radiator cap ISUZU KB P190 2007 Workshop Service Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3180 of 6020

Engine Cooling – V6 Engine Page 6B1–45

3.11 Coolant Outlet Housing

Remove

Refer to 3.1 Service Notes in this Section, for

important safety items.

1 Allow engine to cool to ambient temperature (less than 50 ° C), and then remove the coolant filler cap (located at

the front left-hand side of the engine).

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 1.1

WARNING, CAUTION and NOTES, before

removing the ground lead.

2 Disconnect the battery ground lead. Refer to 8A – Electrical Body & Chassis Battery.

3 Drain the coolant from the system. Refer to 3.3 Draining and Filling Cooling System.

4 Remove the complete intake manifold assembly. Refer to 6A1 Engine Mechanical.

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

5 Remove upper radiator hose clamp (1) at the coolant outlet housing connection (2), disconnect

hose from coolant outlet.

Figure 6B1 – 50

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3181 of 6020

Engine Cooling – V6 Engine Page 6B1–46

6 Remove the two coolant outlet housing attaching

bolts (1), and remove coolant outlet housing (2).

7 Remove and discard coolant outlet housing O-ring (3) and seal (4).

Figure 6B1 – 51

Reinstall

1 Ensure that the coolant outlet housing and front outlet mating surfaces are clean and dry.

2 Install new O-ring and seal to coolant outlet housing.

3 Install coolant outlet housing and attaching bolts. Tighten all bolts to the correct torque specification.

Coolant outlet housing to front

outlet bolt torque specification..............................10 N.m

Always wear protective safety glasses when

working with spring type hose clamps. Failure

to do so could result in eye injury.

4 Connect the upper radiator hose and clamp to the coolant outlet housing connection.

5 Close the radiator drain tap on the lower RHS of the radiator and remove the piece of rubber tubing to the tap outlet.

6 Reinstall the intake manifold assembly. Refer to 6A1 Engine Mechanical.

7 Refill cooling system. Refer to 3.3 Draining and Filling Cooling System in this Section.

8 Check for coolant leaks. Refer to 3.7 Pressure Testing in this Section.

9 Reconnect battery ground lead. Refer to 8A – Electrical Body & Chassis.

3.12 Coolant Inlet Pipe

Remove

Refer to 3.1 Service Notes in this Section, for

important safety items.

1 Allow engine to cool to ambient temperature (less than 50 ° C), and then remove the coolant filler cap (located at

the front left-hand side of the engine).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3189 of 6020

Engine Cooling – V6 Engine Page 6B1–54

3.15 Radiator

Remove

Refer to 3.1 Service Notes in this Section, for

important safety items.

1 Allow engine to cool to ambient temperature (less than 50 ° C), then remove coolant filler cap.

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 00

Warnings, Cautions and Notes, before

removing the ground lead.

2 Disconnect the battery ground lead. Refer to 8A – Electrical Body & Chassis.

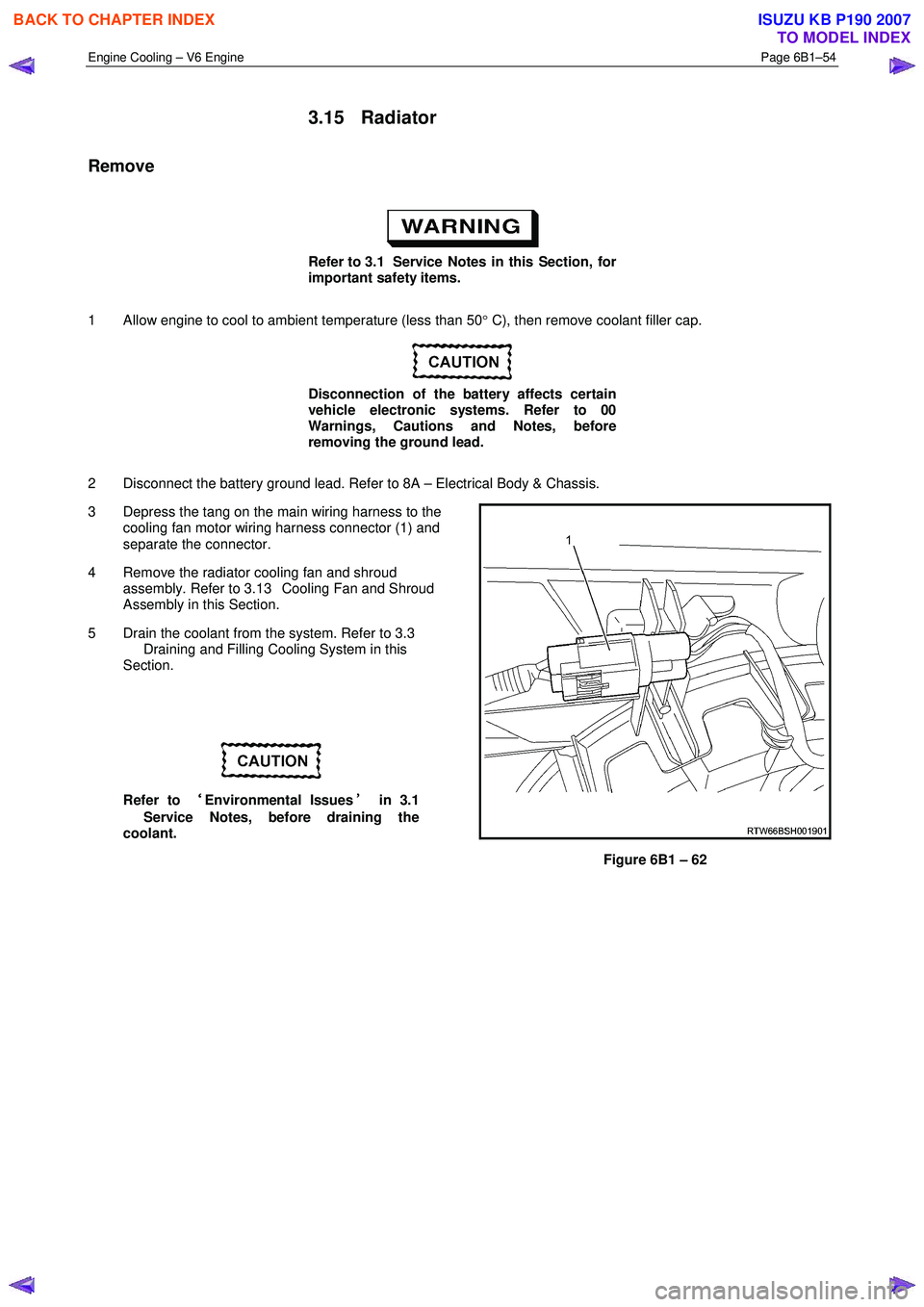

3 Depress the tang on the main wiring harness to the cooling fan motor wiring harness connector (1) and

separate the connector.

4 Remove the radiator cooling fan and shroud assembly. Refer to 3.13 Cooling Fan and Shroud

Assembly in this Section.

5 Drain the coolant from the system. Refer to 3.3 Draining and Filling Cooling System in this

Section.

Refer to ‘

‘‘

‘

Environmental Issues ’

’’

’

in 3.1

Service Notes, before draining the

coolant.

Figure 6B1 – 62

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3193 of 6020

Engine Cooling – V6 Engine Page 6B1–58

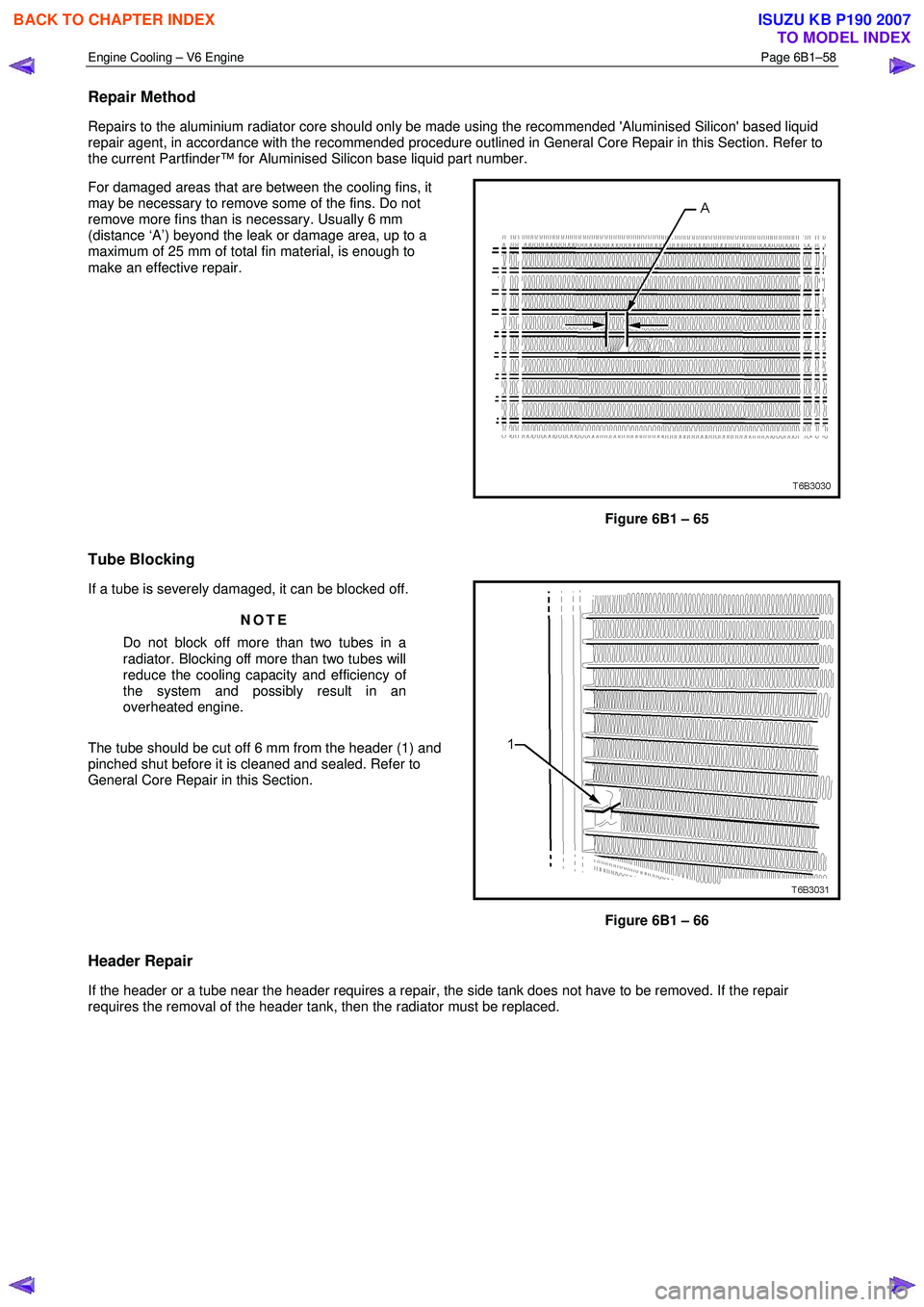

Repair Method

Repairs to the aluminium radiator core should only be made using the recommended 'Aluminised Silicon' based liquid

repair agent, in accordance with the recommended procedure outlined in General Core Repair in this Section. Refer to

the current Partfinder™ for Aluminised Silicon base liquid part number.

For damaged areas that are between the cooling fins, it

may be necessary to remove some of the fins. Do not

remove more fins than is necessary. Usually 6 mm

(distance ‘A’) beyond the leak or damage area, up to a

maximum of 25 mm of total fin material, is enough to

make an effective repair.

Figure 6B1 – 65

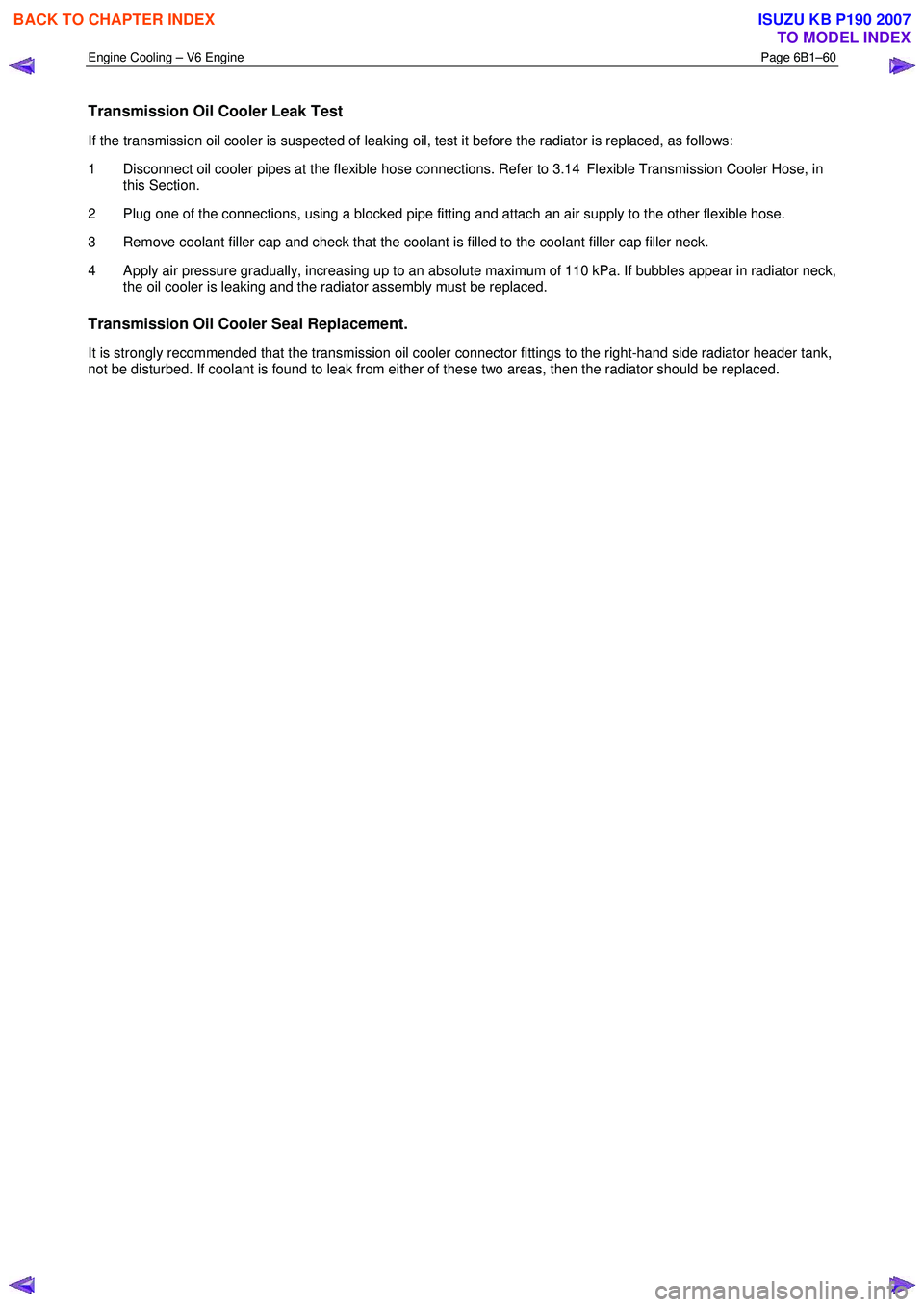

Tube Blocking

If a tube is severely damaged, it can be blocked off.

NOTE

Do not block off more than two tubes in a

radiator. Blocking off more than two tubes will

reduce the cooling capacity and efficiency of

the system and possibly result in an

overheated engine.

The tube should be cut off 6 mm from the header (1) and

pinched shut before it is cleaned and sealed. Refer to

General Core Repair in this Section.

Figure 6B1 – 66

Header Repair

If the header or a tube near the header requires a repair, the side tank does not have to be removed. If the repair

requires the removal of the header tank, then the radiator must be replaced.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3195 of 6020

Engine Cooling – V6 Engine Page 6B1–60

Transmission Oil Cooler Leak Test

If the transmission oil cooler is suspected of leaking oil, test it before the radiator is replaced, as follows:

1 Disconnect oil cooler pipes at the flexible hose connections. Refer to 3.14 Flexible Transmission Cooler Hose, in this Section.

2 Plug one of the connections, using a blocked pipe fitting and attach an air supply to the other flexible hose.

3 Remove coolant filler cap and check that the coolant is filled to the coolant filler cap filler neck.

4 Apply air pressure gradually, increasing up to an absolute maximum of 110 kPa. If bubbles appear in radiator neck, the oil cooler is leaking and the radiator assembly must be replaced.

Transmission Oil Cooler Seal Replacement.

It is strongly recommended that the transmission oil cooler connector fittings to the right-hand side radiator header tank,

not be disturbed. If coolant is found to leak from either of these two areas, then the radiator should be replaced.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3197 of 6020

Engine Cooling – V6 Engine Page 6B1–62

Refer to 3.1 Service Notes in this Section, for

important safety items before removing the

coolant filler pressure cap or servicing the

system.

The cooling system is designed to operate at

120 –

––

–

130 kPa and a maximum temperature

not above 130 °

°°

°

C.

Cooling System Diagnosis

Step Action Result Yes No

1

Check Temperature gauge reading High Temp.

Low Temp. Go to Step 2

Go to Step 6 –

2

Check drive belt condition and tension. Refer to 6A1

Engine Mechanical. To Specification Go to Step 3 Replace drive

belt or

tensioner.

3 Check coolant Boiling Go to Step 4 Go to Step 5

4 Check coolant level. Refer to 3.2 Coolant

Maintenance in this Section. Low Go to Step 10 Go to Step 6

5

Check coolant filler cap. Refer to 3.7 Pressure

Testing – Coolant Filler Cap Pressure Testing in this

Section OK? Go to Step 8

Replace

Coolant filler

cap

6 Check thermostat. Refer to 3.8 Thermostat in this

Section. OK? Go to Step 9 Go to Step 13

7

Check Engine Coolant Temperature (ECT) sensor.

Refer to 6C1 Engine Management General Information. Faulty Replace Go to Step 12

8

Check cooling fan operation. Refer to 6C1 Engine

Management General Information. Operational Go to Step 10 Repair

9

Check for collapsed upper or lower radiator hose. Collapsed Replace Go to Step 13

10 Visual system check Leaks Go to Step 13 Go to Step 11

11 Check coolant concentration. Refer to 3.2 Coolant

Maintenance. To Specification Go to Step 12 Correct

Concentration Level

12 Check radiator core for bent fins, dirt, bugs or other

obstructions. Obstructed Clean or

straighten Go to Step 14

13

Pressure Test cooling system. Refer to 3.7 Pressure

Testing in this Section. Leaks Repair System OK

14

If none of the above require repair, the problem is

complex or of a major nature.

Refer to 4.5 Problems Not Requiring Disassembly of

Cooling System or 4.6 Problems Requiring Disassembly

of Cooling System. – – –

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3198 of 6020

Engine Cooling – V6 Engine Page 6B1–63

4.5 Problems Not Requiring Disassembly of

Cooling System

1 Large obstructions blocking radiator or condenser airflow.

• Auxiliary oil coolers

• License plate

• Obstruction of radiator grille, for example, driving lights or mud

2 Loose, damaged or missing air chute side panels.

3 Missing or damaged air baffle.

4 Cracked or loose coolant recovery system hose.

5 Leaking heater component such as the heater core or water valve.

4.6 Problems Requiring Disassembly of Cooling System

1 Damaged cooling fan or faulty motor operation.

2 Pressure test cooling system.

3 Defective coolant pump.

• Eroded or broken impeller vanes

• Failed bearing or seal – check for shaft or bearing end play

4 Internally blocked radiator core.

5 Obstruction of coolant recovery system.

6 Internal system leaks.

• Head gaskets

• Cracked cylinder block

• Engine front cover

• Intake manifold gaskets

7 Blocked coolant passages in cylinder heads or block – remove cylinder heads and check.

4.7 Black Light and Dye Leak Diagnosis Method

It is strongly recommended that this diagnostic method be used to diagnose fluid leaks. This method is a proven and

reliable method that identifies the specific leak source.

The black light kit can be used for the leak detection of a number of fluids, when used with the appropriate tracer dye.

Examples are: Coolant, Engine Oil, Automatic Transmission Fluid and Air Conditioning Refrigerant (R134A).

The following is a summary of the steps involved in detecting a cooling system fluid leak using black light and dye:

1 Pour specified amount of dye into the cooling system via the coolant filler cap on the outlet housing. Refer 3.1 Service Notes in this Section.

2 Road test the vehicle under normal operating conditions.

3 Direct the light towards the suspect area. The fluid leak will appear as a brightly coloured path leading from the source.

4 Repair fluid leak and recheck to ensure that leak has been rectified.

5 Refer to the manufacturer’s directions when using this method.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3199 of 6020

Engine Cooling – V6 Engine Page 6B1–64

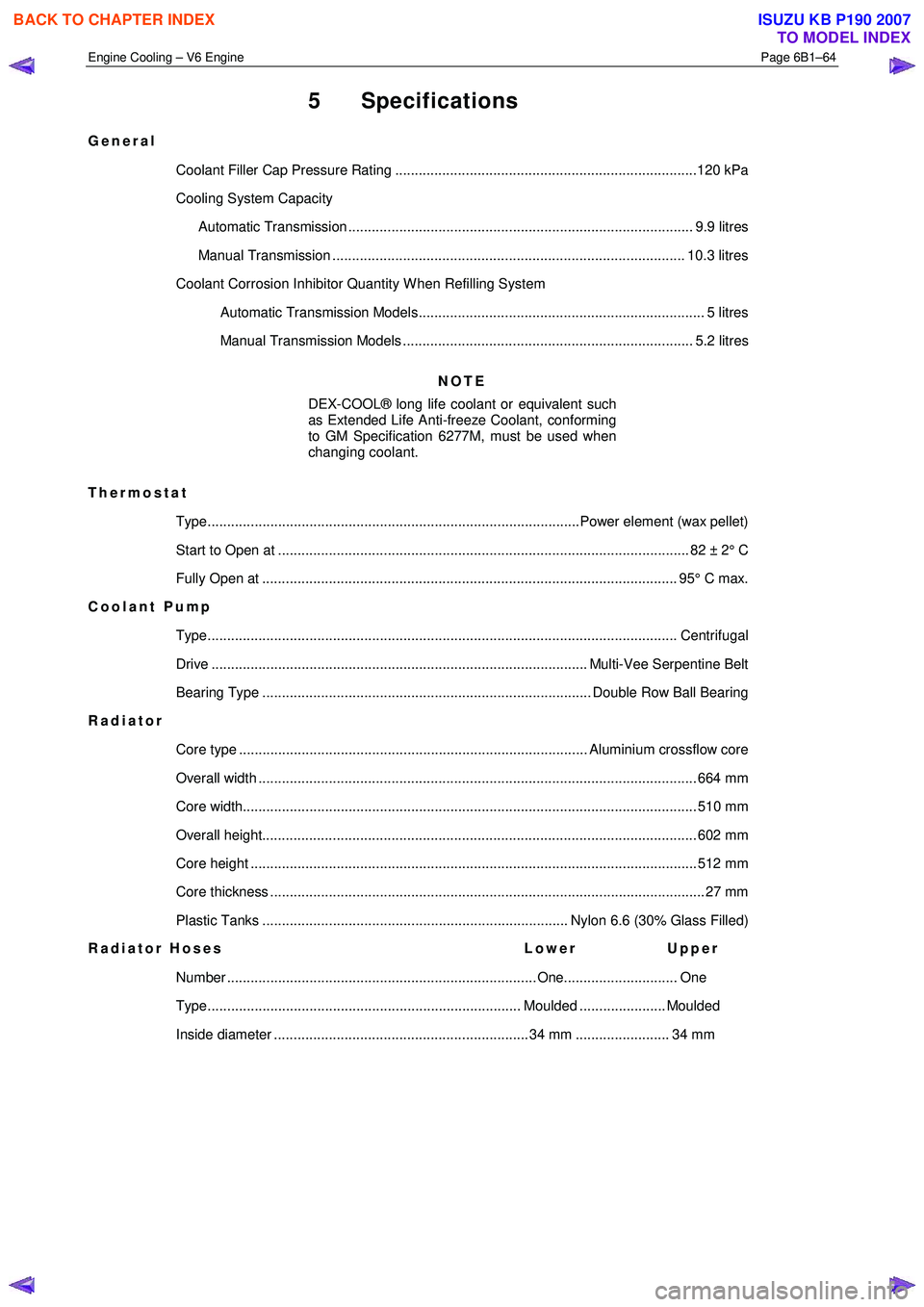

5 Specifications

General

Coolant Filler Cap Pressure Rating .............................................................................120 kPa

Cooling System Capacity

Automatic Transmission ........................................................................................ 9.9 litres

Manual Transmission .......................................................................................... 10.3 litres

Coolant Corrosion Inhibitor Quantity W hen Refilling System Automatic Transmission Models......................................................................... 5 litres

Manual Transmission Models .......................................................................... 5.2 litres

NOTE

DEX-COOL® long life coolant or equivalent such

as Extended Life Anti-freeze Coolant, conforming

to GM Specification 6277M, must be used when

changing coolant.

Thermostat Type...............................................................................................Power element (wax pellet)

Start to Open at ......................................................................................................... 82 ± 2 ° C

Fully Open at .......................................................................................................... 95° C ma x.

Coolant Pump

Type........................................................................................................................ Cen trifugal

Drive ................................................................................................ Multi-Vee Serpentine Belt

Bearing Type .................................................................................... Double Row Ball Bearing

Radiator

Core type ......................................................................................... Aluminium crossflow core

Overall width ................................................................................................................ 66 4 mm

Core width.................................................................................................................... 5 10 mm

Overall height............................................................................................................... 60 2 mm

Core height .................................................................................................................. 51 2 mm

Core thickness ............................................................................................................... 27 mm

Plastic Tanks .............................................................................. Nylon 6.6 (30% Glass Filled)

Radiator Hoses Lower Upper

Number ............................................................................... One............................. One

Type................................................................................ Moulded ...................... Moulded

Inside diameter ................................................................. 34 mm ........................ 34 mm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3777 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–17

7 Transmission Specifications

7.1 General

Type

Hydra-matic 4L60E

Special Features

Electronically controlled shift pattern, feel and torque

Converter clutch operation

Overdrive 4th speed range

Selector Location ..................................................................................Floor mounted console

Gear Ratios Park (P) ....................................................................................................................... ........... –

Reverse (R) .................................................................................................................... ... 2.29

Neutral (N) .............................................................................................................................. –

Drive (D – 4) .................................................................................................................. ...... 0.7

Drive (D – 3) .................................................................................................................. ...... 1.0

Second (2) ......................................................................................................................... 1.63

First (1) ...................................................................................................................... ........ 3.06

Shift Speeds Refer to 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis

Oil Pressure

Refer to 7C3 Automatic Transmission – 4L60E – Hydraulic and Mechanical Diagnosis

Torque Converter

Number of Elements .................................................................. 3 plus torque converter clutch

Torque Converter Diameter and End Play

HFV6 ........................................................................................................................... 258 mm

End Play .............................................................................................................. 0.1 – 0.5 mm

Lubricant

Type recommended ................................................................................................ Dexron

® III

Capacity......................... Nominal only. Check when transmission is at operating temperature

Service Refill ............................................................................................................... 4. 8 litres

Total (Dry)................................................................................................................... 8 .8 litres

Fluid Cooling.....................................Transmission fluid to engine coolant in one radiator tank

Clutches and Band 2 – 4 Band:

Type........................................................................................... Composition lined, steel band

Operation: ..................................................................................................................... .. Servo

Adjustment: ................................................................................................ Selective Apply Pin

Pin Size and Identification.

65.82 – 66.12 mm ...................................................................................................... 1 Groove

67.23 – 67.53 mm ...................................................................................................... 2 Groove

68.64 – 68.94 mm ....................................................................................................No Groove

Reverse Input Clutch Type................................................................................................................Multiple we t disc

Backing plate ........................................................................................................ (1) Select ive

Clutch plate (numbers):

Steel ....................................................................................................................................... 4

Composition............................................................................................................................ 4

Belleville ..................................................................................................................... ............ 1

Backing Plate ........................................................................................................ 1 (Selecti ve)

Backing plate, identification and thickness:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007