bulb ISUZU KB P190 2007 Workshop Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 5178 of 6020

8A-240 ELECTRICAL-BODY AND CHASSIS

B Type

RTW 580SH000401

A Type

RTW 780SH001401

4. Turn the bulb 1 counterclockwise to remove it.

B Type

RTW 78ASH002601

Installation

Follow the removal procedure in the reverse order to install the

rear combination light.

Pay close attention to the important points mentioned in the

following paragraphs.

Bulbs

Be absolutely sure that each bulb is correctly installed.

This will prevent a poor contact and an open circuit.

RTW 780SH001501

This illustration is based on RHD model

HAZARD WARNING FLASHER SWITCH

Removal

1. Disconnect the battery ground cable.

2. Instrument Panel Cluster Assembly • Refer to Section 10 “BODY” for instrument panel cluste

r

assembly removal steps.

3. Hazard W arning Switch • Disconnect the switch connector.

• To remove the switch, push the lock from the back side

of the cluster assembly.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5197 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-259

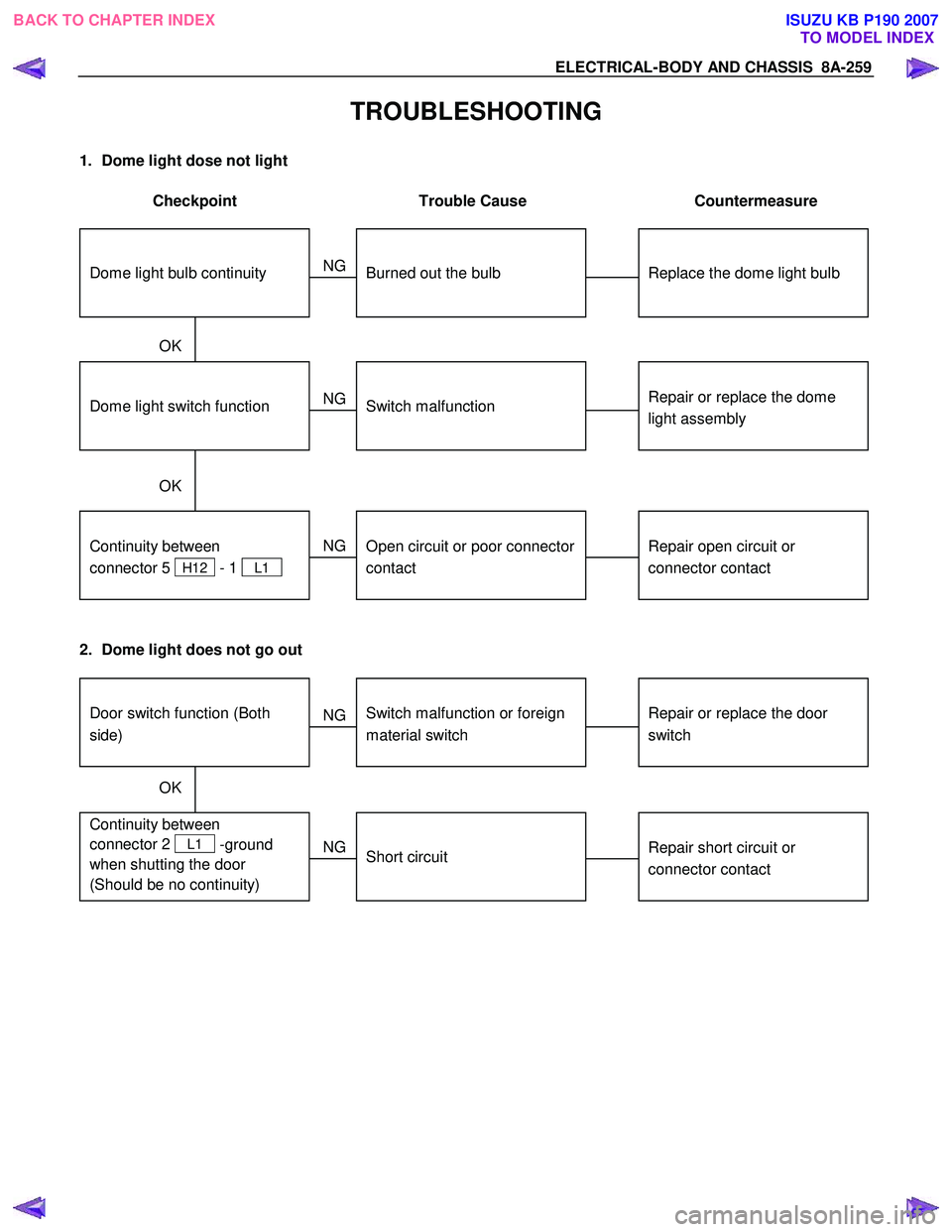

TROUBLESHOOTING

1. Dome light dose not light

Checkpoint Trouble Cause Countermeasure

Replace the dome light bulb

Burned out the bulb

NG

Repair or replace the dome

light assembly

Dome light switch function

Switch malfunction

Repair open circuit or

connector contact

Continuity between

connector 5

H12 - 1 L1

Open circuit or poor connector

contact

NG

NG

OK

OK

Dome light bulb continuity

2. Dome light does not go out

Repair or replace the door

switch

Switch malfunction or foreign

material switch

NG

Repair short circuit or

connector contact

Continuity between

connector 2

L1 -ground

when shutting the door

(Should be no continuity)

Short circuit

NG

OK

Door switch function (Both

side)

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5198 of 6020

8A-260 ELECTRICAL-BODY AND CHASSIS

REMOVAL AND INSTALLATION

DOME LIGHT

Removal

1. Remove the dome light lens 1 free.

2. Remove two dome light fixing screws.

3. Remove the wiring connector.

4. Remove the dome light.

5. Pull the bulb

2 to remove it.

Installation

Follow the removal procedure in the reverse order to install the

dome light.

Pay close attention to the important points mentioned in the

following paragraphs.

Bulb

Be absolutely sure that the dome light bulb is correctly

installed.

This will prevent a poor contact and an open circuit.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5200 of 6020

8A-262 ELECTRICAL-BODY AND CHASSIS

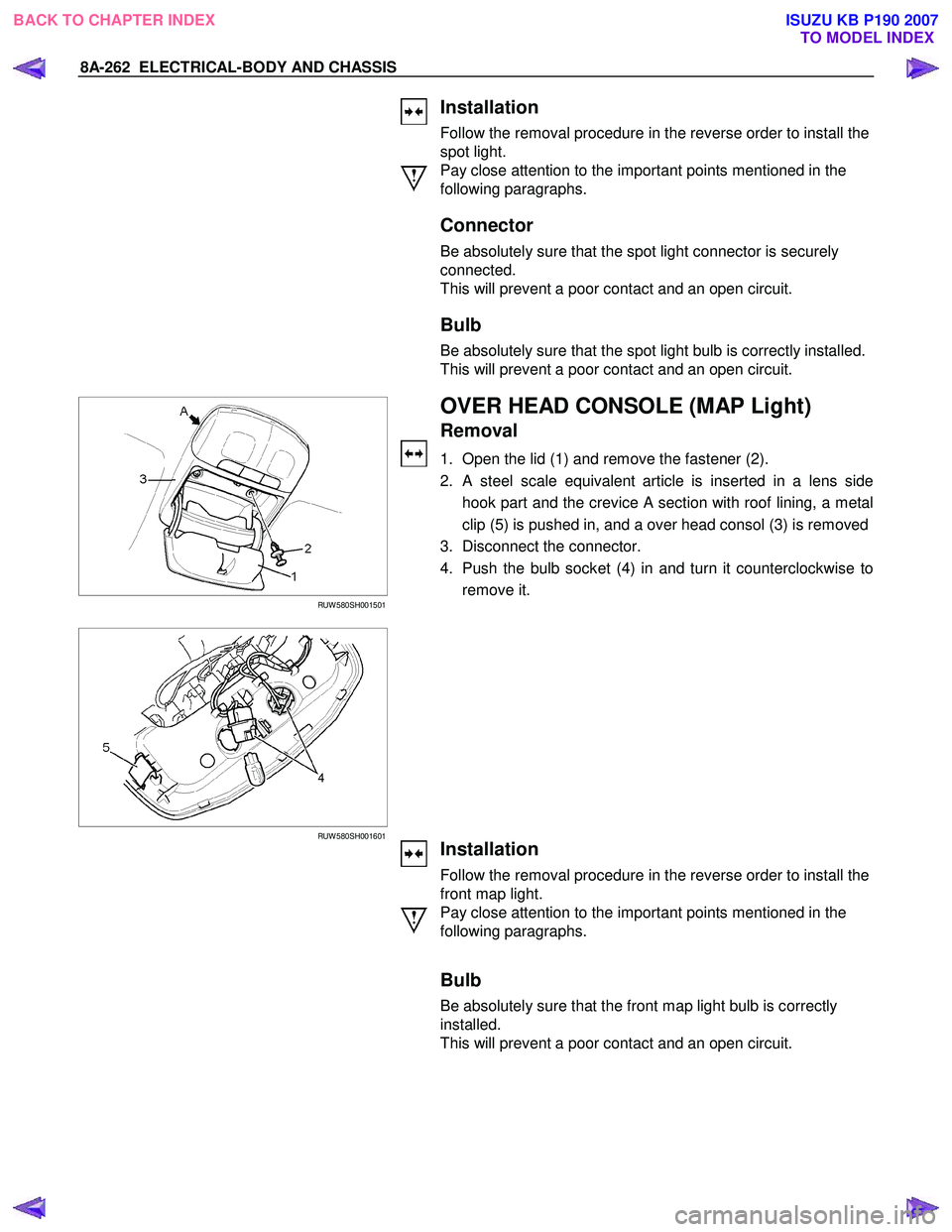

Installation

Follow the removal procedure in the reverse order to install the

spot light.

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that the spot light connector is securely

connected.

This will prevent a poor contact and an open circuit.

Bulb

Be absolutely sure that the spot light bulb is correctly installed.

This will prevent a poor contact and an open circuit.

RUW 580SH001501

RUW 580SH001601

OVER HEAD CONSOLE (MAP Light)

Removal

1. Open the lid (1) and remove the fastener (2).

2. A steel scale equivalent article is inserted in a lens side hook part and the crevice A section with roof lining, a metal

clip (5) is pushed in, and a over head consol (3) is removed

3. Disconnect the connector.

4. Push the bulb socket (4) in and turn it counterclockwise to remove it.

Installation

Follow the removal procedure in the reverse order to install the

front map light.

Pay close attention to the important points mentioned in the

following paragraphs.

Bulb

Be absolutely sure that the front map light bulb is correctly

installed.

This will prevent a poor contact and an open circuit.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5284 of 6020

8A-346 ELECTRICAL-BODY AND CHASSIS

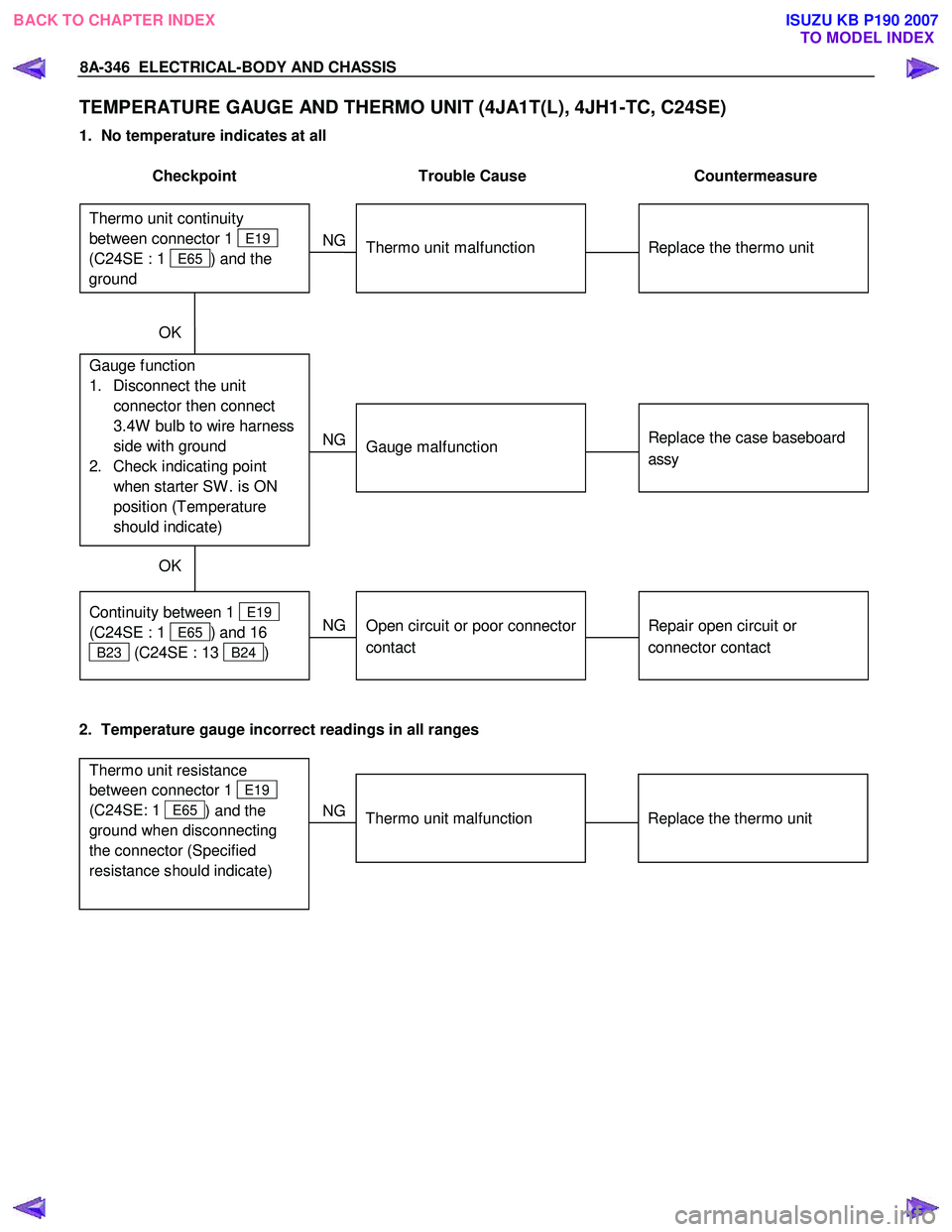

TEMPERATURE GAUGE AND THERMO UNIT (4JA1T(L), 4JH1-TC, C24SE)

1. No temperature indicates at all

Checkpoint Trouble Cause Countermeasure

Replace the thermo unit

Thermo unit malfunction

NG

Replace the case baseboard

assy

Gauge function

1. Disconnect the unit connector then connect

3.4W bulb to wire harness

side with ground

2. Check indicating point when starter SW . is ON

position (Temperature

should indicate)

Gauge malfunction

Repair open circuit or

connector contact

Continuity between 1 E19

(C24SE : 1

E65 ) and 16

B23 (C24SE : 13 B24 )

Open circuit or poor connector

contact

NG

NG

OK

OK

Thermo unit continuity

between connector 1

E19

(C24SE : 1

E65 ) and the

ground

2. Temperature gauge incorrect readings in all ranges

Replace the thermo unit

Thermo unit malfunction

NG

Thermo unit resistance

between connector 1

E19

(C24SE: 1

E65 ) and the

ground when disconnecting

the connector (Specified

resistance should indicate)

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5285 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-347

ENGINE COOLANT TEMPERATURE GAUGE (4JJ1-TC/4JK1-TC)

Refer to “Inspection and Repair” in this Manual for a detailed description of the coolant temperature gauge self-

diagnosis procedure.

1. No engine coolant temperature indicates at all

Checkpoint Trouble Cause Countermeasure

Replace the engine coolant

temperature sensor

Engine coolant temperature

sensor malfunction

NG

Replace the meter assembly

Gauge function

1. Disconnect the sensor connector then connect

3.4W bulb to wire harness

side with ground

2. Check indicating point when starter SW . is ON

position (Temperature

should indicate)

Gauge malfunction

Repair open circuit or

connector contact

Continuity between 3

E41

and 16

B23

Open circuit or poor connector

contact

NG

NG

OK

OK

Engine coolant temperature

sensor continuity between

connector 3

E41 and the

ground

2. Engine coolant temperature gauge incorrect readings in all ranges

Replace the sensor

The sensor malfunction

NG

Engine coolant temperature

sensor resistance between

connector 3

E41 and the

ground when disconnecting

the connector (Specified

resistance should indicate)

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5286 of 6020

8A-348 ELECTRICAL-BODY AND CHASSIS

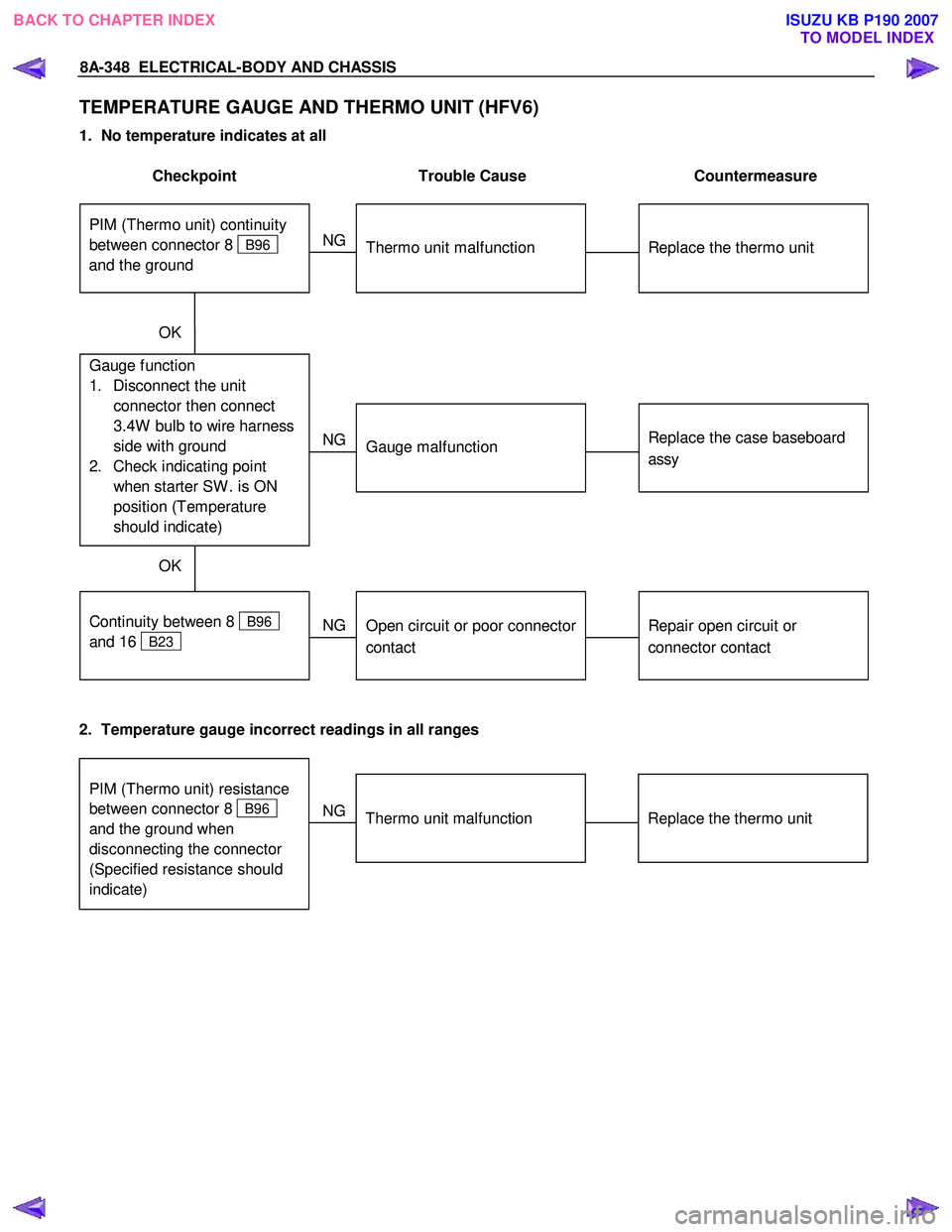

TEMPERATURE GAUGE AND THERMO UNIT (HFV6)

1. No temperature indicates at all

Checkpoint Trouble Cause Countermeasure

Replace the thermo unit

Thermo unit malfunction

NG

Replace the case baseboard

assy

Gauge function

1. Disconnect the unit connector then connect

3.4W bulb to wire harness

side with ground

2. Check indicating point when starter SW . is ON

position (Temperature

should indicate)

Gauge malfunction

Repair open circuit or

connector contact

Continuity between 8 B96

and 16

B23

Open circuit or poor connector

contact

NG

NG

OK

OK

PIM (Thermo unit) continuity

between connector 8

B96

and the ground

2. Temperature gauge incorrect readings in all ranges

Replace the thermo unit

Thermo unit malfunction

NG

PIM (Thermo unit) resistance

between connector 8

B96

and the ground when

disconnecting the connector

(Specified resistance should

indicate)

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5287 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-349

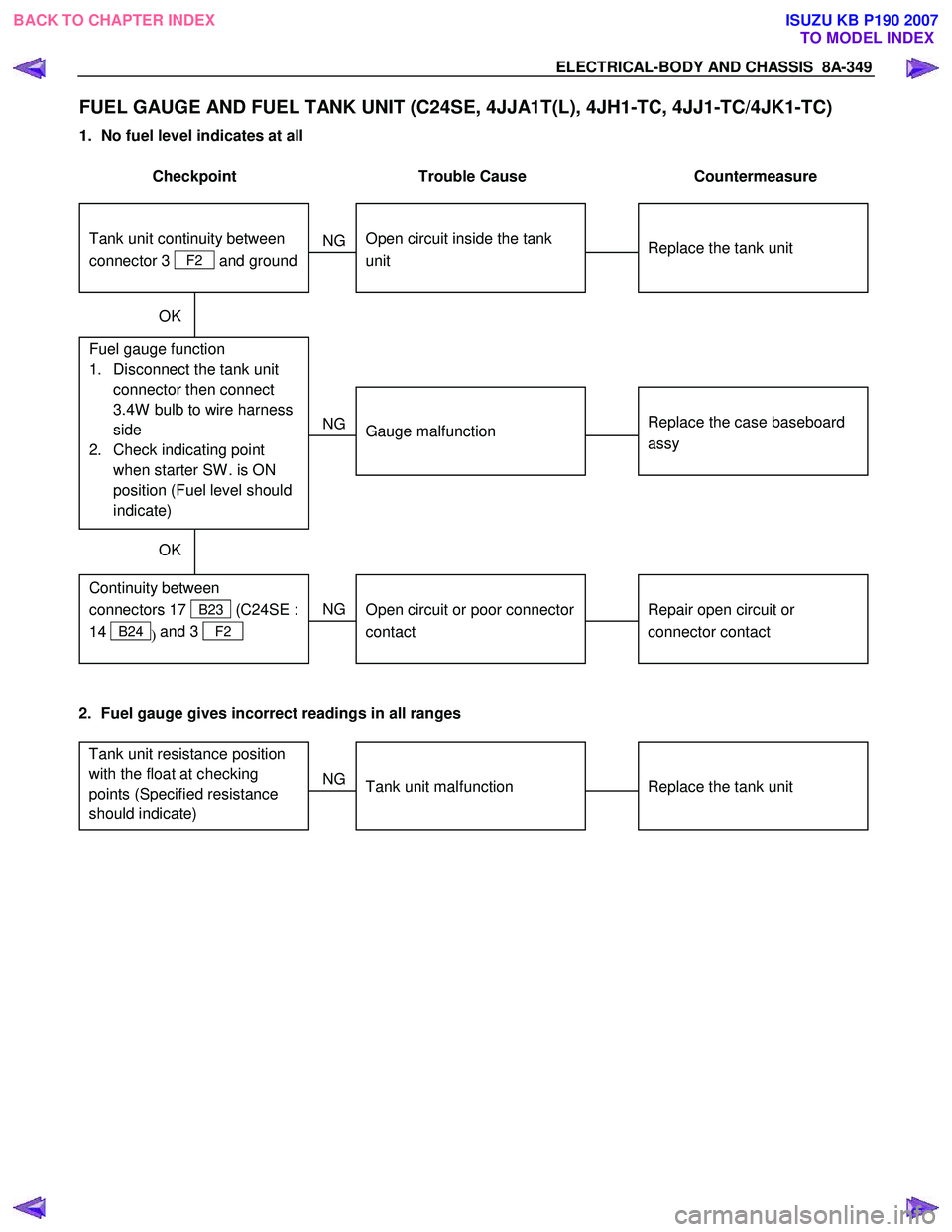

FUEL GAUGE AND FUEL TANK UNIT (C24SE, 4JJA1T(L), 4JH1-TC, 4JJ1-TC/4JK1-TC)

1. No fuel level indicates at all

Checkpoint Trouble Cause Countermeasure

Replace the tank unit

Open circuit inside the tank

unit

NG

Thermo unit malfunction

Replace the case baseboard

assy

Fuel gauge function

1. Disconnect the tank unit connector then connect

3.4W bulb to wire harness

side

2. Check indicating point when starter SW . is ON

position (Fuel level should

indicate)

Gauge malfunction

Repair open circuit or

connector contact

Continuity between

connectors 17

B23 (C24SE :

14

B24 ) and 3

F2

Open circuit or poor connector

contact

NG

NG

OK

OK

Tank unit continuity between

connector 3

F2 and ground

2. Fuel gauge gives incorrect readings in all ranges

Replace the tank unitTank unit malfunction

NG

Tank unit resistance position

with the float at checking

points (Specified resistance

should indicate)

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5288 of 6020

8A-350 ELECTRICAL-BODY AND CHASSIS

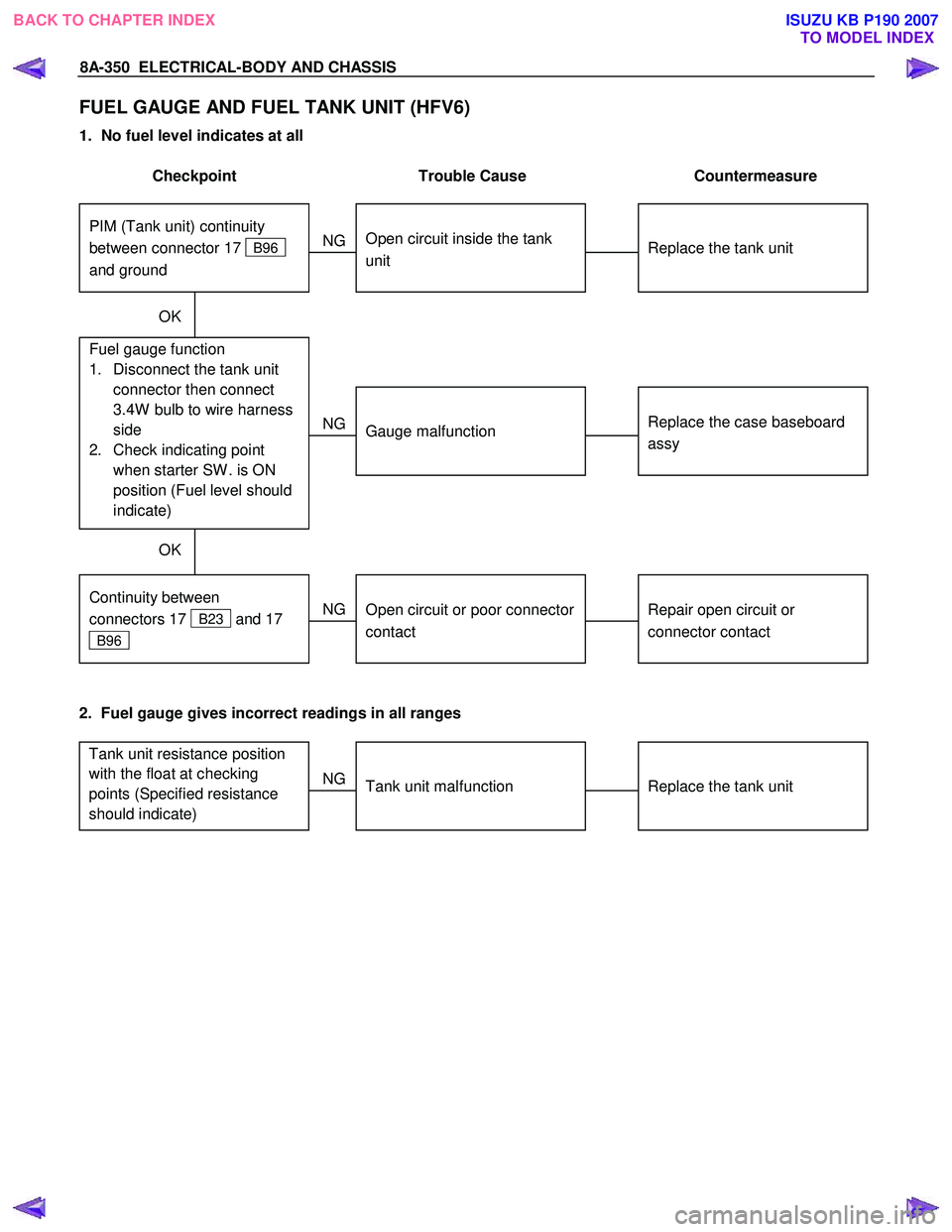

FUEL GAUGE AND FUEL TANK UNIT (HFV6)

1. No fuel level indicates at all

Checkpoint Trouble Cause Countermeasure

Replace the tank unit

Open circuit inside the tank

unit

NG

Thermo unit malfunction

Replace the case baseboard

assy

Fuel gauge function

1. Disconnect the tank unit connector then connect

3.4W bulb to wire harness

side

2. Check indicating point when starter SW . is ON

position (Fuel level should

indicate)

Gauge malfunction

Repair open circuit or

connector contact

Continuity between

connectors 17

B23 and 17

B96

Open circuit or poor connector

contact

NG

NG

OK

OK

PIM (Tank unit) continuity

between connector 17

B96

and ground

2. Fuel gauge gives incorrect readings in all ranges

Replace the tank unitTank unit malfunction

NG

Tank unit resistance position

with the float at checking

points (Specified resistance

should indicate)

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5289 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-351

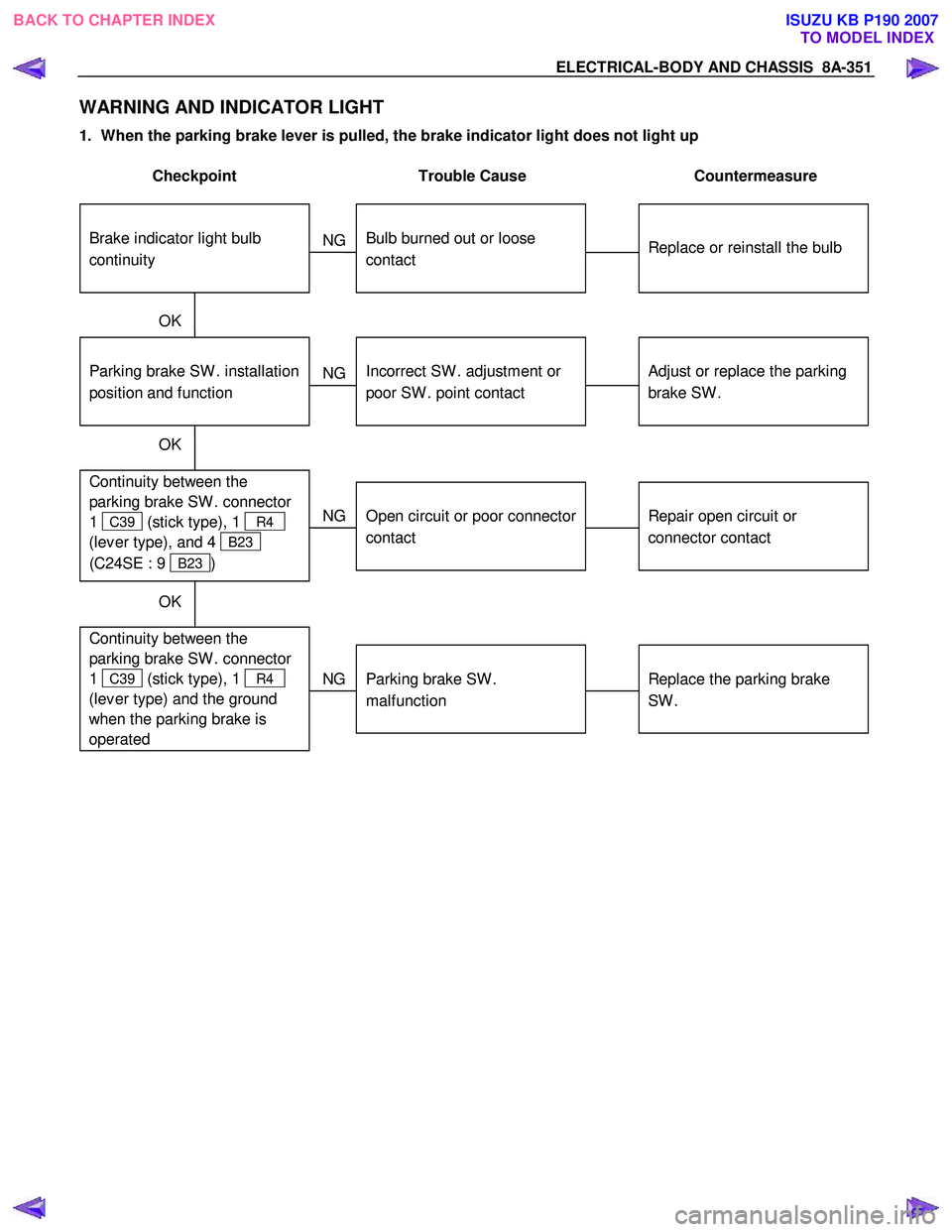

WARNING AND INDICATOR LIGHT

1. When the parking brake lever is pulled, the brake indicator light does not light up

Checkpoint Trouble Cause Countermeasure

Replace or reinstall the bulb

Bulb burned out or loose

contact

NG

Adjust or replace the parking

brake SW .

Parking brake SW . installation

position and function

Incorrect SW . adjustment or

poor SW . point contact

Continuity between the

parking brake SW . connector

1

C39 (stick type), 1 R4

(lev er type), and 4

B23

(C24SE : 9

B23 )

Repair open circuit or

connector contact

Open circuit or poor connector

contact

NG

NG

OK

OK

Brake indicator light bulb

continuity

NG

OK

Continuity between the

parking brake SW . connector

1

C39 (stick type), 1 R4

(lev er type) and the ground

when the parking brake is

operated

Replace the parking brake

SW .

Parking brake SW .

malfunction

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007