engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1318 of 6020

6E-284 Engine Control System (4JH1)

Important:

To prevent possible electrostatic discharge damage,

follow these guidelines: • Do not touch the ECM connector pins or soldered

components on the ECM circuit board.

• Do not open the replacement part package until

the part is ready to be installed.

• Before removing the part from the package,

ground the package to a known good ground on

the vehicle.

• If the part has been handled while sliding across

the seat, while sitting down from a standing

position, or while walking a distance, touch a

known good ground before installing the part.

• Charge by induction occurs when a person with

well insulated shoes stands near a highly charged

object and momentarily touches ground. Charges

of the same polarity are drained off leaving the

person highly charged with opposite polarity.

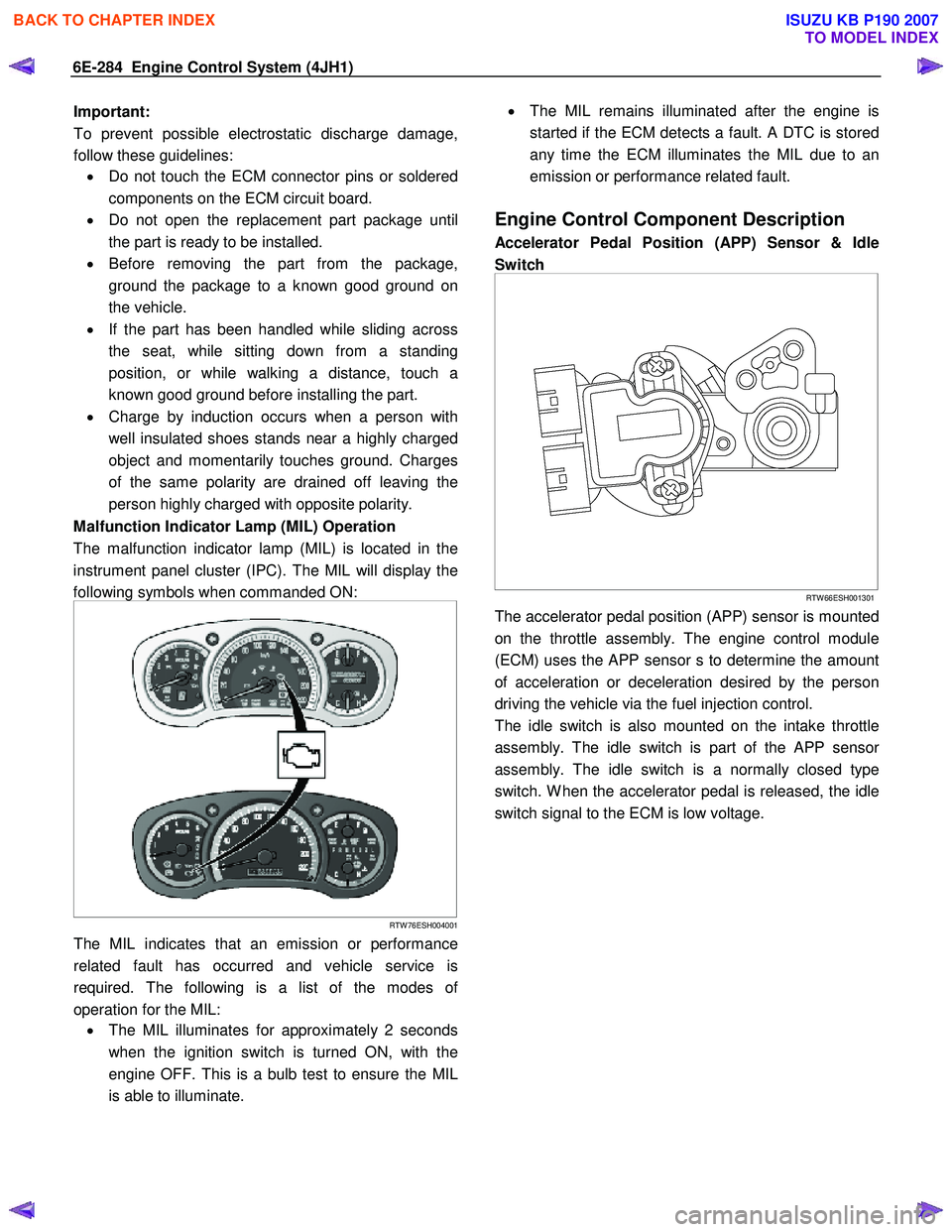

Malfunction Indicator Lamp (MIL) Operation

The malfunction indicator lamp (MIL) is located in the

instrument panel cluster (IPC). The MIL will display the

following symbols when commanded ON:

RTW 76ESH004001

The MIL indicates that an emission or performance

related fault has occurred and vehicle service is

required. The following is a list of the modes o

f

operation for the MIL: • The MIL illuminates for approximately 2 seconds

when the ignition switch is turned ON, with the

engine OFF. This is a bulb test to ensure the MIL

is able to illuminate.

•

The MIL remains illuminated after the engine is

started if the ECM detects a fault. A DTC is stored

any time the ECM illuminates the MIL due to an

emission or performance related fault.

Engine Control Component Description

Accelerator Pedal Position (APP) Sensor & Idle

Switch

RTW 66ESH001301

The accelerator pedal position (APP) sensor is mounted

on the throttle assembly. The engine control module

(ECM) uses the APP sensor s to determine the amount

of acceleration or deceleration desired by the person

driving the vehicle via the fuel injection control.

The idle switch is also mounted on the intake throttle

assembly. The idle switch is part of the APP senso

r

assembly. The idle switch is a normally closed type

switch. W hen the accelerator pedal is released, the idle

switch signal to the ECM is low voltage.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1319 of 6020

Engine Control System (4JH1) 6E-285

Crankshaft Position (CKP) Sensor

RTW 06ESH000101

RTW 66ESH001401

Legend

1. Crankshaft Position (CKP) Sensor

2. Flywheel

3. Slit

The crankshaft position (CKP) sensor is located on top

of the flywheel housing. There are 4 slits spaced 90 °

on the flywheel circumference. The CKP sensor is a

magnetic coil type sensor , which generates an AC

signal voltage based on the crankshaft rotational speed.

The ECM monitors both the CKP sensor and injection

pump camshaft position (CMP) sensor signals to

ensure they correlate with each other.

The following waveform aids to diagnose when there is

an oscilloscope or equivalent.

Engine Coolant Temperature (ECT) Sensor

- Amplitudes of CKP sensor signal (CH1) increase as engine speed increases.

- Each waveform cycle shorten as the engine speed increases.

Terminal: 90 (CH1), 91 (CH2) (+) / GND (-)

Scale: 10V/div 2ms/div

Condition: Approximately 1000RPM

CH1

0V

CH2 0V

RTW 66ESH001501

Legend

1. Engine Coolant Temperature (ECT) Sensor

The engine coolant temperature (ECT) sensor is

installed to the thermostat housing. The ECT sensor is

a variable resistor. The ECT sensor measures the

temperature of the engine coolant. The engine control

module (ECM) supplies 5 volts to the ECT signal circuit

and a ground for the ECT low reference circuit. W hen

the ECT sensor is cold, the sensor resistance is high.

W hen the engine coolant temperature increases, the

sensor resistance decreases. W ith high senso

r

resistance, the ECM detects a high voltage on the ECT

signal circuit. W ith lower sensor resistance, the ECM

detects a lower voltage on the ECT signal circuit.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1320 of 6020

6E-286 Engine Control System (4JH1)

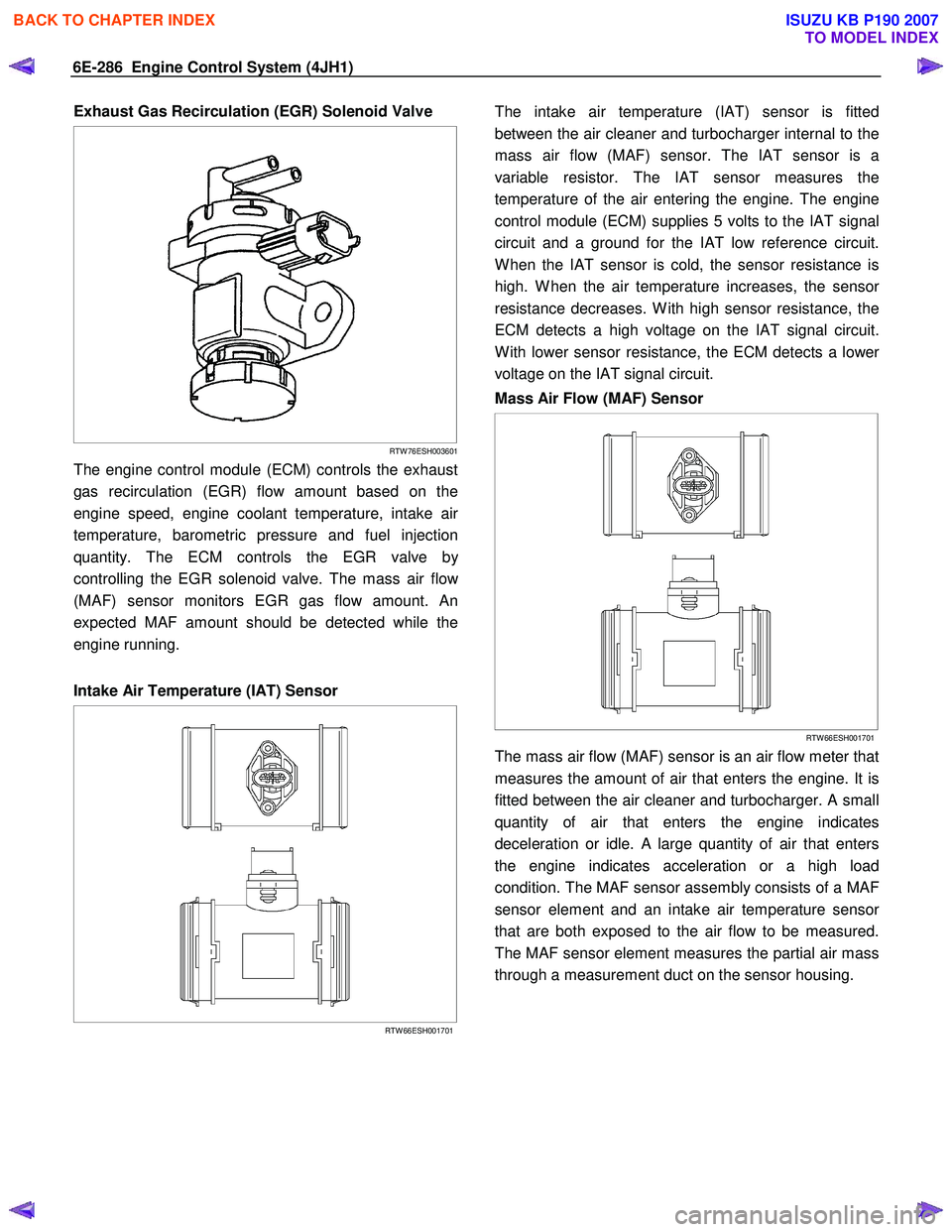

Exhaust Gas Recirculation (EGR) Solenoid Valve

RTW 76ESH003601

The engine control module (ECM) controls the exhaust

gas recirculation (EGR) flow amount based on the

engine speed, engine coolant temperature, intake ai

r

temperature, barometric pressure and fuel injection

quantity. The ECM controls the EGR valve b

y

controlling the EGR solenoid valve. The mass air flo

w

(MAF) sensor monitors EGR gas flow amount. An

expected MAF amount should be detected while the

engine running.

Intake Air Temperature (IAT) Sensor

RTW 66ESH001701

The intake air temperature (IAT) sensor is fitted

between the air cleaner and turbocharger internal to the

mass air flow (MAF) sensor. The IAT sensor is a

variable resistor. The IAT sensor measures the

temperature of the air entering the engine. The engine

control module (ECM) supplies 5 volts to the IAT signal

circuit and a ground for the IAT low reference circuit.

W hen the IAT sensor is cold, the sensor resistance is

high. W hen the air temperature increases, the senso

r

resistance decreases. W ith high sensor resistance, the

ECM detects a high voltage on the IAT signal circuit.

W ith lower sensor resistance, the ECM detects a lowe

r

voltage on the IAT signal circuit.

Mass Air Flow (MAF) Sensor

RTW 66ESH001701

The mass air flow (MAF) sensor is an air flow meter that

measures the amount of air that enters the engine. It is

fitted between the air cleaner and turbocharger. A small

quantity of air that enters the engine indicates

deceleration or idle. A large quantity of air that enters

the engine indicates acceleration or a high load

condition. The MAF sensor assembly consists of a MAF

sensor element and an intake air temperature senso

r

that are both exposed to the air flow to be measured.

The MAF sensor element measures the partial air mass

through a measurement duct on the sensor housing.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1321 of 6020

Engine Control System (4JH1) 6E-287

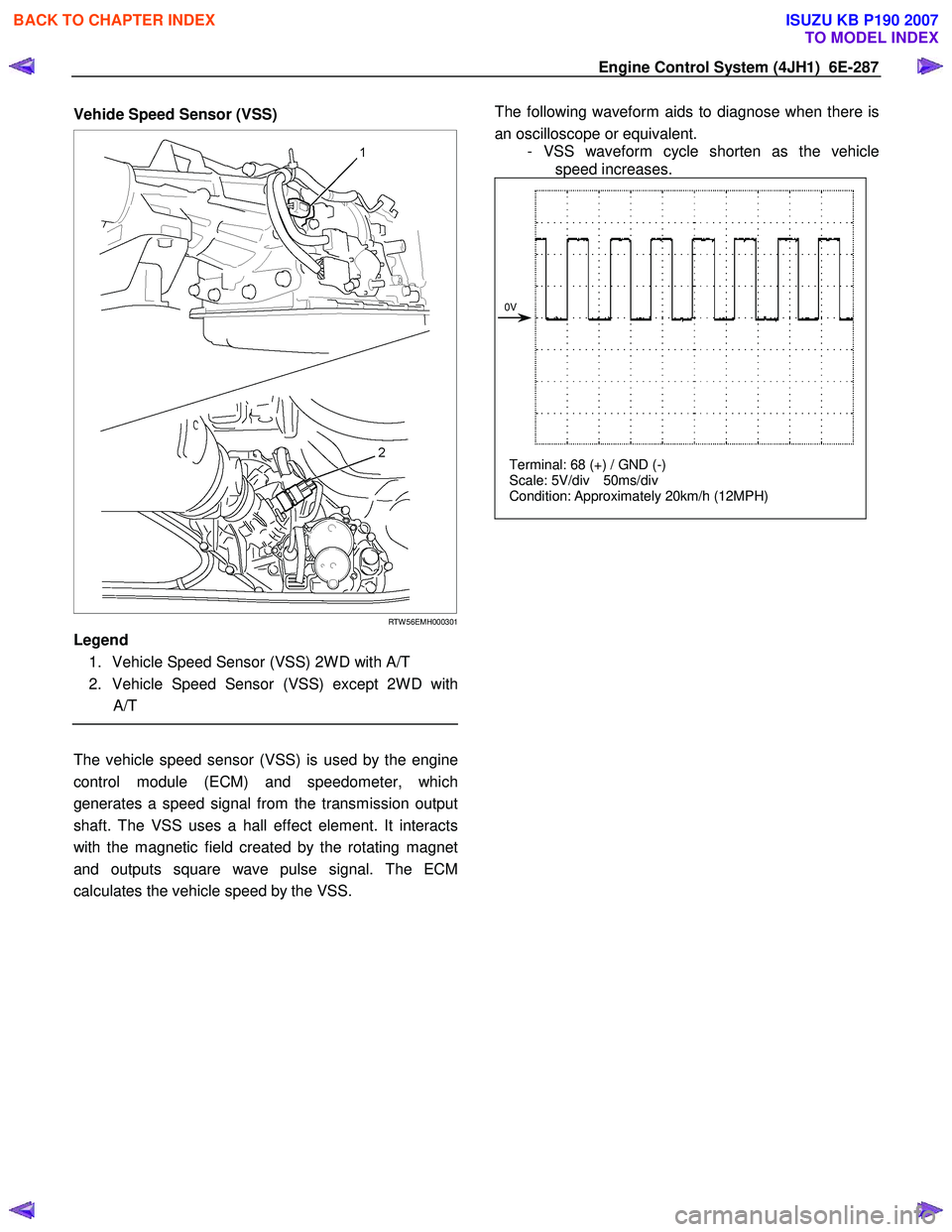

Vehide Speed Sensor (VSS)

RTW 56EMH000301

Legend

1. Vehicle Speed Sensor (VSS) 2W D with A/T

2. Vehicle Speed Sensor (VSS) except 2W D with A/T

The vehicle speed sensor (VSS) is used by the engine

control module (ECM) and speedometer, which

generates a speed signal from the transmission output

shaft. The VSS uses a hall effect element. It interacts

with the magnetic field created by the rotating magnet

and outputs square wave pulse signal. The ECM

calculates the vehicle speed by the VSS.

The following waveform aids to diagnose when there is

an oscilloscope or equivalent. - VSS waveform cycle shorten as the vehicle speed increases.

Terminal: 68 (+) / GND (-)

Scale: 5V/div 50ms/div

Condition: Approximately 20km/h (12MPH)

0V

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1322 of 6020

6E-288 Engine Control System (4JH1)

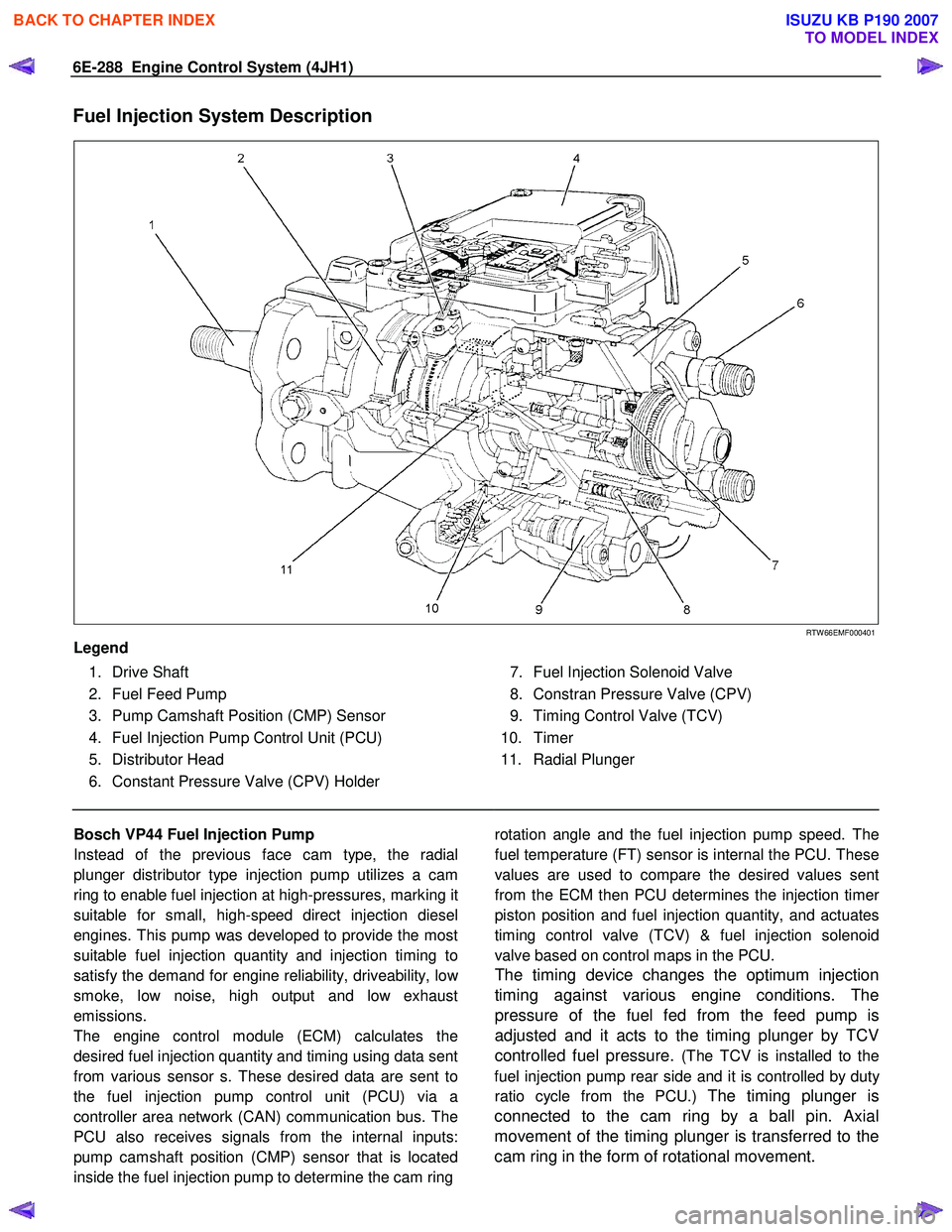

Fuel Injection System Description

RTW 66EMF000401

Legend

1. Drive Shaft

2. Fuel Feed Pump

3. Pump Camshaft Position (CMP) Sensor

4. Fuel Injection Pump Control Unit (PCU)

5. Distributor Head

6. Constant Pressure Valve (CPV) Holder

7. Fuel Injection Solenoid Valve

8. Constran Pressure Valve (CPV)

9. Timing Control Valve (TCV)

10. Timer

11. Radial Plunger

Bosch VP44 Fuel Injection Pump

Instead of the previous face cam type, the radial

plunger distributor type injection pump utilizes a cam

ring to enable fuel injection at high-pressures, marking it

suitable for small, high-speed direct injection diesel

engines. This pump was developed to provide the most

suitable fuel injection quantity and injection timing to

satisfy the demand for engine reliability, driveability, lo

w

smoke, low noise, high output and low exhaust

emissions.

The engine control module (ECM) calculates the

desired fuel injection quantity and timing using data sent

from various sensor s. These desired data are sent to

the fuel injection pump control unit (PCU) via a

controller area network (CAN) communication bus. The

PCU also receives signals from the internal inputs:

pump camshaft position (CMP) sensor that is located

inside the fuel injection pump to determine the cam ring rotation angle and the fuel injection pump speed. The

fuel temperature (FT) sensor is internal the PCU. These

values are used to compare the desired values sent

from the ECM then PCU determines the injection time

r

piston position and fuel injection quantity, and actuates

timing control valve (TCV) & fuel injection solenoid

valve based on control maps in the PCU.

The timing device changes the optimum injection

timing against various engine conditions. The

pressure of the fuel fed from the feed pump is

adjusted and it acts to the timing plunger by TCV

controlled fuel pressure.

(The TCV is installed to the

fuel injection pump rear side and it is controlled by dut

y

ratio cycle from the PCU.) The timing plunger is

connected to the cam ring by a ball pin. Axial

movement of the timing plunger is transferred to the

cam ring in the form of rotational movement.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1323 of 6020

Engine Control System (4JH1) 6E-289

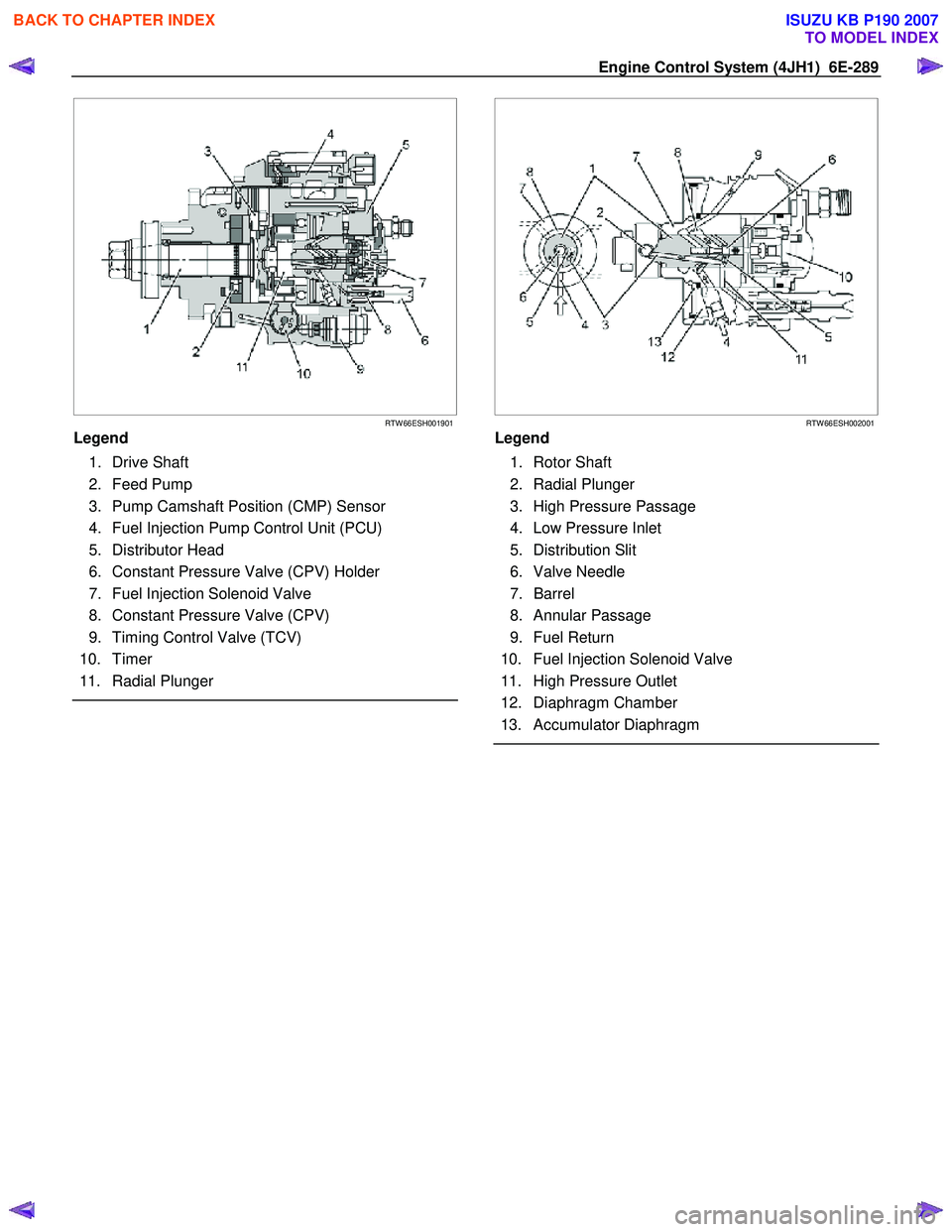

RTW 66ESH001901

Legend

1. Drive Shaft

2. Feed Pump

3. Pump Camshaft Position (CMP) Sensor

4. Fuel Injection Pump Control Unit (PCU)

5. Distributor Head

6. Constant Pressure Valve (CPV) Holder

7. Fuel Injection Solenoid Valve

8. Constant Pressure Valve (CPV)

9. Timing Control Valve (TCV)

10. Timer

11. Radial Plunger

RTW 66ESH002001

Legend

1. Rotor Shaft

2. Radial Plunger

3. High Pressure Passage

4. Low Pressure Inlet

5. Distribution Slit

6. Valve Needle

7. Barrel

8. Annular Passage

9. Fuel Return

10. Fuel Injection Solenoid Valve

11. High Pressure Outlet

12. Diaphragm Chamber

13. Accumulator Diaphragm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1324 of 6020

6E-290 Engine Control System (4JH1)

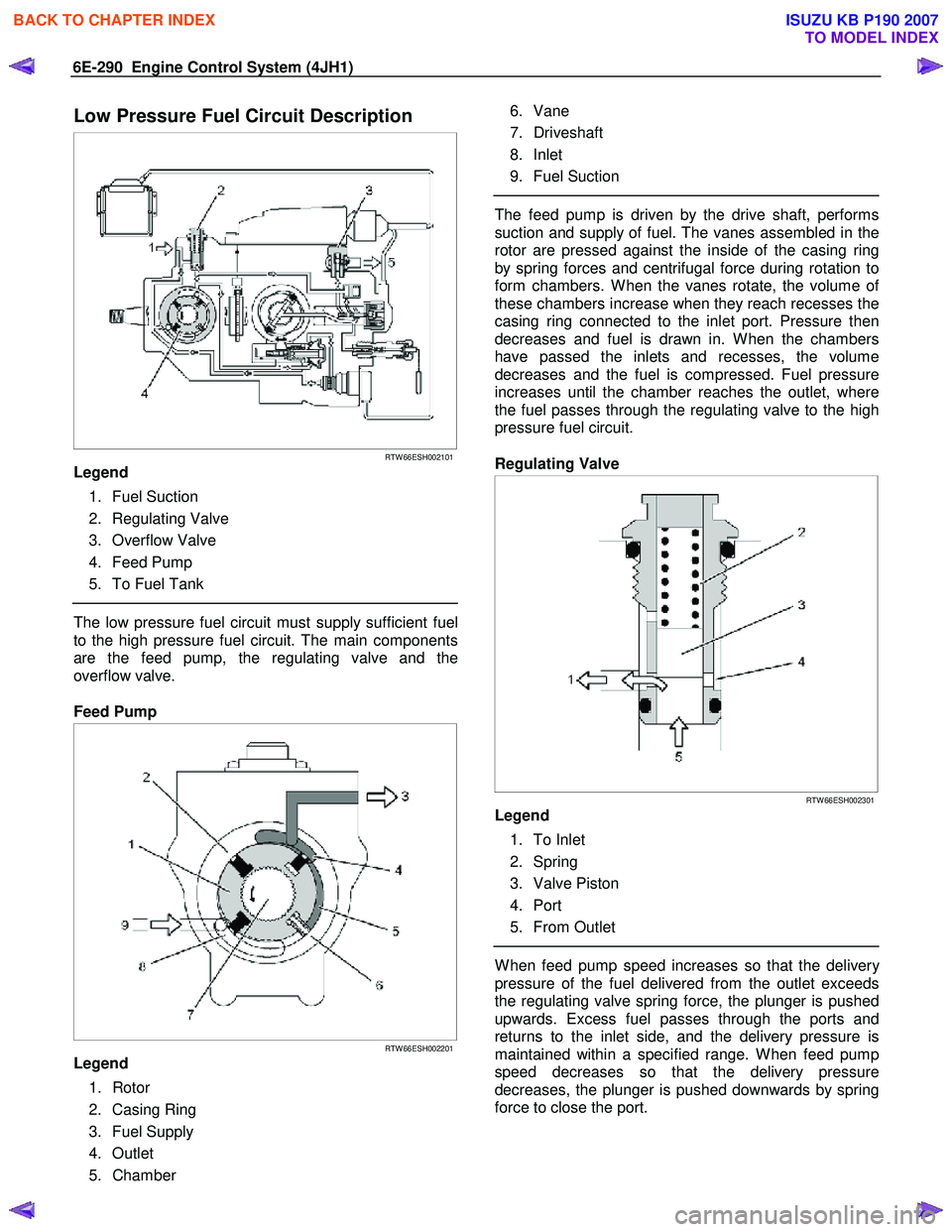

Low Pressure Fuel Circuit Description

RTW 66ESH002101

Legend

1. Fuel Suction

2. Regulating Valve

3. Overflow Valve

4. Feed Pump

5. To Fuel Tank

The low pressure fuel circuit must supply sufficient fuel

to the high pressure fuel circuit. The main components

are the feed pump, the regulating valve and the

overflow valve.

Feed Pump

RTW 66ESH002201

Legend

1. Rotor

2. Casing Ring

3. Fuel Supply

4. Outlet

5. Chamber

6. Vane

7. Driveshaft

8. Inlet

9. Fuel Suction

The feed pump is driven by the drive shaft, performs

suction and supply of fuel. The vanes assembled in the

rotor are pressed against the inside of the casing ring

by spring forces and centrifugal force during rotation to

form chambers. W hen the vanes rotate, the volume o

f

these chambers increase when they reach recesses the

casing ring connected to the inlet port. Pressure then

decreases and fuel is drawn in. W hen the chambers

have passed the inlets and recesses, the volume

decreases and the fuel is compressed. Fuel pressure

increases until the chamber reaches the outlet, where

the fuel passes through the regulating valve to the high

pressure fuel circuit.

Regulating Valve

RTW 66ESH002301

Legend

1. To Inlet

2. Spring

3. Valve Piston

4. Port

5. From Outlet

W hen feed pump speed increases so that the delivery

pressure of the fuel delivered from the outlet exceeds

the regulating valve spring force, the plunger is pushed

upwards. Excess fuel passes through the ports and

returns to the inlet side, and the delivery pressure is

maintained within a specified range. W hen feed pump

speed decreases so that the delivery pressure

decreases, the plunger is pushed downwards by spring

force to close the port.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1325 of 6020

Engine Control System (4JH1) 6E-291

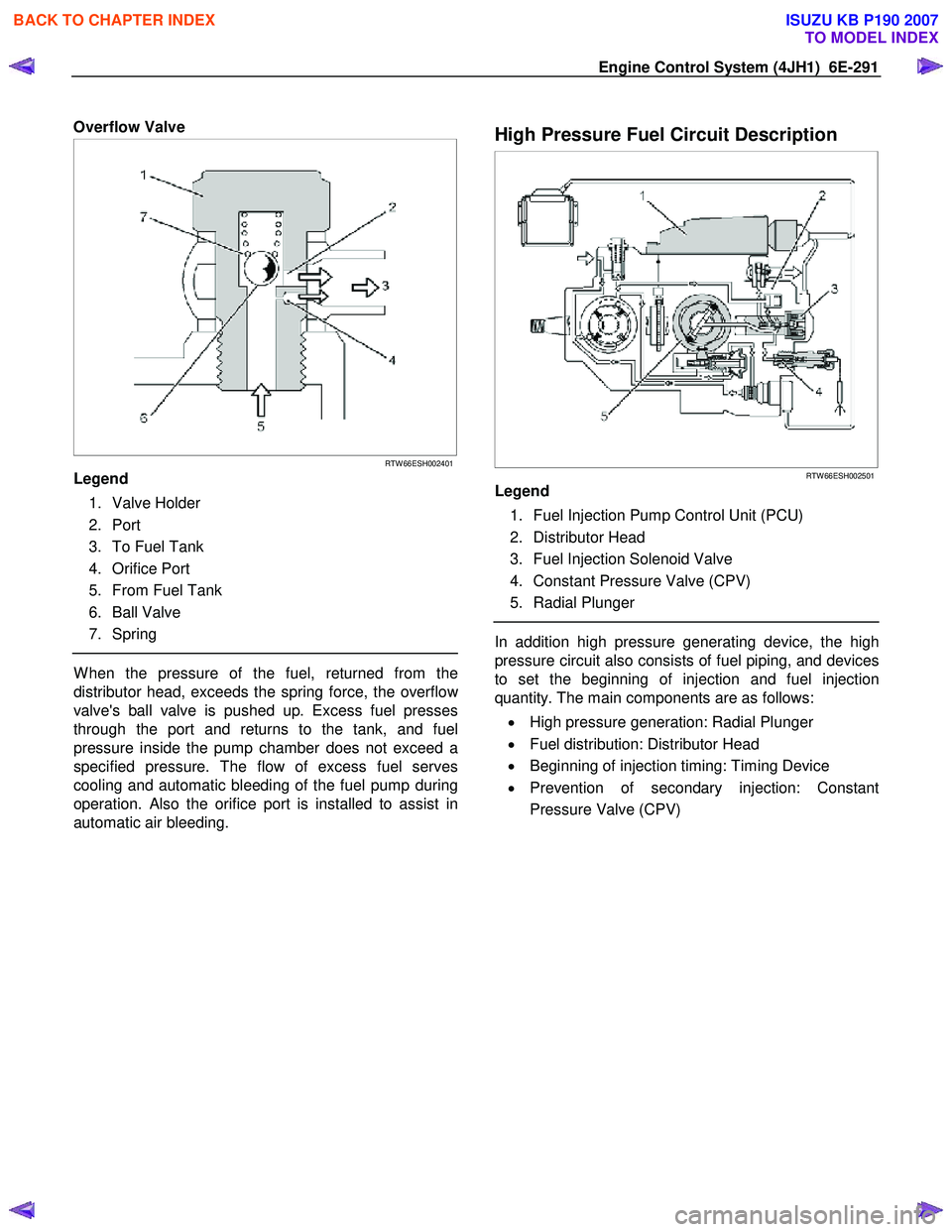

Overflow Valve

RTW 66ESH002401

Legend

1. Valve Holder

2. Port

3. To Fuel Tank

4. Orifice Port

5. From Fuel Tank

6. Ball Valve

7. Spring

W hen the pressure of the fuel, returned from the

distributor head, exceeds the spring force, the overflo

w

valve's ball valve is pushed up. Excess fuel presses

through the port and returns to the tank, and fuel

pressure inside the pump chamber does not exceed a

specified pressure. The flow of excess fuel serves

cooling and automatic bleeding of the fuel pump during

operation. Also the orifice port is installed to assist in

automatic air bleeding.

High Pressure Fuel Circuit Description

RTW 66ESH002501

Legend

1. Fuel Injection Pump Control Unit (PCU)

2. Distributor Head

3. Fuel Injection Solenoid Valve

4. Constant Pressure Valve (CPV)

5. Radial Plunger

In addition high pressure generating device, the high

pressure circuit also consists of fuel piping, and devices

to set the beginning of injection and fuel injection

quantity. The main components are as follows:

• High pressure generation: Radial Plunger

• Fuel distribution: Distributor Head

• Beginning of injection timing: Timing Device

• Prevention of secondary injection: Constant

Pressure Valve (CPV)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1326 of 6020

6E-292 Engine Control System (4JH1)

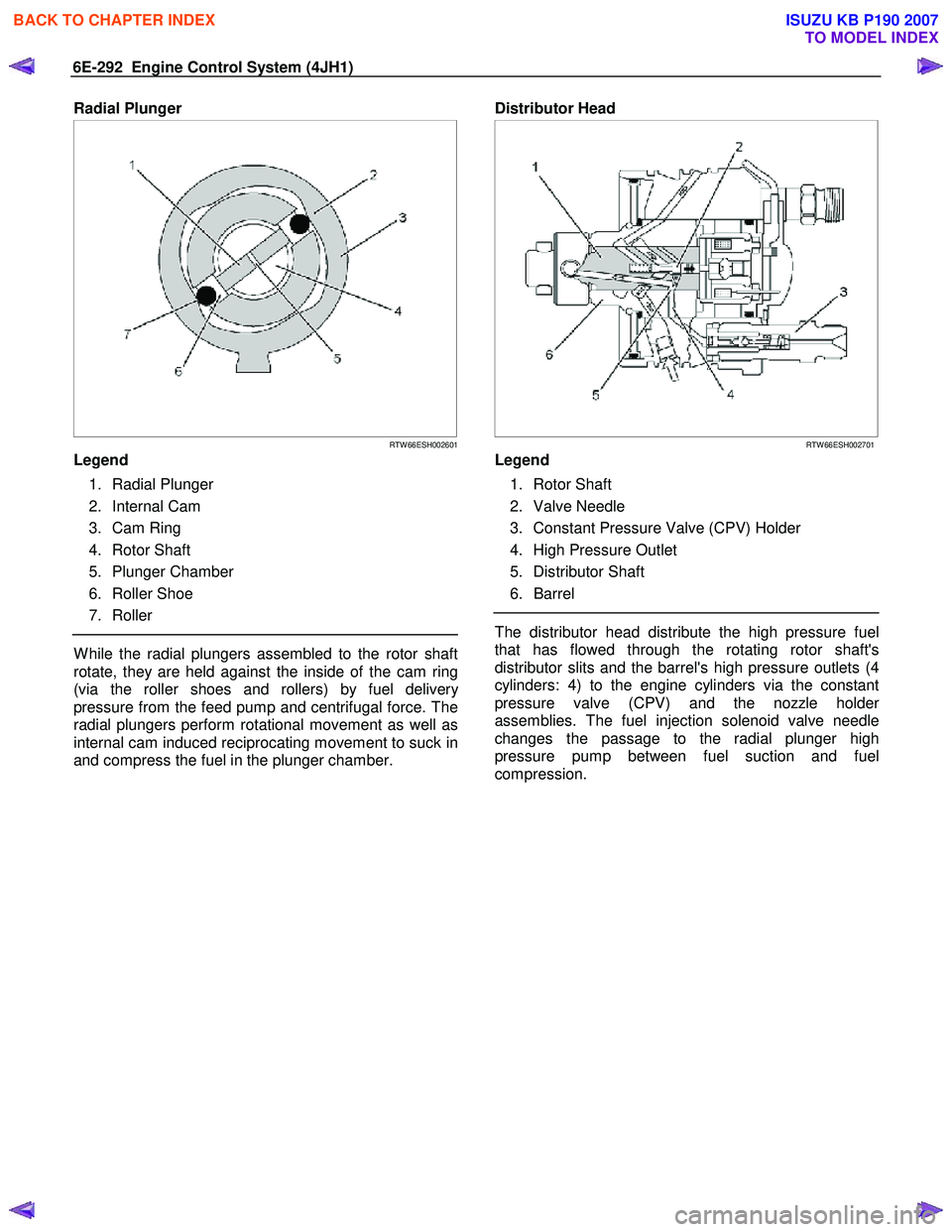

Radial Plunger

RTW 66ESH002601

Legend

1. Radial Plunger

2. Internal Cam

3. Cam Ring

4. Rotor Shaft

5. Plunger Chamber

6. Roller Shoe

7. Roller

W hile the radial plungers assembled to the rotor shaft

rotate, they are held against the inside of the cam ring

(via the roller shoes and rollers) by fuel deliver

y

pressure from the feed pump and centrifugal force. The

radial plungers perform rotational movement as well as

internal cam induced reciprocating movement to suck in

and compress the fuel in the plunger chamber.

Distributor Head

RTW 66ESH002701

Legend

1. Rotor Shaft

2. Valve Needle

3. Constant Pressure Valve (CPV) Holder

4. High Pressure Outlet

5. Distributor Shaft

6. Barrel

The distributor head distribute the high pressure fuel

that has flowed through the rotating rotor shaft's

distributor slits and the barrel's high pressure outlets (4

cylinders: 4) to the engine cylinders via the constant

pressure valve (CPV) and the nozzle holde

r

assemblies. The fuel injection solenoid valve needle

changes the passage to the radial plunger high

pressure pump between fuel suction and fuel

compression.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1327 of 6020

Engine Control System (4JH1) 6E-293

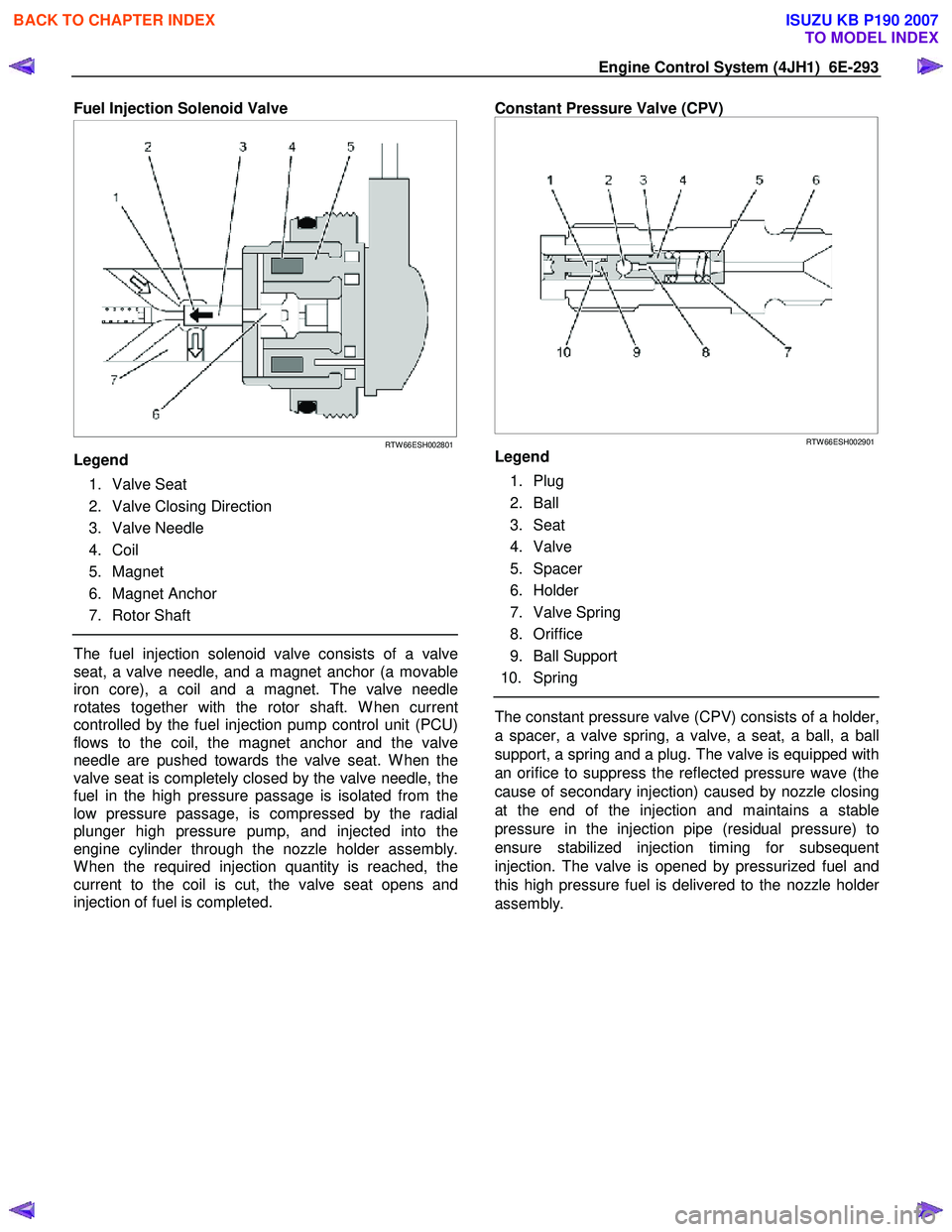

Fuel Injection Solenoid Valve

RTW 66ESH002801

Legend

1. Valve Seat

2. Valve Closing Direction

3. Valve Needle

4. Coil

5. Magnet

6. Magnet Anchor

7. Rotor Shaft

The fuel injection solenoid valve consists of a valve

seat, a valve needle, and a magnet anchor (a movable

iron core), a coil and a magnet. The valve needle

rotates together with the rotor shaft. W hen current

controlled by the fuel injection pump control unit (PCU)

flows to the coil, the magnet anchor and the valve

needle are pushed towards the valve seat. W hen the

valve seat is completely closed by the valve needle, the

fuel in the high pressure passage is isolated from the

low pressure passage, is compressed by the radial

plunger high pressure pump, and injected into the

engine cylinder through the nozzle holder assembly.

W hen the required injection quantity is reached, the

current to the coil is cut, the valve seat opens and

injection of fuel is completed.

Constant Pressure Valve (CPV)

RTW 66ESH002901

Legend

1. Plug

2. Ball

3. Seat

4. Valve

5. Spacer

6. Holder

7. Valve Spring

8. Oriffice

9. Ball Support

10. Spring

The constant pressure valve (CPV) consists of a holder,

a spacer, a valve spring, a valve, a seat, a ball, a ball

support, a spring and a plug. The valve is equipped with

an orifice to suppress the reflected pressure wave (the

cause of secondary injection) caused by nozzle closing

at the end of the injection and maintains a stable

pressure in the injection pipe (residual pressure) to

ensure stabilized injection timing for subsequent

injection. The valve is opened by pressurized fuel and

this high pressure fuel is delivered to the nozzle holde

r

assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007