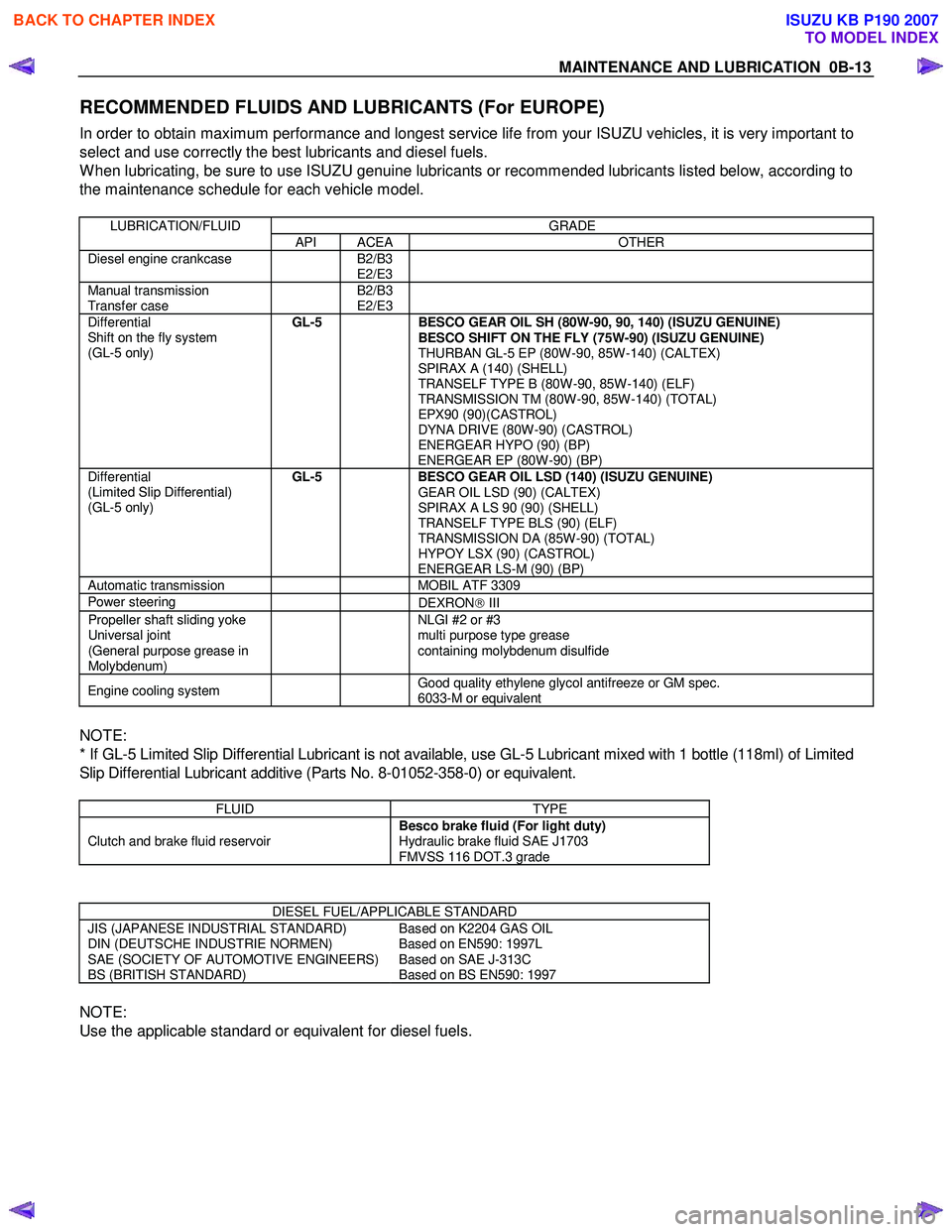

RECOMMENDED FLUIDS AND LUBRICANTS (For EUROPE)

In order to obtain maximum performance and longest service life from your ISUZU vehicles, it is very important to

select and use correctly the best lubricants and diesel fuels.

W hen lubricating, be sure to use ISUZU genuine lubricants or recommended lubricants listed below, according to

the maintenance schedule for each vehicle model.

LUBRICATION/FLUID GRADE

API ACEA OTHER

Diesel engine crankcase B2/B3

E2/E3

Manual transmission

Transfer case B2/B3

E2/E3

Differential

Shift on the fly system

(GL-5 only)

GL-5

BESCO GEAR OIL SH (80W-90, 90, 140) (ISUZU GENUINE)

BESCO SHIFT ON THE FLY (75W-90) (ISUZU GENUINE)

THURBAN GL-5 EP (80W-90, 85W-140) (CALTEX)

SPIRAX A (140) (SHELL)

TRANSELF TYPE B (80W-90, 85W-140) (ELF)

TRANSMISSION TM (80W-90, 85W-140) (TOTAL)

EPX90 (90)(CASTROL)

DYNA DRIVE (80W-90) (CASTROL)

ENERGEAR HYPO (90) (BP)

ENERGEAR EP (80W-90) (BP)

Differential

(Limited Slip Differential)

(GL-5 only) GL-5

BESCO GEAR OIL LSD (140) (ISUZU GENUINE)

GEAR OIL LSD (90) (CALTEX)

SPIRAX A LS 90 (90) (SHELL)

TRANSELF TYPE BLS (90) (ELF)

TRANSMISSION DA (85W-90) (TOTAL)

HYPOY LSX (90) (CASTROL)

ENERGEAR LS-M (90) (BP)

Automatic transmission MOBIL ATF 3309

Power steering

DEXRON III

Propeller shaft sliding yoke

Universal joint

(General purpose grease in

Molybdenum) NLGI #2 or #3

multi purpose type grease

containing molybdenum disulfide

Engine cooling system Good quality ethylene glycol antifreeze or GM spec.

6033-M or equivalent

NOTE:

* If GL-5 Limited Slip Differential Lubricant is not available, use GL-5 Lubricant mixed with 1 bottle (118ml) of Limited

Slip Differential Lubricant additive (Parts No. 8-01052-358-0) or equivalent.

FLUID TYPE

Clutch and brake fluid reservoir Besco brake fluid (For light duty)

Hydraulic brake fluid SAE J1703

FMVSS 116 DOT.3 grade

DIESEL FUEL/APPLICABLE STANDARD

JIS (JAPANESE INDUSTRIAL STANDARD)

DIN (DEUTSCHE INDUSTRIE NORMEN)

SAE (SOCIETY OF AUTOMOTIVE ENGINEERS)

BS (BRITISH STANDARD) Based on K2204 GAS OIL

Based on EN590: 1997L

Based on SAE J-313C

Based on BS EN590: 1997

NOTE:

Use the applicable standard or equivalent for diesel fuels.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 64 of 6020

1-30 HEATER AND AIR CONDITIONING

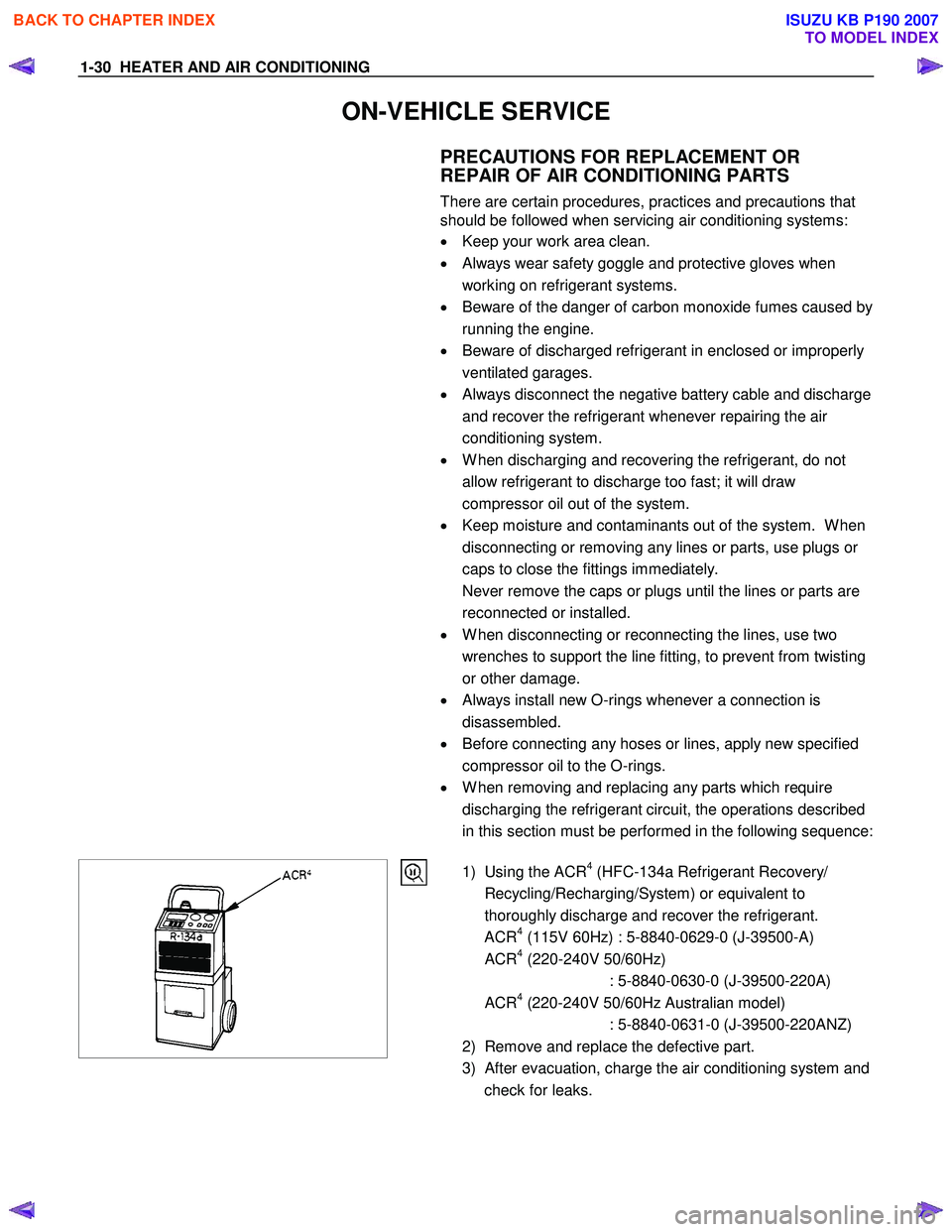

ON-VEHICLE SERVICE

PRECAUTIONS FOR REPLACEMENT OR

REPAIR OF AIR CONDITIONING PARTS

There are certain procedures, practices and precautions that

should be followed when servicing air conditioning systems:

• Keep your work area clean.

• Always wear safety goggle and protective gloves when

working on refrigerant systems.

• Beware of the danger of carbon monoxide fumes caused by

running the engine.

• Beware of discharged refrigerant in enclosed or improperly

ventilated garages.

•

Always disconnect the negative battery cable and discharge

and recover the refrigerant whenever repairing the air

conditioning system.

• W hen discharging and recovering the refrigerant, do not

allow refrigerant to discharge too fast; it will draw

compressor oil out of the system.

• Keep moisture and contaminants out of the system. W hen

disconnecting or removing any lines or parts, use plugs or

caps to close the fittings immediately.

Never remove the caps or plugs until the lines or parts are reconnected or installed.

• W hen disconnecting or reconnecting the lines, use two

wrenches to support the line fitting, to prevent from twisting

or other damage.

• Always install new O-rings whenever a connection is

disassembled.

• Before connecting any hoses or lines, apply new specified

compressor oil to the O-rings.

• W hen removing and replacing any parts which require

discharging the refrigerant circuit, the operations described

in this section must be performed in the following sequence:

1) Using the ACR

4 (HFC-134a Refrigerant Recovery/

Recycling/Recharging/System) or equivalent to

thoroughly discharge and recover the refrigerant.

ACR

4 (115V 60Hz) : 5-8840-0629-0 (J-39500-A)

ACR4 (220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR

4 (220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

2) Remove and replace the defective part.

3)

After evacuation, charge the air conditioning system and

check for leaks.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 65 of 6020

HEATER AND AIR CONDITIONING 1-31

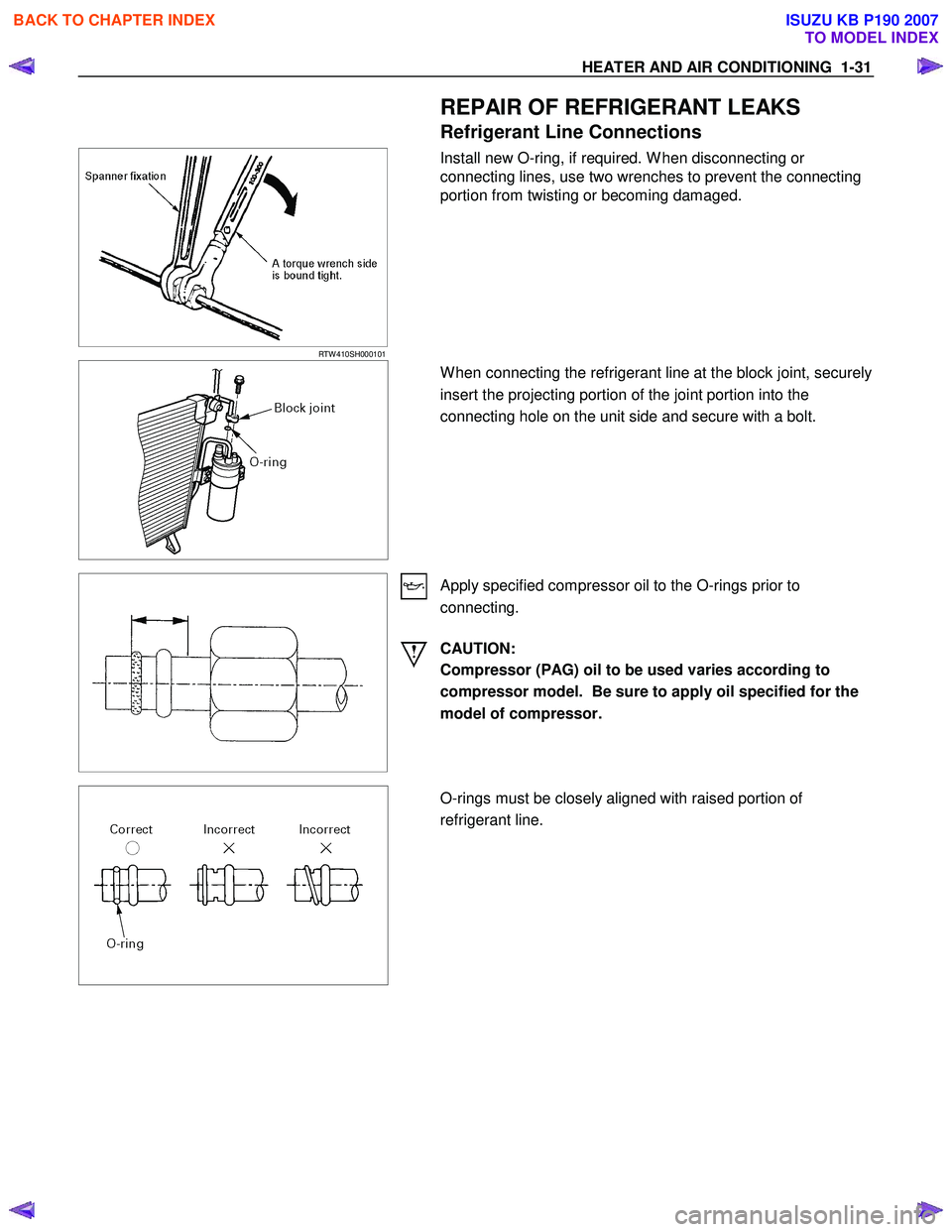

REPAIR OF REFRIGERANT LEAKS

Refrigerant Line Connections

RTW 410SH000101

Install new O-ring, if required. W hen disconnecting or

connecting lines, use two wrenches to prevent the connecting

portion from twisting or becoming damaged.

W hen connecting the refrigerant line at the block joint, securely

insert the projecting portion of the joint portion into the

connecting hole on the unit side and secure with a bolt.

Apply specified compressor oil to the O-rings prior to

connecting.

CAUTION:

Compressor (PAG) oil to be used varies according to

compressor model. Be sure to apply oil specified for the

model of compressor.

O-rings must be closely aligned with raised portion of

refrigerant line.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 66 of 6020

1-32 HEATER AND AIR CONDITIONING

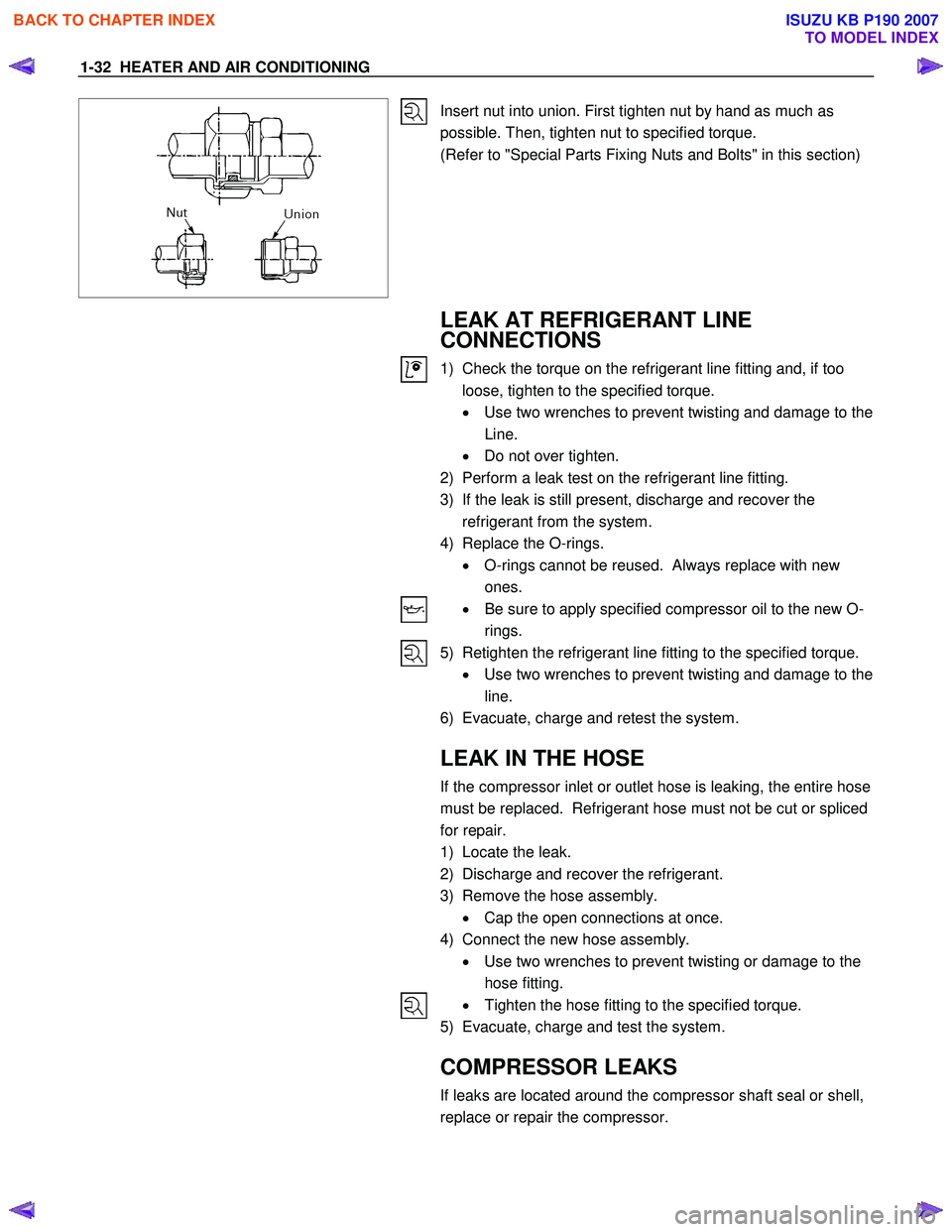

Insert nut into union. First tighten nut by hand as much as

possible. Then, tighten nut to specified torque.

(Refer to "Special Parts Fixing Nuts and Bolts" in this section)

LEAK AT REFRIGERANT LINE

CONNECTIONS

1) Check the torque on the refrigerant line fitting and, if too

loose, tighten to the specified torque.

• Use two wrenches to prevent twisting and damage to the

Line.

• Do not over tighten.

2) Perform a leak test on the refrigerant line fitting.

3) If the leak is still present, discharge and recover the refrigerant from the system.

4) Replace the O-rings. • O-rings cannot be reused. Always replace with new

ones.

• Be sure to apply specified compressor oil to the new O-

rings.

5) Retighten the refrigerant line fitting to the specified torque.

• Use two wrenches to prevent twisting and damage to the

line.

6) Evacuate, charge and retest the system.

LEAK IN THE HOSE

If the compressor inlet or outlet hose is leaking, the entire hose

must be replaced. Refrigerant hose must not be cut or spliced

for repair.

1) Locate the leak.

2) Discharge and recover the refrigerant.

3) Remove the hose assembly. • Cap the open connections at once.

4) Connect the new hose assembly. • Use two wrenches to prevent twisting or damage to the

hose fitting.

• Tighten the hose fitting to the specified torque.

5) Evacuate, charge and test the system.

COMPRESSOR LEAKS

If leaks are located around the compressor shaft seal or shell,

replace or repair the compressor.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 67 of 6020

HEATER AND AIR CONDITIONING 1-33

RECOVERY, RECYCLING, EVACUATION

AND CHARGING

Handling Refrigerant-134a (HFC-134a)

Air conditioning systems contain HFC-134a.

This is a chemical mixture, which requires special handling

procedures to avoid personal injury.

• Always wear safety goggles and protective gloves.

• Always work in a well-ventilated area. Do not weld or steam

clean on or near any vehicle-installed air conditioning lines

or components.

• If HFC-134a should come in contact with any part of the

body, flush the exposed area with cold water and

immediately seek medical help.

• If it is necessary to transport or carry any container of HFC-

134a in a vehicle, do not carry it in the passenger

compartment.

• If it is necessary to fill a small HFC-134a container from a

large one, never fill the container completely. Space should

always be allowed above the liquid for expansion.

• Keep HFC-134a containers stored below 40 °C (104 °F).

WARNING

•

••

•

SHOULD HFC-134a CONTACT YOUR EYE(S), CONSULT

A DOCTOR IMMEDIATELY.

•

••

•

DO NOT RUB THE AFFECTED EYE(S). INSTEAD,

SPLASH QUANTITIES OF FRESH COLD WATER OVER

THE AFFECTED AREA TO GRADUALLY RAISE THE

TEMPERATURE OF THE REFRIGERANT ABOVE THE

FREEZING POINT.

•

••

•

OBTAIN PROPER MEDICAL TREATMENT AS SOON AS

POSSIBLE. SHOULD THE HFC-134a TOUCH THE SKIN,

THE INJURY MUST BE TREATED THE SAME AS SKIN

WHICH HAS BEEN FROSTBITTEN OR FROZEN.

F06R300012

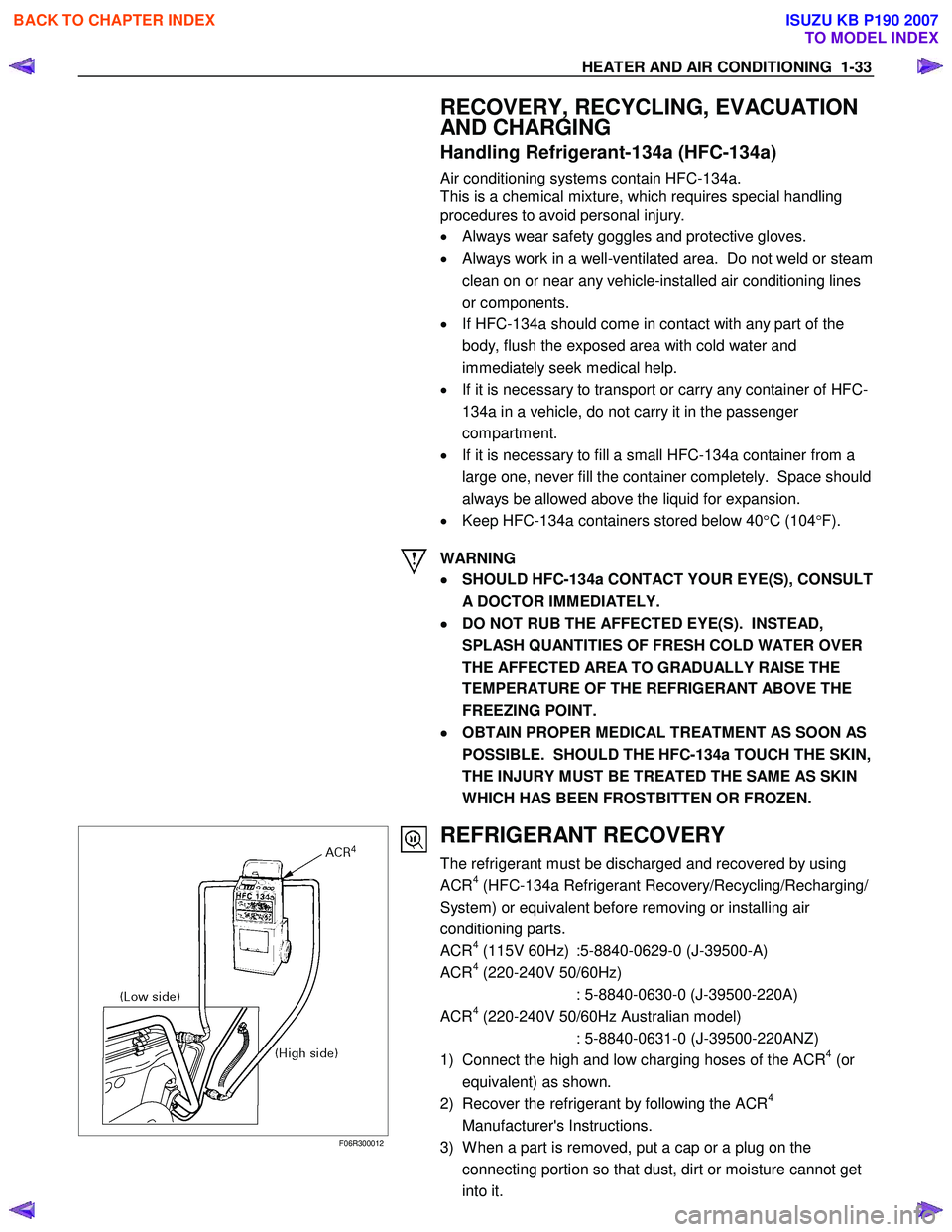

REFRIGERANT RECOVERY

The refrigerant must be discharged and recovered by using

ACR4 (HFC-134a Refrigerant Recovery/Recycling/Recharging/

System) or equivalent before removing or installing air

conditioning parts.

ACR

4 (115V 60Hz) :5-8840-0629-0 (J-39500-A)

ACR4 (220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR

4 (220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

1) Connect the high and low charging hoses of the ACR

4 (or

equivalent) as shown.

2) Recover the refrigerant by following the ACR

4

Manufacturer's Instructions.

3) W hen a part is removed, put a cap or a plug on the connecting portion so that dust, dirt or moisture cannot get

into it.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007