tires ISUZU KB P190 2007 Workshop Owner's Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4930 of 6020

7D1-56 TRANSFER CONTROL SYSTEM

Even after the correction step 1-2(*), the 4WD indicator still blinks at 2Hz when shifting

from 2H to 4H.

Step Action Yes No

1 Check the air pressure and wear

of all the tires. Is any trouble

noticed? After adjusting the air pressure

and repairing the worn tires, try

the correction step 1-2(*). Go to step 2.

2

Check the 4W D detection switch

on the transfer case, neutral

detection switch and each

harness. Is a trouble noticed? 4W D detection switch is open or

the harness failed.

The neutral detection switch is

closed or the harness GND is

shorted.

Replace or repair and then trace

this chart from the beginning. Go to step 3.

3

Is there continuity in the harness

between the transfer controller

and front axle actuator? Has a

body short or disconnection

been detected? Go to step 4.

Body short or disconnection of

the harness between the transfer

controller and front axle actuator.

After repairing, trace this chart

from the beginning.

4 Is trouble detected in the axle

detection harness between the

axle actuator and transfer

controller? Disconnected harness.

After repairing trace this chart

from the beginning. Malfunction of axle actuator.

Refer to the paragraph of the axle

disconnect.

After repairing, trace this chart

from the beginning.

*Before determining a trouble (Non-trouble mode)

Note:

Vehicles with manual hub and rigid hub don’t have axle actuator.

W hen the above-mentioned procedure is followed, check the harness between the axle dummy output terminal and

the axle switch input terminal of the transfer controller, instead of axle actuator.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4933 of 6020

TRANSFER CONTROL SYSTEM 7D1-59

Even after the correction step 2-1(*), the 4WD indicator still blinks at 2Hz when shifting

from 4H to 2H.

Step Action Yes No

1 Check all the tires for air

pressure and wear. Is any

trouble detected? After adjusting the air pressure

and repairing the worn tires, try

the correction step 2-1(*). Go to step 2.

2

Check the 4W D detection switch

on the transfer case and neutral

detection switch and each

harness. Is a trouble detected? 4W D detection switch is closed

or the GND short of harness.

The neutral detection switch is

closed or the harness GND has

shorted.

Replace or repair and then trace

this chart from the beginning. Go to step 3.

3

Is there continuity in the harness

between the transfer controller

and axle actuator?

Has a short or disconnection

been detected?

Is the connection incorrect? Go to step 4.

Body short, disconnection or

incorrect connection of the

harness between the transfer

controller and actuator.

After repairing, trace this chart

from the beginning.

4 Is trouble detected in the axle

detection harness between the

axle actuator and transfer

controller? GND short of harness

Malfunction of axle actuator.

Refer to the paragraph of axle

disconnect.

After repairing, trace this chart

from the beginning.

*Before determining a trouble (Non-trouble mode)

Note:

Vehicle with manual hub and rigid hub don’t have axle actuator.

W hen the above-mentioned procedure is followed, check the harness between the axle dummy output terminal and

the axle switch input terminal of the transfer controller, instead of axle actuator.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5115 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-177

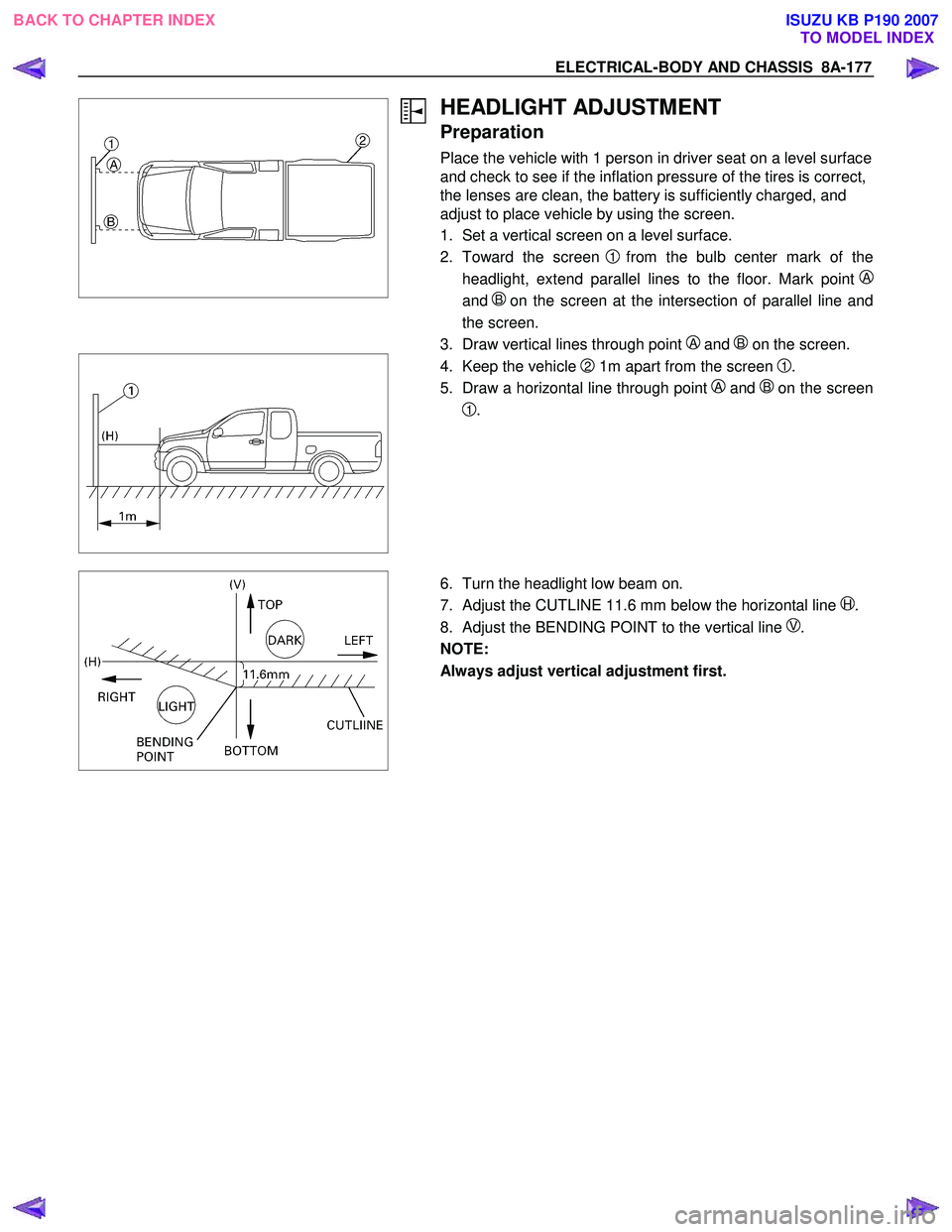

HEADLIGHT ADJUSTMENT

Preparation

Place the vehicle with 1 person in driver seat on a level surface

and check to see if the inflation pressure of the tires is correct,

the lenses are clean, the battery is sufficiently charged, and

adjust to place vehicle by using the screen.

1. Set a vertical screen on a level surface.

2. Toward the screen

1from the bulb center mark of the

headlight, extend parallel lines to the floor. Mark point

A

and B on the screen at the intersection of parallel line and

the screen.

3. Draw vertical lines through point

A and B on the screen.

4. Keep the vehicle 2 1m apart from the screen 1.

5. Draw a horizontal line through point

A and Bon the screen

1.

6. Turn the headlight low beam on.

7. Adjust the CUTLINE 11.6 mm below the horizontal line

H.

8. Adjust the BENDING POINT to the vertical line

V.

NOTE:

Always adjust vertical adjustment first.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007