brake fluid ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4 of 6020

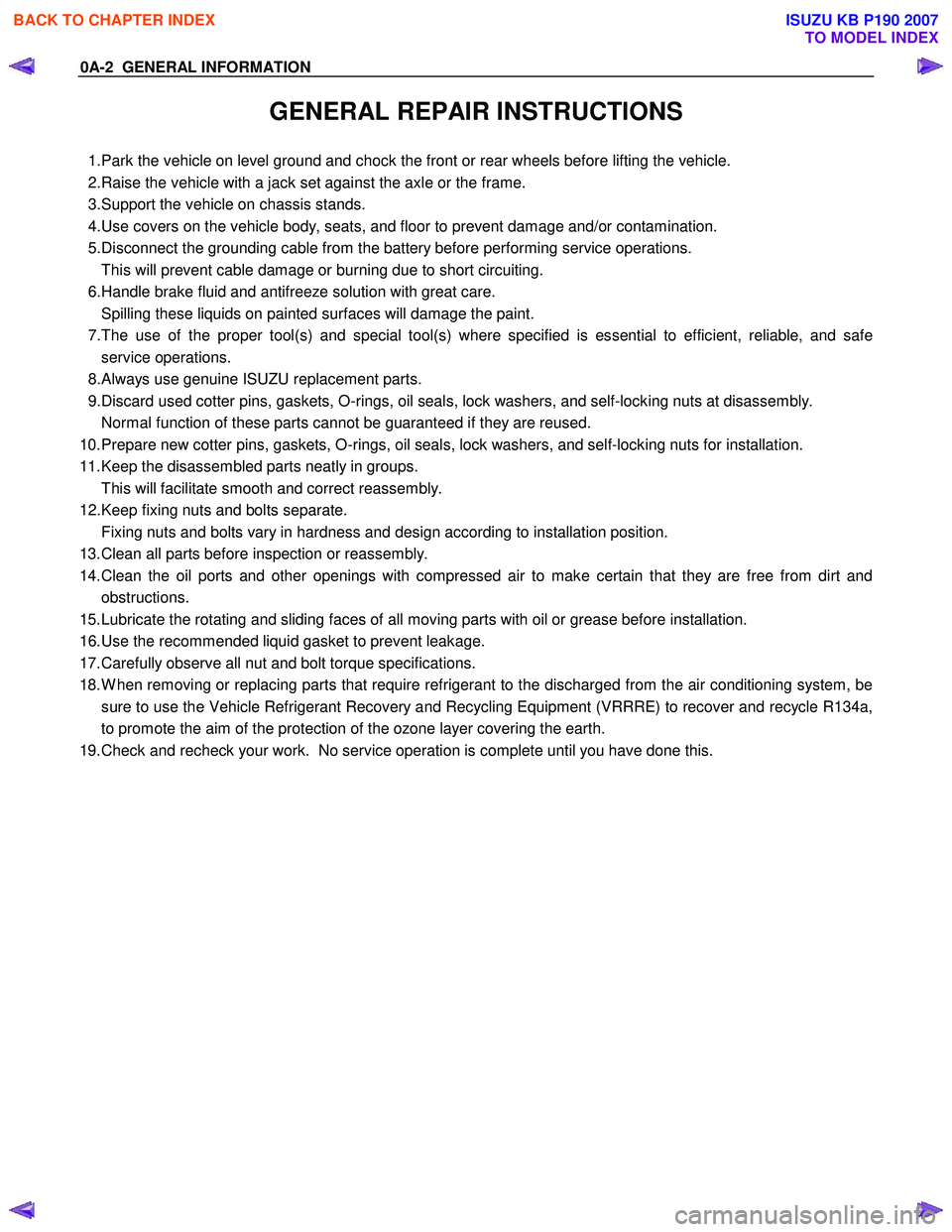

0A-2 GENERAL INFORMATION

GENERAL REPAIR INSTRUCTIONS

1. Park the vehicle on level ground and chock the front or rear wheels before lifting the vehicle.

2. Raise the vehicle with a jack set against the axle or the frame.

3. Support the vehicle on chassis stands.

4. Use covers on the vehicle body, seats, and floor to prevent damage and/or contamination.

5. Disconnect the grounding cable from the battery before performing service operations.

This will prevent cable damage or burning due to short circuiting.

6. Handle brake fluid and antifreeze solution with great care.

Spilling these liquids on painted surfaces will damage the paint.

7. The use of the proper tool(s) and special tool(s) where specified is essential to efficient, reliable, and safe

service operations.

8. Always use genuine ISUZU replacement parts.

9. Discard used cotter pins, gaskets, O-rings, oil seals, lock washers, and self-locking nuts at disassembly.

Normal function of these parts cannot be guaranteed if they are reused.

10. Prepare new cotter pins, gaskets, O-rings, oil seals, lock washers, and self-locking nuts for installation.

11. Keep the disassembled parts neatly in groups. This will facilitate smooth and correct reassembly.

12. Keep fixing nuts and bolts separate. Fixing nuts and bolts vary in hardness and design according to installation position.

13. Clean all parts before inspection or reassembly.

14. Clean the oil ports and other openings with compressed air to make certain that they are free from dirt and obstructions.

15. Lubricate the rotating and sliding faces of all moving parts with oil or grease before installation.

16. Use the recommended liquid gasket to prevent leakage.

17. Carefully observe all nut and bolt torque specifications.

18. W hen removing or replacing parts that require refrigerant to the discharged from the air conditioning system, be sure to use the Vehicle Refrigerant Recovery and Recycling Equipment (VRRRE) to recover and recycle R134a,

to promote the aim of the protection of the ozone layer covering the earth.

19. Check and recheck your work. No service operation is complete until you have done this.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 21 of 6020

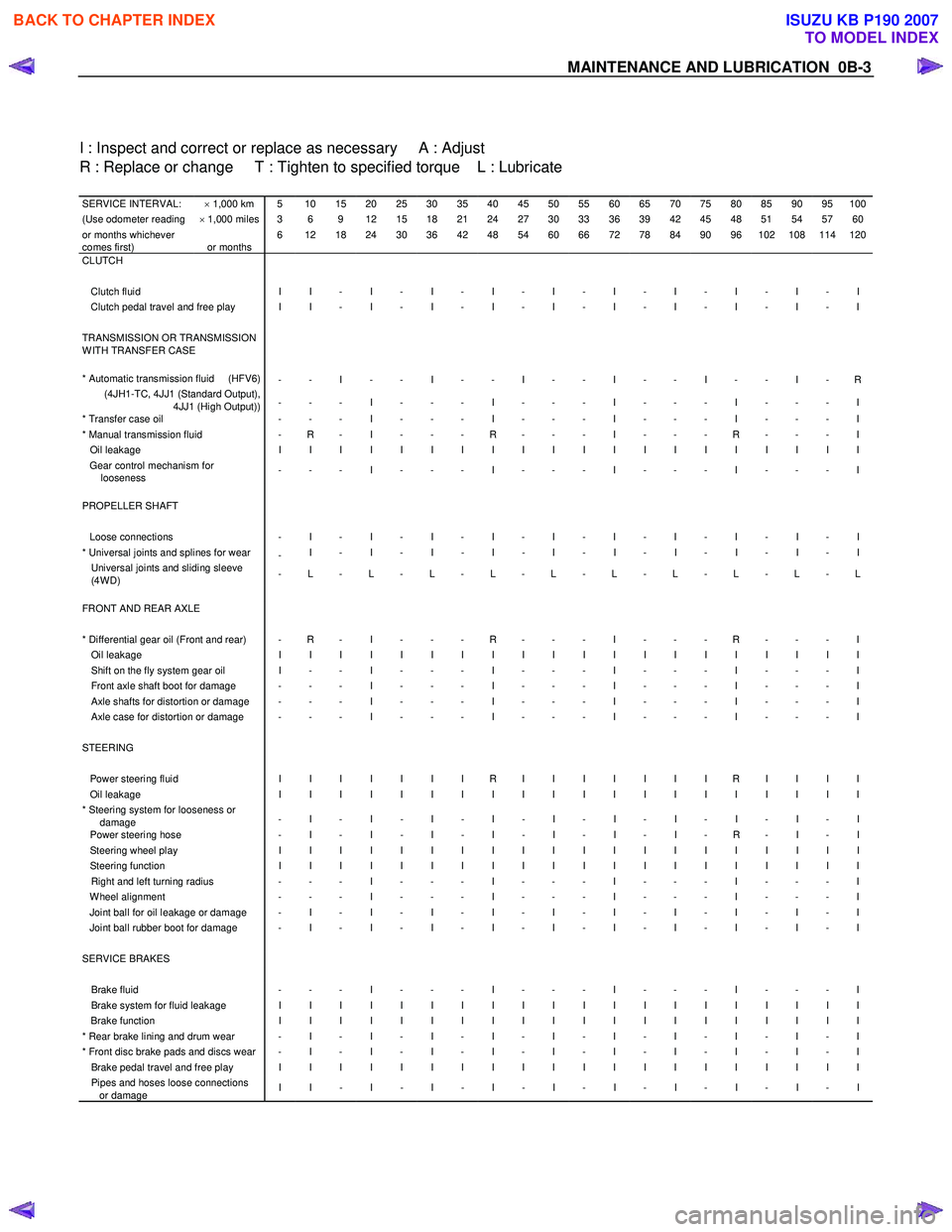

MAINTENANCE AND LUBRICATION 0B-3

I : Inspect and correct or replace as necessary A : Adjust

R : Replace or change T : Tighten to specified torque L : Lubricate

SERVICE INTERVAL: × 1,000 km 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100(Use odometer reading × 1,000 miles 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60or months whichever

comes first)

or months 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

CLUTCH

Clutch fluid I I - I - I - I - I - I - I - I - I - I Clutch pedal travel and free play I I - I - I - I - I - I - I - I - I - I TRANSMISSION OR TRANSMISSION

W ITH TRANSFER CASE

* Automatic transmission fluid (HFV6)

- - I - - I - - I - - I - - I - - I - R (4JH1-TC, 4JJ1 (Standard Output),

4JJ1 (High Output)) - - - I - - - I - - - I - - - I - - - I

* Transfer case oil

- - - I - - - I - - - I - - - I - - - I * Manual transmission fluid - R - I - - - R - - - I - - - R - - - I Oil leakage I I I I I I I I I I I I I I I I I I I I Gear control mechanism for

looseness - - - I - - - I - - - I - - - I - - - I

PROPELLER SHAFT Loose connections - I - I - I - I - I - I - I - I - I - I * Universal joints and splines for wear

- I - I - I - I - I - I - I - I - I - I Universal joints and sliding sleeve

(4W D) - L - L - L - L - L - L - L - L - L - L

FRONT AND REAR AXLE * Differential gear oil (Front and rear) - R - I - - - R - - - I - - - R - - - I Oil leakage I I I I I I I I I I I I I I I I I I I I Shift on the fly system gear oil I - - I - - - I - - - I - - - I - - - I Front axle shaft boot for damage - - - I - - - I - - - I - - - I - - - I Axle shafts for distortion or damage - - - I - - - I - - - I - - - I - - - I Axle case for distortion or damage - - - I - - - I - - - I - - - I - - - I STEERING Power steering fluid I I I I I I I R I I I I I I I R I I I I Oil leakage I I I I I I I I I I I I I I I I I I I I * Steering system for looseness or

damage - I - I - I - I - I - I - I - I - I - I

Power steering hose

- I - I - I - I - I - I - I - R - I - I Steering wheel play I I I I I I I I I I I I I I I I I I I I Steering function I I I I I I I I I I I I I I I I I I I I Right and left turning radius - - - I - - - I - - - I - - - I - - - I W heel alignment - - - I - - - I - - - I - - - I - - - I Joint ball for oil leakage or damage - I - I - I - I - I - I - I - I - I - I Joint ball rubber boot for damage - I - I - I - I - I - I - I - I - I - I SERVICE BRAKES Brake fluid - - - I - - - I - - - I - - - I - - - I Brake system for fluid leakage I I I I I I I I I I I I I I I I I I I I Brake function I I I I I I I I I I I I I I I I I I I I * Rear brake lining and drum wear - I - I - I - I - I - I - I - I - I - I * Front disc brake pads and discs wear - I - I - I - I - I - I - I - I - I - I Brake pedal travel and free play I I I I I I I I I I I I I I I I I I I I Pipes and hoses loose connections

or damage I I - I - I - I - I - I - I - I - I - I

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 24 of 6020

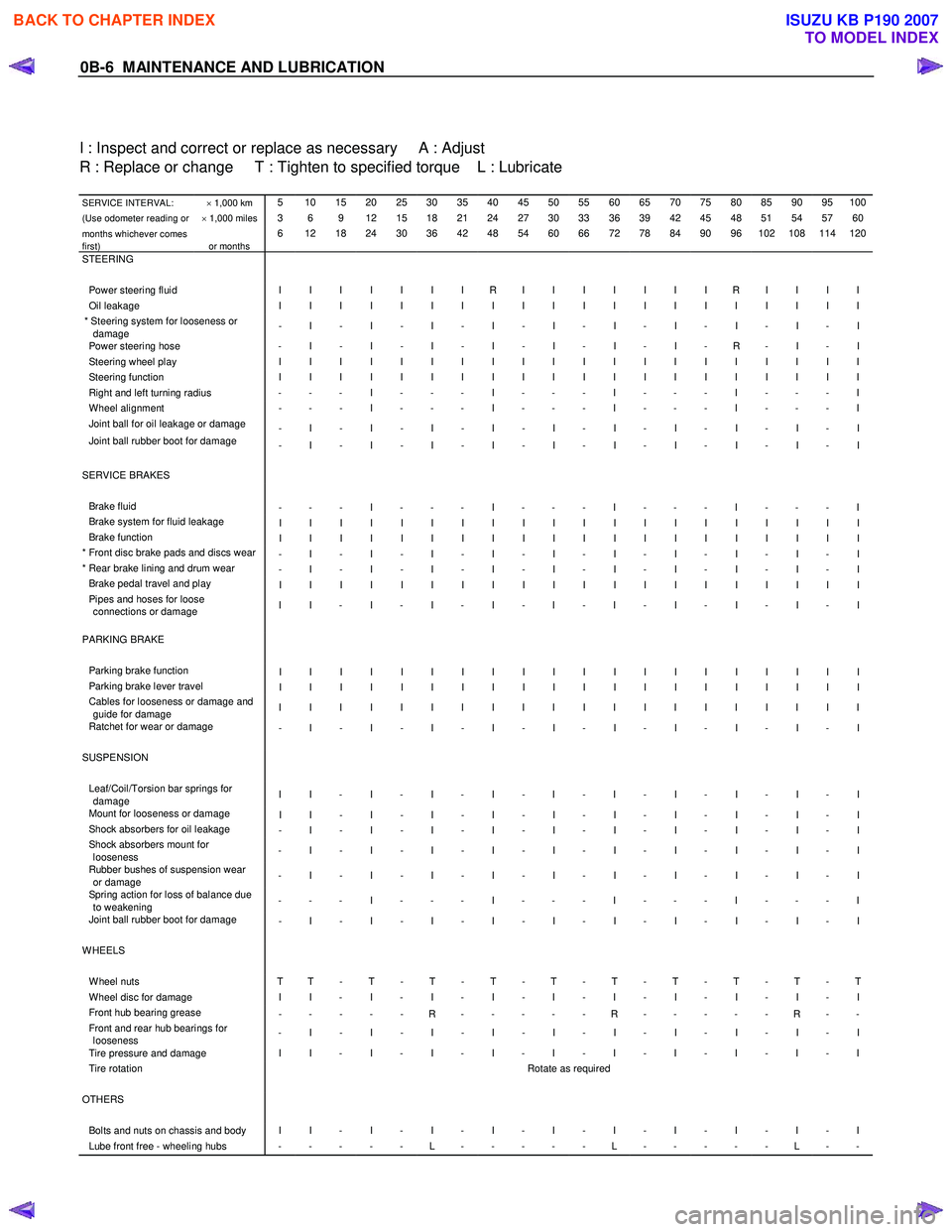

0B-6 MAINTENANCE AND LUBRICATION

I : Inspect and correct or replace as necessary A : Adjust

R : Replace or change T : Tighten to specified torque L : Lubricate

SERVICE INTERVAL: × 1,000 km 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

(Use odometer reading or × 1,000 miles 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60

months whichever comes

first)

or months 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

STEERING Power steering fluid I I I I I I I R I I I I I I I R I I I I Oil leakage I I I I I I I I I I I I I I I I I I I I * Steering system for looseness or

damage - I - I - I - I - I - I - I - I - I - I

Power steering hose

- I - I - I - I - I - I - I - R - I - I Steering wheel play I I I I I I I I I I I I I I I I I I I I Steering function I I I I I I I I I I I I I I I I I I I I Right and left turning radius - - - I - - - I - - - I - - - I - - - I W heel alignment - - - I - - - I - - - I - - - I - - - I Joint ball for oil leakage or damage

- I - I - I - I - I - I - I - I - I - I

Joint ball rubber boot for damage - I - I - I - I - I - I - I - I - I - I

SERVICE BRAKES Brake fluid - - - I - - - I - - - I - - - I - - - I Brake system for fluid leakage I I I I I I I I I I I I I I I I I I I I Brake function I I I I I I I I I I I I I I I I I I I I * Front disc brake pads and discs wear - I - I - I - I - I - I - I - I - I - I * Rear brake lining and drum wear - I - I - I - I - I - I - I - I - I - I Brake pedal travel and play I I I I I I I I I I I I I I I I I I I I Pipes and hoses for loose

connections or damage I I - I - I - I - I - I - I - I - I - I

PARKING BRAKE Parking brake function I I I I I I I I I I I I I I I I I I I I Parking brake lever travel I I I I I I I I I I I I I I I I I I I I Cables for looseness or damage and

guide for damage I I I I I I I I I I I I I I I I I I I I

Ratchet for wear or damage

- I - I - I - I - I - I - I - I - I - I SUSPENSION Leaf/Coil/Torsion bar springs for

damage I I - I - I - I - I - I - I - I - I - I

Mount for looseness or damage

I I - I - I - I - I - I - I - I - I - I Shock absorbers for oil leakage - I - I - I - I - I - I - I - I - I - I Shock absorbers mount for

looseness - I - I - I - I - I - I - I - I - I - I

Rubber bushes of suspension wear

or damage - I - I - I - I - I - I - I - I - I - I

Spring action for loss of balance due

to weakening - - - I - - - I - - - I - - - I - - - I

Joint ball rubber boot for damage

- I - I - I - I - I - I - I - I - I - I WHEELS W heel nuts T T - T - T - T - T - T - T - T - T - T W heel disc for damage I I - I - I - I - I - I - I - I - I - I Front hub bearing grease

- - - - - R - - - - - R - - - - - R - - Front and rear hub bearings for

looseness - I - I - I - I - I - I - I - I - I - I

Tire pressure and damage I I - I - I - I - I - I - I - I - I - I Tire rotation

Rotate as required OTHERS Bolts and nuts on chassis and body I I - I - I - I - I - I - I - I - I - I Lube front free - wheeling hubs - - - - - L - - - - - L - - - - - L - -

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 26 of 6020

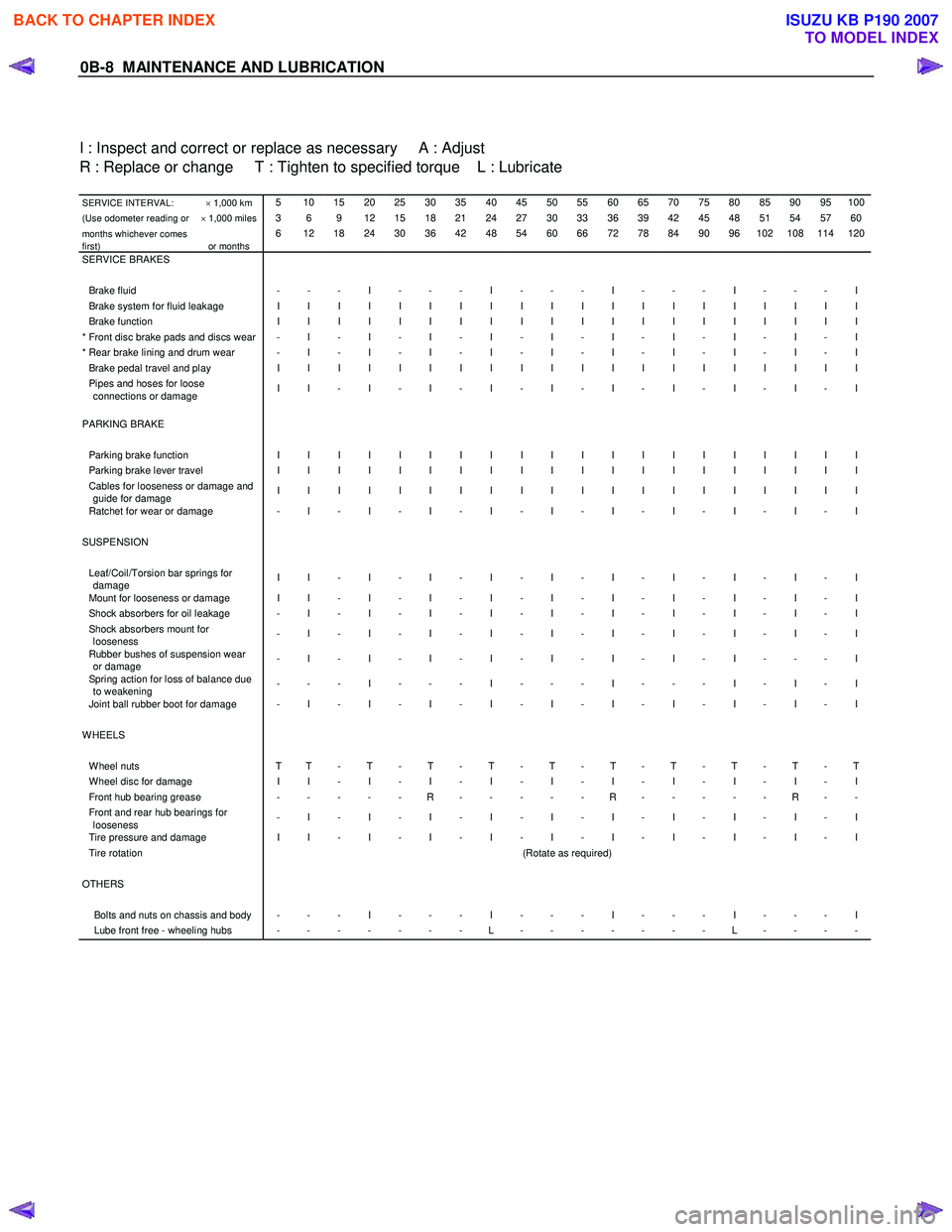

0B-8 MAINTENANCE AND LUBRICATION

I : Inspect and correct or replace as necessary A : Adjust

R : Replace or change T : Tighten to specified torque L : Lubricate

SERVICE INTERVAL: × 1,000 km 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

(Use odometer reading or × 1,000 miles 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60

months whichever comes

first)

or months 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

SERVICE BRAKES Brake fluid - - - I - - - I - - - I - - - I - - - I Brake system for fluid leakage I I I I I I I I I I I I I I I I I I I I Brake function I I I I I I I I I I I I I I I I I I I I * Front disc brake pads and discs wear - I - I - I - I - I - I - I - I - I - I * Rear brake lining and drum wear - I - I - I - I - I - I - I - I - I - I Brake pedal travel and play I I I I I I I I I I I I I I I I I I I I Pipes and hoses for loose

connections or damage I I - I - I - I - I - I - I - I - I - I

PARKING BRAKE Parking brake function I I I I I I I I I I I I I I I I I I I I Parking brake lever travel I I I I I I I I I I I I I I I I I I I I Cables for looseness or damage and

guide for damage I I I I I I I I I I I I I I I I I I I I

Ratchet for wear or damage - I - I - I - I - I - I - I - I - I - I

SUSPENSION Leaf/Coil/Torsion bar springs for

damage I I - I - I - I - I - I - I - I - I - I

Mount for looseness or damage I I - I - I - I - I - I - I - I - I - I Shock absorbers for oil leakage - I - I - I - I - I - I - I - I - I - I Shock absorbers mount for

looseness - I - I - I - I - I - I - I - I - I - I

Rubber bushes of suspension wear

or damage - I - I - I - I - I - I - I - I - - - I

Spring action for loss of balance due

to weakening - - - I - - - I - - - I - - - I - I - I

Joint ball rubber boot for damage - I - I - I - I - I - I - I - I - I - I

WHEELS W heel nuts T T - T - T - T - T - T - T - T - T - T W heel disc for damage I I - I - I - I - I - I - I - I - I - I Front hub bearing grease - - - - - R - - - - - R - - - - - R - - Front and rear hub bearings for

looseness - I - I - I - I - I - I - I - I - I - I

Tire pressure and damage I I - I - I - I - I - I - I - I - I - I Tire rotation

(Rotate as required) OTHERS Bolts and nuts on chassis and body - - - I - - - I - - - I - - - I - - - I Lube front free - wheeling hubs - - - - - - - L - - - - - - - L - - - -

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 30 of 6020

0B-12 MAINTENANCE AND LUBRICATION

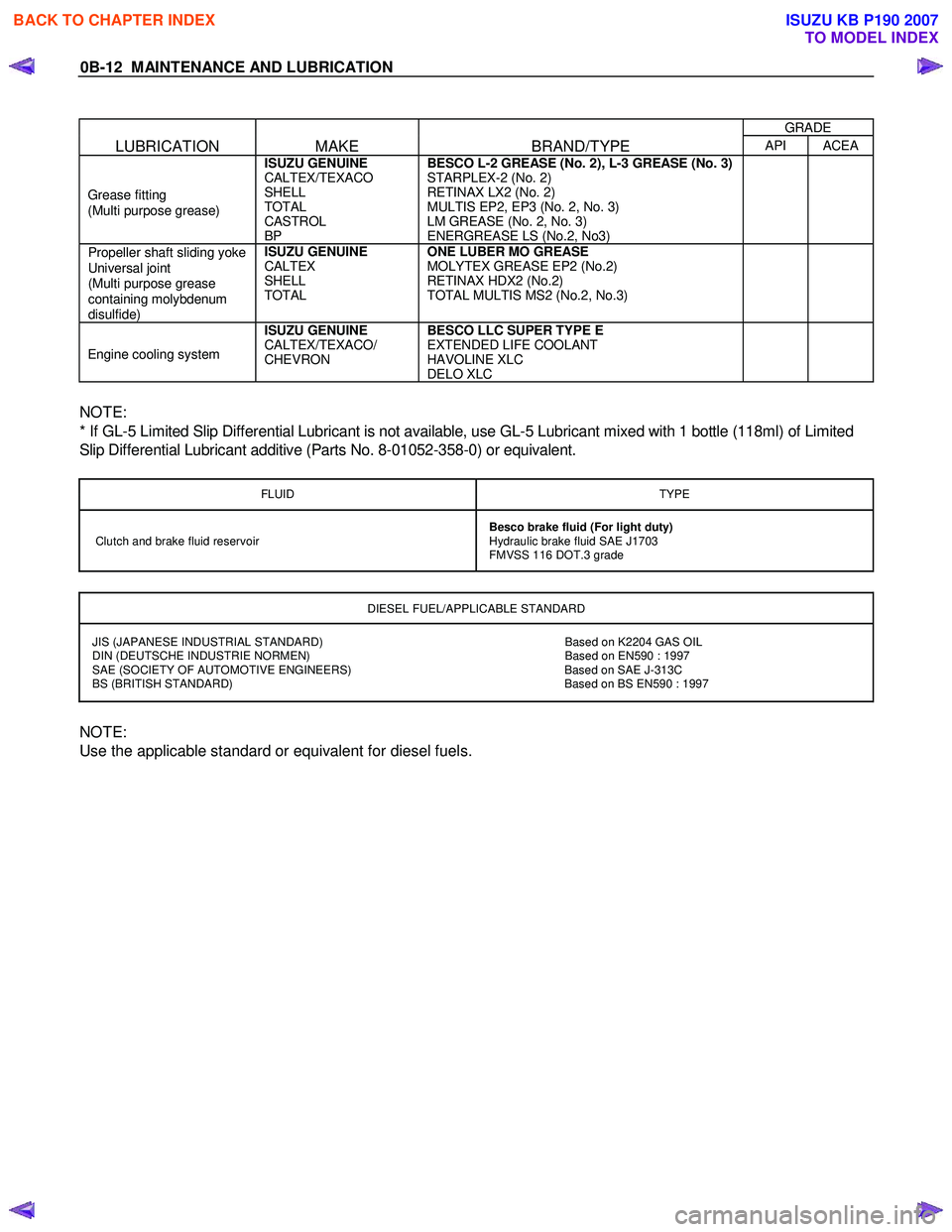

GRADE

LUBRICATION MAKE BRAND/TYPE API ACEA

Grease fitting

(Multi purpose grease) ISUZU GENUINE

CALTEX/TEXACO

SHELL

TOTAL

CASTROL

BP BESCO L-2 GREASE (No. 2), L-3 GREASE (No. 3)

STARPLEX-2 (No. 2)

RETINAX LX2 (No. 2)

MULTIS EP2, EP3 (No. 2, No. 3)

LM GREASE (No. 2, No. 3)

ENERGREASE LS (No.2, No3)

Propeller shaft sliding yoke

Universal joint

(Multi purpose grease

containing molybdenum

disulfide) ISUZU GENUINE

CALTEX

SHELL

TOTAL ONE LUBER MO GREASE

MOLYTEX GREASE EP2 (No.2)

RETINAX HDX2 (No.2)

TOTAL MULTIS MS2 (No.2, No.3)

Engine cooling system ISUZU GENUINE

CALTEX/TEXACO/

CHEVRON

BESCO LLC SUPER TYPE E

EXTENDED LIFE COOLANT

HAVOLINE XLC

DELO XLC

NOTE:

* If GL-5 Limited Slip Differential Lubricant is not available, use GL-5 Lubricant mixed with 1 bottle (118ml) of Limited

Slip Differential Lubricant additive (Parts No. 8-01052-358-0) or equivalent.

FLUID TYPE

Clutch and brake fluid reservoir Besco brake fluid (For light duty)

Hydraulic brake fluid SAE J1703

FMVSS 116 DOT.3 grade

DIESEL FUEL/APPLICABLE STANDARD

JIS (JAPANESE INDUSTRIAL STANDARD) Based on K2204 GAS OIL

DIN (DEUTSCHE INDUSTRIE NORMEN) Based on EN590 : 1997

SAE (SOCIETY OF AUTOMOTIVE ENGINEERS) Based on SAE J-313C

BS (BRITISH STANDARD) Based on BS EN590 : 1997

NOTE:

Use the applicable standard or equivalent for diesel fuels.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 31 of 6020

MAINTENANCE AND LUBRICATION 0B-13

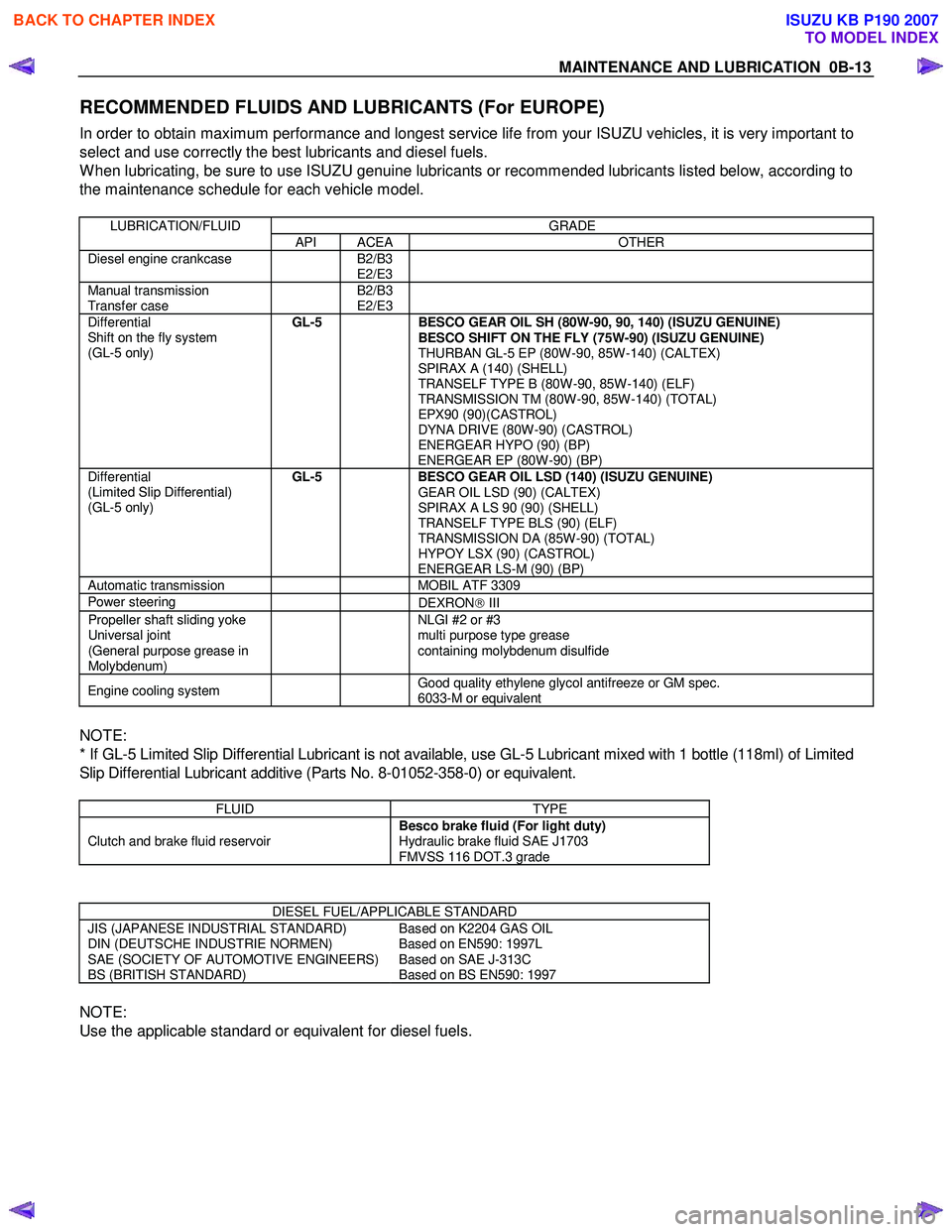

RECOMMENDED FLUIDS AND LUBRICANTS (For EUROPE)

In order to obtain maximum performance and longest service life from your ISUZU vehicles, it is very important to

select and use correctly the best lubricants and diesel fuels.

W hen lubricating, be sure to use ISUZU genuine lubricants or recommended lubricants listed below, according to

the maintenance schedule for each vehicle model.

LUBRICATION/FLUID GRADE

API ACEA OTHER

Diesel engine crankcase B2/B3

E2/E3

Manual transmission

Transfer case B2/B3

E2/E3

Differential

Shift on the fly system

(GL-5 only)

GL-5

BESCO GEAR OIL SH (80W-90, 90, 140) (ISUZU GENUINE)

BESCO SHIFT ON THE FLY (75W-90) (ISUZU GENUINE)

THURBAN GL-5 EP (80W-90, 85W-140) (CALTEX)

SPIRAX A (140) (SHELL)

TRANSELF TYPE B (80W-90, 85W-140) (ELF)

TRANSMISSION TM (80W-90, 85W-140) (TOTAL)

EPX90 (90)(CASTROL)

DYNA DRIVE (80W-90) (CASTROL)

ENERGEAR HYPO (90) (BP)

ENERGEAR EP (80W-90) (BP)

Differential

(Limited Slip Differential)

(GL-5 only) GL-5

BESCO GEAR OIL LSD (140) (ISUZU GENUINE)

GEAR OIL LSD (90) (CALTEX)

SPIRAX A LS 90 (90) (SHELL)

TRANSELF TYPE BLS (90) (ELF)

TRANSMISSION DA (85W-90) (TOTAL)

HYPOY LSX (90) (CASTROL)

ENERGEAR LS-M (90) (BP)

Automatic transmission MOBIL ATF 3309

Power steering

DEXRON III

Propeller shaft sliding yoke

Universal joint

(General purpose grease in

Molybdenum) NLGI #2 or #3

multi purpose type grease

containing molybdenum disulfide

Engine cooling system Good quality ethylene glycol antifreeze or GM spec.

6033-M or equivalent

NOTE:

* If GL-5 Limited Slip Differential Lubricant is not available, use GL-5 Lubricant mixed with 1 bottle (118ml) of Limited

Slip Differential Lubricant additive (Parts No. 8-01052-358-0) or equivalent.

FLUID TYPE

Clutch and brake fluid reservoir Besco brake fluid (For light duty)

Hydraulic brake fluid SAE J1703

FMVSS 116 DOT.3 grade

DIESEL FUEL/APPLICABLE STANDARD

JIS (JAPANESE INDUSTRIAL STANDARD)

DIN (DEUTSCHE INDUSTRIE NORMEN)

SAE (SOCIETY OF AUTOMOTIVE ENGINEERS)

BS (BRITISH STANDARD) Based on K2204 GAS OIL

Based on EN590: 1997L

Based on SAE J-313C

Based on BS EN590: 1997

NOTE:

Use the applicable standard or equivalent for diesel fuels.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 340 of 6020

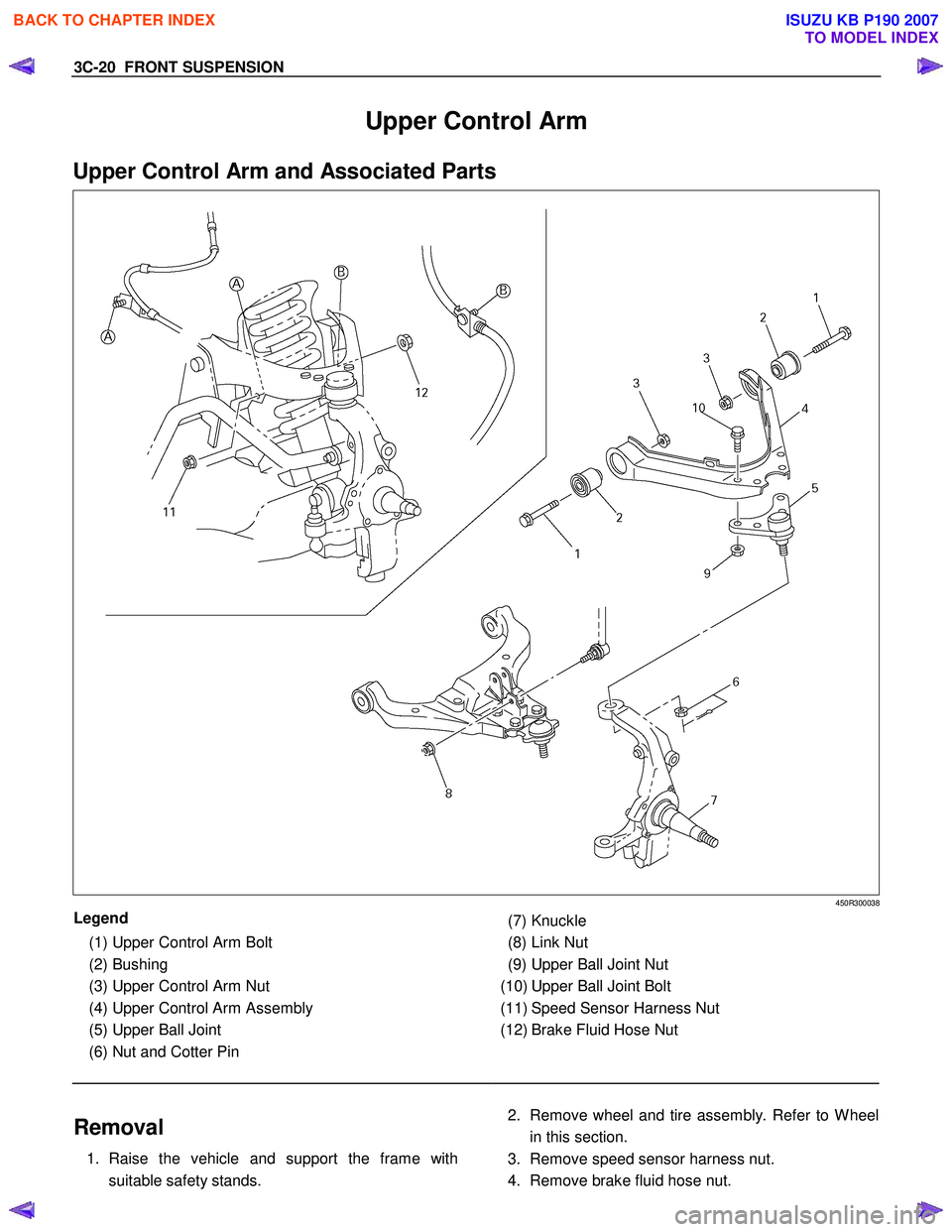

3C-20 FRONT SUSPENSION

Upper Control Arm

Upper Control Arm and Associated Parts

450R300038

Legend

(1) Upper Control Arm Bolt

(2) Bushing

(3) Upper Control Arm Nut

(4) Upper Control Arm Assembly

(5) Upper Ball Joint

(6) Nut and Cotter Pin

(7) Knuckle

(8) Link Nut

(9) Upper Ball Joint Nut

(10) Upper Ball Joint Bolt

(11) Speed Sensor Harness Nut

(12) Brake Fluid Hose Nut

Removal

1. Raise the vehicle and support the frame with

suitable safety stands.

2. Remove wheel and tire assembly. Refer to W heel

in this section.

3. Remove speed sensor harness nut.

4. Remove brake fluid hose nut.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 341 of 6020

FRONT SUSPENSION 3C-21

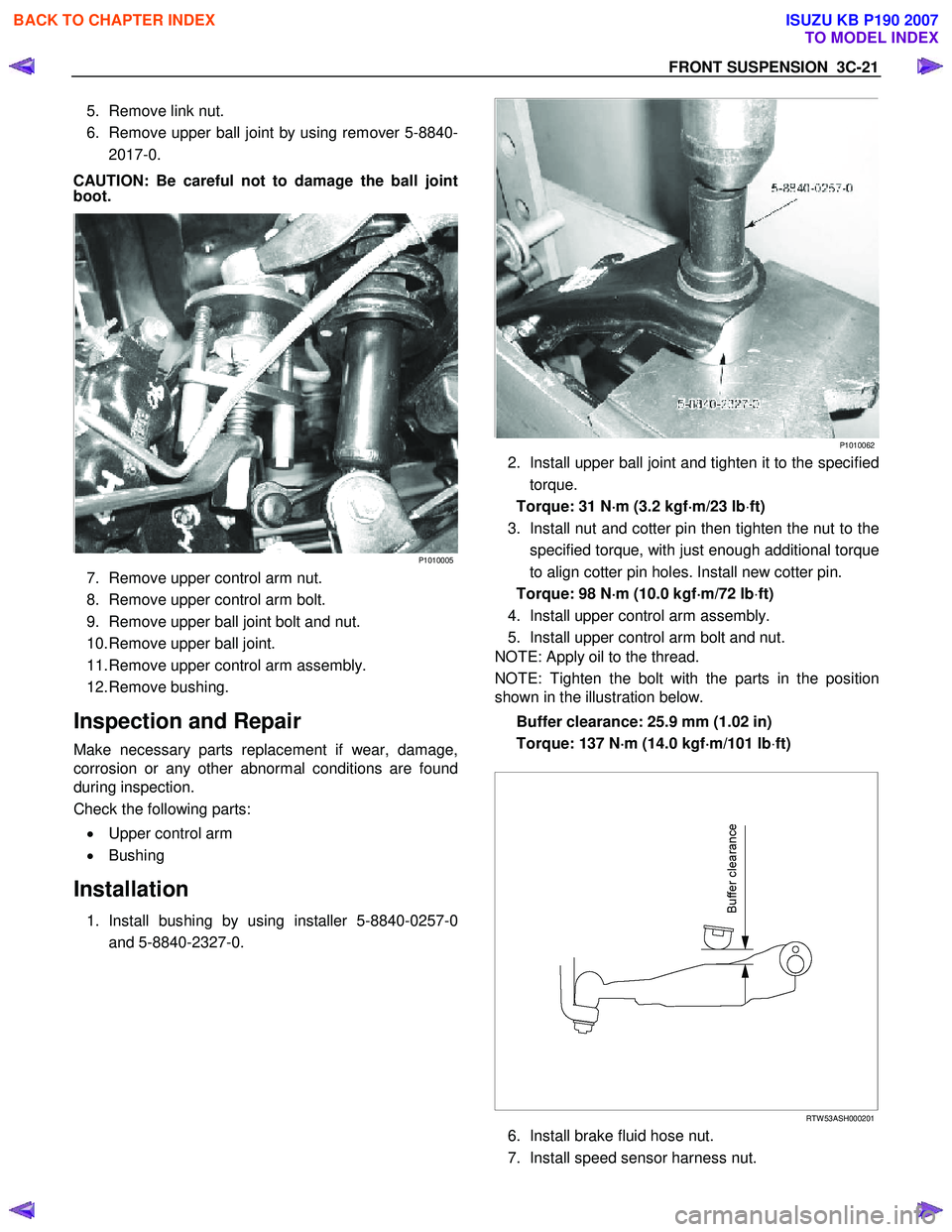

5. Remove link nut.

6. Remove upper ball joint by using remover 5-8840- 2017-0.

CAUTION: Be careful not to damage the ball joint

boot.

P1010005

7. Remove upper control arm nut.

8. Remove upper control arm bolt.

9. Remove upper ball joint bolt and nut.

10. Remove upper ball joint.

11. Remove upper control arm assembly.

12. Remove bushing.

Inspection and Repair

Make necessary parts replacement if wear, damage,

corrosion or any other abnormal conditions are found

during inspection.

Check the following parts:

• Upper control arm

• Bushing

Installation

1. Install bushing by using installer 5-8840-0257-0

and 5-8840-2327-0.

P1010062

2. Install upper ball joint and tighten it to the specified

torque.

Torque: 31 N ⋅

⋅⋅

⋅

m (3.2 kgf ⋅

⋅⋅

⋅

m/23 lb ⋅ft)

3. Install nut and cotter pin then tighten the nut to the specified torque, with just enough additional torque

to align cotter pin holes. Install new cotter pin.

Torque: 98 N ⋅

⋅⋅

⋅

m (10.0 kgf ⋅

⋅⋅

⋅

m/72 lb ⋅ft)

4. Install upper control arm assembly.

5. Install upper control arm bolt and nut.

NOTE: Apply oil to the thread.

NOTE: Tighten the bolt with the parts in the position

shown in the illustration below.

Buffer clearance: 25.9 mm (1.02 in)

Torque: 137 N ⋅

⋅⋅

⋅

m (14.0 kgf ⋅

⋅⋅

⋅

m/101 lb ⋅ft)

RTW 53ASH000201

6. Install brake fluid hose nut.

7. Install speed sensor harness nut.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 600 of 6020

BRAKE CONTROL SYSTEM 5A-7

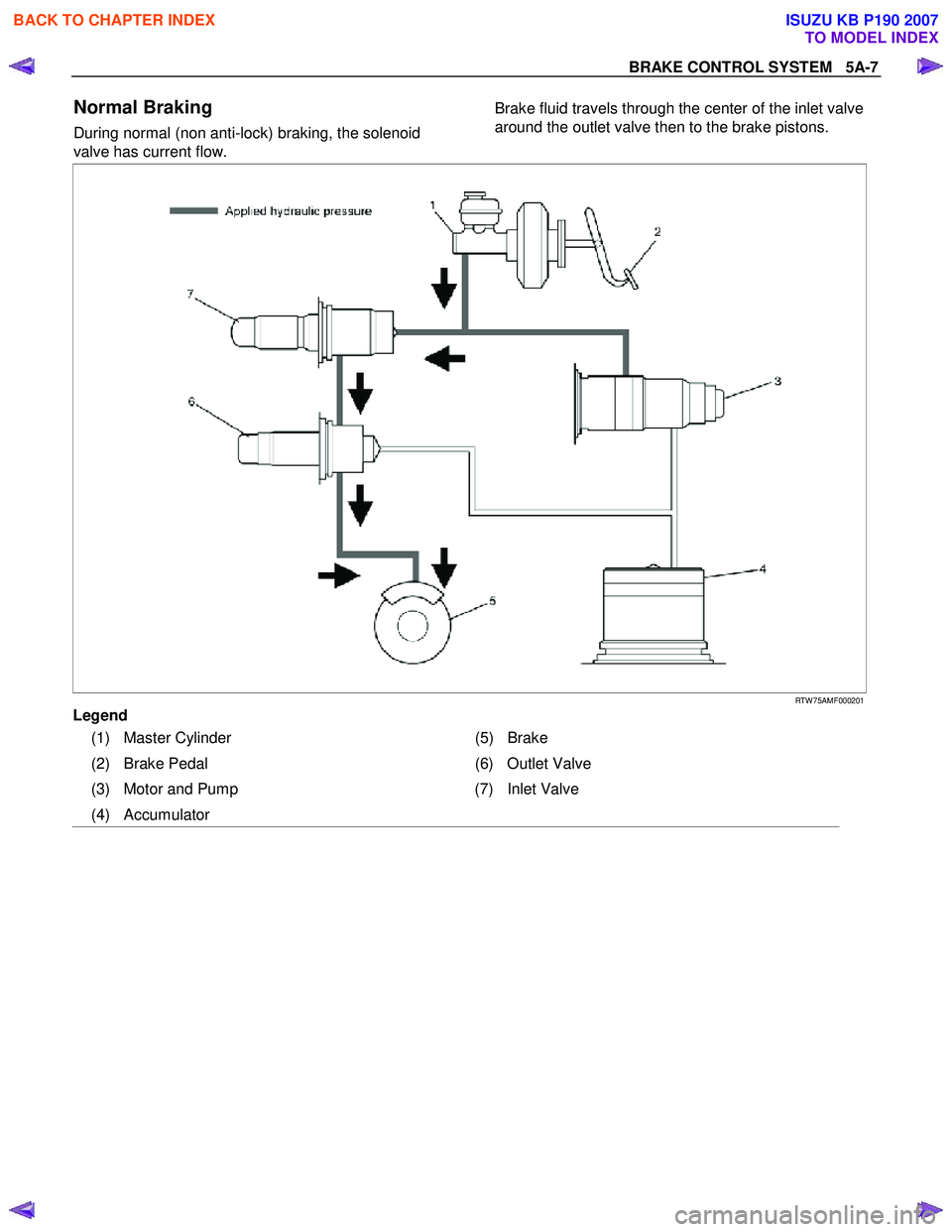

Normal Braking

During normal (non anti-lock) braking, the solenoid

valve has current flow.

Brake fluid travels through the center of the inlet valve

around the outlet valve then to the brake pistons.

RTW 75AMF000201

Legend

(1) Master Cylinder (5) Brake

(2) Brake Pedal (6) Outlet Valve

(3) Motor and Pump (7)Inlet Valve

(4) Accumulator

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 601 of 6020

5A-8 BRAKE CONTROL SYSTEM

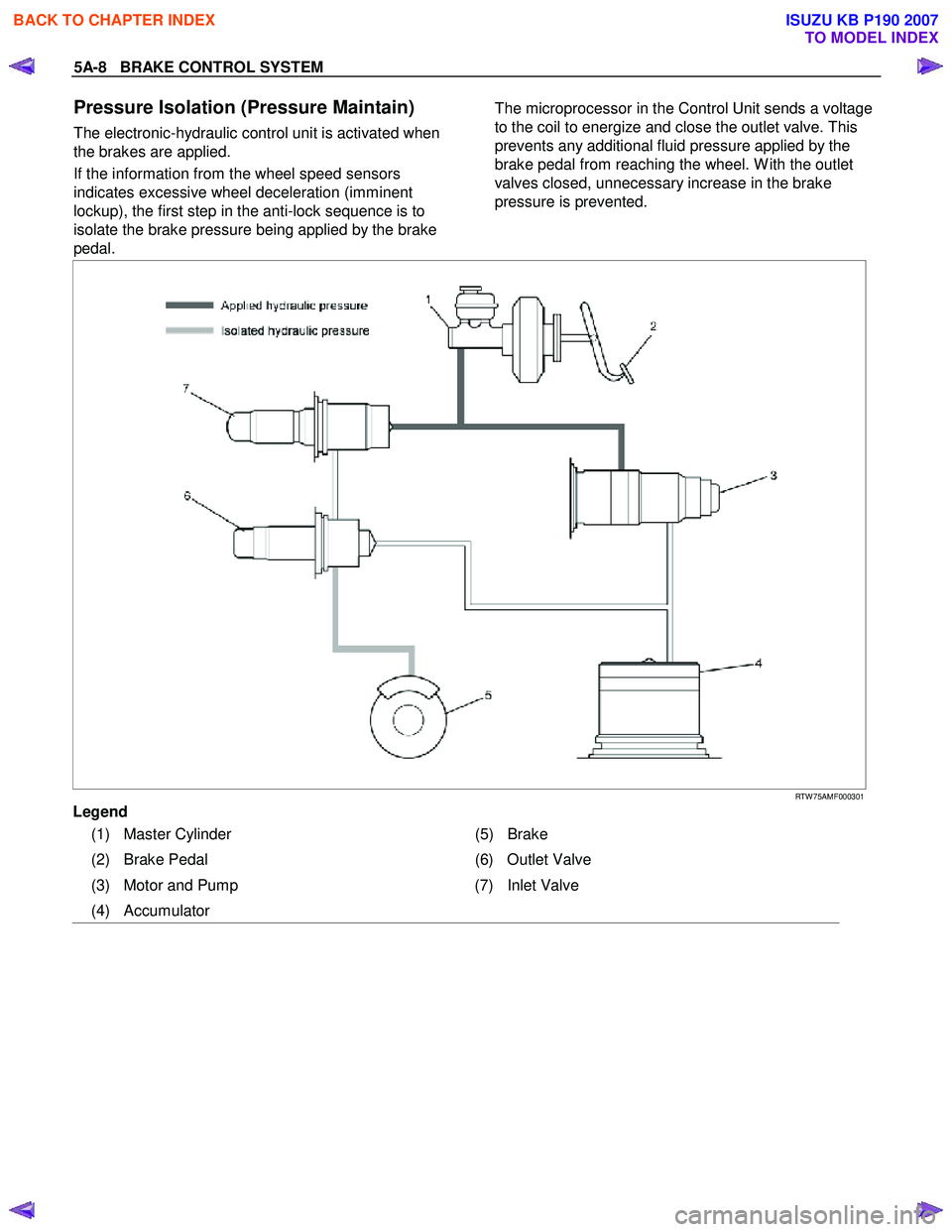

Pressure Isolation (Pressure Maintain)

The electronic-hydraulic control unit is activated when

the brakes are applied.

If the information from the wheel speed sensors

indicates excessive wheel deceleration (imminent

lockup), the first step in the anti-lock sequence is to

isolate the brake pressure being applied by the brake

pedal.

The microprocessor in the Control Unit sends a voltage

to the coil to energize and close the outlet valve. This

prevents any additional fluid pressure applied by the

brake pedal from reaching the wheel. W ith the outlet

valves closed, unnecessary increase in the brake

pressure is prevented.

RTW 75AMF000301

Legend

(1) Master Cylinder (5) Brake

(2) Brake Pedal (6) Outlet Valve

(3) Motor and Pump (7)Inlet Valve

(4) Accumulator

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007