water pump ISUZU KB P190 2007 Workshop Service Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1496 of 6020

6A-136 ENGINE MECHANICAL (4JK1/4JJ1)

Cylinder Block

Components

RTW 76ASF000101

Legend

1. Cylinder Block

Removal

1. Demount the engine assembly.

Refer to "Engine Assembly".

2. Remove the cylinder head cover.

Refer to "Cylinder Head Cover".

3. Remove the camshaft assembly.

Refer to "Camshaft Assembly".

4. Remove the cylinder head.

Refer to "Cylinder Head".

5. Remove the fuel supply pump and fuel rail assembly.

Refer to "Fuel Supply Pump" and "Fuel Rail Assembly" in FUEL SYSTEM Section.

6. Remove the oil filter assembly and oil cooler.

Refer to “Oil Filter Assembly and Oil Cooler”.

7. Remove the crankshaft front oil seal.

Refer to "Crankshaft Front Oil Seal".

8. Remove the crankshaft rear oil seal.

Refer to "Crankshaft Rear Oil Seal".

9. Remove the oil pan.

Refer to "Oil Pan".

10. Remove the water pump.

Refer to "W ater Pump" in Cooling System Section.

11. Remove the front cover.

Refer to "Front Cover".

12. Remove the timing gear train.

Refer to "Timing Gear Train".

13. Remove the oil pump.

Refer to "Oil Pump".

14. Remove pistons and connecting rods.

Refer to "Piston and Connecting Rod".

15. Remove the crankshaft.

Refer to "Crankshaft".

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1499 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-139

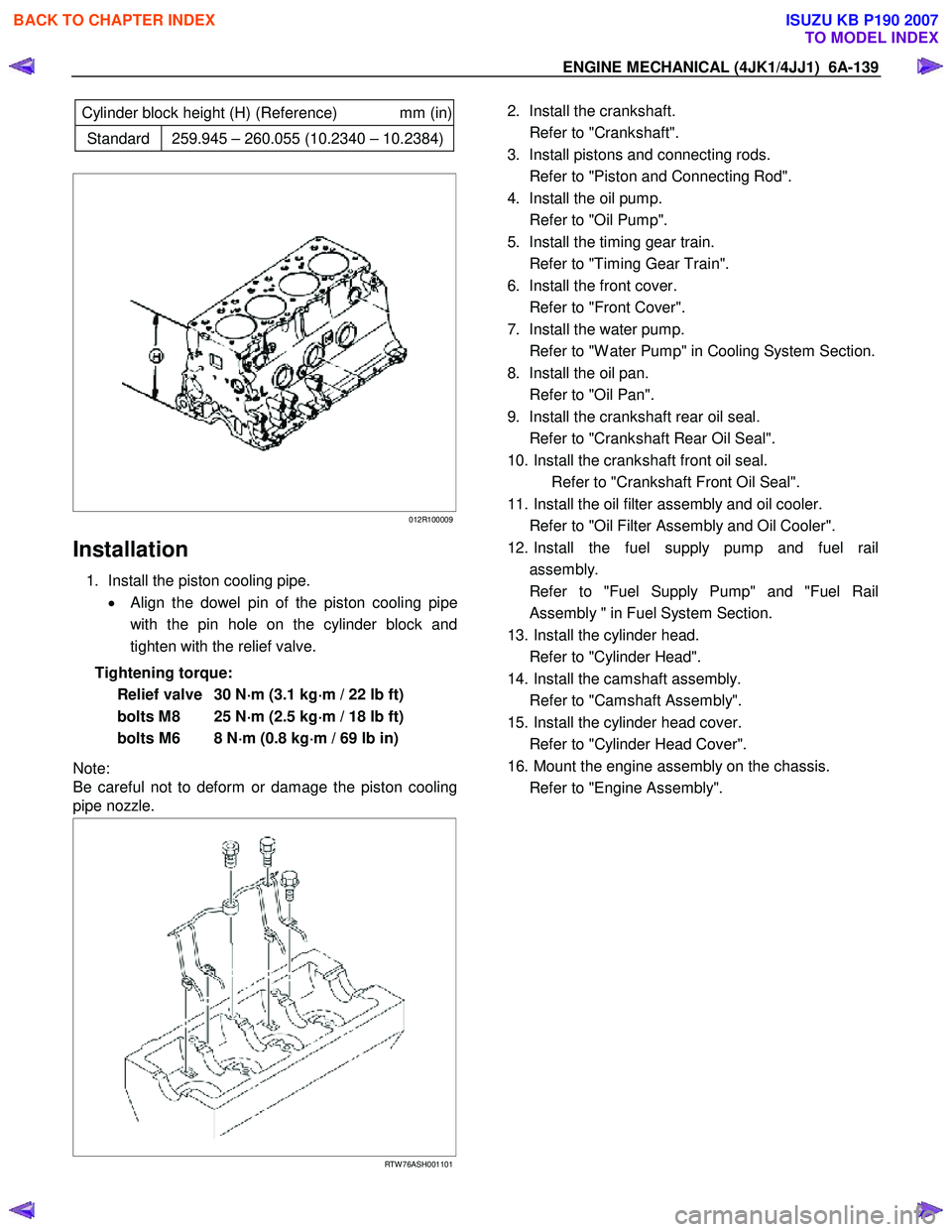

Cylinder block height (H) (Reference) mm (in)

Standard 259.945 – 260.055 (10.2340 – 10.2384)

012R100009

Installation

1. Install the piston cooling pipe.

• Align the dowel pin of the piston cooling pipe

with the pin hole on the cylinder block and

tighten with the relief valve.

Tightening torque: Relief valve 30 N ⋅

⋅⋅

⋅

m (3.1 kg ⋅

⋅⋅

⋅

m / 22 lb ft)

bolts M8 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

bolts M6 8 N ⋅

⋅⋅

⋅

m (0.8 kg ⋅

⋅⋅

⋅

m / 69 lb in)

Note:

Be careful not to deform or damage the piston cooling

pipe nozzle.

RTW 76ASH001101

2. Install the crankshaft.

Refer to "Crankshaft".

3. Install pistons and connecting rods.

Refer to "Piston and Connecting Rod".

4. Install the oil pump.

Refer to "Oil Pump".

5. Install the timing gear train.

Refer to "Timing Gear Train".

6. Install the front cover.

Refer to "Front Cover".

7. Install the water pump.

Refer to "W ater Pump" in Cooling System Section.

8. Install the oil pan.

Refer to "Oil Pan".

9. Install the crankshaft rear oil seal.

Refer to "Crankshaft Rear Oil Seal".

10. Install the crankshaft front oil seal. Refer to "Crankshaft Front Oil Seal".

11. Install the oil filter assembly and oil cooler.

Refer to "Oil Filter Assembly and Oil Cooler".

12. Install the fuel supply pump and fuel rail assembly.

Refer to "Fuel Supply Pump" and "Fuel Rail Assembly " in Fuel System Section.

13. Install the cylinder head.

Refer to "Cylinder Head".

14. Install the camshaft assembly.

Refer to "Camshaft Assembly".

15. Install the cylinder head cover.

Refer to "Cylinder Head Cover".

16. Mount the engine assembly on the chassis.

Refer to "Engine Assembly".

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1500 of 6020

6A-140 ENGINE MECHANICAL (4JK1/4JJ1)

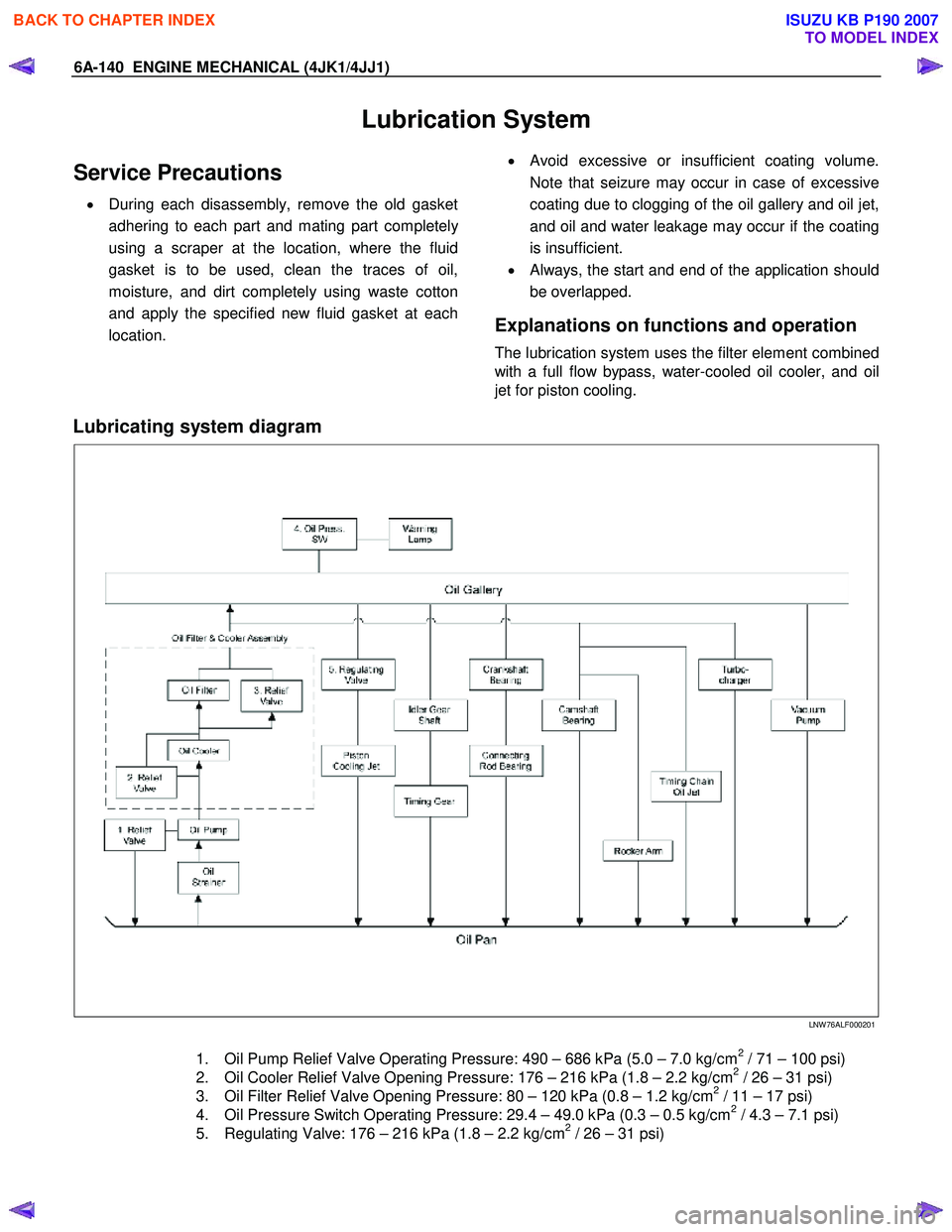

Lubrication System

Service Precautions

• During each disassembly, remove the old gasket

adhering to each part and mating part completel

y

using a scraper at the location, where the fluid

gasket is to be used, clean the traces of oil,

moisture, and dirt completely using waste cotton

and apply the specified new fluid gasket at each

location.

•

Avoid excessive or insufficient coating volume.

Note that seizure may occur in case of excessive

coating due to clogging of the oil gallery and oil jet,

and oil and water leakage may occur if the coating

is insufficient.

• Always, the start and end of the application should

be overlapped.

Explanations on functions and operation

The lubrication system uses the filter element combined

with a full flow bypass, water-cooled oil cooler, and oil

jet for piston cooling.

Lubricating system diagram

LNW 76ALF000201

1. Oil Pump Relief Valve Operating Pressure: 490 – 686 kPa (5.0 – 7.0 kg/cm2 / 71 – 100 psi)

2. Oil Cooler Relief Valve Opening Pressure: 176 – 216 kPa (1.8 – 2.2 kg/cm2 / 26 – 31 psi)

3. Oil Filter Relief Valve Opening Pressure: 80 – 120 kPa (0.8 – 1.2 kg/cm2 / 11 – 17 psi)

4. Oil Pressure Switch Operating Pressure: 29.4 – 49.0 kPa (0.3 – 0.5 kg/cm2 / 4.3 – 7.1 psi)

5. Regulating Valve: 176 – 216 kPa (1.8 – 2.2 kg/cm2 / 26 – 31 psi)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1526 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-3

General Description

Coolant Flow

RTW 76BLF000301

The engine cooling system consists of the radiator, the

water pump, the cooling fan, and the thermostat.

To quickly increase cold engine coolant temperature fo

r

smooth engine operation, the coolant is circulated by

the water pump and thermostat through the bypass pipe

and back to the cylinder body.

The coolant does not circulate through the radiator.

W hen the coolant temperature reaches the specified

value, the thermostat will begin to open and a graduall

y

increasing amount of coolant will circulate through the

radiator.

The thermostat will be fully open when the coolant

temperature reaches the specified value. All of the

coolant is now circulating through the radiator fo

r

effective engine cooling.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1527 of 6020

6B-4 ENGINE COOLING (4JK1/4JJ1)

Water Pump

RTW 56BSF000101

A centrifugal type water pump forcefully circulates the

coolant through the cooling system.

The water pump is not a disassembled type.

Thermostat

RTW 56BSF000201

A wax pellet type thermostat is used.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1531 of 6020

6B-8 ENGINE COOLING (4JK1/4JJ1)

Water Pump

Read this Section carefully before performing any

removal and installation procedure. This Section gives

you important points as well as the order of operation.

Be sure that you understand everything in this Section

before you begin.

Removal

1. Remove the engine cover.

2. Radiator Upper Hose a. Partially drain the engine coolant.

b. Remove the radiator upper hose.

RTW 56FSH000101

3. W ater Outlet Pipe

a. Disconnect the turbocharger-cooling pipe from the outlet pipe.

b. Loosen the fixing bolt and remove the wate

r

outlet bolt.

4. Upper Fan Shroud

5. Fan and Fan Clutch a. Loosen the fan clutch nuts.

b. Remove the fan together with the fan clutch. Take care not to damage the radiator core.

6. Fan Drive Belt and Pulley a. Loosen the tension adjust bolt on the generator.

b. Remove the fan drive belt with the fan pulley.

RTW 56ASH025401

7. W ater Pump

a. Remove the water pump bolts and nuts.

b. Remove the water pump.

RTW 56BSH000201

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1532 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-9

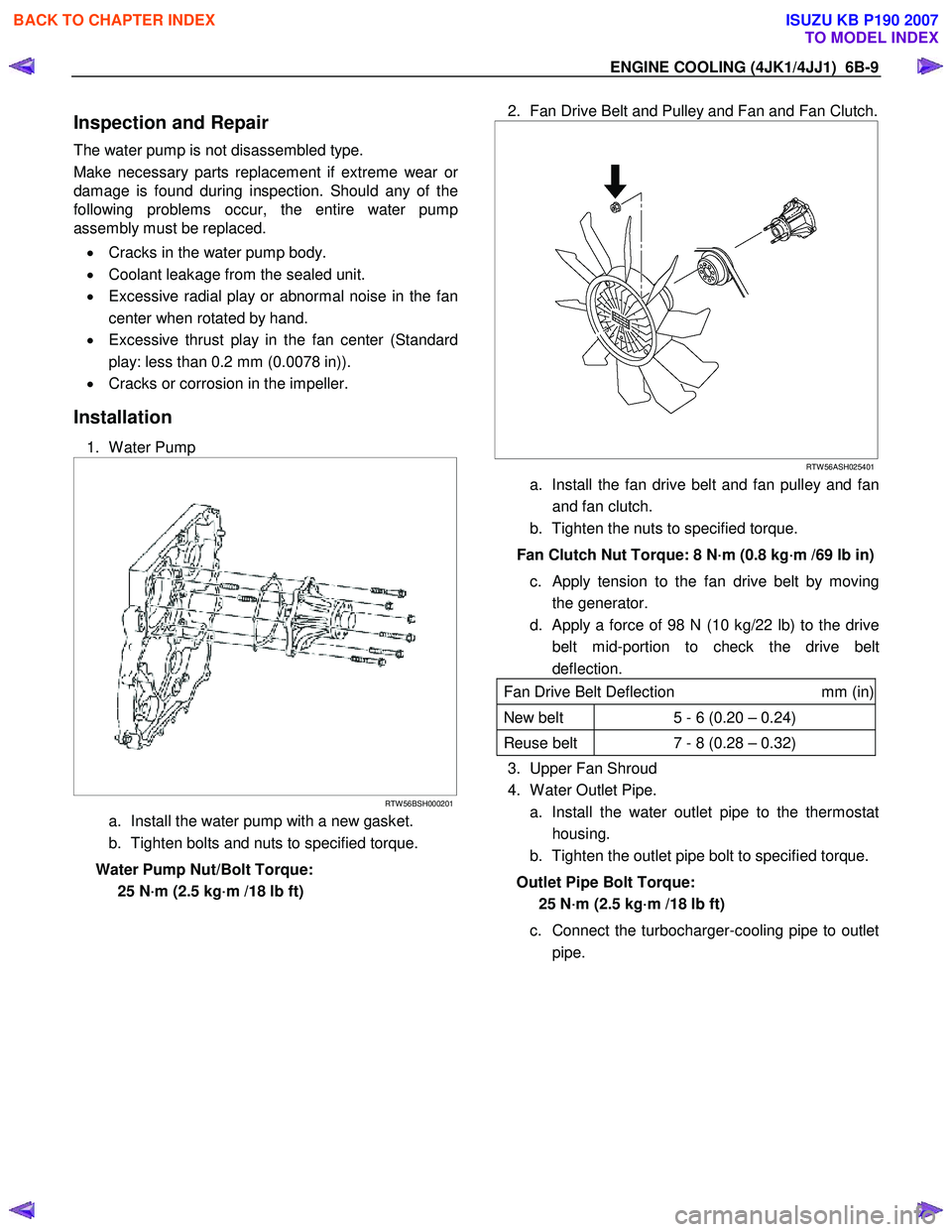

Inspection and Repair

The water pump is not disassembled type.

Make necessary parts replacement if extreme wear o

r

damage is found during inspection. Should any of the

following problems occur, the entire water pump

assembly must be replaced.

• Cracks in the water pump body.

• Coolant leakage from the sealed unit.

• Excessive radial play or abnormal noise in the fan

center when rotated by hand.

• Excessive thrust play in the fan center (Standard

play: less than 0.2 mm (0.0078 in)).

• Cracks or corrosion in the impeller.

Installation

1. W ater Pump

RTW 56BSH000201

a. Install the water pump with a new gasket.

b. Tighten bolts and nuts to specified torque.

Water Pump Nut/Bolt Torque: 25 N·m (2.5 kg·m /18 lb ft)

2. Fan Drive Belt and Pulley and Fan and Fan Clutch.

RTW 56ASH025401

a. Install the fan drive belt and fan pulley and fan

and fan clutch.

b. Tighten the nuts to specified torque.

Fan Clutch Nut Torque: 8 N·m (0.8 kg·m /69 lb in) c. Apply tension to the fan drive belt by moving the generator.

d. Apply a force of 98 N (10 kg/22 lb) to the drive belt mid-portion to check the drive belt

deflection.

Fan Drive Belt Deflection mm (in)

New belt 5 - 6 (0.20 – 0.24)

Reuse belt 7 - 8 (0.28 – 0.32)

3. Upper Fan Shroud

4. W ater Outlet Pipe.

a. Install the water outlet pipe to the thermostat housing.

b. Tighten the outlet pipe bolt to specified torque.

Outlet Pipe Bolt Torque: 25 N·m (2.5 kg·m /18 lb ft)

c. Connect the turbocharger-cooling pipe to outlet pipe.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1538 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-15

Inspection and Repair

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

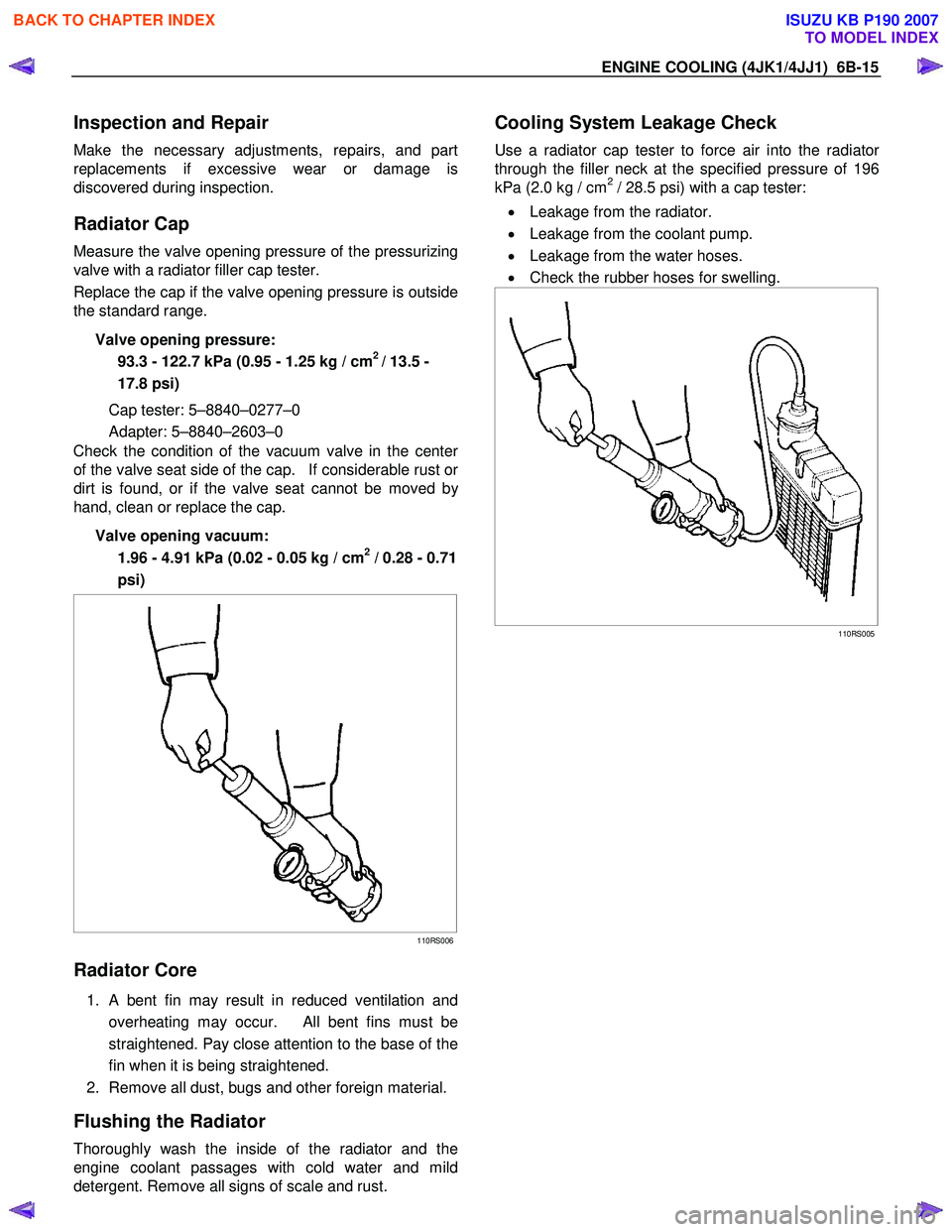

Radiator Cap

Measure the valve opening pressure of the pressurizing

valve with a radiator filler cap tester.

Replace the cap if the valve opening pressure is outside

the standard range.

Valve opening pressure: 93.3 - 122.7 kPa (0.95 - 1.25 kg / cm

2 / 13.5 -

17.8 psi)

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

Check the condition of the vacuum valve in the cente

r

of the valve seat side of the cap. If considerable rust or

dirt is found, or if the valve seat cannot be moved by

hand, clean or replace the cap.

Valve opening vacuum: 1.96 - 4.91 kPa (0.02 - 0.05 kg / cm

2 / 0.28 - 0.71

psi)

110RS006

Radiator Core

1. A bent fin may result in reduced ventilation and

overheating may occur. All bent fins must be

straightened. Pay close attention to the base of the

fin when it is being straightened.

2. Remove all dust, bugs and other foreign material.

Flushing the Radiator

Thoroughly wash the inside of the radiator and the

engine coolant passages with cold water and mild

detergent. Remove all signs of scale and rust.

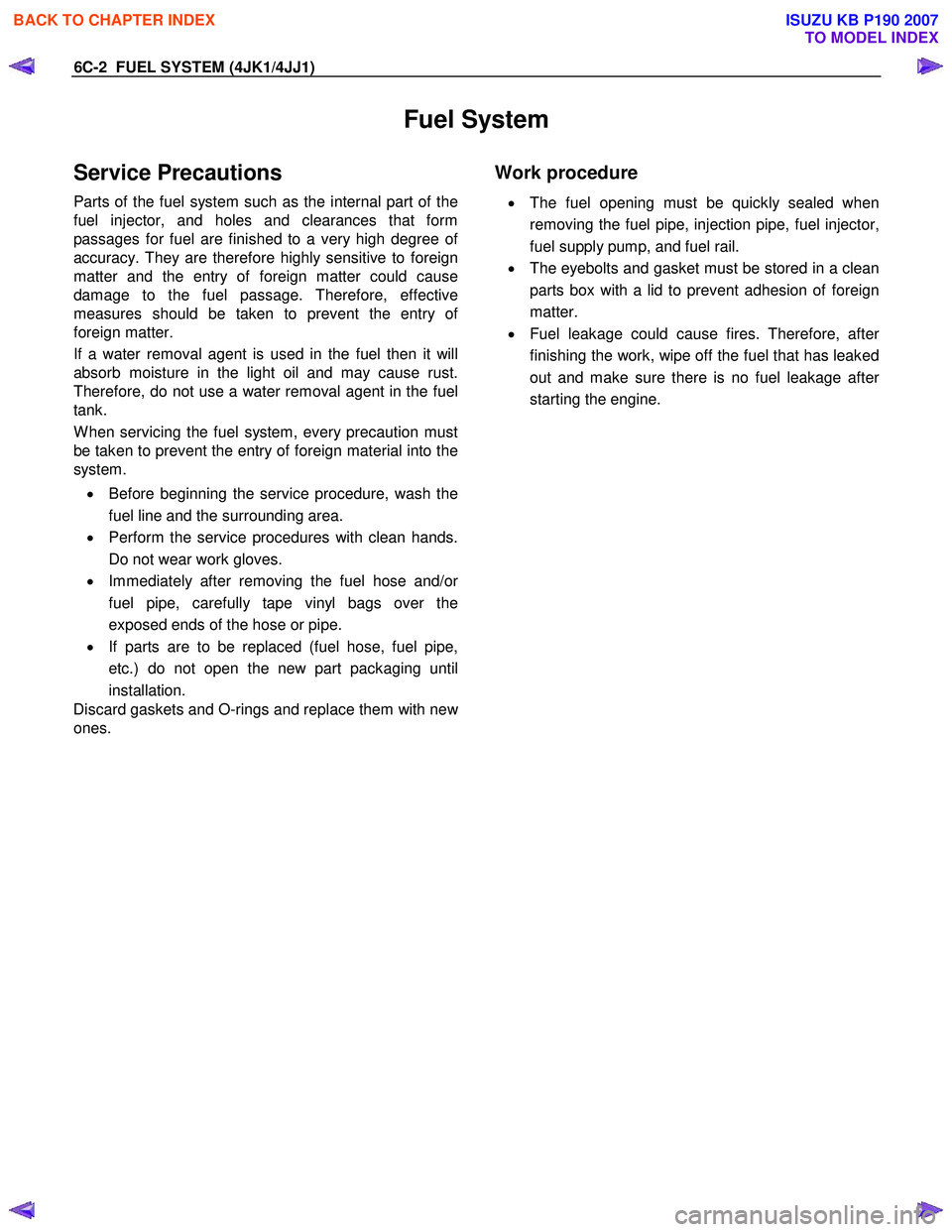

Cooling System Leakage Check

Use a radiator cap tester to force air into the radiator

through the filler neck at the specified pressure of 196

kPa (2.0 kg / cm2 / 28.5 psi) with a cap tester:

• Leakage from the radiator.

• Leakage from the coolant pump.

• Leakage from the water hoses.

• Check the rubber hoses for swelling.

110RS005

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1543 of 6020

6C-2 FUEL SYSTEM (4JK1/4JJ1)

Fuel System

Service Precautions

Parts of the fuel system such as the internal part of the

fuel injector, and holes and clearances that form

passages for fuel are finished to a very high degree o

f

accuracy. They are therefore highly sensitive to foreign

matter and the entry of foreign matter could cause

damage to the fuel passage. Therefore, effective

measures should be taken to prevent the entry o

f

foreign matter.

If a water removal agent is used in the fuel then it will

absorb moisture in the light oil and may cause rust.

Therefore, do not use a water removal agent in the fuel

tank.

W hen servicing the fuel system, every precaution must

be taken to prevent the entry of foreign material into the

system.

• Before beginning the service procedure, wash the

fuel line and the surrounding area.

• Perform the service procedures with clean hands.

Do not wear work gloves.

• Immediately after removing the fuel hose and/o

r

fuel pipe, carefully tape vinyl bags over the

exposed ends of the hose or pipe.

• If parts are to be replaced (fuel hose, fuel pipe,

etc.) do not open the new part packaging until

installation.

Discard gaskets and O-rings and replace them with ne

w

ones.

Work procedure

•

The fuel opening must be quickly sealed when

removing the fuel pipe, injection pipe, fuel injector,

fuel supply pump, and fuel rail.

• The eyebolts and gasket must be stored in a clean

parts box with a lid to prevent adhesion of foreign

matter.

• Fuel leakage could cause fires. Therefore, afte

r

finishing the work, wipe off the fuel that has leaked

out and make sure there is no fuel leakage afte

r

starting the engine.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1548 of 6020

FUEL SYSTEM (4JK1/4JJ1) 6C-7

g. Check that the warning lamp in the meter is off.

2. Draining with drain plug in engine room. a. W ith the engine off, open the engine hood and loosen the drain plug (1) located on the left

hand side of the engine room. (3-4 turns)

b. Turn the starter switch to the “ON” position fo

r

10 seconds, and then turn the starter switch to

the “OFF” position for 10 seconds. Then, once

again turn the starter switch to the “ON”

position for 10 seconds.

c. Tighten the drain plug firmly.

d.

After starting the engine, check that there is no

fuel leakage from the drain plug. Also check

that the water separator indicator has turned

off.

RTW 76CSH001301

NOTE:

• If the water separator requires frequent draining,

have the fuel tank drained at your ISUZU/GM

Dealer.

• Be sure to stop the engine when draining the fuel

tank.

• Confirm that there are no combustible materials

under the drain hose, and use a receptacle to

catch the drained water.

Engine starting cautions

• Before starting the engine, turn the ignition switch

to the “ON” position. W ait 15 seconds. Return the

switch to the “LOCK” position. Repeat this

procedure 5 times.

• After starting the engine, allow it to idle for 10

minutes.

Fuel Pump Functional Check

1. Turn the starter switch to “ON” position.

2. Touch the under portion of the Fuel Tank by the hand as shown in the following figure within 12

seconds.

RTW 56CSH003501

Legend

1. Touch this area by the hand

3. Make sure a vibration by the Fuel Pump is

detected.

Fuel Pump stops within 12 seconds of turning the starter switch to the “ON” position.

W hen the check is repeated, return the starte

r

switch to the “LOCK” position for 10 – 15 seconds

and perform procedures 1 – 3.

WARNING: FUEL PUMP FUNCTIONAL CHECK

MUST BE CONDUCTED UNDER THE FOLLOWING

CONDITIONS TO AVOID INJURY.

•

••

•

APPLY THE PARKING BRAKE.

•

••

•

STOP THE ENGINE.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007