ESP ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 356 of 6020

FRONT SUSPENSION 3C-35

3. Apply the setting marks (2) to the height control

arm and torsion bar, then remove height control

arm.

NOTE: “Besco chassis grease” should be applied on

contact area of height control arm with frame.

(RH & LH Both side)

410RS005

4. Apply the setting marks (3) to the torsion bar and

lower control arm, and then remove torsion bar.

RTW 340SH000301

Inspection and Repair

Make necessary correction or replace parts if wear,

damage, corrosion or any other abnormal condition is

found through inspection.

Check the following parts:

• Torsion bar

• Height control arm

• Adjust bolt

• Rubber seat

Installation

1. Apply grease to the serrated portions, then install

torsion bar. Make sure the bars are on their correct

respective sides and align the setting marks (3).

410RS007

RTW 340SH000301

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 393 of 6020

REAR SUSPENSION 3D-9

Installation

1. Install the bump rubber and bolt and tighten it to thespecified torque.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

42 (4.3/31)

2. Install the leaf spring. • The leaf spring assembly should be installed so that the

built-in rubber bush is toward the front.

• Align the holes of the spring eye and frame bracket.

• Insert the spring pin toward vehicle inner side, through

the frame bracket holes and the spring bush hole.

• Tighten the nut a little and, after the vehicle is lowered,

tighten it to the specified torque.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

152 (15.5/112)

RTW 340LF000101

RTW 63DSH000101

• Apply rubber grease to inside and outside of the rubber

bushing.

• Install the rubber bushings into the hole in the frame

side bracket and the spring rear eye.

• Install the shackle pin and shackle plate.

• Tighten the nuts a little and, after vehicle is lowered,

tighten it to the specified torque.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

98 (10.0/72)

3. Support the lower clamp under the leaf spring.

4. Apply oil to the thread portion of U bolt.

Install the U bolt (1) and seat (2) on the rear axle and insert

the U bolt in the lower clamp holes.

Tolerance of assembling the seat

A

90° ±2°

5. Tighten the nut to the specified torque.

NOTE: Apply oil to the thread.

Torque N⋅m (kgf ⋅m/lb ⋅ft)

78 (8.0/58)

6. Install the shock absorber and inner washer on the lower clamp pin and frame side pin.

7. Install the washer and nut on the frame side pin and tighten the nut to the specified torque.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

39 (4.0/29)

8. Install the washer and nut on the lower clamp pin and tighten the nut to the specified torque.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

39 (4.0/29)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 487 of 6020

REAR AXLE 4B-43

425RS066

2. Measuring dimension between thrust washers at both ends.

Assemble side gear, pinion, pinion shaft pressure

ring and thrust washer.

• Eliminate clearance by pushing pressure ring

against the pinion shaft in axial direction.

• Eliminate backlash by connecting side gear to

the pinion.

• Measure dimension between thrust washers

at both ends. (H)

425RS067

3. After each dimension is measured, perform adjustment with the following procedure.

Adjust so that ((F-B) + G-H) = 0.05 to 0.2 mm (0.002 to 0.008 in).

Also, select a proper thrust

washer so that the dimension difference from

back face of the pressure ring to thrust washer

(left/right side) does not exceed 0.05 mm (0.002

in).

Thickness : 1.5, 1.6, 1.7 mm (0.059, 0.063, 0.067 in)

Note :

When reassembling, sufficiently apply gear oil on

every part, especially on sliding surface.

1. Install thrust washer in differential cage A and B.

2.

Assemble spring plate, friction plate and

friction disc as following illustration.

• Install spring plate with dished side turned

to the differential cage side.

425R300009

Legend

1. Friction Plate

2. Spring Plate

3. Friction Disc

4. Install pressure ring and side gear. • Fit two side gears in two pressure rings, one

from under a ring and the other from above a

ring.

• Fit two pairs of a friction disc and a friction

plate under it on and under these two

pressure rings.

5. Set pinion and pinion shaft on differential cage

A

assembly.

6. Assemble differential cage A and B.

7.

Align the setting marks on differential cage A and

B and tighten screws in diagonal order evenly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 556 of 6020

4C1-52 FRONT WHEEL DRIVE

Preload Adjustment

Tighten the hub nut at 29.4 N⋅m (3 kgf ⋅m / 2 1.7 lb·ft), then

loosen the nut to the full.

Tighten the hub nut at the value given below, using a spring

scale on the wheel pin.

Bearing Preload N (kgf/lb)

New bearing and New oil seal 22 - 27

(2.2 - 2.8 / 4.9 - 6.2)

Used bearing and New oil seal 1

4 - 20

( 1 .4 - 2.0 / 3. 1 - 4.5)

If the measured bearing preload is outside the specifications,

adjust it by loosening or tightening the bearing nut.

9. Lock Washer

Turn the side with larger diameter of the tapered bore to the

vehicle outer side, and attach the washer.

If the bolt holes in the lock plate are not aligned with the

corresponding holes in the nut, reverse the lock plate.

If the bolt holes are still out of alignment, turn in the nut just

enough to obtain alignment,. Screw is to be fastened tightly so

its head may come lower than the surface of the washer.

10. Flange (4×4 model only)

Apply adhesive (LOCTITE 5 15 or equivalent) to both joining

flange faces then install hub flange.

11. Snap ring, shims (4×4 model only)

Adjust the clearance between the flange and the snap ring.

Clearance mm(in) 0 - 0.2 (0 - 0.008)

Adjust shims available mm(in)

0.2, 0.3, 0.5, 1.0

(0.008, 0.0 12, 0.020, 0.039)

RTW 440SH00090 1

13. Bolt

Torque N ⋅m (kgf ⋅m/lb ⋅ft

)

59 (6.0 / 43)

• Refer to SECTION 3E “W HEELS AND TIRES” for wheel

install procedure.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 565 of 6020

FRONT WHEEL DRIVE 4C1-61

Preload Adjustment

Tighten the hub nut at 29 N⋅m (3.0 kgf ⋅m / 22 lb ⋅ft), then loosen

the nut to the full.

Tighten the hub nut at the value given below, using a spring

scale on the wheel pin.

Bearing Preload N (kgf/lb)

New bearing and New oil seal 22 - 27

(2.2 - 2.8 / 4.9 - 6.2)

Used bearing and New oil seal 1

4 - 20

( 1 .4 - 2.0 / 3. 1 - 4.5)

If the measured bearing preload is outside the specifications,

adjust it by loosening or tightening the bearing nut.

21. Lock Washer

Turn the side with larger diameter of the tapered bore to the

vehicle outer side, and attach the washer.

If the bolt holes in the lock plate are not aligned with the

corresponding holes in the nut, reverse the lock plate.

If the bolt holes are still out of alignment, turn in the nut just

enough to obtain alignment,. Screw is to be fastened tightly so

its head may come lower than the surface of the washer.

22. Body Assembly

Apply adhesive (Loctite 5 15 or equivalent) to the both joining

faces.

23. Snap Ring and Shims

Adjust the clearance between the free wheeling hub body and

the snap ring.

Clearance mm(in) 0 - 0.2 (0 - 0.08)

Adjust Shims Available mm(in)

0.2, 0.3, 0.5, 1.0

(0.008, 0.0 11, 0.020, 0.039)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 618 of 6020

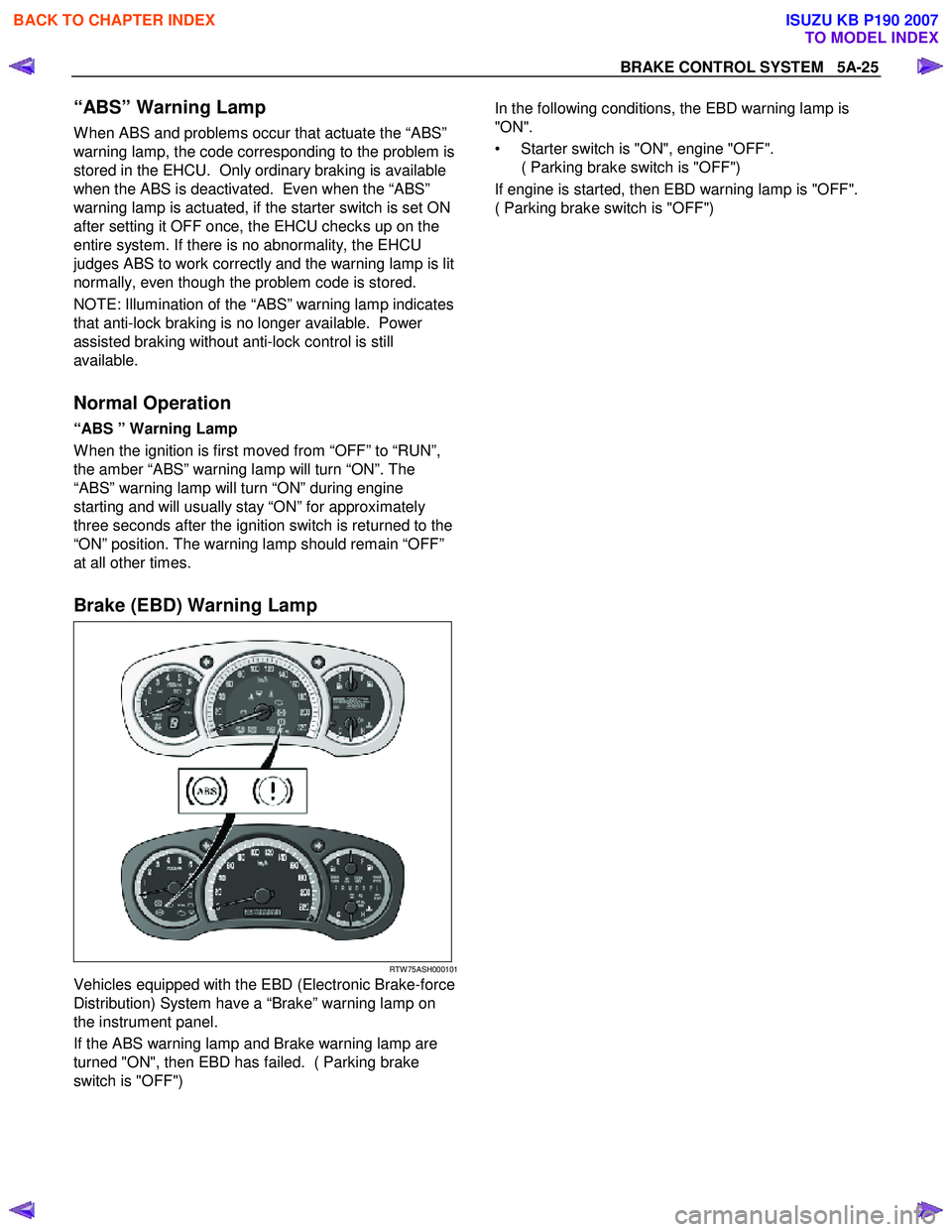

BRAKE CONTROL SYSTEM 5A-25

“ABS” Warning Lamp

W hen ABS and problems occur that actuate the “ABS”

warning lamp, the code corresponding to the problem is

stored in the EHCU. Only ordinary braking is available

when the ABS is deactivated. Even when the “ABS”

warning lamp is actuated, if the starter switch is set ON

after setting it OFF once, the EHCU checks up on the

entire system. If there is no abnormality, the EHCU

judges ABS to work correctly and the warning lamp is lit

normally, even though the problem code is stored.

NOTE: Illumination of the “ABS” warning lamp indicates

that anti-lock braking is no longer available. Power

assisted braking without anti-lock control is still

available.

Normal Operation

“ABS ” Warning Lamp

W hen the ignition is first moved from “OFF” to “RUN”,

the amber “ABS” warning lamp will turn “ON”. The

“ABS” warning lamp will turn “ON” during engine

starting and will usually stay “ON” for approximately

three seconds after the ignition switch is returned to the

“ON” position. The warning lamp should remain “OFF”

at all other times.

Brake (EBD) Warning Lamp

RTW 75ASH000101

Vehicles equipped with the EBD (Electronic Brake-force

Distribution) System have a “Brake” warning lamp on

the instrument panel.

If the ABS warning lamp and Brake warning lamp are

turned "ON", then EBD has failed. ( Parking brake

switch is "OFF")

In the following conditions, the EBD warning lamp is

"ON".

• Starter switch is "ON", engine "OFF". ( Parking brake switch is "OFF")

If engine is started, then EBD warning lamp is "OFF".

( Parking brake switch is "OFF")

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 620 of 6020

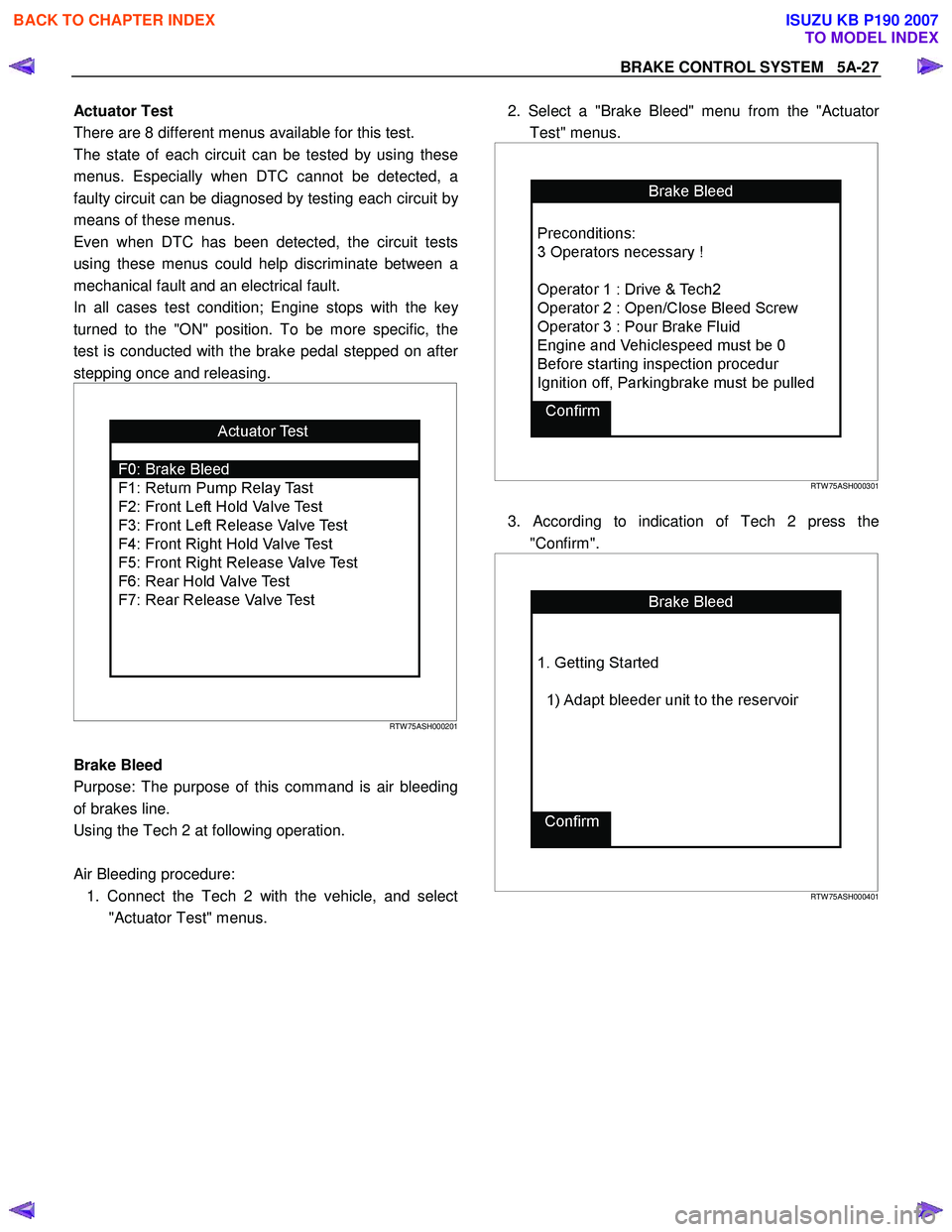

BRAKE CONTROL SYSTEM 5A-27

Actuator Test

There are 8 different menus available for this test.

The state of each circuit can be tested by using these

menus. Especially when DTC cannot be detected, a

faulty circuit can be diagnosed by testing each circuit b

y

means of these menus.

Even when DTC has been detected, the circuit tests

using these menus could help discriminate between a

mechanical fault and an electrical fault.

In all cases test condition; Engine stops with the ke

y

turned to the "ON" position. To be more specific, the

test is conducted with the brake pedal stepped on afte

r

stepping once and releasing.

RTW 75ASH000201

Brake Bleed

Purpose: The purpose of this command is air bleeding

of brakes line.

Using the Tech 2 at following operation.

Air Bleeding procedure: 1. Connect the Tech 2 with the vehicle, and select "Actuator Test" menus.

2. Select a "Brake Bleed" menu from the "Actuato

r

Test" menus.

RTW 75ASH000301

3. According to indication of Tech 2 press the

"Confirm".

RTW 75ASH000401

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 836 of 6020

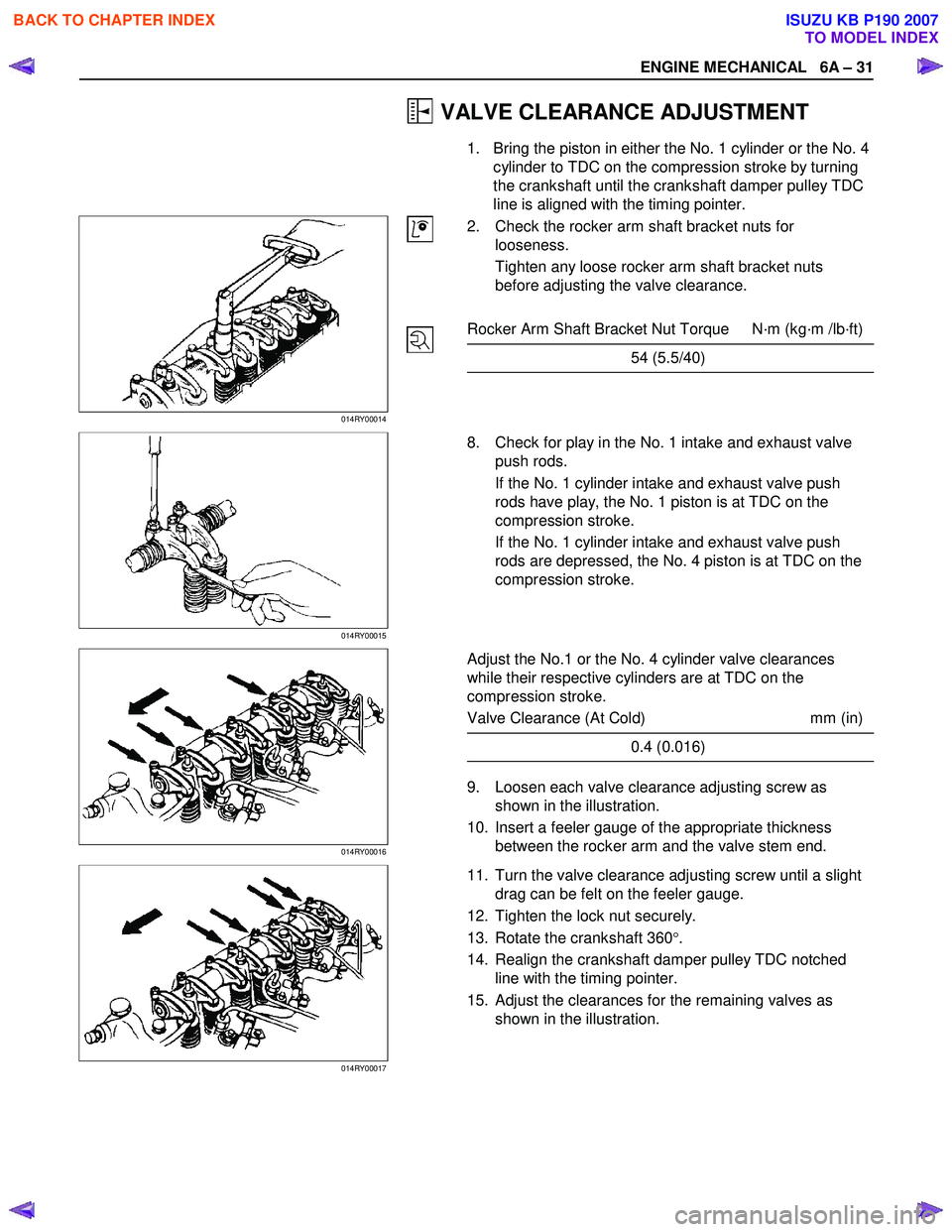

ENGINE MECHANICAL 6A – 31

VALVE CLEARANCE ADJUSTMENT

1. Bring the piston in either the No. 1 cylinder or the No. 4 cylinder to TDC on the compression stroke by turning

the crankshaft until the crankshaft damper pulley TDC

line is aligned with the timing pointer.

014RY00014

2. Check the rocker arm shaft bracket nuts for

looseness.

Tighten any loose rocker arm shaft bracket nuts

before adjusting the valve clearance.

Rocker Arm Shaft Bracket Nut Torque N·m (kg·m /lb·ft)

54 (5.5/40)

014RY00015

8. Check for play in the No. 1 intake and exhaust valve

push rods.

If the No. 1 cylinder intake and exhaust valve push

rods have play, the No. 1 piston is at TDC on the

compression stroke.

If the No. 1 cylinder intake and exhaust valve push

rods are depressed, the No. 4 piston is at TDC on the

compression stroke.

014RY00016

Adjust the No.1 or the No. 4 cylinder valve clearances

while their respective cylinders are at TDC on the

compression stroke.

Valve Clearance (At Cold) mm (in)

0.4 (0.016)

9. Loosen each valve clearance adjusting screw as

shown in the illustration.

10. Insert a feeler gauge of the appropriate thickness between the rocker arm and the valve stem end.

014RY00017

11. Turn the valve clearance adjusting screw until a slight

drag can be felt on the feeler gauge.

12. Tighten the lock nut securely.

13. Rotate the crankshaft 360 °.

14. Realign the crankshaft damper pulley TDC notched line with the timing pointer.

15. Adjust the clearances for the remaining valves as shown in the illustration.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 970 of 6020

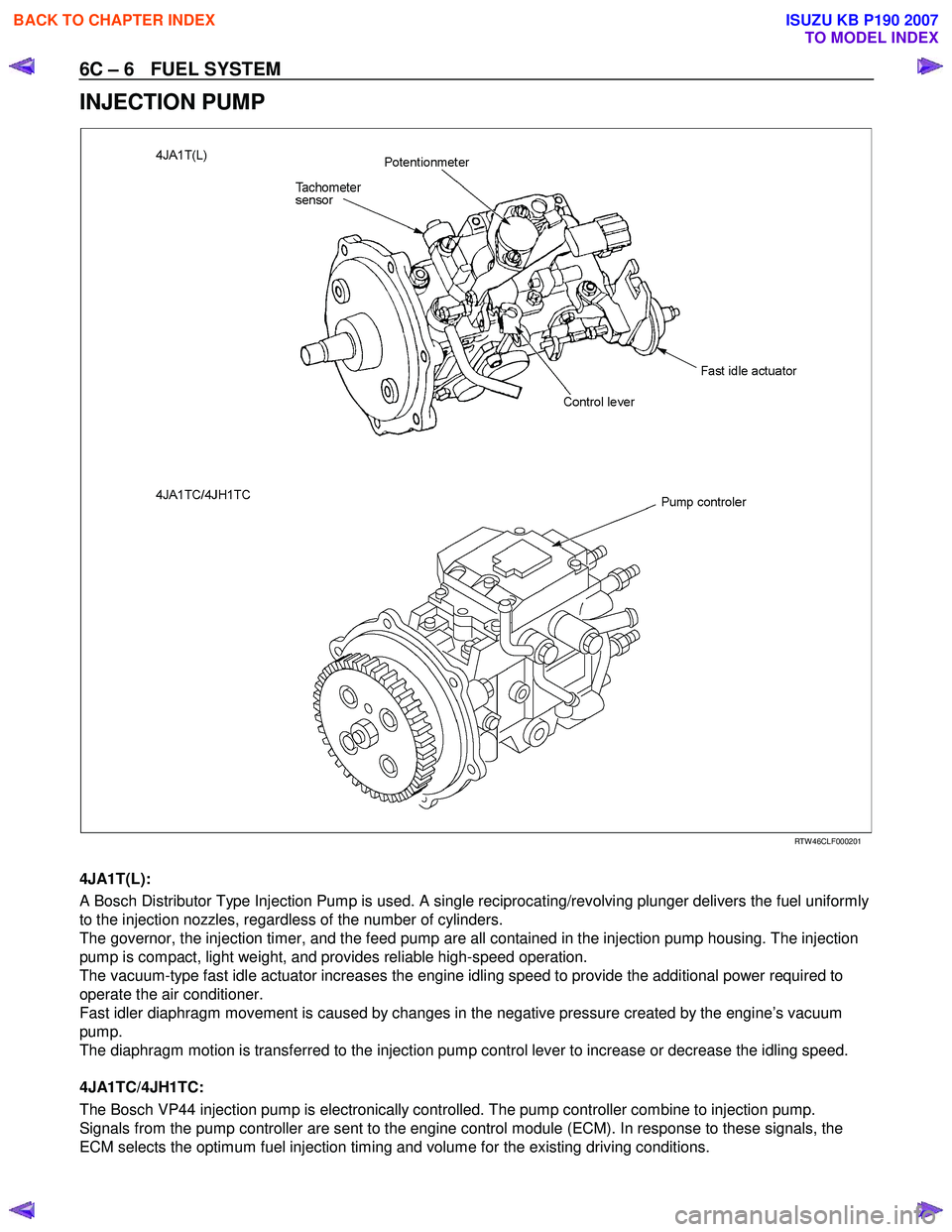

6C – 6 FUEL SYSTEM

INJECTION PUMP

RTW 46CLF000201

4JA1T(L):

A Bosch Distributor Type Injection Pump is used. A single reciprocating/revolving plunger delivers the fuel uniformly

to the injection nozzles, regardless of the number of cylinders.

The governor, the injection timer, and the feed pump are all contained in the injection pump housing. The injection

pump is compact, light weight, and provides reliable high-speed operation.

The vacuum-type fast idle actuator increases the engine idling speed to provide the additional power required to

operate the air conditioner.

Fast idler diaphragm movement is caused by changes in the negative pressure created by the engine’s vacuum

pump.

The diaphragm motion is transferred to the injection pump control lever to increase or decrease the idling speed.

4JA1TC/4JH1TC:

The Bosch VP44 injection pump is electronically controlled. The pump controller combine to injection pump.

Signals from the pump controller are sent to the engine control module (ECM). In response to these signals, the

ECM selects the optimum fuel injection timing and volume for the existing driving conditions.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1097 of 6020

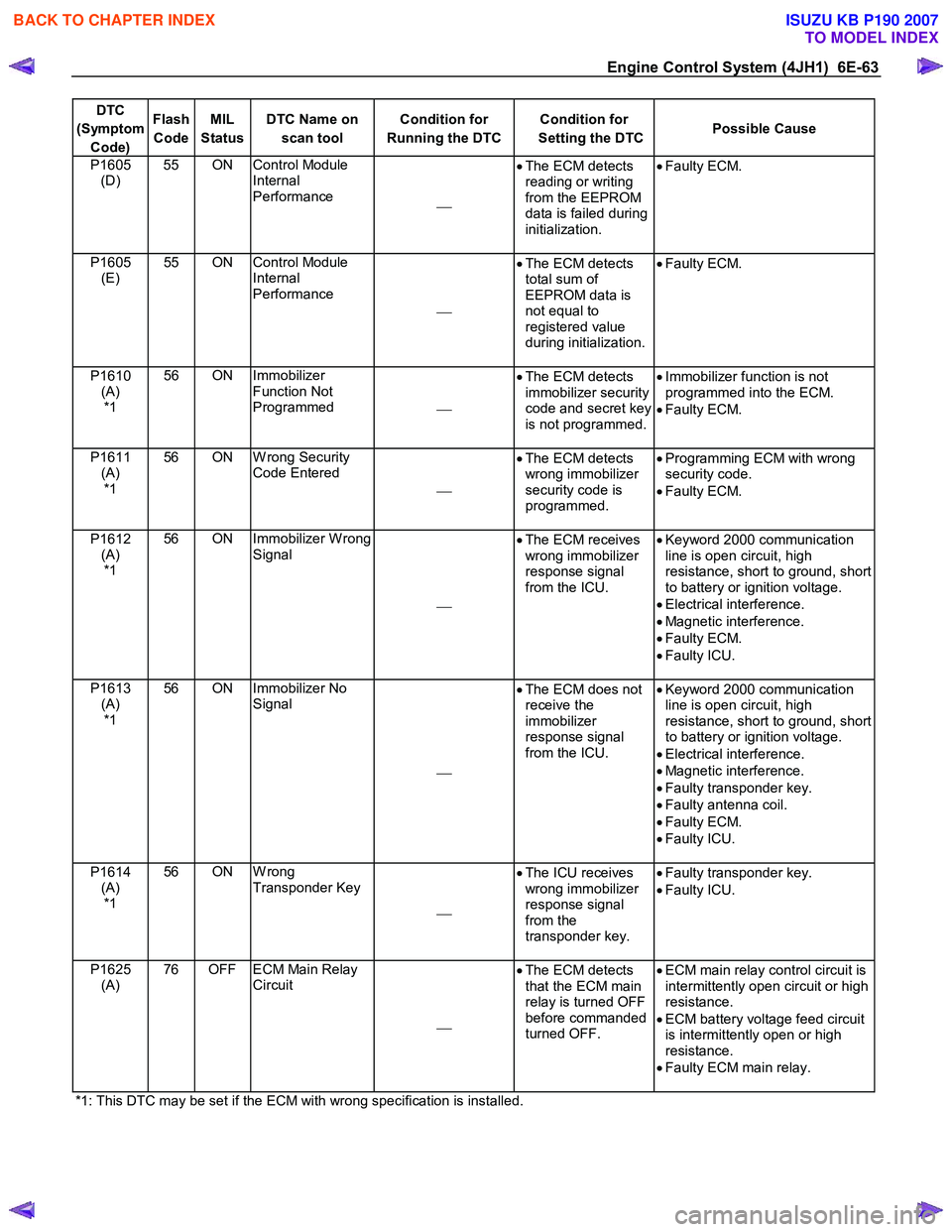

Engine Control System (4JH1) 6E-63

DTC

(Symptom Code) Flash

Code MIL

Status DTC Name on

scan tool Condition for

Running the DTC Condition for

Setting the DTC Possible Cause

P1605

(D) 55 ON Control Module

Internal

Performance •

The ECM detects

reading or writing

from the EEPROM

data is failed during

initialization.

•

Faulty ECM.

P1605

(E) 55 ON Control Module

Internal

Performance

•

The ECM detects

total sum of

EEPROM data is

not equal to

registered value

during initialization.

•

Faulty ECM.

P1610

(A) *1 56 ON Immobilizer

Function Not

Programmed •

The ECM detects

immobilizer security

code and secret key

is not programmed.

•

Immobilizer function is not

programmed into the ECM.

• Faulty ECM.

P1611 (A) *1 56 ON W rong Security

Code Entered

•

The ECM detects

wrong immobilizer

security code is

programmed.

•

Programming ECM with wrong

security code.

• Faulty ECM.

P1612 (A) *1 56 ON Immobilizer W rong

Signal

•

The ECM receives

wrong immobilizer

response signal

from the ICU.

•

Keyword 2000 communication

line is open circuit, high

resistance, short to ground, short

to battery or ignition voltage.

• Electrical interference.

• Magnetic interference.

• Faulty ECM.

• Faulty ICU.

P1613 (A) *1 56 ON Immobilizer No

Signal

•

The ECM does not

receive the

immobilizer

response signal

from the ICU.

•

Keyword 2000 communication

line is open circuit, high

resistance, short to ground, short

to battery or ignition voltage.

• Electrical interference.

• Magnetic interference.

• Faulty transponder key.

• Faulty antenna coil.

• Faulty ECM.

• Faulty ICU.

P1614 (A) *1 56 ON W rong

Transponder Key

•

The ICU receives

wrong immobilizer

response signal

from the

transponder key.

•

Faulty transponder key.

• Faulty ICU.

P1625 (A) 76 OFF ECM Main Relay

Circuit

•

The ECM detects

that the ECM main

relay is turned OFF

before commanded

turned OFF.

•

ECM main relay control circuit is

intermittently open circuit or high

resistance.

• ECM battery voltage feed circuit

is intermittently open or high

resistance.

• Faulty ECM main relay.

*1: This DTC may be set if the ECM with wrong specification is installed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007