bulb ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3156 of 6020

Engine Cooling – V6 Engine Page 6B1–21

Calibrating the Tester

The coolant tester calibration is checked at manufacture. If however, the calibration check detailed in Step 1 of this

method shows that the instrument is not reading correctly, then conduct the following recalibration procedure:

1 Remove the sealant covering the adjustment screw on the underneath of the tester.

2 W ith a distilled water sample on the measuring surface, carefully adjust the screw until a zero reading is obtained.

NOTE

DO NOT completely remove the screw.

3 After recalibration, reseal the screw with a small amount of silicone sealant.

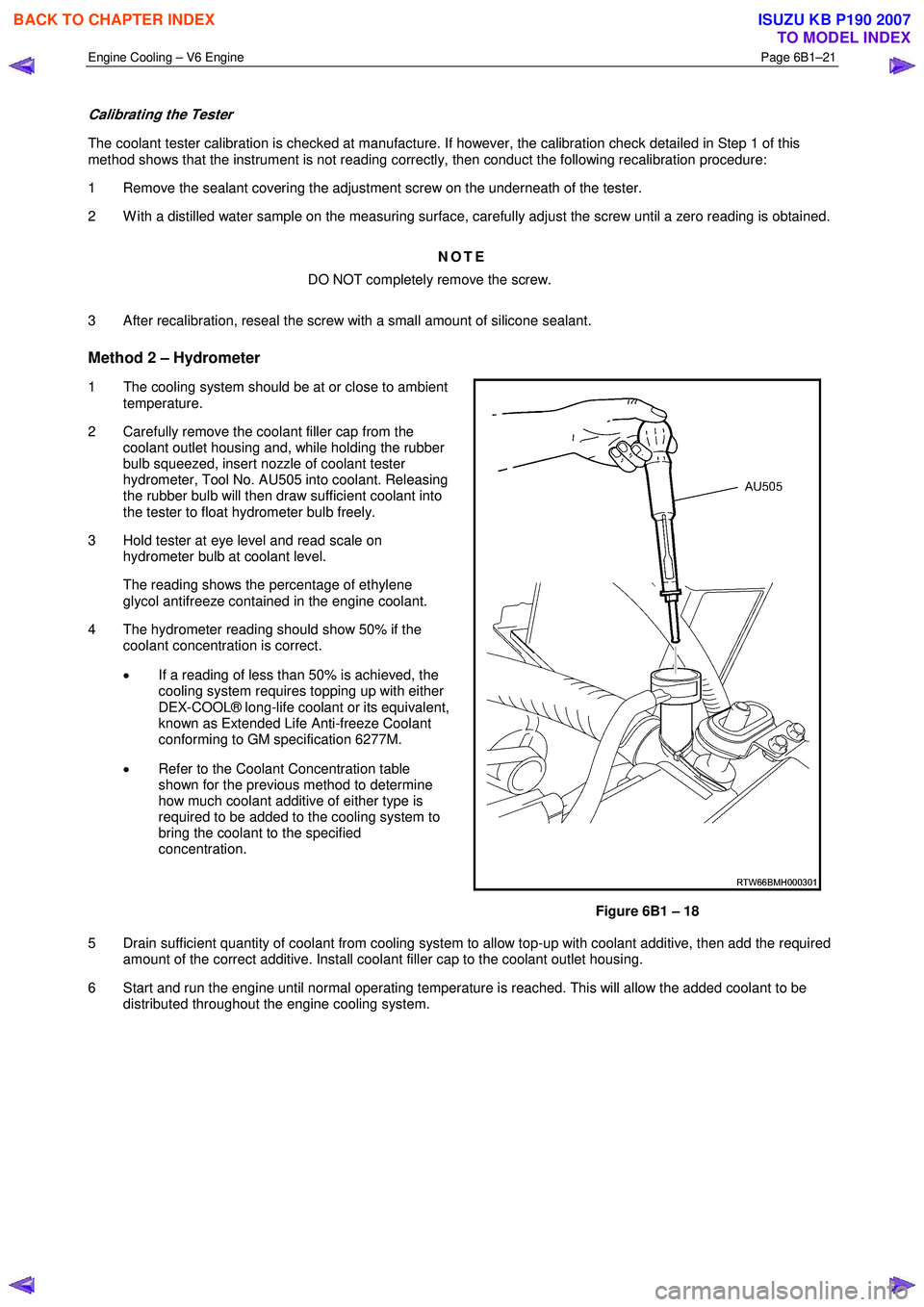

Method 2 – Hydrometer

1 The cooling system should be at or close to ambient temperature.

2 Carefully remove the coolant filler cap from the coolant outlet housing and, while holding the rubber

bulb squeezed, insert nozzle of coolant tester

hydrometer, Tool No. AU505 into coolant. Releasing

the rubber bulb will then draw sufficient coolant into

the tester to float hydrometer bulb freely.

3 Hold tester at eye level and read scale on hydrometer bulb at coolant level.

The reading shows the percentage of ethylene glycol antifreeze contained in the engine coolant.

4 The hydrometer reading should show 50% if the coolant concentration is correct.

• If a reading of less than 50% is achieved, the

cooling system requires topping up with either

DEX-COOL® long-life coolant or its equivalent,

known as Extended Life Anti-freeze Coolant

conforming to GM specification 6277M.

• Refer to the Coolant Concentration table

shown for the previous method to determine

how much coolant additive of either type is

required to be added to the cooling system to

bring the coolant to the specified

concentration.

Figure 6B1 – 18

5 Drain sufficient quantity of coolant from cooling system to allow top-up with coolant additive, then add the required amount of the correct additive. Install coolant filler cap to the coolant outlet housing.

6 Start and run the engine until normal operating temperature is reached. This will allow the added coolant to be distributed throughout the engine cooling system.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3649 of 6020

Battery Page 6D1-3–9

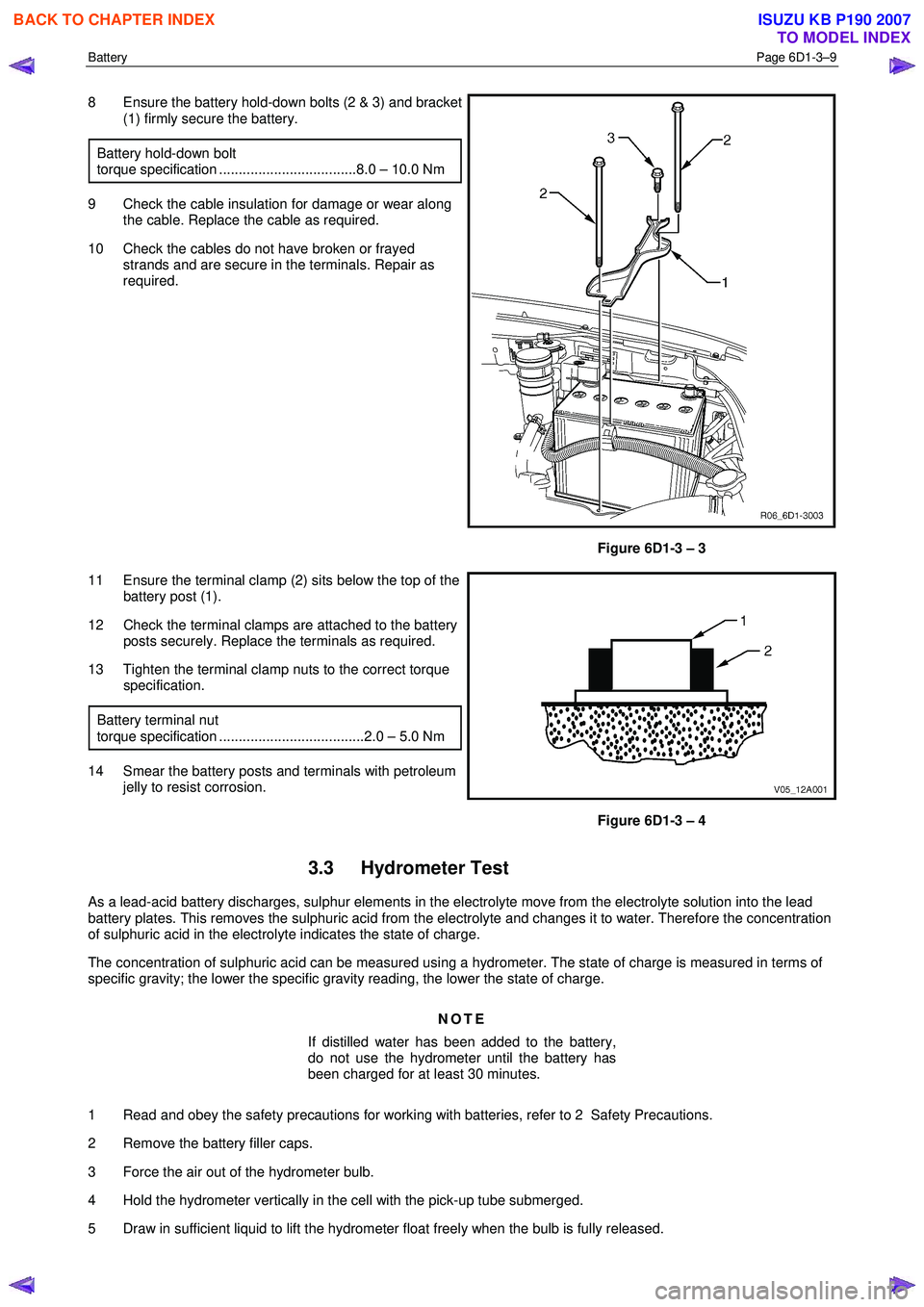

8 Ensure the battery hold-down bolts (2 & 3) and bracket

(1) firmly secure the battery.

Battery hold-down bolt

torque specification ...................................8.0 – 10.0 Nm

9 Check the cable insulation for damage or wear along the cable. Replace the cable as required.

10 Check the cables do not have broken or frayed strands and are secure in the terminals. Repair as

required.

Figure 6D1-3 – 3

11 Ensure the terminal clamp (2) sits below the top of the battery post (1).

12 Check the terminal clamps are attached to the battery posts securely. Replace the terminals as required.

13 Tighten the terminal clamp nuts to the correct torque specification.

Battery terminal nut

torque specification .....................................2.0 – 5.0 Nm

14 Smear the battery posts and terminals with petroleum jelly to resist corrosion.

Figure 6D1-3 – 4

3.3 Hydrometer Test

As a lead-acid battery discharges, sulphur elements in the electrolyte move from the electrolyte solution into the lead

battery plates. This removes the sulphuric acid from the electrolyte and changes it to water. Therefore the concentration

of sulphuric acid in the electrolyte indicates the state of charge.

The concentration of sulphuric acid can be measured using a hydrometer. The state of charge is measured in terms of

specific gravity; the lower the specific gravity reading, the lower the state of charge.

NOTE

If distilled water has been added to the battery,

do not use the hydrometer until the battery has

been charged for at least 30 minutes.

1 Read and obey the safety precautions for working with batteries, refer to 2 Safety Precautions.

2 Remove the battery filler caps.

3 Force the air out of the hydrometer bulb.

4 Hold the hydrometer vertically in the cell with the pick-up tube submerged.

5 Draw in sufficient liquid to lift the hydrometer float freely when the bulb is fully released.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4438 of 6020

7A2-154 TRANSMISSION CONTROL SYSTEM (JR405E)

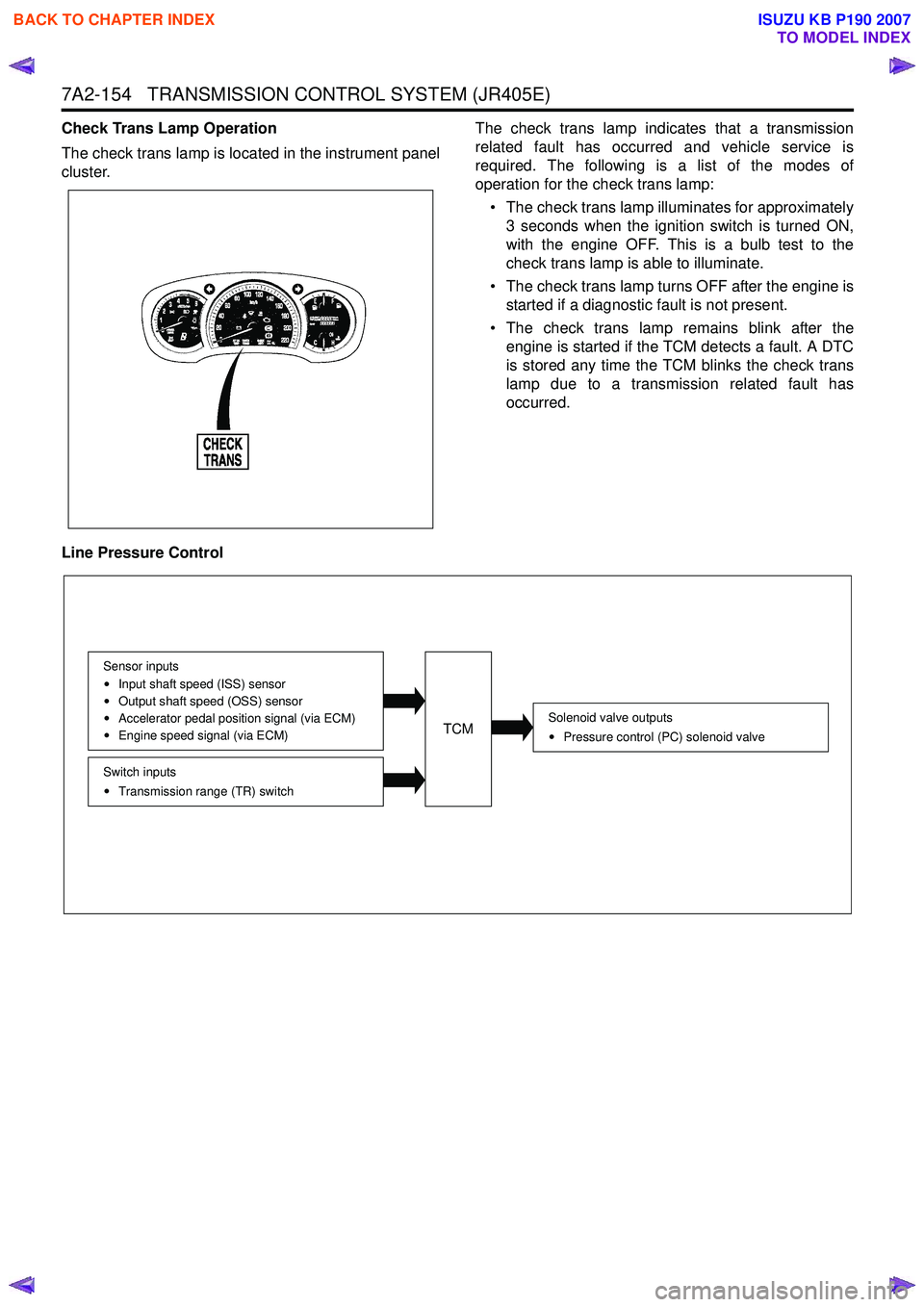

Check Trans Lamp Operation

The check trans lamp is located in the instrument panel

cluster. The check trans lamp indicates that a transmission

related fault has occurred and vehicle service is

required. The following is a list of the modes of

operation for the check trans lamp:

• The check trans lamp illuminates for approximately 3 seconds when the ignition switch is turned ON,

with the engine OFF. This is a bulb test to the

check trans lamp is able to illuminate.

• The check trans lamp turns OFF after the engine is started if a diagnostic fault is not present.

• The check trans lamp remains blink after the engine is started if the TCM detects a fault. A DTC

is stored any time the TCM blinks the check trans

lamp due to a transmission related fault has

occurred.

Line Pressure Control

Solenoid valve outputs Pressure control (PC) solenoid valve

Switch inputsTransmission range (TR) switch

Sensor inputs

Input shaft speed (ISS) sensor

Output shaft speed (OSS) sensor

Accelerator pedal position signal (via ECM)

Engine speed signal (via ECM)TCM

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4939 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-1

SECTION 8A

ELECTRICAL-BODY AND CHASSIS

TABLE OF CONTENTS

PAGE

General Information ........................................................................................................... .........8A- 4

Notes for Working on Electrical Items .......................................................................................8A - 5

Symbols and A bbreviations ..................................................................................................... ..8A- 11

Symbols ....................................................................................................................... ................ 8A- 11

Abbreviations ................................................................................................................. ..............8A- 12

Parts for Electri cal Circuit .................................................................................................. ........8A- 13

Wiring ........................................................................................................................ ...................8A- 13

Fuse .......................................................................................................................... ....................8A- 15

Fusible Link .................................................................................................................. ...............8A- 15

Relay ......................................................................................................................... ....................8A- 16

Diode ......................................................................................................................... ...................8A- 17

Connector ..................................................................................................................... ...............8A- 18

Battery ....................................................................................................................... ...................8A- 19

Reading the Circuit Diagram ................................................................................................... ...8A- 22

Parts Location ................................................................................................................ ..............8A- 22

Circuit Diagram ............................................................................................................... .............8A- 23

Connector List ................................................................................................................ .............8A- 23

Main Data and Specifications .................................................................................................. ...8A- 24

Bulb Specifications ........................................................................................................... ..........8A- 24

Relay and Fuse ................................................................................................................ ............8A- 26

Relay and Fuse Box Location (RHD) .........................................................................................8A- 26

Relay and Fuse Box Location (LHD) ..........................................................................................8A- 27

Relay Location ................................................................................................................ .............8A- 28

Fuse and Slow Blow Fuse Location ...........................................................................................8A- 31

Fuse Location ................................................................................................................. .............8A- 33

Diode Location ................................................................................................................ .............8A- 34

Fuse Block Circuit (C24SE) .................................................................................................... ....8A- 35/36

Fuse Block Circuit (HFV6) ...................................................................................................... .....8A- 37

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4962 of 6020

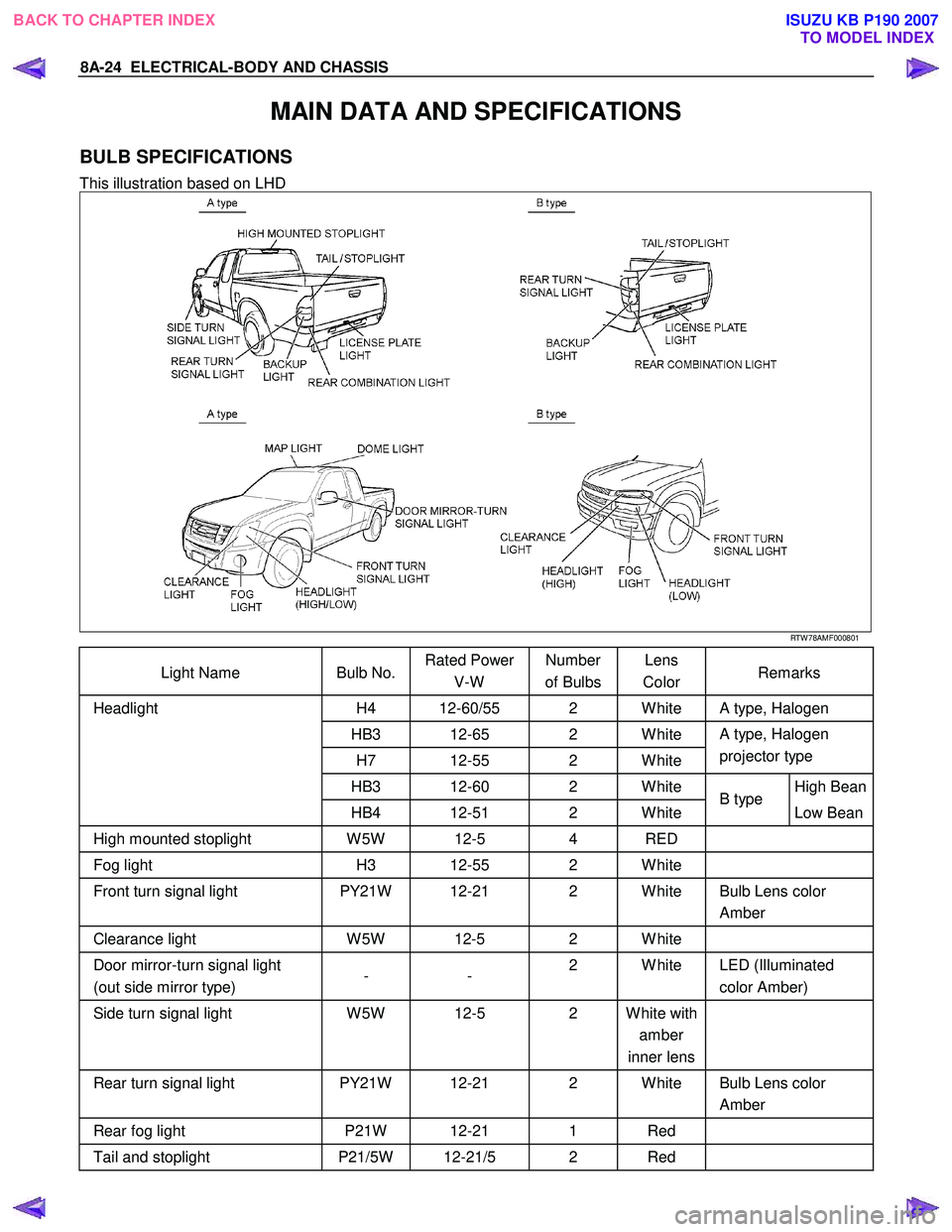

8A-24 ELECTRICAL-BODY AND CHASSIS

MAIN DATA AND SPECIFICATIONS

BULB SPECIFICATIONS

This illustration based on LHD

RTW 78AMF000801

Light Name Bulb No. Rated Power

V-W Number

of Bulbs Lens

Color Remarks

H4 12-60/55 2 W hite A type, Halogen

HB3 12-65 2 W hite

H7 12-55 2 W hite A type, Halogen

projector type

HB3 12-60 2 W hite High Bean

Headlight

HB4 12-51 2 W hite B type

Low Bean

High mounted stoplight W 5W 12-5 4 RED

Fog light H3 12-55 2 W hite

Front turn signal light PY21W 12-21 2 W hite Bulb Lens color

Amber

Clearance light W 5W 12-5 2 W hite

Door mirror-turn signal light

(out side mirror type) - -

2 W hite LED (Illuminated

color Amber)

Side turn signal light W 5W 12-5 2 W hite with

amber

inner lens

Rear turn signal light

PY21W 12-21 2 W hite Bulb Lens color

Amber

Rear fog light P21W 12-21 1 Red

Tail and stoplight P21/5W 12-21/5 2 Red

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 4963 of 6020

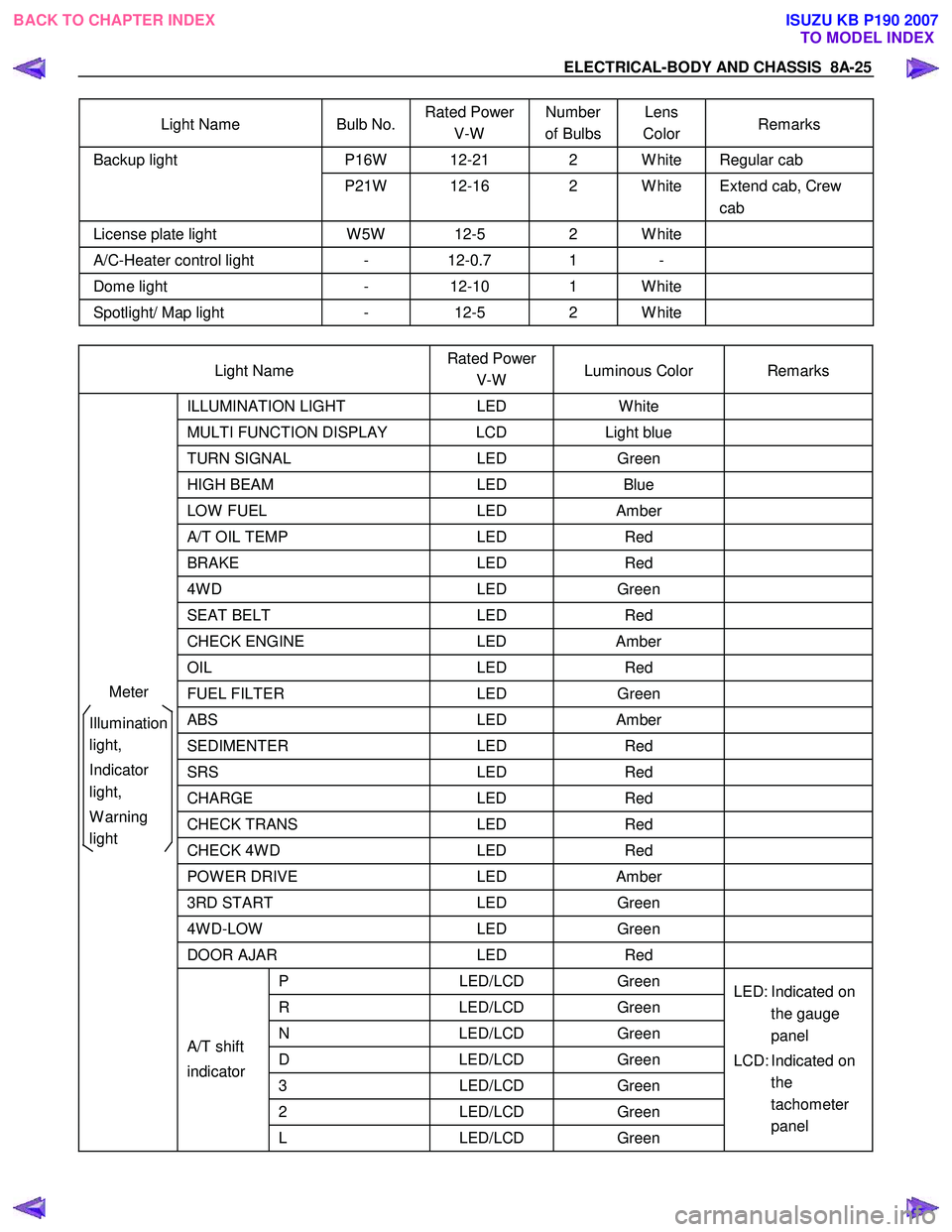

ELECTRICAL-BODY AND CHASSIS 8A-25

Light Name Bulb No. Rated Power

V-W Number

of Bulbs Lens

Color Remarks

P16W 12-21 2 W hite Regular cab Backup light

P21W 12-16 2 W hite Extend cab, Crew cab

License plate light W 5W 12-5 2 W hite

A/C-Heater control light - 12-0.7 1 -

Dome light - 12-10 1 W hite

Spotlight/ Map light - 12-5 2 W hite

Light Name Rated Power

V-W Luminous Color Remarks

ILLUMINATION

LIGHT LED W hite

MULTI FUNCTION DISPLAY LCD Light blue

TURN SIGNAL LED Green

HIGH BEAM LED Blue

LOW FUEL LED Amber

A/T OIL TEMP LED Red

BRAKE LED Red

4W D LED Green

SEAT BELT LED Red

CHECK ENGINE LED Amber

OIL LED Red

FUEL FILTER LED Green

ABS LED Amber

SEDIMENTER LED Red

SRS LED Red

CHARGE LED Red

CHECK TRANS LED Red

CHECK 4W D LED Red

POW ER DRIVE LED Amber

3RD START LED Green

4W D-LOW LED Green

DOOR AJAR LED Red

P LED/LCD Green

R LED/LCD Green

N LED/LCD Green

D LED/LCD Green

3 LED/LCD Green

2 LED/LCD Green

A/T shift

indicator

L LED/LCD Green LED: Indicated on

the gauge

panel

LCD: Indicated on the

tachometer

panel

Meter

Illumination

light,

Indicator

light,

W arning

light

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5099 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-161

2. High or low beam does not light on both headlights

Checkpoint Trouble Cause Countermeasure

Repair or replace the

combination switch

Dimmer ⋅passing switch

continuity

Poor switch contact or switch

faulty

NG

Repair open circuit or

connector contact

Voltage between

4

X4 - ground and

4

B60 - ground

Open circuit between

headlight and dimmer ⋅passing

switch

NG

OK

3. RH (or LH) high and low beam does not light

Replace the headlight bulb

Headlight connector continuity

Blown filament or air leakage

NG

Repair or replace the wire

and/or connector

W iring continuity between

connector 3

C19 - fuse No.

EB7 or 3

C26 fuse No.

EB8

Open circuit and/or poor

connector contact

NG

OK

Reinstall or replace fuse No.

EB7 or No. EB8

Fuse No. EB7 (10A) or

No. EB8 (10A) (Relay and

fuse box)

(No. EB7 RH, No. EB8: LH)

Poor installation or blown fuse

NG

OK

4. High or low beam does not light on one headlight (RH or LH)

Replace the headlight

assemblyHeadlight connector continuityBlown filament

NG

Repair open circuit or

connector contactW iring continuity between

headlight and dimmer ⋅passing

switchOpen circuit between

headlight and dimmer ⋅passing

switch

NG

OK

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5100 of 6020

8A-162 ELECTRICAL-BODY AND CHASSIS

5. Headlight does not go out

Checkpoint Trouble Cause Countermeasure

Replace the lighting relay

Lighting relay continuity

between connector 1

X6

- 2

X6 (Should be no

continuity)

Relay point fused

NG

Replay the combination

switch Lighting switch continuity

between connector 3

B60

-1

B60 when switch is

OFF(S hould be no continuity)

point fused or faulty

NG

OK

OK

Repair or replace the

combination switch

Dimmer ⋅passing switch con-

tinuity between connector

3

B60 - 1 B60 when switch

is not operating

(Should be no continuity)

Switch point fused or faulty

NG

Repair short circuit

between 3

X6 - 3 B60

and 5

X2 - 2 B60

Check if headlight goes out

when connector

C2 , C36

is disconnected

Short circuit

NG

OK

6. Insufficient headlight brightness

Replace the headlight bulb

Headlight bulb

Bulb filament faulty

NG

Repair the wiring

Dimmer ⋅passing switch

W ire continuity between con-

nector 1

B60 - C2

Poor ground point contact

NG

OK

Clean the light lens

Headlight lens

Lens dirty

NG

OK

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5102 of 6020

8A-164 ELECTRICAL-BODY AND CHASSIS

TAIL LIGHT, LICENSE PLATE LIGHT, CLEARANCE LIGHT

1. All lights do not light

Checkpoint Trouble Cause Countermeasure

Repair or replace the

combination switch

Lighting switch continuity

between connector

2

B60 - 1 B60

Poor switch point or connector

contact

NG

Reinstall or replace the tail

relay

Tail relay

Poor relay contact or relay

faulty

NG

OK

Reinstall or replace the fuse

No. EB12 (LH), EB11 (RH)

Fuse No. EB12 (LH) or EB11

(RH) (10A, Relay and fuse

box)

Poor fuse contact or blown

NG

OK

2. Tail light does not light

Replace the bulb or repair

connector contact

Tail light bulb continuity

Bulb burned out or poor

connector contact

NG

Repair open circuit or

connector contact

Continuity between connector

3

F5 - 4 F5 (RH)

or 3

F6 - 4 F6 (LH)

Open circuit or poor connector

contact

NG

OK

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5103 of 6020

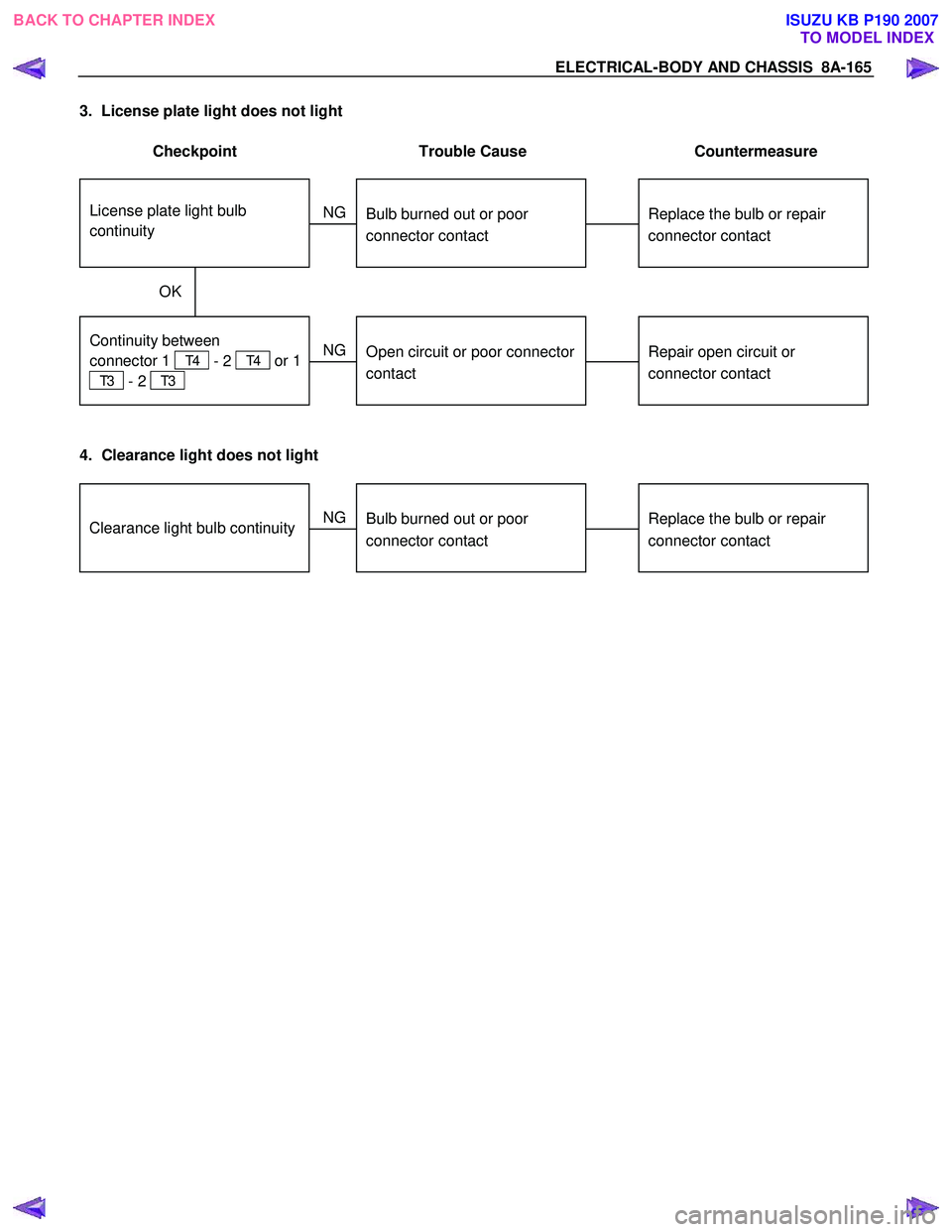

ELECTRICAL-BODY AND CHASSIS 8A-165

3. License plate light does not light

Checkpoint Trouble Cause Countermeasure

Repair open circuit or

connector contact

Continuity between

connector 1

T4 - 2 T4 or 1

T3 - 2 T3

Open circuit or poor connector

contact

NG

Replace the bulb or repair

connector contact

License plate light bulb

continuity

Bulb burned out or poor

connector contact

NG

OK

4. Clearance light does not light

Replace the bulb or repair

connector contactClearance light bulb continuityBulb burned out or poor

connector contact

NG

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007