check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1828 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-211

Circuit/ System Testing DTC P0653

11Replace the FRP sensor. Refer to FRP Sensor

Replacement.

Did you complete the replacement? —

Go to Step 15

—

12Replace the CMP sensor. Refer to CMP Sensor

Replacement.

Did you complete the replacement? —

Go to Step 15

—

13Replace the APP sensor. Refer to APP Sensor

Replacement.

Did you complete the replacement? —

Go to Step 15

—

14Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 15

—

151. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 16

16 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1830 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-213

DTC P0661 or P0662 (Flash Code 58)

Circuit Description

The ECM controls the swirl levels, which energize the

swirl control solenoid valve based on the engine

running condition. The ECM commands the swirl

control solenoid valve to apply vacuum pressure to the

diaphragm actuator to operate swirl control butterflies

that is provided each intake port. If the ECM detects an

open circuit or short circuit on the solenoid valve circuit,

DTC P0661 or P0662 will set.

Condition for Running the DTC • The battery voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects a low voltage condition on the swirl control solenoid valve circuit when the

solenoid is commanded OFF. (DTC P0661)

• The ECM detects a high voltage condition on the swirl control solenoid valve circuit when the

solenoid is commanded ON. (DTC P0662)

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification) • The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM limits fuel injection quantity. (DTC P0661)

• The ECM inhibits cruise control. (DTC P0661)

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Vacuum Hose Routing

Diagram and Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0661

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Disconnect the swirl control solenoid valve harness connector.

3. Connect a test lamp between the ignition voltage feed circuit (pin 2 of E-67) and a

known good ground.

4. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate? —

Go to Step 4 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1831 of 6020

6E-214 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

41. Connect a test lamp between the control

circuit (pin 1 of E-67) and battery voltage.

2. Perform the Swirl Control Solenoid Test with a scan tool.

3. Command the solenoid valve ON and OFF.

Does the test lamp turn ON and OFF with each

command (if test is aborted, go to Step 5)? —

Go to Step 9 Go to Step 5

5 Does the test lamp remain illuminated with each

command? —

Go to Step 8 Go to Step 7

6 Repair the open circuit or high resistance between

the Engine (10A) fuse and the solenoid valve (pin 2

of E-67). Check the Engine (10A) fuse first.

Did you complete the repair? —

Go to Step 13

—

71. Test the control circuit between the ECM (pin

67 of E-90) and the solenoid valve (pin 1 of E-

67) for an open circuit or high resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 10

8 1. Test the control circuit between the ECM (pin

67 of E-90) and the solenoid valve (pin 1 of E-

67) for a short to ground.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 12

9 1. Inspect for an intermittent and for poor

connections at the harness connector of the

solenoid valve (pins 1 and 2 of E-67).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 11

10 1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for a poor connection at harness connector of the ECM

(pin 67 of E-90).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 12

11 Replace the swirl control solenoid valve.

Did you complete the replacement? —

Go to Step 13

—

12Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 13

—

Step Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1832 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-215

Circuit/ System Testing DTC P0662

131. Reconnect all previously disconnected fuse or

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Turn ON the ignition, with the engine OFF.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 14

14 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step Action Value(s) Yes No

Step

Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Disconnect the swirl control solenoid valve harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Is DTC P0661 set, but not P0662? —

Go to Step 5 Go to Step 4

4 1. Test the control circuit between the ECM (pin

67 of E-90) and the solenoid valve (pin 1 of E-

67) for a short to battery or ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 7 Go to Step 6

5 Replace the swirl control solenoid valve.

Did you complete the replacement? —

Go to Step 7

—

6Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 7

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1834 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-217

DTC P0698 or P0699 (Flash Code 57)

Circuit Description

The ECM provides 5 volts reference voltage through

the reference circuit 3 to the following sensors:

• Accelerator pedal position (APP) sensor 3

• Boost pressure sensor

• Crankshaft position (CKP) sensor

• Intake throttle position sensor

The 5 volts reference circuits are independent of each

other outside the ECM, but are bussed together inside

the ECM. Therefore, a short circuit condition on one 5

volts reference circuit affects the entire 5 volts

reference circuit 3. The ECM monitors the voltage on

the 5 volts reference circuit 3. If the ECM detects the

voltage is excessively low or high, DTC P0698 or

P0699 will set.

Condition for Running the DTC • The battery voltage is more than 6 volts.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects that the 5 volts reference circuit 3 voltage is less than 4.7 volts. (DTC P0698) • The ECM detects that the 5 volts reference circuit

3 voltage is less than 5.3 volts. (DTC P0699)

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits EGR control.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0698

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Disconnect the accelerator pedal position (APP) sensor harness connector.

3. Connect a DMM between the 5 volts reference circuit (pin 1 of C-40) and a known good

ground.

4. Turn ON the ignition, with engine OFF.

Is the DMM voltage more than the specified value? 4.7 volts

Go to Step 8 Go to Step 4

4 Notice:

If no boost pressure sensor is installed,

skip to Step 5.

1. Leave the DMM connected to the APP sensor harness connector.

2. Turn OFF the ignition.

3. Disconnect the boost pressure harness connector.

4. Turn ON the ignition, with the engine OFF.

Does the DMM voltage change to more than the

specified value? 4.7 volts

Go to Step 9 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1836 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-219

Circuit/ System Testing DTC P0699

131. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 14

14 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step Action Value(s) Yes No

Step

Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Test the 5 volts reference circuit between the

ECM and the following components for a short

to battery or ignition voltage:

• ECM (pin 7 of C-58) and APP sensor 3 (pin 1 of C-40)

• ECM (pin 20 of E-90) and boost pressure sensor (pin 3 of E-107)

• ECM (pin 36 of E-90) and intake throttle position sensor (pin 6 of E-38)

• ECM (pin 37 of E-90) and CKP sensor (pin 3 of E-52)

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 5 Go to Step 4

4 Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 5

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1838 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-221

DTC P0700 (Flash Code 185)

Circuit Description

The transmission control module (TCM) requests to

illuminate the malfunction indicator lamp (MIL) via a

controller area network (CAN) communication bus to

the ECM when the TCM sets a MIL request DTC(s). If

the ECM detects the MIL illumination request signal,

this DTC will set.

Condition for Running the DTC • DTCs U0001 and U0101 are not set.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects that the MIL illumination is requested by the TCM.

Action Taken When the DTC Sets • The ECM illuminates MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for Action

Taken When the DTC Sets - Type A. • The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • Under normal conditions if the TCM sets a DTC that requests the MIL to be illuminated, P0700 will

set.

Test Description

The number below refers to the step number on the

Circuit/ System Testing.

2. If the TCM has DTCs set that are requesting MIL

illumination, diagnose that DTC first.

3. If the TCM has DTCs set, clear the DTCs in the TCM

first.

Circuit/ System Testing DTC P0700

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the transmission DTC Information with a scan tool.

Are there any transmission DTCs set? —

Go to Applicable

DTC in Automatic

Transmission Section Go to Step 3

3 1. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 2 Go to Step 4

4 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1839 of 6020

6E-222 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P1064 or P1065 (Flash Code 247)

Circuit Description

The fuel rail pressure (FRP) regulator is installed to the

fuel supply pump and controls the suction fuel quantity

into the fuel rail. The FRP regulator is fully opened in

the normal state and larger drive current results in

smaller opening. The ECM calculates desired fuel rail

pressure and fuel flow rate and it compares the

calculated desired fuel rail pressure to the actual value

to determine the FRP regulator position. When the

actual fuel rail pressure is higher than the desired

value, the FRP regulator is closed to decease the flow

rate.

If the ECM detects an over current condition on the

FRP regulator feedback circuit, DTC P1064 will set.

If the ECM detects an improper voltage level on the

FRP regulator control high side circuit, DTC P1065 will

set.

Condition for Running the DTC • DTC P1064 is not set. (DTC P1065)

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects an over current condition on the FRP regulator feedback circuit. (DTC P1064) • The ECM detects a low or high voltage condition

on the FRP regulator high side circuit. (DTC

P1065)

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P1064

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 Important:

The ECM may be damaged if the FRP

regulator low side circuit is shorted to a voltage

source.

1. Test the low side circuits between the ECM (pins 50 and 70 of E-90) and the FRP

regulator (pin 2 of E-50) for a short to battery

or ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 5 Go to Step 4

4 Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 5

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1840 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-223

Circuit/ System Testing DTC P1065

51. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 6

6 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 Is DTC P0091 or P0092 also set?

—Go to Applicable

DTC Go to Step 4

4 Observe the Fuel Rail Pressure (FRP) Regulator

Feedback parameter with a scan tool.

Is the scan tool parameter more than the specified

value? 300 mA

Go to Step 7 Go to Step 5

5 1. Turn OFF the ignition for 30 seconds.

2. Disconnect the FRP regulator harness connector.

3. Connect a test lamp between the high side circuit (pin 1 of E-50) and a known good

ground.

4. Turn ON the ignition, with the engine OFF. DO NOT start the engine.

Does the test lamp illuminate then go out? —

Go to Step 6 Go to Step 8

6 1. Turn OFF the ignition for 30 seconds.

2. Connect a test lamp between the low side circuit (pin 2 of E-50) and battery voltage.

3. Turn ON the ignition, with the engine OFF. DO NOT start the engine.

Does the test lamp illuminate then go out? —

Go to Step 10 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1843 of 6020

6E-226 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

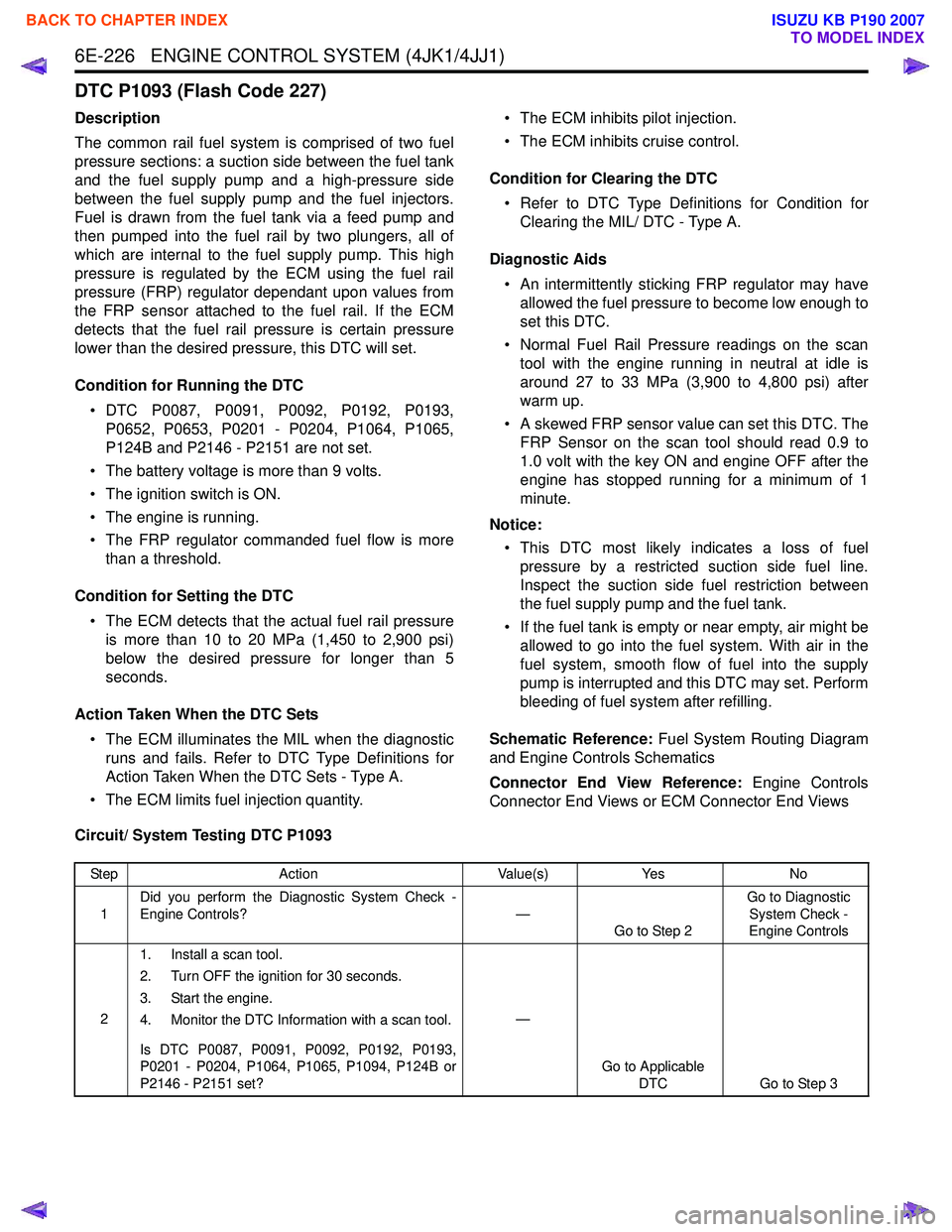

DTC P1093 (Flash Code 227)

Description

The common rail fuel system is comprised of two fuel

pressure sections: a suction side between the fuel tank

and the fuel supply pump and a high-pressure side

between the fuel supply pump and the fuel injectors.

Fuel is drawn from the fuel tank via a feed pump and

then pumped into the fuel rail by two plungers, all of

which are internal to the fuel supply pump. This high

pressure is regulated by the ECM using the fuel rail

pressure (FRP) regulator dependant upon values from

the FRP sensor attached to the fuel rail. If the ECM

detects that the fuel rail pressure is certain pressure

lower than the desired pressure, this DTC will set.

Condition for Running the DTC • DTC P0087, P0091, P0092, P0192, P0193, P0652, P0653, P0201 - P0204, P1064, P1065,

P124B and P2146 - P2151 are not set.

• The battery voltage is more than 9 volts.

• The ignition switch is ON.

• The engine is running.

• The FRP regulator commanded fuel flow is more than a threshold.

Condition for Setting the DTC • The ECM detects that the actual fuel rail pressure is more than 10 to 20 MPa (1,450 to 2,900 psi)

below the desired pressure for longer than 5

seconds.

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity. • The ECM inhibits pilot injection.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • An intermittently sticking FRP regulator may have allowed the fuel pressure to become low enough to

set this DTC.

• Normal Fuel Rail Pressure readings on the scan tool with the engine running in neutral at idle is

around 27 to 33 MPa (3,900 to 4,800 psi) after

warm up.

• A skewed FRP sensor value can set this DTC. The FRP Sensor on the scan tool should read 0.9 to

1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1

minute.

Notice: • This DTC most likely indicates a loss of fuel pressure by a restricted suction side fuel line.

Inspect the suction side fuel restriction between

the fuel supply pump and the fuel tank.

• If the fuel tank is empty or near empty, air might be allowed to go into the fuel system. With air in the

fuel system, smooth flow of fuel into the supply

pump is interrupted and this DTC may set. Perform

bleeding of fuel system after refilling.

Schematic Reference: Fuel System Routing Diagram

and Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P1093

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0087, P0091, P0092, P0192, P0193,

P0201 - P0204, P1064, P1065, P1094, P124B or

P2146 - P2151 set? —

Go to Applicable DTC Go to Step 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007