bulb ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 5307 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-369

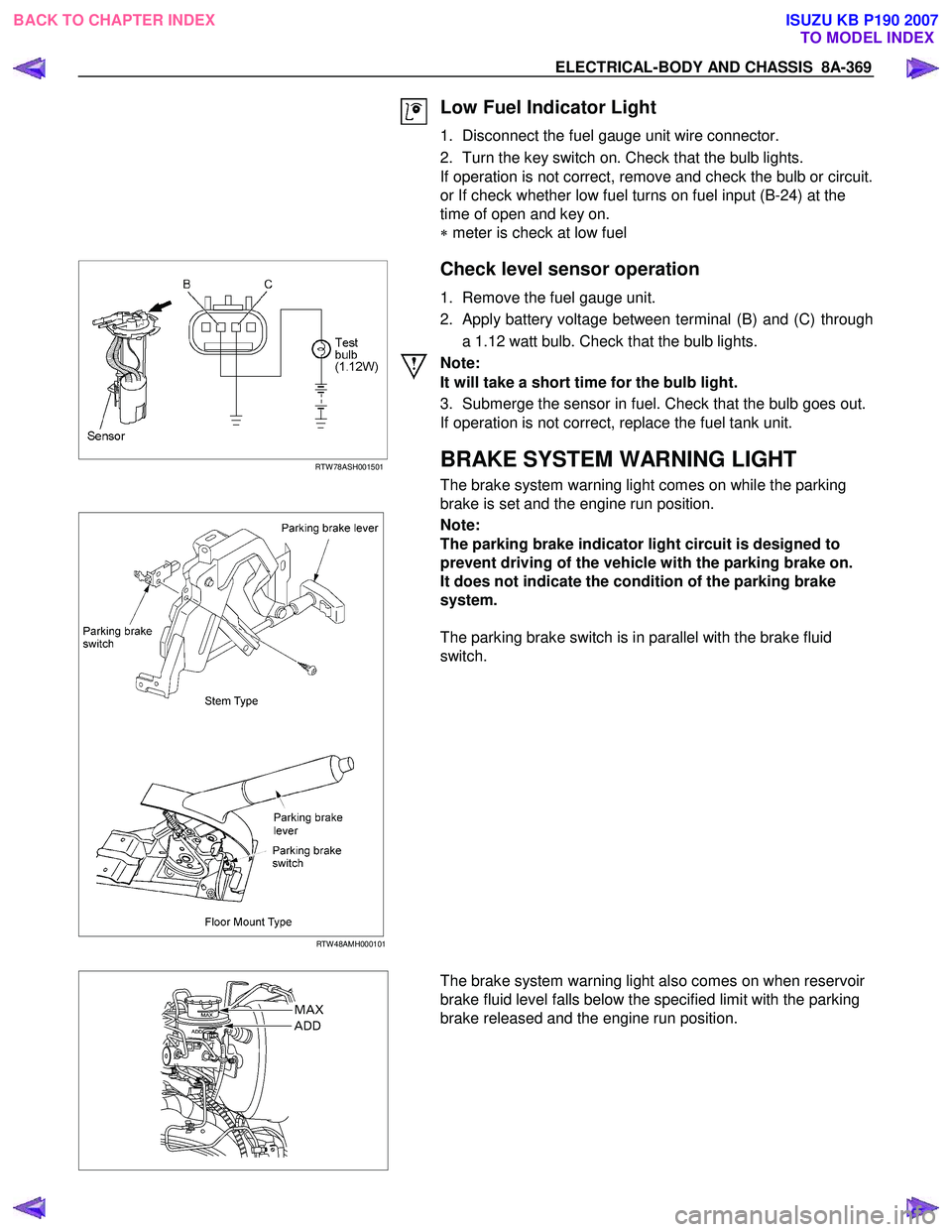

Low Fuel Indicator Light

1. Disconnect the fuel gauge unit wire connector.

2. Turn the key switch on. Check that the bulb lights.

If operation is not correct, remove and check the bulb or circuit.

or If check whether low fuel turns on fuel input (B-24) at the

time of open and key on.

∗ meter is check at low fuel

RTW 78ASH001501

Check level sensor operation

1. Remove the fuel gauge unit.

2. Apply battery voltage between terminal (B) and (C) through a 1.12 watt bulb. Check that the bulb lights.

Note:

It will take a short time for the bulb light.

3. Submerge the sensor in fuel. Check that the bulb goes out.

If operation is not correct, replace the fuel tank unit.

BRAKE SYSTEM WARNING LIGHT

The brake system warning light comes on while the parking

brake is set and the engine run position.

RTW 48AMH000101

Note:

The parking brake indicator light circuit is designed to

prevent driving of the vehicle with the parking brake on.

It does not indicate the condition of the parking brake

system.

The parking brake switch is in parallel with the brake fluid

switch.

The brake system warning light also comes on when reservoir

brake fluid level falls below the specified limit with the parking

brake released and the engine run position.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5651 of 6020

9A-16 SUPPLEMENTAL RESTRAINT SYSTEM

RTW 79ASH000201

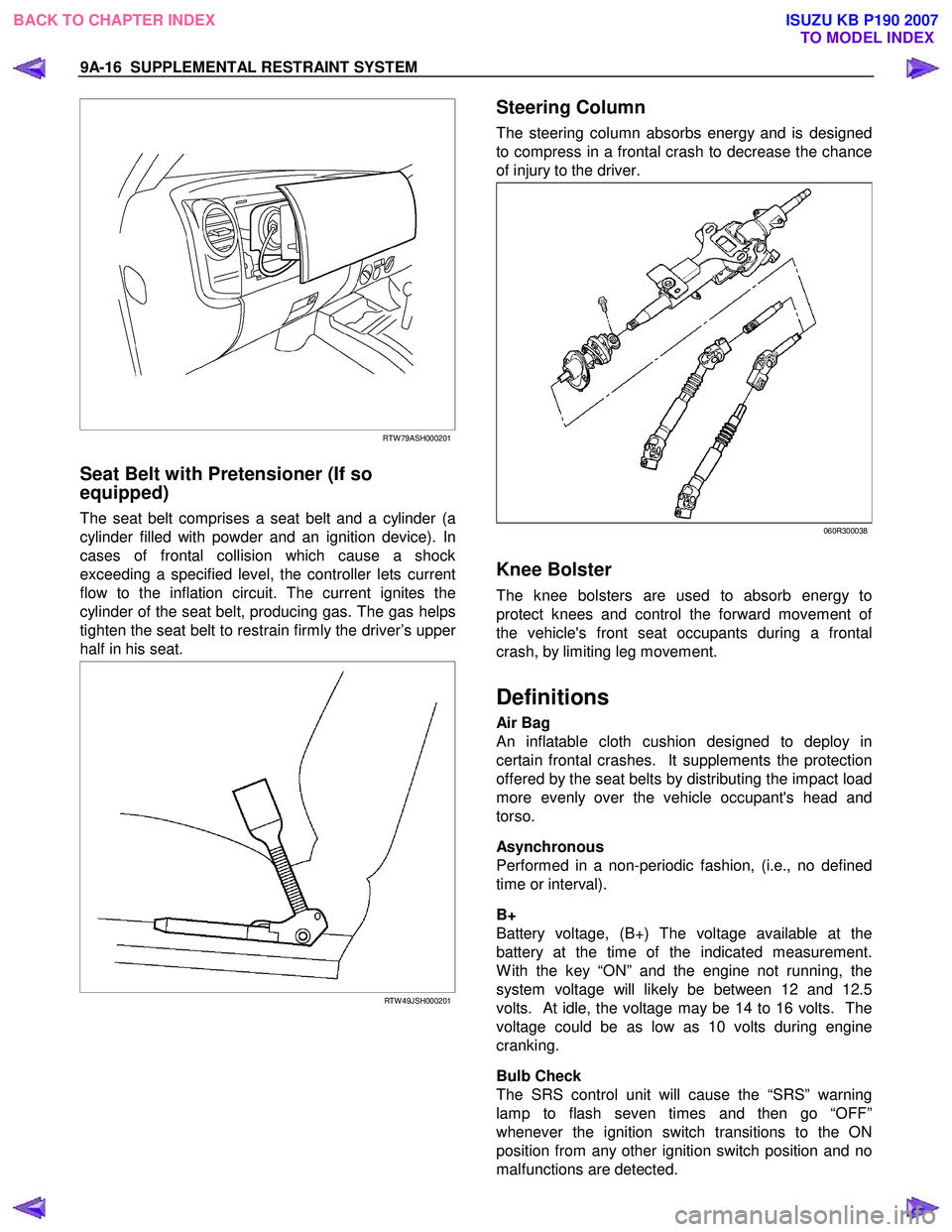

Seat Belt with Pretensioner (If so

equipped)

The seat belt comprises a seat belt and a cylinder (a

cylinder filled with powder and an ignition device). In

cases of frontal collision which cause a shock

exceeding a specified level, the controller lets current

flow to the inflation circuit. The current ignites the

cylinder of the seat belt, producing gas. The gas helps

tighten the seat belt to restrain firmly the driver’s uppe

r

half in his seat.

RTW 49JSH000201

Steering Column

The steering column absorbs energy and is designed

to compress in a frontal crash to decrease the chance

of injury to the driver.

060R300038

Knee Bolster

The knee bolsters are used to absorb energy to

protect knees and control the forward movement o

f

the vehicle's front seat occupants during a frontal

crash, by limiting leg movement.

Definitions

Air Bag

An inflatable cloth cushion designed to deploy in

certain frontal crashes. It supplements the protection

offered by the seat belts by distributing the impact load

more evenly over the vehicle occupant's head and

torso.

Asynchronous

Performed in a non-periodic fashion, (i.e., no defined

time or interval).

B+

Battery voltage, (B+) The voltage available at the

battery at the time of the indicated measurement.

W ith the key “ON” and the engine not running, the

system voltage will likely be between 12 and 12.5

volts. At idle, the voltage may be 14 to 16 volts. The

voltage could be as low as 10 volts during engine

cranking.

Bulb Check

The SRS control unit will cause the “SRS” warning

lamp to flash seven times and then go “OFF”

whenever the ignition switch transitions to the ON

position from any other ignition switch position and no

malfunctions are detected.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5697 of 6020

RESTRAINT CONTROL SYSTEM 9A1-15

Chart C “SRS” Warning Lamp Does Not Come “ON” Steady

Step Action Yes No

1

1. W hen measurements are requested in this chart, use a 5-

8840-0366-0DMM with a correct terminal adapter from 5-

8840-0385-0.

2. Ignition switch is at “LOCK”.

3. Remove and inspect the “METER” fuse to the “SRS” warning lamp.

Is the fuse good? Go to Step 2 Go to Step 7

2

1. Ignition switch is at “LOCK”.

2. Disconnect the SRS coil and passenger air bag assembly

yellow connector which is located at the base of the steering

column and behind the glove box assembly.

3. Disconnect the SRS control unit.

4. Ignition switch is “ON”.

5. Measure the voltage on the SRS control unit harness connector from the terminal “4” to terminal “3” (ground).

Is system voltage present on terminal “4”? Go to Step 4 Go to Step 3

3

1. Ignition switch is at “LOCK”.

2. Remove instrument meter cluster.

3. Check for proper connection to instrument cluster at the SRS warning lamp circuit terminal.

4. If ok, then remove and inspect the “AIR BAG” bulb.

Is the bulb good? Go to Step 5 Replace bulb.

Go to Step 6

4

1. Ignition switch is at “LOCK”.

2. Disconnect instrument meter cluster harness connector.

3. Ignition switch is “ON”.

4. Measure the voltage on the SRS control unit harness

connector from terminal “4” to terminal “3” (ground).

Is the voltage 1 volt or less? Go to Chart A Replace SRS

harness.

Go to Step 6

5

1. Install the bulb.

2. Measure the resistance from the instrument meter cluster

harness connector SRS warning lamp circuit terminal to the

SRS control unit harness connector terminal “4”.

Is the resistance 5.0 ohms or less? Service instrument

meter cluster.

Install instrument meter cluster. Go to Step 6 Replace SRS

harness.

Go to Step 6

6 Reconnect all SRS components and ensure all components are

properly mounted.

Is this step finished? Repeat the “SRS

Diagnostic System Check” Go to Step 6

7

Perform chart C.

Is this step finished? Go to Step 8 Go to Step 1

8

1. Replace the “METER” fuse.

2. Ignition switch is “ON”. W ait 10 Seconds then ignition switch

is at “LOCK”.

3. Remove and inspect the “METER” fuse.

Is the fuse good? Install “METER”

fuse.

Go to Step 10 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5700 of 6020

9A1-18 RESTRAINT CONTROL SYSTEM

DTC Will Clear When

Resistance value returns specified resistance value.

DTC Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SRS control unit.

3. This test verifies proper connection of the yello

w

connector.

4. This test checks for proper contact and/or corrosion

of the yellow connector terminals.

5. This test checks for a malfunctioning passenger ai

r

bag assembly.

6. This test determines whether the malfunction is due

to a high resistance in the wiring.

Diagnostic Aids

An intermittent condition is likely to be caused by a poor

connection at the passenger air bag assembly harness

connector terminals “1” and “2”, SRS control unit

terminal “17” and “16”, or a poor wire to terminal

connection in circuits “Passenger Bag High” and

“Passenger Bag Low”. The test for this diagnostic

trouble code is only run while the “SRS” warning lamp is

performing the bulb check. W hen the scan tool “Clea

r

Codes” command is issued and the malfunction is still

present, the DTC will not reappear until the next ignition

cycle.

DTC B0015 (Flash Code 15) Passenger Air Bag Squib Circuit High Resistance

Step Action Yes No

1 W as the “SRS Diagnostic System Check” Performed?

Go to Step 2 Go to The “SRS

Diagnostic System Check”

2

1. Check the passenger air bag squib circuit for open.

2. If a problem is found, repair as necessary.

W as a problem found? Verify repair Go to Step 3

3

1. Ignition switch is at “LOCK”.

2. Make sure the passenger air bag assembly yellow connector

located behind the glove box assembly is seated properly.

Is the yellow connector connected properly? Go to Step 4 Seat passenger Air

Bag assembly

yellow connector properly.

Go to Step 7

4

1. Disconnect and inspect the passenger air bag assembly

yellow connector located behind the glove box assembly.

2. If OK, reconnect the passenger air bag assembly connector.

3. Ignition switch is “ON”.

Is DTC B0015 current? Go to Step 5 Go to Step 7

5

1. Ignition switch is at “LOCK”.

2. Disconnect the SRS coil and passenger air bag assembly,

yellow connector located at the base of the steering column

and behind the glove box assembly.

3. Connect a 5-8840-2421-0 SRS driver / passenger load tool

and appropriate adapters to the SRS coil and passenger air

bag assembly harness connectors.

4. Ignition switch is “ON”.

Is DTC B0015 Current? Go to Step 6 Ignition switch

“LOCK”.

Replace the

passenger air bag assembly.

Go to Step 7

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5703 of 6020

RESTRAINT CONTROL SYSTEM 9A1-21

DTC Will Clear When

Resistance value returns to specified resistance value.

DTC Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SRS control unit.

3. This test verifies connection of the yellow connector.

4. This test checks for proper operation of the shorting

clip on the yellow connector.

5. This test checks for a malfunctioning passenger ai

r

bag assembly.

6. This test determines whether the malfunction is due

to shortening in the wiring.

Diagnostic Aids

An intermittent condition is likely to be caused by a short

between circuits “Passenger Bag High” and “Passenge

r

Bag Low” or a malfunctioning shorting clip on the

passenger air bag assembly which would require

replacement of the air bag assembly. The test for this

diagnostic trouble code is only run while the “SRS”

warning lamp is performing the bulb check. W hen the

scan tool “Clear Codes” command is issued and the

malfunction is still present, the DTC will not reappea

r

until the next ignition cycle.

DTC B0016 (Flash Code 16) Passenger Air Bag Squib Circuit Low Resistance

Step Action Yes No

1 W as the “SRS Diagnostic System Check” performed?

Go to Step 2 Repeat the “SRS

Diagnostic System Check”

2

1. Check the passenger air bag squib circuit for short to voltage

or short to ground.

2. If a problem is found, repair as necessary.

W as a problem found? Verify repair Go to Step 3

3

1. Ignition switch is at “LOCK”.

2. Make sure the passenger air bag assembly yellow connector

located behind the glove box assembly is seated properly.

Is the yellow connector connected properly? Go to Step 4 Seat passenger air

bag assembly

yellow connector properly.

Go to Step 7

4

1. Disconnect and inspect the passenger air bag assembly

yellow connector located behind the glove box assembly.

2. If ok, reconnect the passenger air bag assembly connector.

3. Ignition switch is “ON”.

Is DTC B0016 Current? Go to Step 5 Go to Step 7

5

1. Ignition switch is at “LOCK”.

2. Disconnect the SRS coil and passenger air bag assembly

yellow connector located at the base of the steering column

and behind the glove box assembly.

3. Connect 5-8840-2421-0 SRS driver/passenger load tool and

appropriate adapters to the SRS coil and the passenger air

bag assembly harness connectors.

4. Ignition switch is “ON”.

Is DTC B0016 current? Go to Step 6 Ignition switch

“LOCK”.

Replace the

passenger air bag assembly.

Go to Step 7

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5711 of 6020

RESTRAINT CONTROL SYSTEM 9A1-29

DTC Will Set When

The combined resistance of the driver air bag

assembly, the SRS Coil assembly, the harness wiring

circuits “Driver Bag High” and “Driver Bag Low”, and

connector terminal contact is above a specified value.

This test runs once for each ignition cycle during the

“Resistance Measurement Test” when:

1. No “higher priority faults” are detected during “Turn–

ON”.

2. “Ignition 1” voltage is in the specified value.

Action Taken

The SRS control unit turns “ON” the “SRS” warning

lamp and sets DTC B0021.

DTC Will Clear When

Resistance value returns to specified resistance value.

DTC Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SRS control unit.

3. This test verifies proper connection of the yello

w

connector at the base of the steering column.

4. This test checks for proper contact and/or corrosion

of the connector terminals at the base of the steering

column.

5. This test isolates the malfunction to one side of the

SRS coil assembly yellow connector located at the

base of the steering column.

6. This test determines whether the malfunction is due

to high resistance in the wiring.

7. This test determines whether the malfunction is in

the SRS coil assembly or the driver air bag

assembly.

Diagnostic Aids

An intermittent condition is likely to be caused by a poor

connection at terminals “1” and “2” of the SRS coil

connector at the base of the steering column, terminal

“1” and “2” of the driver air bag assembly connector at

the top of the steering column, the SRS control unit

terminals “14” and “13” or a poor wire to terminal

connection in circuit “Driver Bag High” or “Driver Bag

Low” The test for this diagnostic trouble code is only run

while the “SRS” warning lamp is performing the bulb

check. W hen a scan tool “Clear Codes” command is

issued and the malfunction is still present, the DTC will

not reappear until the next ignition cycle.

DTC B0021 (Flash Code 21) Driver Air Bag Squib Circuit High Resistance

Step Action Yes No

1 Perform the “SRS Diagnostic System Check”.

W as the “SRS Diagnostic System Check” performed? Go to Step 2 Repeat the “SRS

Diagnostic System Check”

2

1. Check the driver air bag squib circuit for open.

2. If a the problem is found, repair as necessary.

W as a problem found? Verify repair Go to Step 3

3

1. Ignition switch to “LOCK”.

2. Disconnect the SRS coil assembly yellow connector located

at the base of the steering column and check it is seated

properly.

Is the connector connected properly? Go to Step 4 Seat SRS coil

assembly

connector properly. Go to Step 8

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5714 of 6020

9A1-32 RESTRAINT CONTROL SYSTEM

DTC Will Set When

The combined resistance of the driver air bag

assembly, SRS Coil assembly, harness wiring circuits

“Driver Bag High” and “Driver Bag Low”, and connecto

r

terminal contact is above a specified value. This test is

run once for each ignition cycle during the “Resistance

Measurement Test” when:

1. No “higher priority faults” are detected during “Turn–

ON”

2. “Ignition 1” voltage is in the specified value.

Action Taken

The SRS control unit turns “ON” the “SRS” warning

lamp and sets DTC B0022.

DTC Will Clear When

Resistance value returns to specified resistance value.

DTC Chart Test Description

Number(s) below refer to circled number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SRS control unit.

3. This test verifies proper connection of the yello

w

connector at the base of the steering column.

4. This test checks for proper operation of the shorting

clip in the yellow connector.

5. This test isolates the malfunction to one side of the

SRS coil assembly yellow connector located at the

base of the steering column.

6. This test determines whether the malfunction is due

to shortening in the wiring.

7. This test determines whether the malfunction is in

the SRS coil assembly or the driver air bag

assembly.

Diagnostic Aids

An intermittent condition is likely to be caused by a short

between circuit “Driver Bag High” or “Driver Bag Low”

and a malfunctioning shorting clip on the driver air bag

assembly or the SRS coil assembly which would require

replacement of the component. The test for this

diagnostic trouble code is only run while the “SRS”

warning lamp is performing the bulb check. W hen the

scan tool “Clear Codes” command is issued and the

malfunction is still present, the DTC will not reappea

r

until the next ignition cycle.

DTC B0022 (Flash Code 22) Driver Air Bag Squib Circuit Low Resistance

Step Action Yes No

1 Perform the “SRS Diagnostic System Check.”

W as the “SRS Diagnostic System Check” performed? Go to Step 2 Go to the “SRS

Diagnostic System Check”

2

1. Check the driver air bag squib circuit for short to voltage or

short to ground.

2. If a problem is found, repair as necessary.

W as a problem found? Verify repair Go to Step 3

3

1. Ignition switch to “LOCK”.

2. Make sure the SRS coil assembly yellow connector located at

the base of steering column is seated properly.

Is the connector connected properly? Go to Step 4 Seat driver air bag

assembly

connector properly. Go to Step 8

4

1. Disconnect and inspect the SRS coil assembly yellow

connector located at the base of the steering column.

2. If ok, reconnect the SRS coil assembly yellow connector.

3. Ignition switch is “ON”.

Is DTC B0022 current? Go to Step 5 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5723 of 6020

RESTRAINT CONTROL SYSTEM 9A1-41

DTC Will Set When

The combined resistance of the passenger air

pretensioner assembly, harness wiring circuits

“Passenger Pretensioner High” and “Passenge

r

Pretensioner Low”, and connector terminal contact is

above a specified value. This test is run once each

ignition cycle during the “Resistance Measurement

Test” when:

1. No “higher priority faults” are detected during “Turn–

ON”,

2. “Ignition 1” voltage is in the specified value.

Action Taken

SRS control unit turns “ON” the “AIR BAG” warning

lamp and sets a diagnostic trouble code.

DTC Will Clear When

The ignition switch is at “LOCK”.

DTC Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SRS control unit.

3. This test verifies proper connection of the yello

w

connector.

4. This test checks for proper contact and/or corrosion

of the yellow connector terminals.

5. The test checks for a malfunctioning passenge

r

pretensioner assembly.

6. This test determines whether the malfunction is due

to high resistance in the wiring.

Diagnostic Aids

An intermittent condition is likely to be caused by a poor

connection at the passenger pretensioner assembly

harness connector terminals “1” and “2”, SRS control

unit terminal “11” and “10”, or a poor wire to terminal

connection in circuits “Passenger Pretensioner High”

and “Passenger Pretensioner Low”. This test for this

diagnostic trouble code is only run while the “AIR BAG”

warning lamp is performing the bulb check. W hen a

scan tool “Clear Codes” command is issued and the

malfunction is still present, the DTC will not reappea

r

until the next ignition cycle.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5726 of 6020

9A1-44 RESTRAINT CONTROL SYSTEM

DTC Will Set When

The combined resistance of the passenger pretensioner

assembly, harness wiring circuits “Passsenger

Pretensioner High” and “Passenger Pretensioner Low”,

and connector terminal contact is above a specified

value. This test is run once each ignition cycle during

the “Resistance Measurement Test” when:

1. No “higher priority faults” are detected during “Turn–

ON”,

2. “Ignition 1” voltage is in the specified value.

Action Taken

SRS control unit turns “ON” the “AIR BAG” warning

lamp and sets a diagnostic trouble code.

DTC Will Clear When

The ignition switch is turned “LOCK”.

DTC Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SRS control unit.

3. This test verifies connection of the yellow connector.

4. This test cheeks for proper operation of the shorting

clip in the yellow connector.

5. The test checks for a malfunction passenge

r

pretensioner assembly.

6. This test determines whether the malfunctioning is

due to shortening in the wiring.

Diagnostic Aids

An intermittent condition is likely to be caused by a short

between circuits “Passenger Pretensioner High” and

“Passenger Pretensioner Low” or a malfunctioning

shorting clip on the passenger pretensioner assembl

y

which would require replacement of the pretensione

r

assembly. The test for this diagnostic trouble code is

only run while “AIR BAG” warning lamp is performing

the bulb check. W hen a scan tool “Clear Codes”

command is issued and the malfunction is still present,

the DTC will not reappear until the next ignition cycle.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5734 of 6020

9A1-52 RESTRAINT CONTROL SYSTEM

DTC Will Set When

The combined resistance of the driver pretensioner

assembly, harness wiring circuits “Driver Pretensioner

High” and “Driver Pretensioner Low”, and connector

terminal contact is above a specified value. This test is

run once each ignition cycle during the “Resistance

Measurement Test” when:

1. No “higher priority faults” are detected during “Turn–

ON”

2. “Ignition 1” voltage is in the specified value.

Action Taken

SRS control unit turns “ON” the “AIR BAG” warning

lamp and sets DTC B0041.

DTC Will Clear When

The ignition switch is turned “LOCK”.

DTC Chart Test Description

Number(s) below refer to circled number(s) on the

diagnostic chart:

2. This test determines whether the malfunction is in

the SRS control unit.

3. This test verifies proper connection of the yello

w

connector at the base of the driver seat.

4. This test checks for proper operation of the shorting

clip in the yellow connector.

5. This test isolate the malfunction to one side of the

SRS coil assembly yellow connector located at the

base of the driver seat.

6. This test determines whether the malfunction is due

to shortening in the wiring.

7. This test determines whether the malfunction is in

the driver pretensionerassembly.

Diagnostic Aids

An intermittent condition is likely to be caused by a short

between circuit “Driver Pretensioner High” or “Drive

r

Pretensioner Low” or a malfunctioning shorting clip on

the driver pretensioner assembly which would require

replacement of the component. The test for this

diagnostic trouble code is only run while the “AIR BAG”

warning lamp is performing the bulb check. W hen a

scan tool “Clear Codes” command is issued and the

malfunction is still present, the DTC will not reappea

r

until the next ignition cycle.

DTC B0041 (Flash Code 41) Driver Pretensioner Squib Circuit Low Resistance

Step Action Yes No

1 Perform the “SRS Diagnostic System Check.”

W as the “SRS Diagnostic System Check” performed? Go to Step 2 Go to the “SRS

Diagnostic System Check”

2

1. Check the driver pretensioner squib circuit for short to voltage

or short to ground.

2. If the problem found, repair as necessary.

W as a problem found? Verify repair Go to Step 3

3

1. Ignition switch is at “LOCK”.

2. Make sure the pretensioner assembly yellow connector

located at the base of the driver seat connected properly.

Is the connector connected properly? Go to Step 4 Seat driver

pretensioner assembly

connector properly.

Go to Step 8

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007