sensor ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1956 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-339

Fuel System ChecksInspect the fuel system for the following conditions. Refer to Fuel System Check Chart

and appropriate procedure in the Fuel System section.

• Air in the fuel system.

• Water contamination in the fuel.

• Fuel waxing or icing.

• Fuel filter indicator lamp is continuously or frequently turned ON with engine run.

• External fuel leaks or high engine oil level.

• In-tank fuel pump operation. Refer to In-tank Fuel Pump System Check in this section.

• Fuel leak off from the fuel pressure limiter valve and fuel injectors.

• Fuel lines between the fuel tank and fuel supply pump for being crushed, kinked, tightness, cracks and plugged.

• A plugged fuel tank vent valve and hose.

• Inside the fuel tank for any foreign material that may be getting drawn into the fuel line pickup causing a blocked condition.

• Fuel supply pump operation.

Notice: The fuel supply pump must be timed to the engine and adjustment value must

be learned to the ECM.

• Perform the Cylinder Balance Test with a scan tool.

• Perform the Injector Force Drive with a scan tool.

• Observe the Fuel Compensation for each cylinder at idle on the scan tool.

Air Intake System Checks Inspect the air intake system for the following conditions.

• Air cleaner, air intake ducts and charge air cooler for a restriction, holes, or leaks.

• A restriction in the turbocharger inlet duct.

• Intake throttle valve for a stuck condition.

• A restriction or leak in the intake manifold.

• A restriction or damaged at MAF sensor.

• Perform the Swirl Control Solenoid Test with a scan tool. Inspect the diaphragm valve operation when it commanded ON/ OFF.

• A worn or damaged turbocharger turbine wheel, shaft or compressor wheel. Refer to turbocharger inspection in the Engine Mechanical section.

• Turbocharger wastegate valve operation. Refer to wastegate valve inspection in the Engine Mechanical section. (Standard output)

• Turbocharger nozzle control actuator operation. Refer to Turbocharger Control System Check in this section. (High output)

Exhaust System Checks Inspect the exhaust system for a possible restriction. Refer to the Exhaust System

section.

Engine Mechanical Checks Inspect the engine mechanical for the following conditions. Refer to the Engine

Mechanical section.

• Poor cylinder compression.

• Improper valve gap.

• Broken or weak valve springs.

• Worn camshaft lobes.

Additional Checks • Inspect the EGR system operating correctly. Refer to EGR Control System Check in

this section.

• Inspect for an engine overheat condition. Refer to Engine Cooling section.

• Inspect the A/C operation.

• Inspect the torque converter clutch (TCC) operation. (A/T only)

Checks

Action

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1957 of 6020

6E-340 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Abnormal Combustion Noise

ChecksAction

Definition:

A mild to severe ping, usually worse under acceleration. The engine makes sharp metallic knocks that change with the throttle

opening.

Preliminary Checks • Diagnostic System Check - Engine Controls.

• Ensure the vehicle has an actual problem.

• Inspect for smoke associated with the combustion noise.

• Inspect the fuel quality (cetane index).

• Inspect the programmed fuel injector ID code for each cylinder.

• Inspect the Scan Tool Data List in this section.

• Inspect the Service Bulletin.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the Scan Tool

Data List in this section.

• Compare the Coolant Temperature with the Intake Air Temperature (IAT) and Fuel Temperature (FT) parameters on a cold engine condition. If the difference among

temperature reading is more than 5 °C (9 °F) on a cold engine, check for high

resistance in each circuit or for a skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT may indicate

a higher than normal intake air temperature if the ignition switch is being ON.

• Observe the Fuel Rail Pressure (FRP) Sensor parameter with the engine OFF. The FRP Sensor should read 0.9 to 1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1 minute. If not, check for high

resistance in each circuit or for a skewed sensor.

• Observe the Fuel Rail Pressure and Desired Fuel Rail Pressure parameter between idle and W.O.T. (accelerator pedal full travel) in Neutral. Fuel Rail Pressure

parameter should follow within ± 5 MPa ( ± 725 psi) quick enough.

• Crankshaft position (CKP) sensor is tight and the sensor rotor is not damaged.

Fuel System Checks • If excessive smoke is present, check for a stuck open fuel injector. Inspect for fuel

leakage into the combustion chamber.

• Inspect the fuel injectors. Remove the injectors and visually inspect.

• Perform the Cylinder Balance Test with a scan tool.

• Perform the Injector Force Drive with a scan tool.

• Observe the Fuel Compensation for each cylinder at idle on the scan tool.

Engine Mechanical Checks Inspect the engine mechanical for the following conditions. Refer to the Engine

Mechanical section.

• Poor cylinder compression.

• Incorrect basic engine parts such as camshaft, cylinder head, pistons, etc..

• Inspect for any excessive oil entering combustion chamber.

Additional Checks • Inspect other possible causes that can make similar noise such as loose component

parts, bracket, mount and weak clutch damper spring.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1958 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-341

Poor Fuel Economy

ChecksAction

Definition:

Fuel economy, as measured by actual road tests and several tanks of fuel, is noticeably lower than expected. Also, the

economy is noticeably lower than it was on this vehicle at one time, as previously shown by actual road tests.

Preliminary Checks • Remove the air cleaner and check for dirt, or for air ducts being plugged or

restricted. Replace as necessary.

• Inspect the driving habits of the owner.

• Is the A/C ON full time, defroster mode ON?

• Are the tires at the correct pressure?

• Are the tire sizes changed?

• Are excessively heavy loads being carried?

• Is the acceleration too much, too often?

• Inspect for clutch slip.

• Inspect brake drag.

• Inspect dive belt tension.

• Inspect for a proper transmission shift pattern and down shift operation.

• Inspect the fuel quality (cetane index).

• Inspect the engine oil level and quality.

• Suggest to the owner to fill the fuel tank and recheck the fuel economy.

• Inspect the odometer is correctly operated.

• Inspect the Scan Tool Data List in this section.

• Inspect the Service Bulletin.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the Scan Tool

Data List in this section.

• Compare the Coolant Temperature with the Intake Air Temperature (IAT) and Fuel Temperature (FT) parameters on a cold engine condition. If the difference among

temperature reading is more than 5 °C (9 °F) on a cold engine, check for high

resistance in each circuit or for a skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT may indicate

a higher than normal intake air temperature if the ignition switch is being ON.

Fuel System Checks Inspect the fuel system for the following conditions. Refer to the Fuel System section.

• Fuel type and quality.

• Check fuel leak.

Cooling System Checks Inspect the cooling system for the following conditions. Refer to the Cooling System

Section.

• Engine coolant level.

• Engine thermostat for always being open or for the wrong heat range.

• Engine cooling fan for always being ON.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1959 of 6020

6E-342 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Air Intake System ChecksInspect the air intake system for the following conditions.

• Air cleaner, air intake ducts and charge air cooler for a restriction, holes, or leaks.

• A restriction in the turbocharger inlet duct.

• Intake throttle valve for a stuck condition.

• A restriction or leak in the intake manifold.

• A restriction or damaged at MAF sensor.

• Perform the Swirl Control Solenoid Test with a scan tool. Inspect the diaphragm valve operation when it commanded ON/ OFF.

• A worn or damaged turbocharger turbine wheel, shaft or compressor wheel. Refer to turbocharger inspection in the Engine Mechanical section.

• Turbocharger wastegate valve operation. Refer to wastegate valve inspection in the Engine Mechanical section. (Standard output)

• Turbocharger nozzle control actuator operation. Refer to Turbocharger Control System Check in this section. (High output)

Exhaust System Checks Inspect the exhaust system for a possible restriction. Refer to the Exhaust System

section.

Engine Mechanical Checks Inspect the engine mechanical for the following conditions. Refer to the Engine

Mechanical section.

• Poor cylinder compression.

• Improper valve gap.

• Broken or weak valve springs.

• Worn camshaft lobes.

Checks

Action

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1960 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-343

Excessive Smoke (Black Smoke)

ChecksAction

Definition:

Black smoke under load, idle or start up hot or cold.

Preliminary Check • Ensure the vehicle has an actual problem.

• Inspect the ECM grounds for being clean, tight, and in their proper locations.

• Remove the air cleaner and check for dirt, or for air ducts being plugged or restricted. Replace as necessary.

• Inspect the fuel quality (cetane index).

• Inspect the engine oil level and quality.

• Inspect the programmed fuel injector ID code for each cylinder.

• Inspect the Scan Tool Data List in this section.

• Inspect the Service Bulletin.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the Scan Tool

Data List in this section.

• Compare the Coolant Temperature with the Intake Air Temperature (IAT) and Fuel Temperature (FT) parameters on a cold engine condition. If the difference among

temperature reading is more than 5 °C (9 °F) on a cold engine, check for high

resistance in each circuit or for a skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT may indicate

a higher than normal intake air temperature if the ignition switch is being ON.

• Observe the MAF parameter for a skewed or slow MAF sensor.

• Observe the Fuel Rail Pressure (FRP) Sensor parameter with the engine OFF. The FRP Sensor should read 0.9 to 1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1 minute. If not, check for high

resistance in each circuit or for a skewed sensor.

• Observe the Fuel Rail Pressure and Desired Fuel Rail Pressure parameter between idle and W.O.T. (accelerator pedal full travel) in Neutral. Fuel Rail Pressure

parameter should follow within ±5 MPa ( ±725 psi) quick enough.

• Observe the Barometric Pressure (BARO) parameter. The BARO parameter should indicate near surrounding barometric pressure. Refer to Altitude vs. Barometric

Pressure. (Standard output)

• Observe the Boost Pressure and BARO with ignition ON and engine OFF. Both parameters should be within the 7.0 kPa (1.0 psi) each other. (High output)

Fuel System Checks Inspect the fuel system for the following conditions. Refer to the Fuel System section.

• Fuel injectors. Remove the injectors and visually inspect.

• Perform the Cylinder Balance Test with a scan tool.

• Perform the Pilot Injection Control with a scan tool.

• Observe the Fuel Compensation for each cylinder at idle on the scan tool.

Air Intake System Checks Inspect the air intake system for the following conditions.

• Air cleaner, air intake ducts and charge air cooler for a restriction, holes, or leaks.

• A restriction in the turbocharger inlet duct.

• Intake throttle valve for a stuck condition.

• A restriction or leak in the intake manifold.

• A restriction or damaged at MAF sensor.

• A worn or damaged turbocharger turbine wheel, shaft or compressor wheel. Refer to turbocharger inspection in the Engine Mechanical section.

Exhaust System Checks Inspect the exhaust system for a possible restriction. Refer to the Exhaust System

section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1962 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-345

Excessive Smoke (White Smoke)

ChecksAction

Difinition:

White smoke under load, idle or start up hot or cold.

Preliminary Check • Ensure the vehicle has an actual problem.

• Inspect the ECM grounds for being clean, tight, and in their proper locations.

• Inspect the fuel quality (cetane index).

• Inspect the programmed fuel injector ID code for each cylinder.

• Inspect the Scan Tool Data List in this section.

• Inspect the Service Bulletin.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the Scan Tool

Data List in this section.

• Compare the Coolant Temperature with the Intake Air Temperature (IAT) and Fuel Temperature (FT) parameters on a cold engine condition. If the difference among

temperature reading is more than 5 °C (9 °F) on a cold engine, check for high

resistance in each circuit or for a skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT may indicate

a higher than normal intake air temperature if the ignition switch is being ON.

• Observe the Fuel Rail Pressure (FRP) Sensor parameter with the engine OFF. The FRP Sensor should read 0.9 to 1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1 minute. If not, check for high

resistance in each circuit or for a skewed sensor.

• Observe the Fuel Rail Pressure and Desired Fuel Rail Pressure parameter between idle and W.O.T. (accelerator pedal full travel) in Neutral. Fuel Rail Pressure

parameter should follow within ± 5 MPa ( ± 725 psi) quick enough.

• Observe the Accelerator Pedal Position (APP). APP parameter should change linearly from 0 to 100% according to the accelerator pedal operation.

• Observe the Boost Pressure and Barometric Pressure (BARO) with ignition ON and engine OFF. Both parameters should be within the 7.0 kPa (1.0 psi) each other.

• Crankshaft position (CKP) sensor is tight and the sensor rotor is not damaged.

Fuel System Checks • If excessive smoke is present, check for a stuck open fuel injector. Inspect for fuel

leakage into the combustion chamber.

• Fuel injectors. Remove the injectors and visually inspect.

• Perform the Cylinder Balance Test with a scan tool.

• Perform the Pilot Injection Control with a scan tool.

• Observe the Fuel Compensation for each cylinder at idle on the scan tool.

Air Intake System Checks Inspect the air intake system for the following conditions.

• Air cleaner, air intake ducts and charge air cooler for a restriction, holes, or leaks.

• A restriction in the turbocharger inlet duct.

• Intake throttle valve for a stuck condition.

• A restriction or leak in the intake manifold.

• A restriction or damaged at MAF sensor.

• Perform the Swirl Control Solenoid Test with a scan tool. Inspect the diaphragm valve operation when it commanded ON/ OFF.

• A worn or damaged turbocharger turbine wheel, shaft or compressor wheel. Oil leak from turbocharger. Refer to turbocharger inspection in the Engine Mechanical

section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1970 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-353

Description and Operation

Engine Control Module (ECM) Description

Engine Control Module (ECM) Service Precautions

Important:The symbol ! warns you of an electric shock

hazard. To avoid shock and possible serious injury, DO NOT

touch the terminals. When disconnecting the harness

connectors, always turn OFF the ignition switch or disconnect

the battery cable.

The engine control module (ECM) is designed to

withstand normal current draws associated with vehicle

operation. Avoid overloading any circuit. When testing

for opens and shorts, do not ground or apply voltage to

any of the ECM circuits unless instructed to do so. In

some cases, these circuits should only be tested using

a DMM. The ECM should remain connected to the

ECM harness.

The ECM is located inside of engine compartment via

mounting bracket and is behind air cleaner case. The

ECM mainly controls the following. • The fuel system control

• The exhaust gas recirculation (EGR) system control

• The preheating (glow) system control

• The A/C compressor control

• The immobilizer control

• On-board diagnostics for engine control

The ECM constantly observes the information from

various sensors. The ECM controls the systems that

affect vehicle performance. The ECM performs the

diagnostic function of the system. The ECM can

recognize operational problems, alert the driver

through the malfunction indicator lamp (MIL), and store

diagnostic trouble codes (DTCs). DTCs identify the

system faults to aid the technician in making repairs.

RTW56ESH000201

RTW56ESH004401

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1971 of 6020

6E-354 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

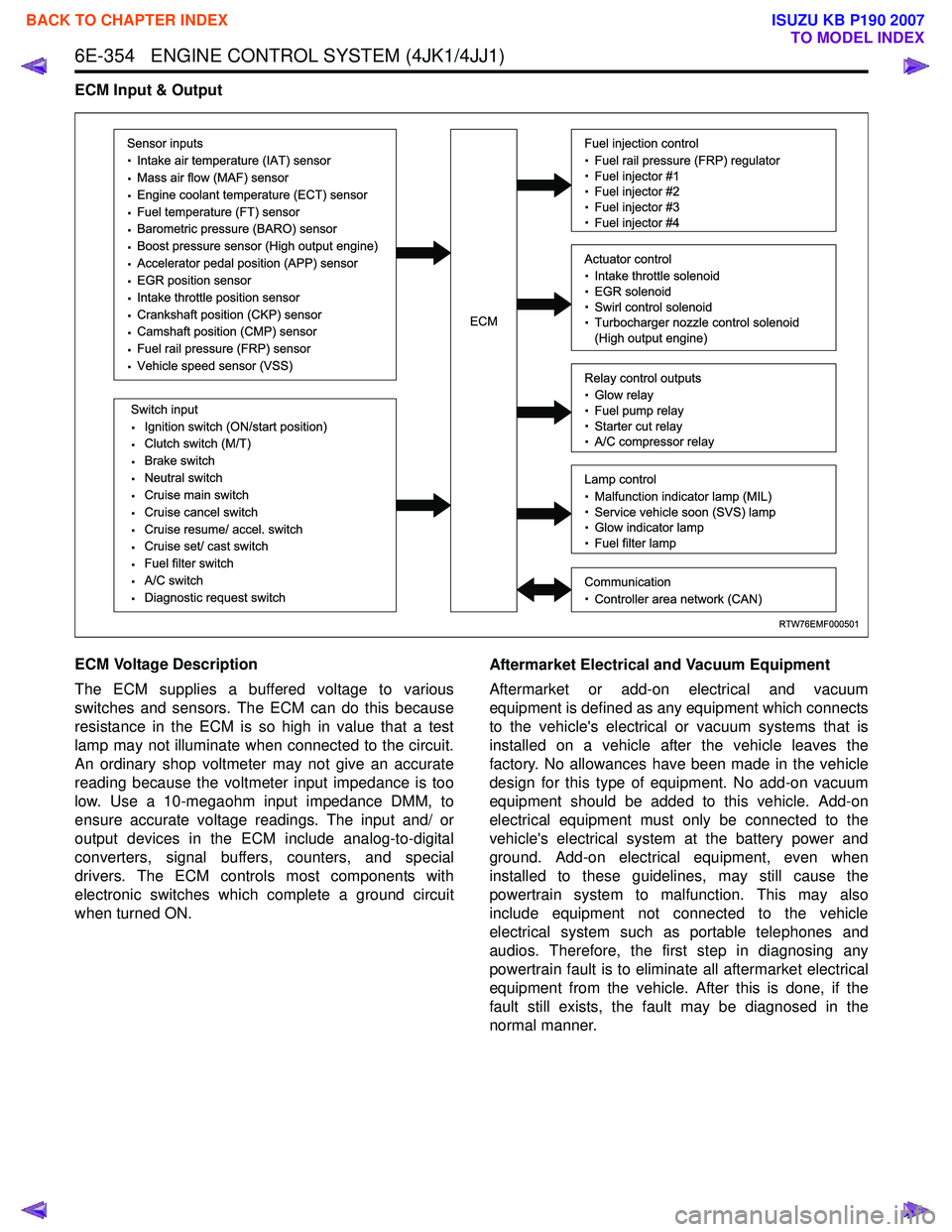

ECM Input & Output

ECM Voltage Description

The ECM supplies a buffered voltage to various

switches and sensors. The ECM can do this because

resistance in the ECM is so high in value that a test

lamp may not illuminate when connected to the circuit.

An ordinary shop voltmeter may not give an accurate

reading because the voltmeter input impedance is too

low. Use a 10-megaohm input impedance DMM, to

ensure accurate voltage readings. The input and/ or

output devices in the ECM include analog-to-digital

converters, signal buffers, counters, and special

drivers. The ECM controls most components with

electronic switches which complete a ground circuit

when turned ON. Aftermarket Electrical and Vacuum Equipment

Aftermarket or add-on electrical and vacuum

equipment is defined as any equipment which connects

to the vehicle's electrical or vacuum systems that is

installed on a vehicle after the vehicle leaves the

factory. No allowances have been made in the vehicle

design for this type of equipment. No add-on vacuum

equipment should be added to this vehicle. Add-on

electrical equipment must only be connected to the

vehicle's electrical system at the battery power and

ground. Add-on electrical equipment, even when

installed to these guidelines, may still cause the

powertrain system to malfunction. This may also

include equipment not connected to the vehicle

electrical system such as portable telephones and

audios. Therefore, the first step in diagnosing any

powertrain fault is to eliminate all aftermarket electrical

equipment from the vehicle. After this is done, if the

fault still exists, the fault may be diagnosed in the

normal manner.

RTW76EMF000501

Sensor inputs

· Intake air temperature (IAT) sensor

· Mass air flow (MAF) sensor

· Engine coolant temperature (ECT) sensor

· Fuel temperature (FT) sensor

· Barometric pressure (BARO) sensor

· Boost pressure sensor (High output engine)

· Accelerator pedal position (APP) sensor

· EGR position sensor

· Intake throttle position sensor

· Crankshaft position (CKP) sensor

· Camshaft position (CMP) sensor

· Fuel rail pressure (FRP) sensor

· Vehicle speed sensor (VSS)

Switch input

· Ignition switch (ON/start position)

· Clutch switch (M/T)

· Brake switch

· Neutral switch

· Cruise main switch

· Cruise cancel switch

· Cruise resume/ accel. switch

· Cruise set/ cast switch

· Fuel filter switch

· A/C switch

· Diagnostic request switch

Fuel injection control

· Fuel rail pressure (FRP) regulator

· Fuel injector #1

· Fuel injector #2

· Fuel injector #3

· Fuel injector #4

Relay control outputs

· Glow relay

· Fuel pump relay

· Starter cut relay

· A/C compressor relay

Lamp control

· Malfunction indicator lamp (MIL)

· Service vehicle soon (SVS) lamp

· Glow indicator lamp

· Fuel filter lamp

Communication

· Controller area network (CAN)

Actuator control

· Intake throttle solenoid

· EGR solenoid

· Swirl control solenoid

· Turbocharger nozzle control solenoid

(High output engine)ECM

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1973 of 6020

6E-356 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Engine Control Component Description

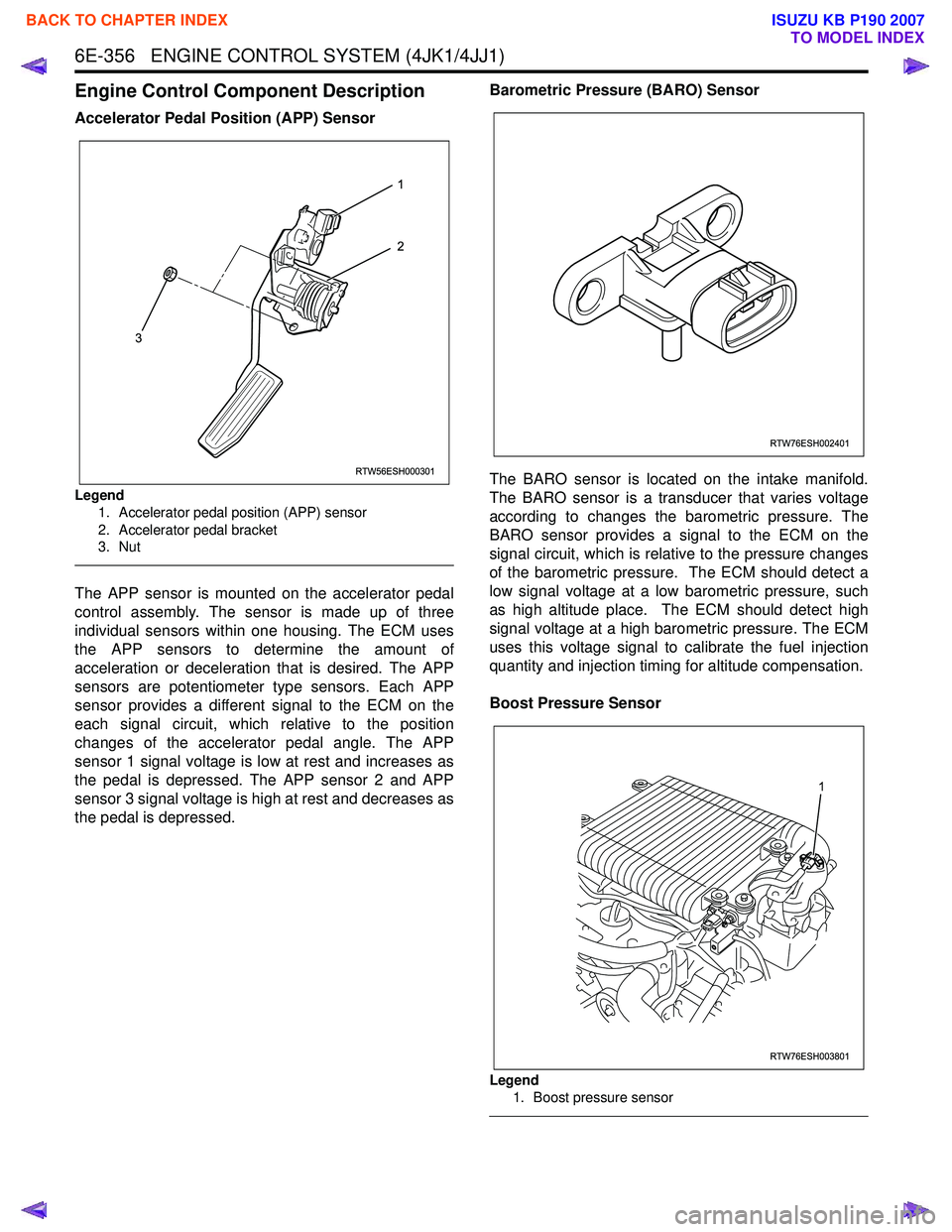

Accelerator Pedal Position (APP) Sensor

Legend1. Accelerator pedal position (APP) sensor

2. Accelerator pedal bracket

3. Nut

The APP sensor is mounted on the accelerator pedal

control assembly. The sensor is made up of three

individual sensors within one housing. The ECM uses

the APP sensors to determine the amount of

acceleration or deceleration that is desired. The APP

sensors are potentiometer type sensors. Each APP

sensor provides a different signal to the ECM on the

each signal circuit, which relative to the position

changes of the accelerator pedal angle. The APP

sensor 1 signal voltage is low at rest and increases as

the pedal is depressed. The APP sensor 2 and APP

sensor 3 signal voltage is high at rest and decreases as

the pedal is depressed. Barometric Pressure (BARO) Sensor

The BARO sensor is located on the intake manifold.

The BARO sensor is a transducer that varies voltage

according to changes the barometric pressure. The

BARO sensor provides a signal to the ECM on the

signal circuit, which is relative to the pressure changes

of the barometric pressure. The ECM should detect a

low signal voltage at a low barometric pressure, such

as high altitude place. The ECM should detect high

signal voltage at a high barometric pressure. The ECM

uses this voltage signal to calibrate the fuel injection

quantity and injection timing for altitude compensation.

Boost Pressure Sensor

Legend 1. Boost pressure sensor

RTW56ESH000301

1

2

3

RTW76ESH002401

RTW76ESH003801

1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1974 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-357

The boost pressure sensor is located in the air

induction tubing. The boost pressure sensor is a

transducer that varies voltage according to changes in

the air pressure inside the air tubing. The boost

pressure sensor provides a signal to the ECM on the

signal circuit, which is relative to the pressure changes

in the air tubing. The ECM should detect a low signal

voltage at a low boost pressure, such as low engine

load. The ECM should detect high signal voltage at a

high boost pressure, such as high engine load.

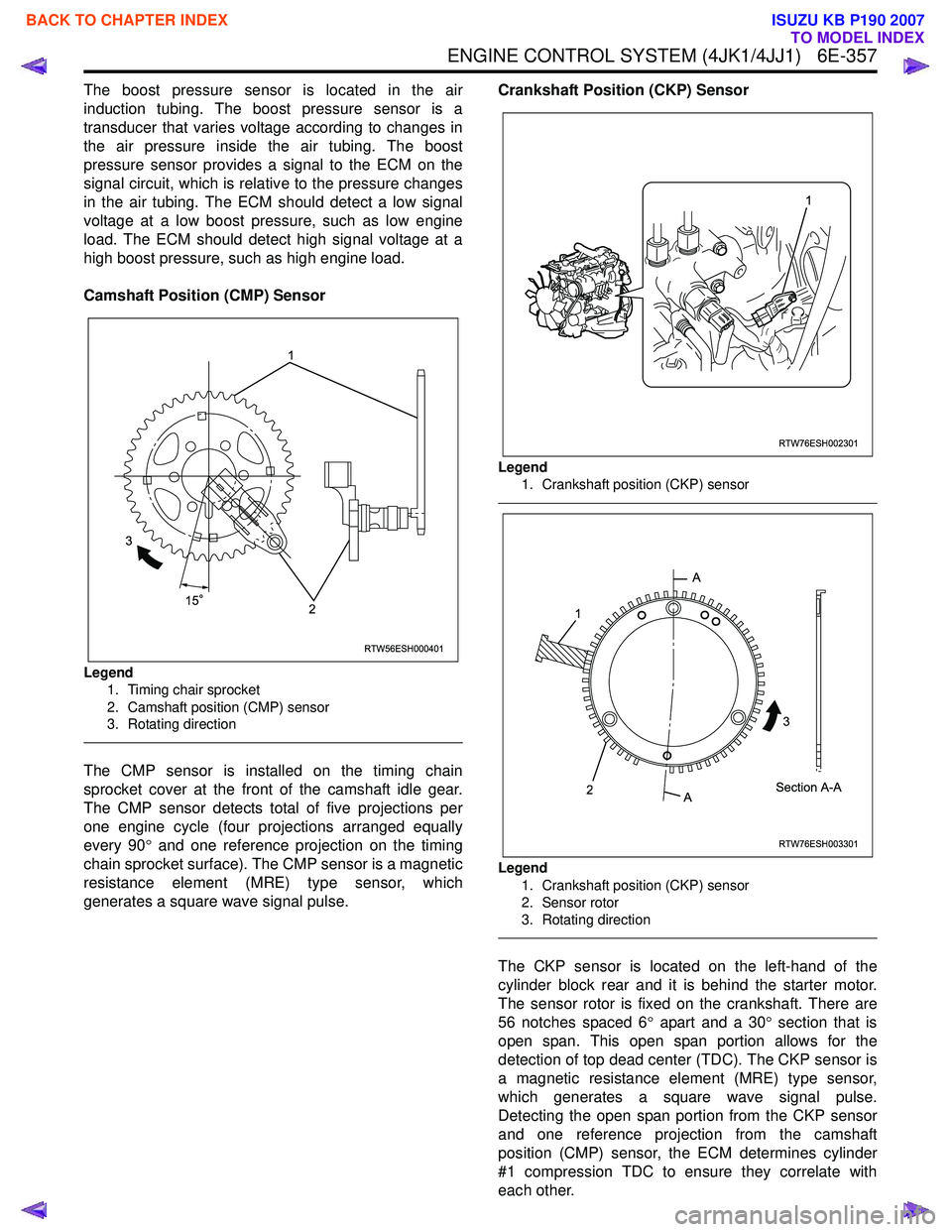

Camshaft Position (CMP) Sensor

Legend 1. Timing chair sprocket

2. Camshaft position (CMP) sensor

3. Rotating direction

The CMP sensor is installed on the timing chain

sprocket cover at the front of the camshaft idle gear.

The CMP sensor detects total of five projections per

one engine cycle (four projections arranged equally

every 90 ° and one reference projection on the timing

chain sprocket surface). The CMP sensor is a magnetic

resistance element (MRE) type sensor, which

generates a square wave signal pulse. Crankshaft Position (CKP) Sensor

Legend

1. Crankshaft position (CKP) sensor

Legend

1. Crankshaft position (CKP) sensor

2. Sensor rotor

3. Rotating direction

The CKP sensor is located on the left-hand of the

cylinder block rear and it is behind the starter motor.

The sensor rotor is fixed on the crankshaft. There are

56 notches spaced 6 ° apart and a 30 ° section that is

open span. This open span portion allows for the

detection of top dead center (TDC). The CKP sensor is

a magnetic resistance element (MRE) type sensor,

which generates a square wave signal pulse.

Detecting the open span portion from the CKP sensor

and one reference projection from the camshaft

position (CMP) sensor, the ECM determines cylinder

#1 compression TDC to ensure they correlate with

each other.

RTW56ESH000401

1

3 2

15

RTW76ESH002301

1

RTW76ESH003301

A

A Section A-A

1

2 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007