DTC CHECK ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3283 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–5

• fuel trim DTCs, or

• catalyst DTCs.

1.3 Symptoms Diagnostics

The Diagnostic System Check directs the service technician to the symptoms diagnostics if the following conditions

exist:

• a vehicle driveability fault condition exists,

• there is no current diagnostic trouble code presently stored in the ECM, and

• all Tech 2 engine data parameters are within normal operating range.

1.4 Diagnostic Trouble Codes

The ECM constantly performs self-diagnostic tests on the engine management system. W hen the ECM detects a fault

condition in the engine operating parameters, the ECM sets a diagnostic trouble code (DTC) to represent that fault

condition. The following are the types of DTCs programmed in the ECM. In addition, DTCs are classified as either a

current or history DTC.

• Type A – emission related DTCs,

• Type B – emission related DTCs, and

• Type C – non-emission related DTCs.

NOTE

Depending on the type of DTC set, the ECM may

command the malfunction indicator lamp (MIL) to

illuminate and warn the driver there is a fault in

the engine management system.

Type A – Emission Related DTCs

The ECM takes the following action when a Type A DTC runs and fails:

• sets a current Type A DTC that represents the fault condition,

• illuminates the instrument cluster malfunction indicator lamp (MIL), and

• records the operating condition at the time the diagnostic fails and stores this information in the freeze frame

failure record.

Type B – Emission Related DTCs

The ECM takes the following action when a Type B DTC runs and fails:

• On the first time a Type B DTC fails, the ECM takes the following actions:

− sets a current Type B DTC that represents the fault condition, and

− records the operating conditions at the time the fault sets and stores this information in the failure records.

• On the second consecutive ignition cycle that a Type B DTC fails, the ECM takes the following actions:

− activates the instrument cluster malfunction indicator lamp (MIL), and

− records the operating condition at the time the diagnostic fails and stores this information in the freeze frame

failure record.

Conditions for Clearing Type A or Type B DTCs

• The current DTC clears when there is no fault condition in the current ECM self-diagnostics.

• If there are no DTCs logged after three or four consecutive ignition cycles, the ECM deactivates the instrument

cluster malfunction indicator lamp (MIL).

• Type A or Type B History DTC clears when there is no fault condition after 40 consecutive warm-up cycles.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3297 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–19

• Do not start the engine if the battery terminal is not properly secured to the battery.

• Do not disconnect or reconnect the following while the ignition is switched on or when the engine is running:

− Any engine management system component electrical wiring connector, or

− Battery terminal leads.

• Ensure the correct procedure for disconnecting and connecting engine management system electrical wiring

connectors is always followed. For information on the correct procedure for disconnecting and connecting specific

wiring connectors, refer to 6C1-3 Engine Management – V6 – Service Operations.

• Ensure that all wiring harness connectors are fitted correctly.

• W hen steam or pressure cleaning engines, do not direct the cleaning nozzle at engine management system

components.

• Do not clear any DTCs unless instructed.

• The fault must be present when using the diagnostic trouble code (DTC) diagnostic tables. Otherwise,

misdiagnosis or replacement of good parts may occur.

• Do not touch the ECM connector pins or soldered components on the ECM circuit board to prevent ECM

Electrostatic Discharge damage. Refer to 8A Electrical - Body and Chassis for information on Electrostatic

Discharge.

• Use only the test equipment specified in the diagnostic tables as other test equipment may give incorrect results or

damage good components.

• The ECM is designed to withstand normal current draw associated with vehicle operations. However, the following

fault conditions or incorrect test procedure may overload the ECM internal circuit and damage the ECM:

− A short to voltage fault condition in any of the ECM low reference circuits may cause internal ECM and / or

sensor damage. Therefore, any short to voltage fault condition in the ECM low reference circuits must be

rectified before replacing a faulty component.

− A short to ground fault condition in any of the ECM 5 V reference circuits may cause internal ECM and / or

sensor damage. Therefore, any short to ground fault condition in the ECM 5 V reference circuits must be

rectified before replacing a faulty component.

− W hen using a test lamp to test an electrical circuit, do not use any of the ECM low reference circuits or 5 V

reference circuits as a reference point. Otherwise, excessive current draw from the test lamp may damage

the ECM.

• Disregard DTCs that set while performing the following diagnostic Steps:

− Using Tech 2 actuator tests, or

− Disconnecting an engine management system sensor connector then switching on the ignition.

• After completing the required diagnostics and service operations, road test the vehicle to ensure correct engine

management system operation.

4.3 Preliminary Checks

The preliminary checks are a set of visual and physical checks or inspections that may quickly identify engine

management system fault condition.

• Refer to the appropriate Service Techlines for relevant information regarding the fault condition.

• Ensure the battery is fully charged.

• Inspect the battery connections for corrosion or a loose terminal.

• Ensure that all engine management system related fuses are serviceable.

• Inspect for incorrect aftermarket theft deterrent devices, lights or mobile phone installation.

• Ensure there is no speaker magnet positioned too close to any electronic module that contains relays.

• Inspect the engine wiring harness for proper connections, pinches or cuts.

• Ensure that all engine management related electrical wiring connectors are fitted correctly.

• Inspect the ECM ground connections for corrosion, loose terminal or incorrect position.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3298 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–20

• Ensure the resistance between the ECM housing and the battery negative cable is less than 0.5 Ω.

• Check the ECM bracket fasteners for correct torque value.

• Check all engine management related components for correct installation.

• Inspect the vacuum hoses for splits, kinks, oil contamination and proper connections, refer to the vehicle emission

control information label. Check the hoses thoroughly for any type of leak or restriction.

• Inspect the air intake ducts for being collapsed, split or for having damaged areas.

• Inspect for air leaks at the throttle body mounting area, mass air flow (MAF) sensor, intake manifold and intake

manifold sealing surfaces.

• Check for wiring harness routing that may be positioned too close to a high voltage or high current device such as

the following:

− Secondary ignition components, and

− Motors and generators.

NOTE

High voltage or high current devices may induce

electrical noise on a circuit, which can interfere

with normal circuit operation.

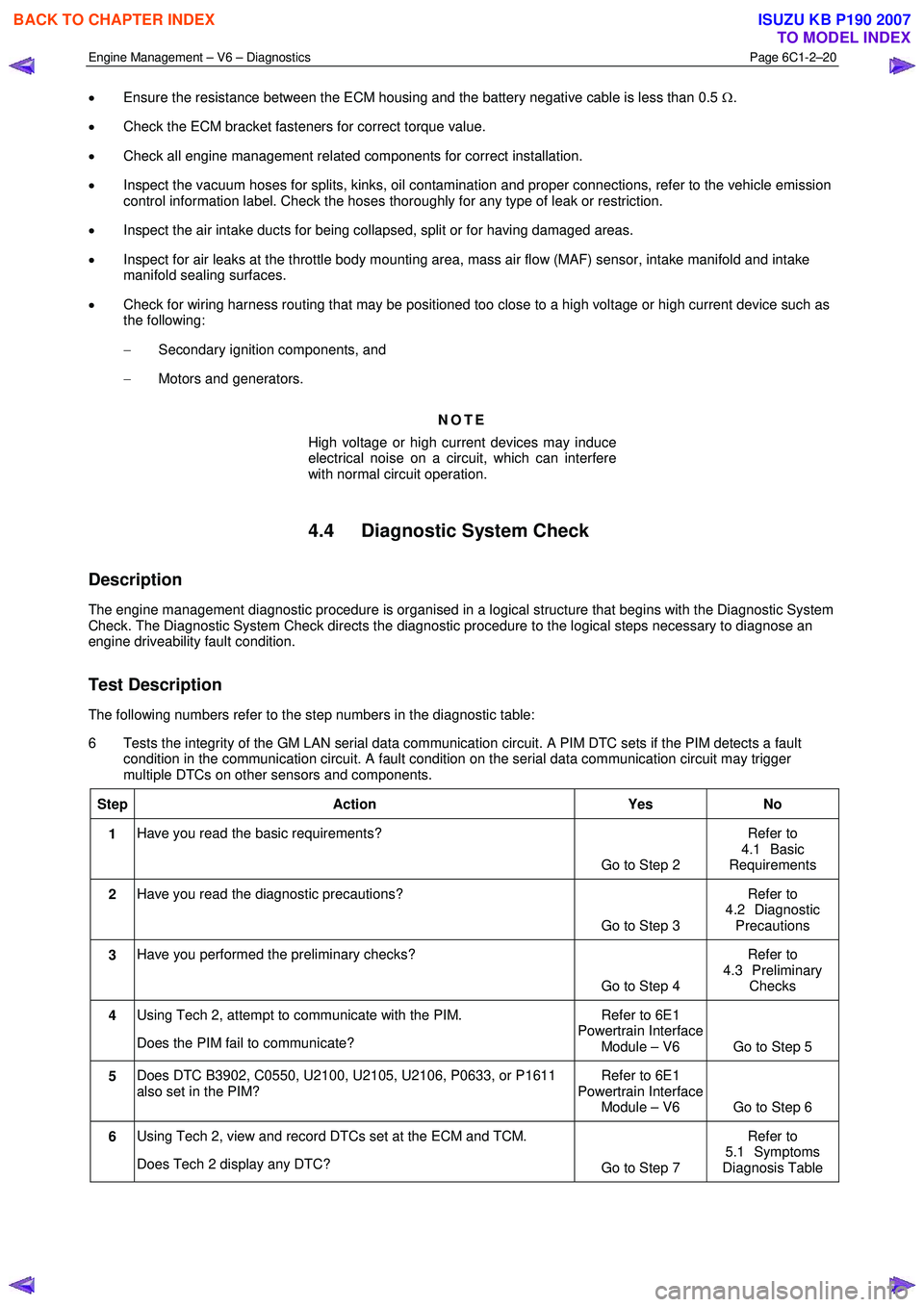

4.4 Diagnostic System Check

Description

The engine management diagnostic procedure is organised in a logical structure that begins with the Diagnostic System

Check. The Diagnostic System Check directs the diagnostic procedure to the logical steps necessary to diagnose an

engine driveability fault condition.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

6 Tests the integrity of the GM LAN serial data communication circuit. A PIM DTC sets if the PIM detects a fault condition in the communication circuit. A fault condition on the serial data communication circuit may trigger

multiple DTCs on other sensors and components.

Step Action Yes No

1 Have you read the basic requirements?

Go to Step 2 Refer to

4.1 Basic

Requirements

2 Have you read the diagnostic precautions?

Go to Step 3 Refer to

4.2 Diagnostic Precautions

3 Have you performed the preliminary checks?

Go to Step 4 Refer to

4.3 Preliminary Checks

4 Using Tech 2, attempt to communicate with the PIM.

Does the PIM fail to communicate? Refer to 6E1

Powertrain Interface Module – V6 Go to Step 5

5 Does DTC B3902, C0550, U2100, U2105, U2106, P0633, or P1611

also set in the PIM? Refer to 6E1

Powertrain Interface Module – V6 Go to Step 6

6 Using Tech 2, view and record DTCs set at the ECM and TCM.

Does Tech 2 display any DTC? Go to Step 7 Refer to

5.1 Symptoms

Diagnosis Table

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3299 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–21

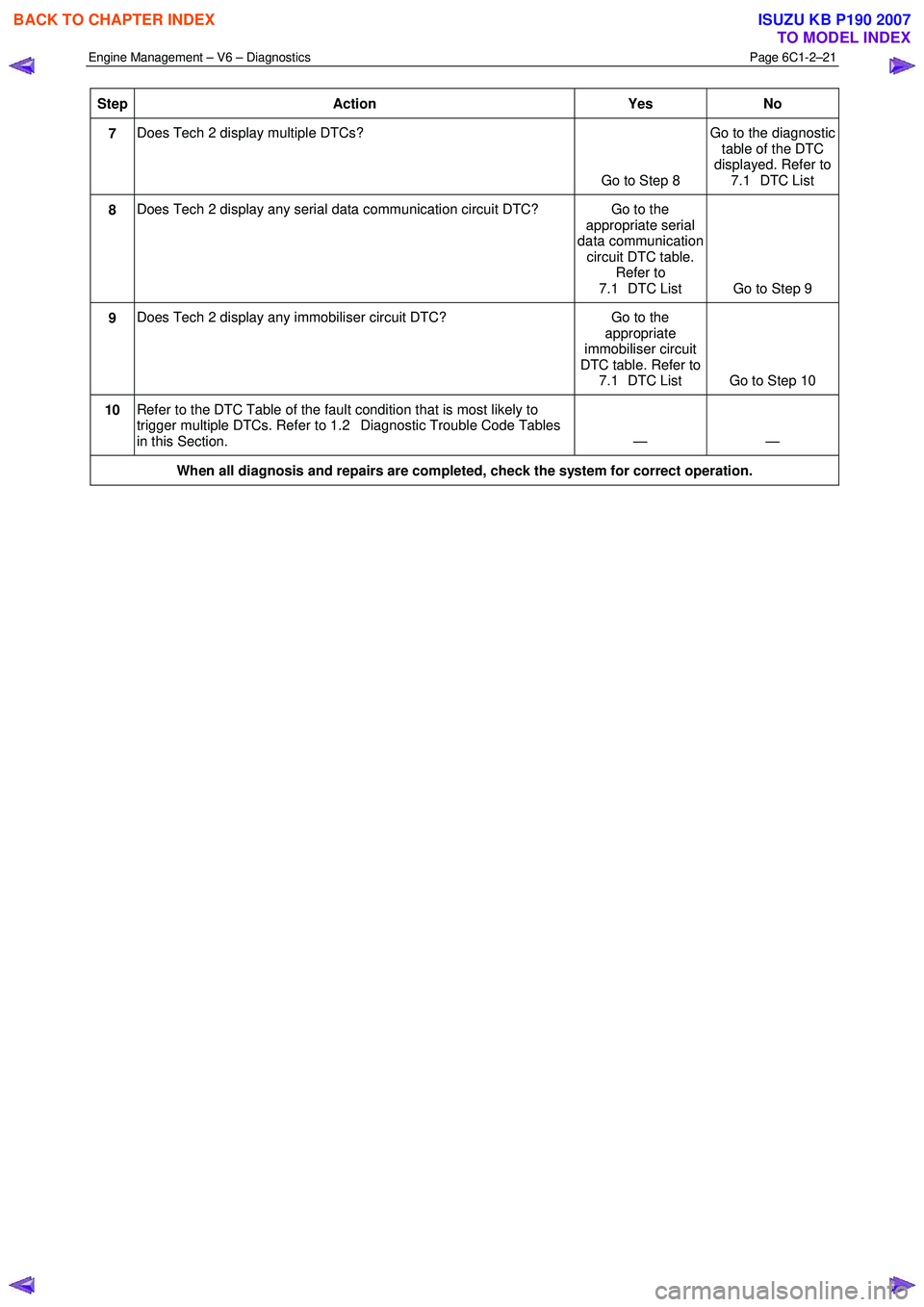

Step Action Yes No

7 Does Tech 2 display multiple DTCs?

Go to Step 8 Go to the diagnostic

table of the DTC

displayed. Refer to 7.1 DTC List

8 Does Tech 2 display any serial data communication circuit DTC? Go to the

appropriate serial

data communication circuit DTC table. Refer to

7.1 DTC List Go to Step 9

9 Does Tech 2 display any immobiliser circuit DTC? Go to the

appropriate

immobiliser circuit

DTC table. Refer to 7.1 DTC List Go to Step 10

10 Refer to the DTC Table of the fault condition that is most likely to

trigger multiple DTCs. Refer to 1.2 Diagnostic Trouble Code Tables

in this Section. — —

When all diagnosis and repairs are completed, check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3301 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–23

• there is no Current DTC but a History DTC is stored.

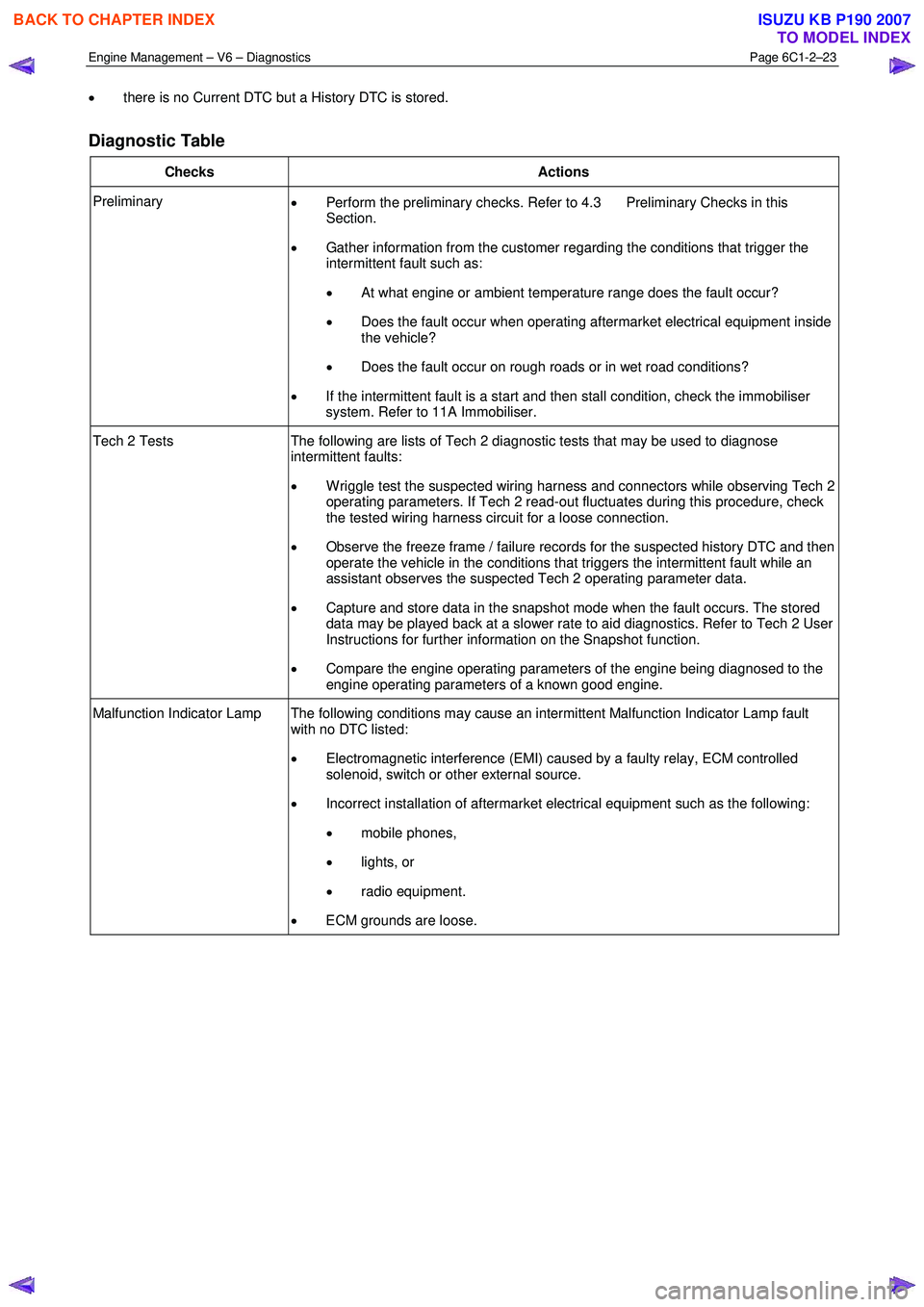

Diagnostic Table

Checks Actions

Preliminary

• Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

• Gather information from the customer regarding the conditions that trigger the

intermittent fault such as:

• At what engine or ambient temperature range does the fault occur?

• Does the fault occur when operating aftermarket electrical equipment inside

the vehicle?

• Does the fault occur on rough roads or in wet road conditions?

• If the intermittent fault is a start and then stall condition, check the immobiliser

system. Refer to 11A Immobiliser.

Tech 2 Tests The following are lists of Tech 2 diagnostic tests that may be used to diagnose

intermittent faults:

• W riggle test the suspected wiring harness and connectors while observing Tech 2

operating parameters. If Tech 2 read-out fluctuates during this procedure, check

the tested wiring harness circuit for a loose connection.

• Observe the freeze frame / failure records for the suspected history DTC and then

operate the vehicle in the conditions that triggers the intermittent fault while an

assistant observes the suspected Tech 2 operating parameter data.

• Capture and store data in the snapshot mode when the fault occurs. The stored

data may be played back at a slower rate to aid diagnostics. Refer to Tech 2 User

Instructions for further information on the Snapshot function.

• Compare the engine operating parameters of the engine being diagnosed to the

engine operating parameters of a known good engine.

Malfunction Indicator Lamp The following conditions may cause an intermittent Malfunction Indicator Lamp fault with no DTC listed:

• Electromagnetic interference (EMI) caused by a faulty relay, ECM controlled

solenoid, switch or other external source.

• Incorrect installation of aftermarket electrical equipment such as the following:

• mobile phones,

• lights, or

• radio equipment.

• ECM grounds are loose.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3305 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–27

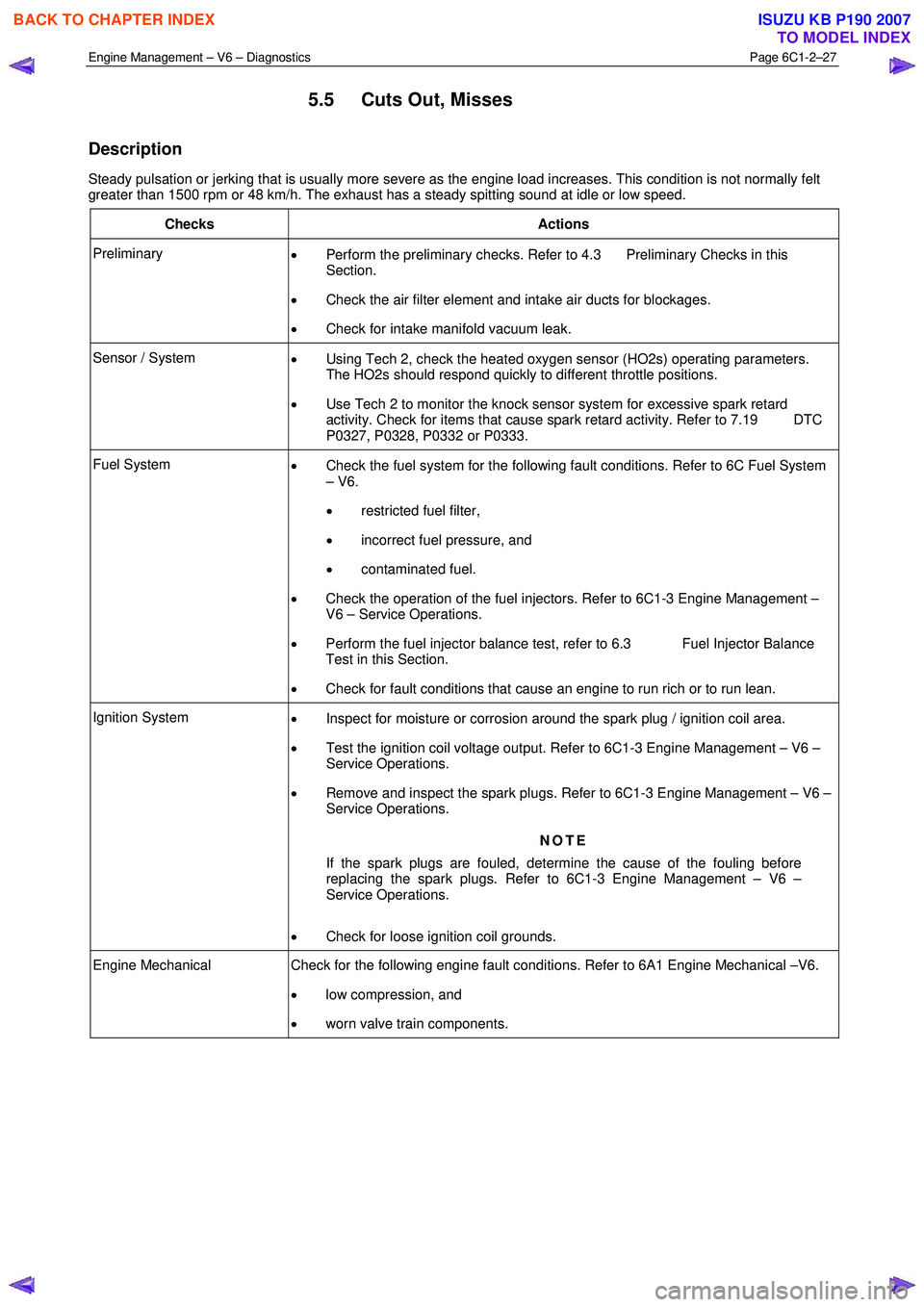

5.5 Cuts Out, Misses

Description

Steady pulsation or jerking that is usually more severe as the engine load increases. This condition is not normally felt

greater than 1500 rpm or 48 km/h. The exhaust has a steady spitting sound at idle or low speed.

Checks Actions

Preliminary • Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

• Check the air filter element and intake air ducts for blockages.

• Check for intake manifold vacuum leak.

Sensor / System

• Using Tech 2, check the heated oxygen sensor (HO2s) operating parameters.

The HO2s should respond quickly to different throttle positions.

• Use Tech 2 to monitor the knock sensor system for excessive spark retard

activity. Check for items that cause spark retard activity. Refer to 7.19 DTC

P0327, P0328, P0332 or P0333.

Fuel System • Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6.

• restricted fuel filter,

• incorrect fuel pressure, and

• contaminated fuel.

• Check the operation of the fuel injectors. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

• Perform the fuel injector balance test, refer to 6.3 Fuel Injector Balance

Test in this Section.

• Check for fault conditions that cause an engine to run rich or to run lean.

Ignition System

• Inspect for moisture or corrosion around the spark plug / ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Check for loose ignition coil grounds.

Engine Mechanical Check for the following engine fault conditions. Refer to 6A1 Engine Mechanical –V6.

• low compression, and

• worn valve train components.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3308 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–30

Checks Actions

Ignition System

• Inspect for moisture or corrosion around the spark plug / ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Check for loose ignition coil ground circuit.

Engine Mechanical

• Check for excessive oil in combustion chamber. Refer to 6A1 Engine Mechanical

– V6.

• Check for the following engine fault conditions. Refer to 6A1 Engine Mechanical –

V6.

• low compression, and

• worn valve train components.

When all diagnosis and repairs are completed, check the system for correct operation.

5.9 Hesitation, Sag and Stumble

Description

Momentary lack of response or hesitation as the accelerator is depressed. This condition is usually more severe when

first trying to make the vehicle move from a standing start but can occur at any vehicle speed.

Checks Actions

Preliminary • Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

• Check the air filter element and intake air ducts for blockages.

Sensor / System

• Using Tech 2, check the heated oxygen sensor (HO2s) operating parameters.

The HO2s should respond quickly to different throttle positions.

• Inspect the accelerator pedal position (APP) sensor harness connector for correct

connection. Poor connection of this connector will not set a DTC.

Fuel System • Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6.

• restricted fuel filter,

• incorrect fuel pressure, and

• contaminated fuel.

• Check the operation of the fuel injectors. Refer to 6C Fuel System – V6.

• Perform the fuel injector balance test, refer to 6.3 Fuel Injector Balance

Test in this Section.

• Check for fault conditions that cause an engine to run rich or to run lean.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3309 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–31

Checks Actions

Ignition System

• Inspect for moisture or corrosion around the spark plug / ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Check for loose ignition coil ground circuit.

Engine Cooling System Check the engine thermostat for correct operation and heat range. Refer to 6B1 Engine

Cooling – V6.

Additional Checks • Check the generator output voltage. Refer to 6D1-1 Charging System – V6.

When all diagnosis and repairs are completed, check the system for correct operation.

5.10 Lack of Power, Sluggishness or

Sponginess

Description

The engine delivers less than normal power. There is little or no increase in vehicle speed when the accelerator pedal is

partially depressed.

Checks Actions

Preliminary • Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

• Check the air filter element and intake air ducts for blockages.

Sensor / System

• Use Tech 2 to monitor the knock sensor system for excessive spark retard

activity. Check for items that cause spark retard activity.

• Inspect the accelerator pedal position (APP) sensor harness connector for correct

connection. Poor connection of this connector will not set a DTC.

Fuel System • Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6.

• restricted fuel filter,

• incorrect fuel pressure, and

• contaminated fuel.

• Check the operation of the fuel injectors. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

• Perform the fuel injector balance test, refer to 6.3 Fuel Injector Balance

Test in this Section.

• Check for fault conditions that can cause the engine to run rich or run lean.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3315 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–37

6 Functional Checks

6.1 General Information

The items detailed in the following pages are to be used when there is a customer complaint and there are no diagnostic

trouble codes set, or one or more of the Tech 2 data values are not within the typical values. They are also to be used

when instructed from a DTC table. Before using these tables, you should refer to 5 Symptoms Diagnostics in this

Section, which may direct you to using the following functional checks.

The purpose of these tables is to diagnose engine control module (ECM) controlled components or sub-systems that do

not have diagnostic trouble codes assigned to them. Another purpose of these tables is for Technicians who feel

confident that a particular part of the sub-system is not operating properly and wants only to check that particular item

for proper operation without going through lengthy diagnostic procedures.

6.2 Fuel Injector Coil Test

The fuel injector coil test is divided into two parts. Begin by performing the fuel injector coil quick test. Then only perform

the Injector Coil Test – W ith Special Tool J39021 procedure if the quick test determines that there is a faulty fuel injector.

Fuel Injector Coil Quick Test

Test Description

The following numbers refer to the step numbers in the diagnostic table:

1 This step checks if the engine coolant temperature is within the correct range.

2 This step tests each fuel injector resistance within a specific temperature range.

3 This step determines if all of the fuel injectors are within 3 ohms of each other.

Step Action Value(s) Yes No

1 Using Tech 2, observe the engine coolant temperature

(ECT).

Is the ECT within the specified range? 10 – 32 °C Go to Step 2 Go to Step 3

2 1 Disconnect the fuel injector harness connector,

refer to 2.13 Fuel Rail Assembly, in 6C1-3 Engine

Management – V6 – Service Operations.

2 Using a digital ohmmeter and connector test adaptor kit J 35616-A, measure the resistance of

each fuel injector between the ignition voltage

circuit and the fuel injector control circuit. Refer to

8A Electrical - Body and Chassis for information

on testing for continuity and to Figure 6C1-2 – 9

and Figure 6C1-2 – 10 for the fuel injector

harness connector.

Do any of the fuel injectors display a resistance outside

the specified range? 11 – 14 ΩRefer to Injector

Coil Test – W ith

Special Tool J39021 in this Section Injectors OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3326 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–48

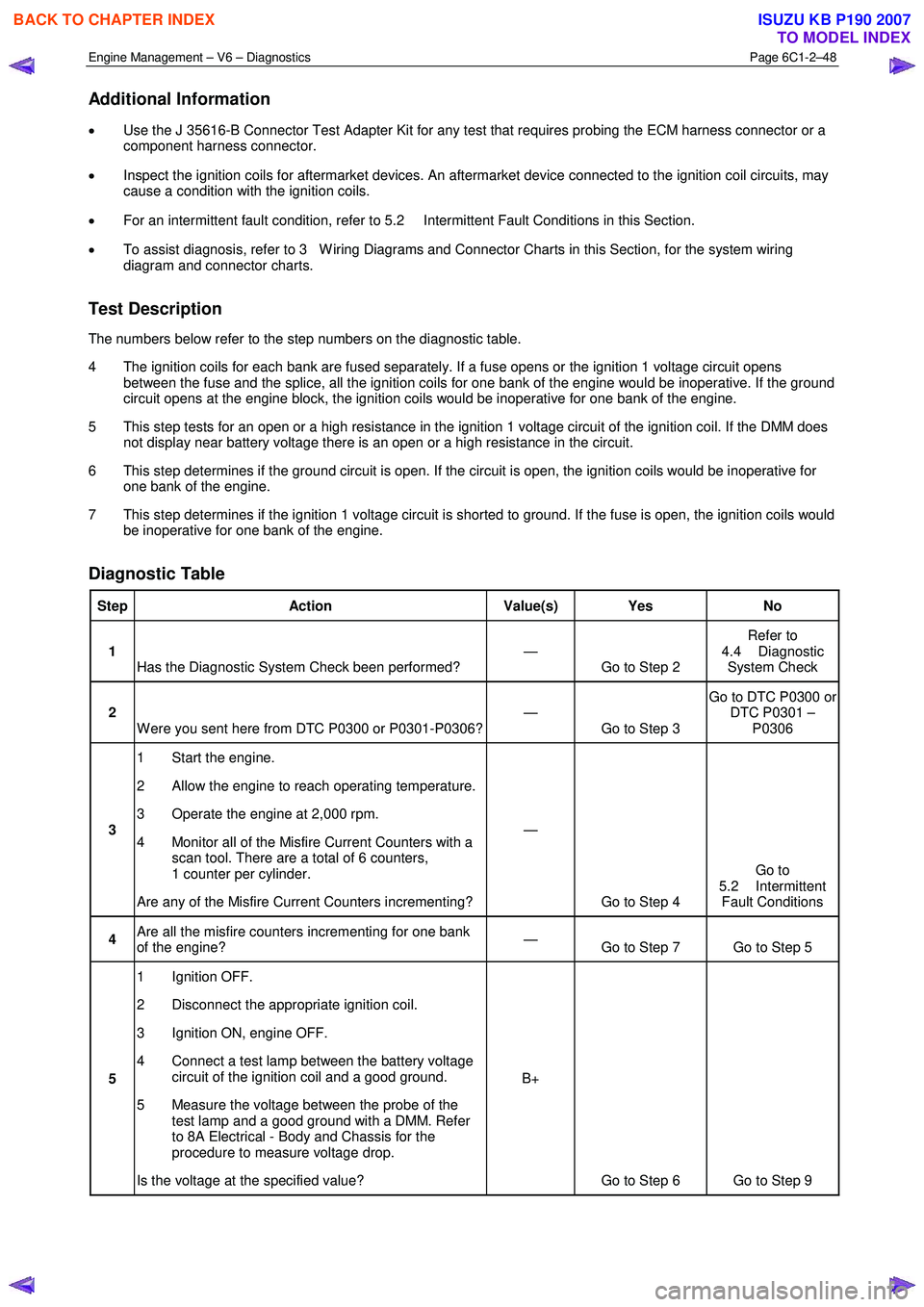

Additional Information

• Use the J 35616-B Connector Test Adapter Kit for any test that requires probing the ECM harness connector or a

component harness connector.

• Inspect the ignition coils for aftermarket devices. An aftermarket device connected to the ignition coil circuits, may

cause a condition with the ignition coils.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

4 The ignition coils for each bank are fused separately. If a fuse opens or the ignition 1 voltage circuit opens between the fuse and the splice, all the ignition coils for one bank of the engine would be inoperative. If the ground

circuit opens at the engine block, the ignition coils would be inoperative for one bank of the engine.

5 This step tests for an open or a high resistance in the ignition 1 voltage circuit of the ignition coil. If the DMM does not display near battery voltage there is an open or a high resistance in the circuit.

6 This step determines if the ground circuit is open. If the circuit is open, the ignition coils would be inoperative for one bank of the engine.

7 This step determines if the ignition 1 voltage circuit is shorted to ground. If the fuse is open, the ignition coils would be inoperative for one bank of the engine.

Diagnostic Table

Step Action Value(s) Yes No

1

Has the Diagnostic System Check been performed? —

Go to Step 2 Refer to

4.4 Diagnostic System Check

2 W ere you sent here from DTC P0300 or P0301-P0306? —

Go to Step 3 Go to DTC P0300 or

DTC P0301 – P0306

3 1 Start the engine.

2 Allow the engine to reach operating temperature.

3 Operate the engine at 2,000 rpm.

4 Monitor all of the Misfire Current Counters with a scan tool. There are a total of 6 counters,

1 counter per cylinder.

Are any of the Misfire Current Counters incrementing? —

Go to Step 4 Go to

5.2 Intermittent Fault Conditions

4 Are all the misfire counters incrementing for one bank

of the engine? —

Go to Step 7 Go to Step 5

5 1 Ignition OFF.

2 Disconnect the appropriate ignition coil.

3 Ignition ON, engine OFF.

4 Connect a test lamp between the battery voltage circuit of the ignition coil and a good ground.

5 Measure the voltage between the probe of the test lamp and a good ground with a DMM. Refer

to 8A Electrical - Body and Chassis for the

procedure to measure voltage drop.

Is the voltage at the specified value? B+

Go to Step 6 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007