engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1328 of 6020

6E-294 Engine Control System (4JH1)

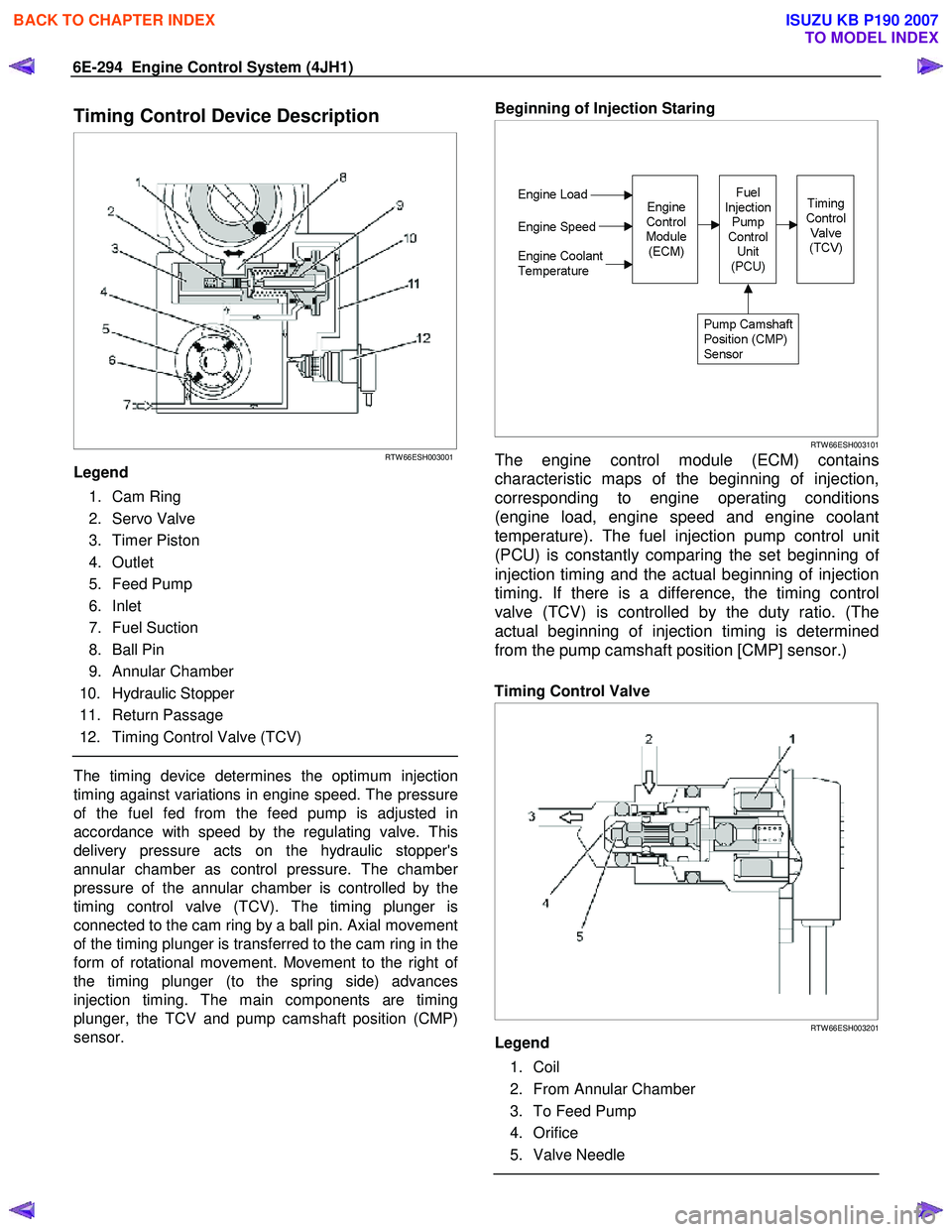

Timing Control Device Description

RTW 66ESH003001

Legend

1. Cam Ring

2. Servo Valve

3. Timer Piston

4. Outlet

5. Feed Pump

6. Inlet

7. Fuel Suction

8. Ball Pin

9. Annular Chamber

10. Hydraulic Stopper

11. Return Passage

12. Timing Control Valve (TCV)

The timing device determines the optimum injection

timing against variations in engine speed. The pressure

of the fuel fed from the feed pump is adjusted in

accordance with speed by the regulating valve. This

delivery pressure acts on the hydraulic stopper's

annular chamber as control pressure. The chambe

r

pressure of the annular chamber is controlled by the

timing control valve (TCV). The timing plunger is

connected to the cam ring by a ball pin. Axial movement

of the timing plunger is transferred to the cam ring in the

form of rotational movement. Movement to the right o

f

the timing plunger (to the spring side) advances

injection timing. The main components are timing

plunger, the TCV and pump camshaft position (CMP)

sensor.

Beginning of Injection Staring

RTW 66ESH003101

The engine control module (ECM) contains

characteristic maps of the beginning of injection,

corresponding to engine operating conditions

(engine load, engine speed and engine coolant

temperature). The fuel injection pump control unit

(PCU) is constantly comparing the set beginning o

f

injection timing and the actual beginning of injection

timing. If there is a difference, the timing control

valve (TCV) is controlled by the duty ratio. (The

actual beginning of injection timing is determined

from the pump camshaft position [CMP] sensor.)

Timing Control Valve

RTW 66ESH003201

Legend

1. Coil

2. From Annular Chamber

3. To Feed Pump

4. Orifice

5. Valve Needle

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1329 of 6020

Engine Control System (4JH1) 6E-295

The timing control valve (TCV) acts as a variable

throttle, using the rapid opening and closing (cycling)

of the valve needle in the TCV.

At normal operation,

the TCV controls the pressure acting on the annula

r

chamber so that the hydraulic stopper cam move to

any position, from the retard position to the advance

position. At this time, the duty ratio is set by the fuel

injection pump control unit (PCU).

When control current flows to the TCV coil, the valve

needle opens and the fuel annular chamber flows

through the orifice to the feed pump inlet.

Consequently, the pressure of the annular chambe

r

decreases and the hydraulic stopper is moved to the

retard side.

When control current to the TCV coil is cut, the valve

needle closes and the return passage is closed.

Consequently, the pressure of the annular chambe

r

increases and the hydraulic stopper is moved to the

advance side.

Pump Camshaft Position (CMP) Sensor

RTW 66ESH003301

Legend

1. Pump Camshaft Position (CMP) Sensor

2. Flexible Connecting Harness

3. Drive Shaft

4. Pump Camshaft Position (CMP) Sensor Retaining Ring

5. Sensor W heel

W hen the drive shaft rotates, the pump camshaft

position (CMP) sensor receives signal form the senso

r

wheel, and an electric pulse is sent through the flexible

connecting harness to the fuel injection pump control

unit (PCU). From these signals the PCU can determine

the average pump speed and the momentary pump

speed. The pump CMP sensor is mounted to the cam

ring. Thus, the relationship between the cam ring and

the pump CMP sensor signal is constant. The pump

CMP sensor signal is utilized for the following purposes:

• To determine the momentary angular position o

f

the cam ring.

• To calculate the actual speed of the fuel injection

pump.

• To determine the actual timing plunger position.

RTW 66ESH003401Legend

1. Pump Camshaft Position (CMP) Sensor Signal

2. Crankshaft Position (CKP) Sensor Signal

3. Fuel Injection Solenoid Valve Control Pulse

4. Fuel Injection Solenoid Needle Valve Lift

5. Cam Lift (Cam Profile)

6. Pulse Count

7. Fuel Injection Solenoid Valve Close

8. Fuel Injection Solenoid Valve Open

9. Start of Pressure Delivery

10. End of Pressure Delivery

11. Pressure Delivery Angle

12. Effective Stroke

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1330 of 6020

6E-296 Engine Control System (4JH1)

• Momentary Cam Ring Angular Position

The momentary angular position of the cam ring is input into the fuel injection PCU as a fuel injection

solenoid valve control signal. From momentar

y

input of angular position for fluctuations in running

conditions, the fuel injection solenoid valve open

and close intervals corresponding to the cam ring's

cam lift can be accurately determined.

• Actual Injection Pump Speed

W hen the crankshaft position (CKP) sensor is faulty, the engine control module (ECM) uses the

pump CMP signal as a replacement signal.

• Actual Timing Plunger Position

The actual timing plunger position can be determined by comparing the CKP sensor signal

with the pump CMP sensor angle. This position is

used for timer control.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1331 of 6020

Engine Control System (4JH1) 6E-297

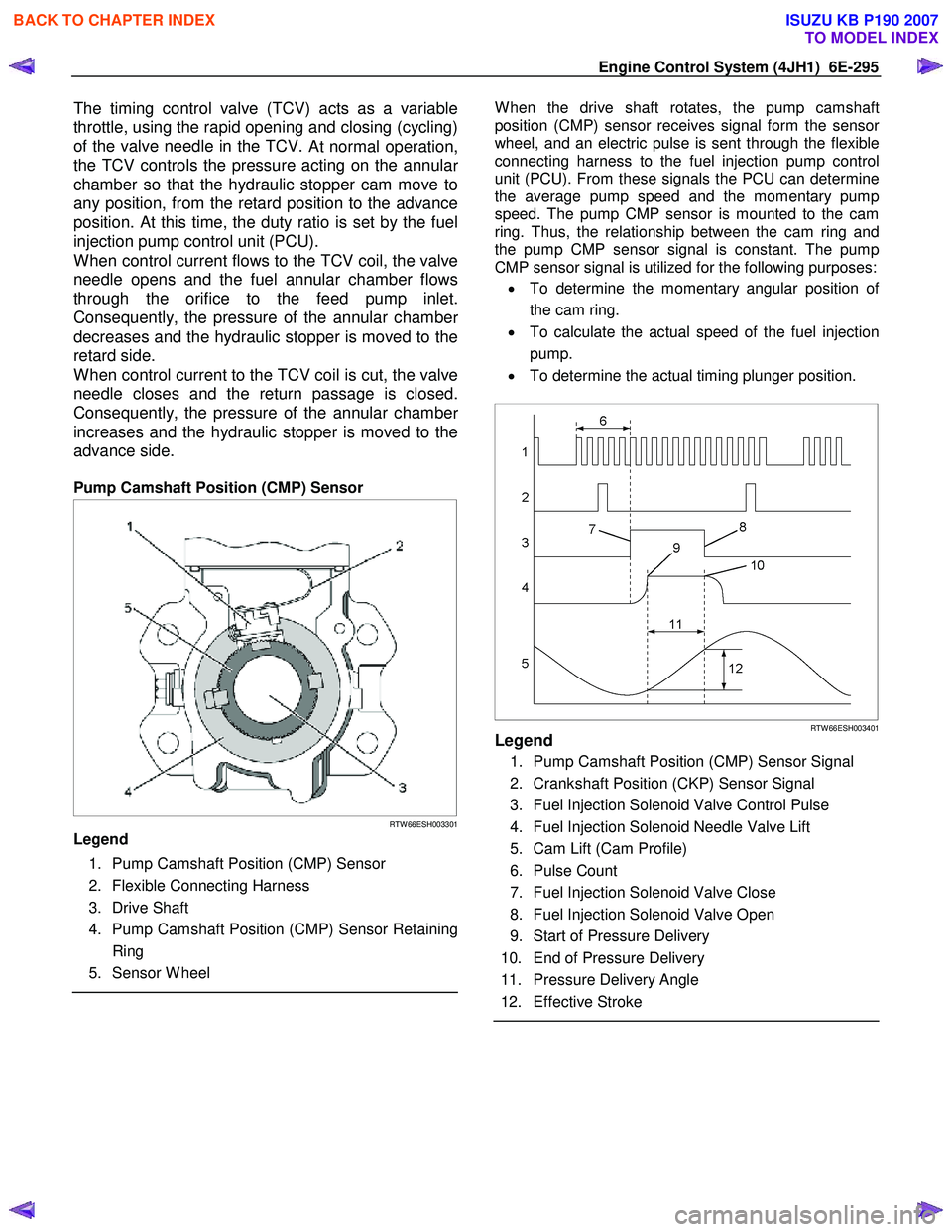

Exhaust Gas Recirculation (EGR) System Description

RTW 66ELF000101

Legend

1. EGR Cooler

2. Engine Coolant Outlet

3. Engine Coolant Inlet

4. EGR Valve

5. ECM

6. MAF & IAT Sensor

7. Intake Throttle Valve

The EGR system recirculates a part of exhaust gas

back into the intake manifold, which results in reducing

nitrogen oxide (NOx) emissions. The EGR control

system uses an electronic control system solenoid valve

and vacuum control EGR valve to ensure both

driveability and low emission. The engine control

module (ECM) controls the EGR flow amount based on

the engine speed, engine coolant temperature, intake

air temperature, barometric pressure and fuel injection

quantity. The ECM controls the EGR valve opening b

y

controlling the EGR solenoid valve drive duty. The mass

air flow (MAF) sensor monitors EGR gas flow amount.

An expected MAF amount should be detected while the

engine running.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1332 of 6020

6E-298 Engine Control System (4JH1)

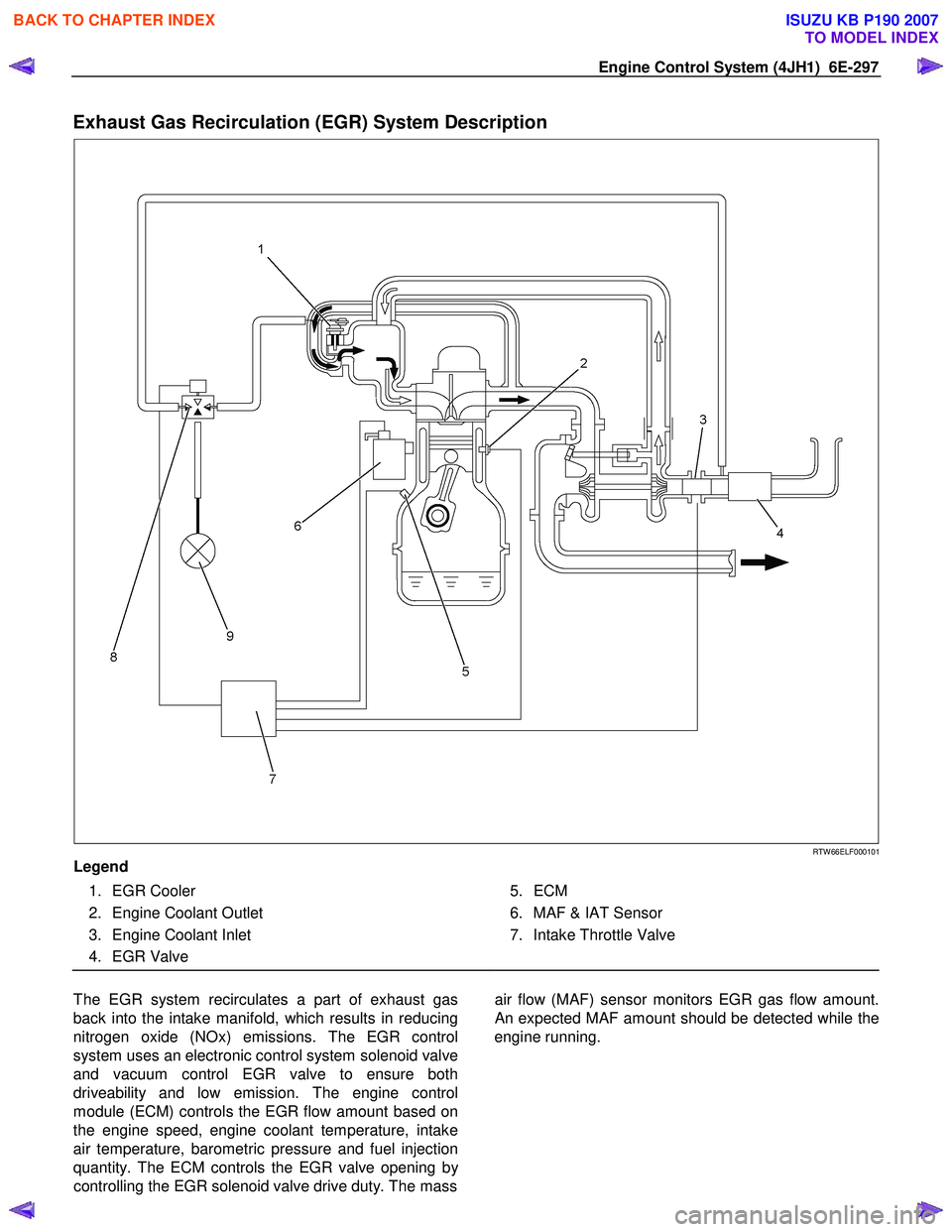

Turbocharger Description

RTW 66EMF000501

Legend

1. Exhaust Gas

2. W astegate Valve

3. Turbine W heel

4. Compressor W heel

5. Air Cleaner

6. Vacuum Pressure Sensor

7. Engine Control Module (ECM)

8. Turbocharger Solenoid Valve

9. Vacuum Pump (ACG)

10. Change Air Cooler (Intercooler)

The turbocharger is used to increase the amount of ai

r

that enters the engine cylinders. This allows a

proportional increase of fuel to be injected into the

cylinders, resulting in increased power output, more

complete combustion of fuel, and increased cooling o

f

the cylinder heads, pistons, valves, and exhaust gas.

This cooling effect helps extend engine life.

Heat energy and pressures in the engine exhaust gas

are utilized to drive the turbine. Exhaust gas is directed

to the turbine housing. The turbine housing acts as a

nozzle to direct the shaft wheel assembly. Since the

compressor wheel is attached directly to the shaft, the

compressor wheel rotates at the same speed as the

turbine wheel. Clean air from the air cleaner is drawn

into the compressor housing and wheel. The air is

compressed and delivered through a crossover pipe to

the engine air intake manifold, then into the cylinders.

The amount of air pressure rise and air volume

delivered to the engine from the compressor outlet is

regulated by a wastegate valve in the exhaust housing.

The position of the wastegate valve is controlled by the

amount of pressure built up on the intake side of the

turbocharger. The diaphragm on the inside of the

wastegate is pressure sensitive, and controls the

position of the valve inside the turbocharger. The

position of the valve will increase or decrease the

amount of boost to the turbocharger.

The charge air cooler also helps the performance of the

diesel. Intake air is drawn through the air cleaner and

into the turbocharger compressor housing. Pressurized

air from the turbocharger then flows forward through the

charge air cooler located in the front of the radiator.

From the charge air cooler, the air flows back into the

intake manifold.

The charge air cooler is a heat exchanger that uses ai

r

flow to dissipate heat from the intake air. As the

turbocharger increases air pressure, the air temperature

increases. Lowering the intake air temperature

increases the engine efficiency and power by packing

more air molecules into the same space.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1333 of 6020

Engine Control System (4JH1) 6E-299

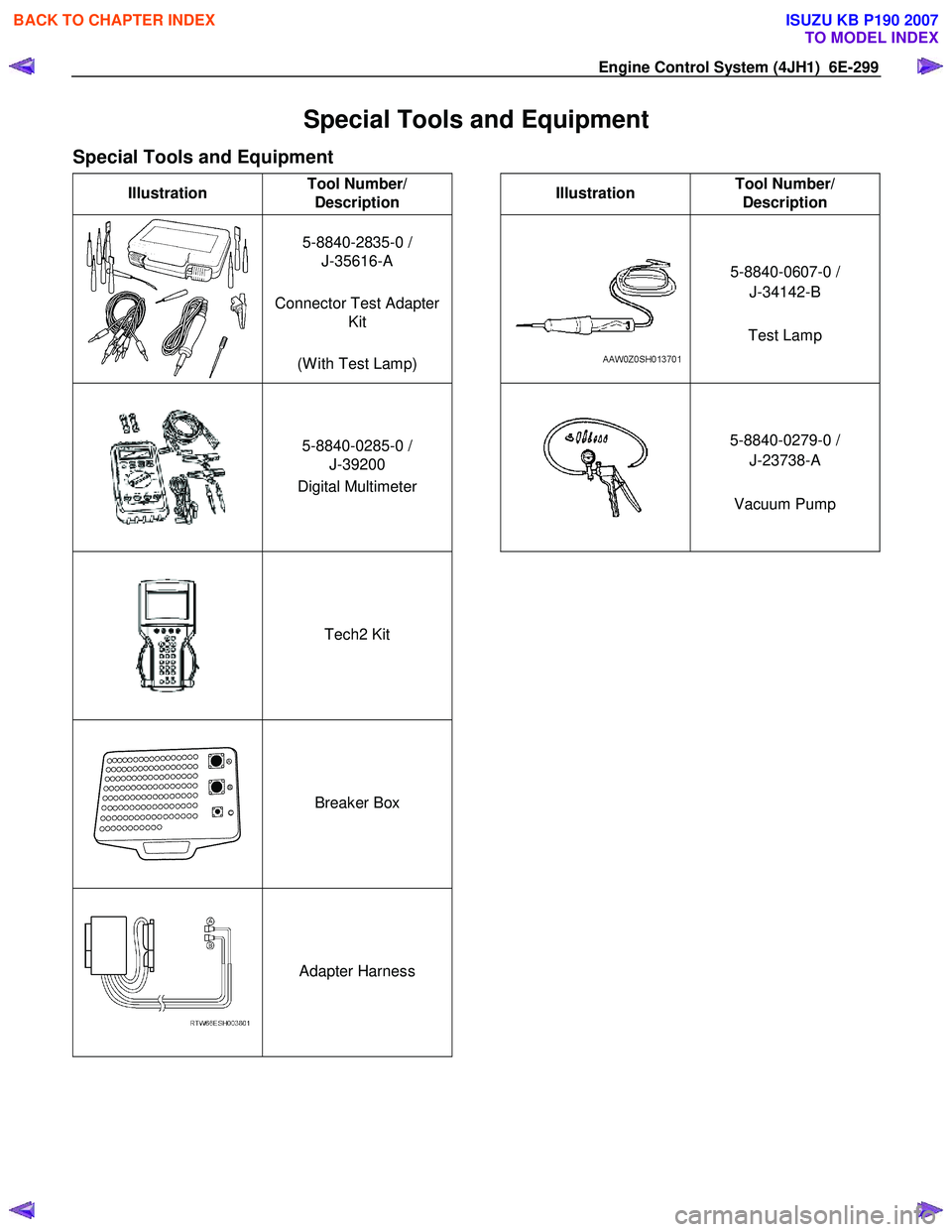

Special Tools and Equipment

Special Tools and Equipment

Illustration Tool Number/

Description

Illustration Tool Number/

Description

5-8840-2835-0 /

J-35616-A

Connector Test Adapter Kit

(W ith Test Lamp)

5-8840-0607-0 /

J-34142-B

Test Lamp

5-8840-0285-0 /

J-39200

Digital Multimeter

5-8840-0279-0 /

J-23738-A

Vacuum Pump

Tech2 Kit

Breaker Box

Adapter Harness

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1340 of 6020

EXHAUST SYSTEM 6F – 7

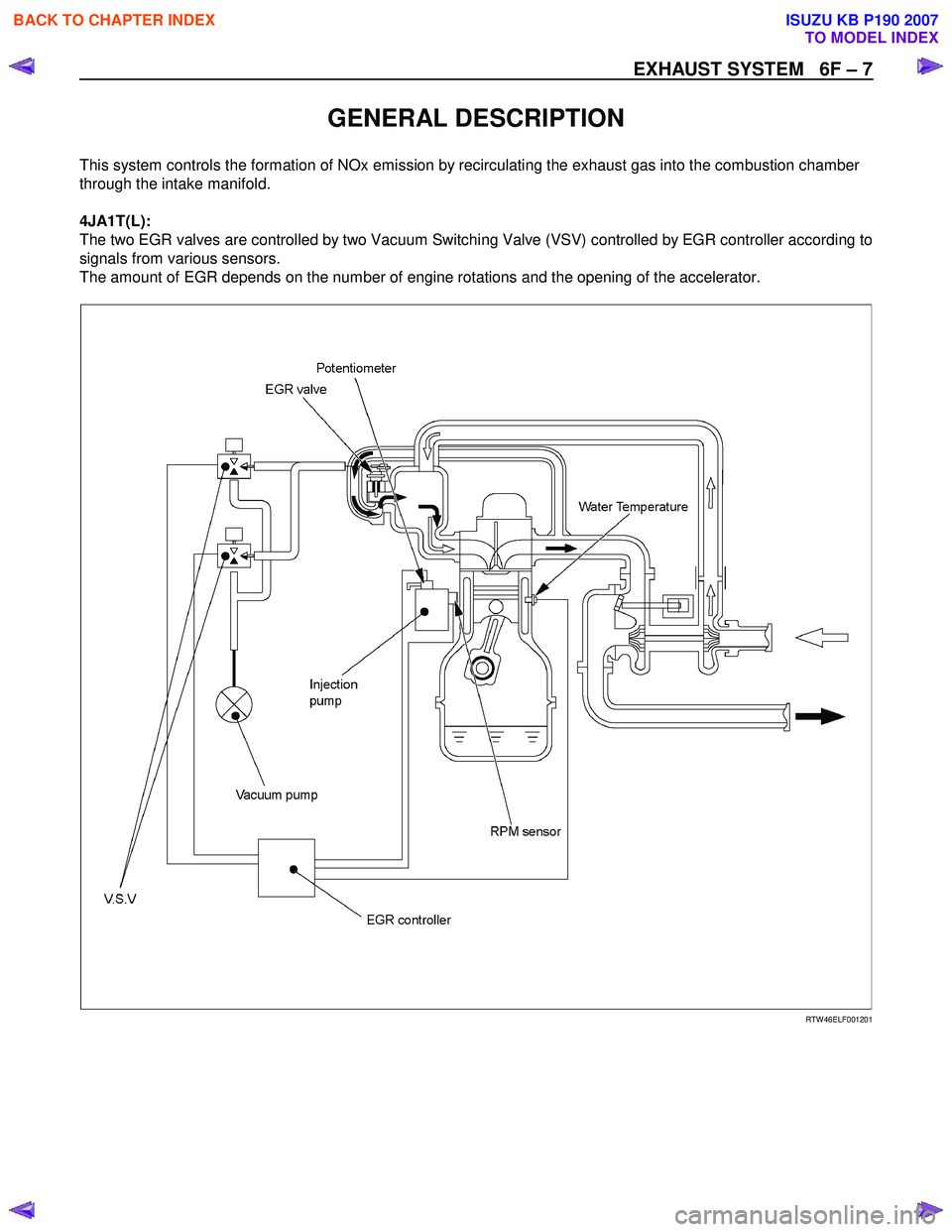

GENERAL DESCRIPTION

This system controls the formation of NOx emission by recirculating the exhaust gas into the combustion chamber

through the intake manifold.

4JA1T(L):

The two EGR valves are controlled by two Vacuum Switching Valve (VSV) controlled by EGR controller according to

signals from various sensors.

The amount of EGR depends on the number of engine rotations and the opening of the accelerator.

RTW 46ELF001201

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1341 of 6020

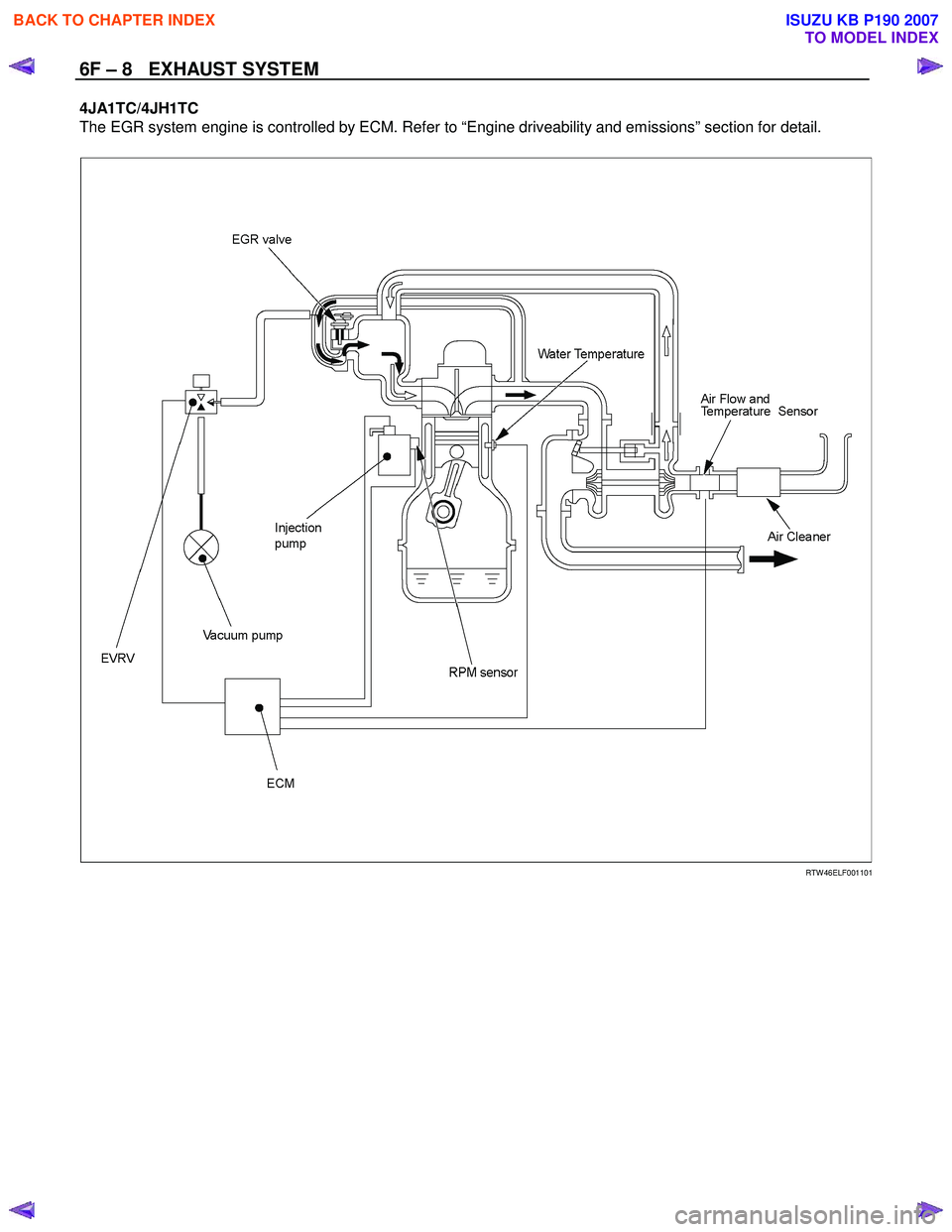

6F – 8 EXHAUST SYSTEM

4JA1TC/4JH1TC

The EGR system engine is controlled by ECM. Refer to “Engine driveability and emissions” section for detail.

RTW 46ELF001101

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1342 of 6020

EXHAUST SYSTEM 6F – 9

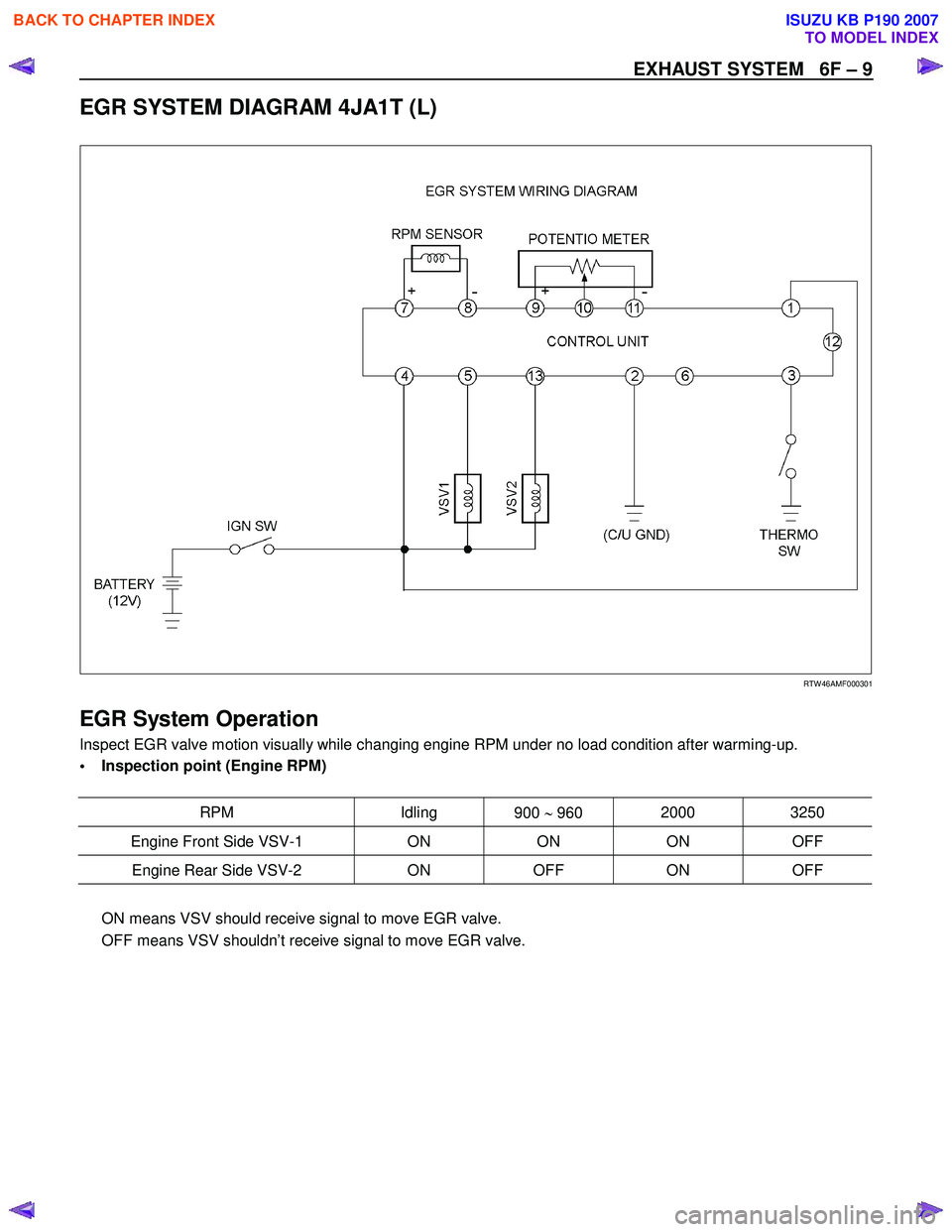

EGR SYSTEM DIAGRAM 4JA1T (L)

RTW 46AMF000301

EGR System Operation

Inspect EGR valve motion visually while changing engine RPM under no load condition after warming-up.

• Inspection point (Engine RPM)

RPM Idling 900 ∼ 960 2000 3250

Engine Front Side VSV-1

ON ON ON OFF

Engine Rear Side VSV-2 ON OFF ON OFF

ON means VSV should receive signal to move EGR valve.

OFF means VSV shouldn’t receive signal to move EGR valve.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1343 of 6020

6F – 10 EXHAUST SYSTEM

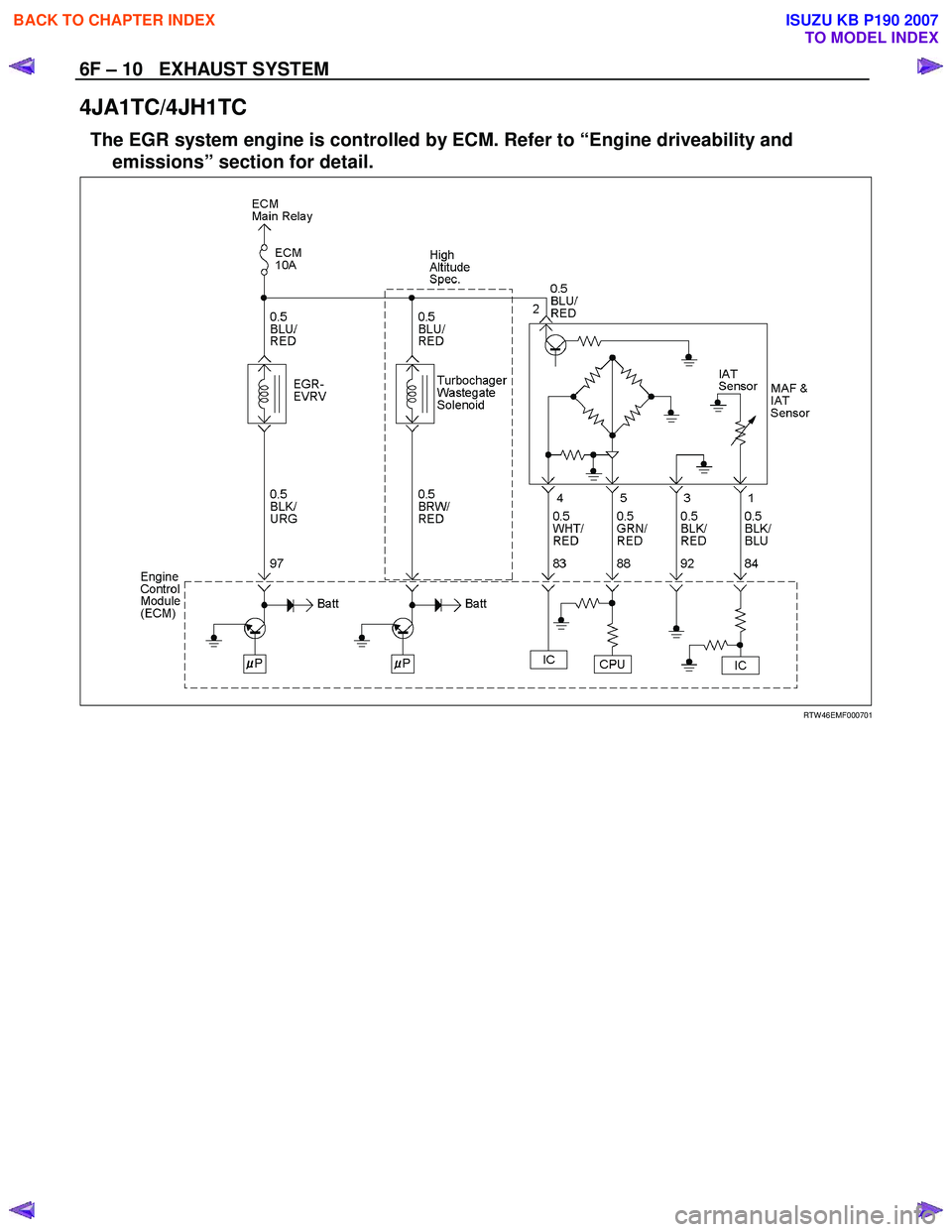

4JA1TC/4JH1TC

The EGR system engine is controlled by ECM. Refer to “Engine driveability and emissions” section for detail.

RTW 46EMF000701

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007