compression ratio ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3753 of 6020

Exhaust System – V6 Page 6F – 5

Service Notes

1. Vehicles fitted with catalytic converters should not be operated with leaded petrol. Lead will contaminate

the ceramic monolith.

2. Do not drop the catalytic converter as it will damage the ceramic monolith.

3. Replace the catalytic converter if it is damaged.

4. Do not allow water, oil or fuel to enter the converter as the ceramic monolith will be contaminated.

5. Do not use engine and/or fuel additives unless approved by General Motors. Many additives contain phosphorous that will contaminate the ceramic monolith.

6. The vehicle must not be started by pushing or towing, as unburned fuel could reach the catalytic converter and destroy the ceramic monolith. Always use jumper leads to start a vehicle that has a flat or

defective battery.

7. W hen carrying out a compression test, for V6 engines use Tech 2 to ensure the output control Engine Compression Test is set to enable, refer to 6A1 Engine Mechanical. This prevents fuel injection and

ignition during engine cranking.

8. Do not drive the vehicle with the engine misfiring or with any of the spark plug leads disconnected, as the catalytic converter will overheat.

9. Do not coast downhill with the engine misfiring or with any of the spark plug leads disconnected.

10. The catalytic converter is serviceable as part of the front exhaust assembly only. Refer to the service operations in this section for details of front exhaust pipe assembly removal and reinstallation.

11. The exhaust flange gaskets must be replaced whenever a new exhaust pipe, muffler or catalytic converter is installed.

1.3 WARNING, CAUTION and NOTES

This Section contains various W ARNINGS, CAUTIONS and NOTE statements that you must observe carefully to reduce

the risk of death or injury during service, repair procedures or vehicle operation. Incorrect service or repair procedures

may damage the vehicle or cause operational faults. W ARNINGS, CAUTION and NOTE statements are not exhaustive.

HOLDEN LTD can not possibly warn of all the potentially hazardous consequences of failure to follow these instructions.

1.1 Definition of WARNING, CAUTION and NOTE Statements

Diagnosis and repair procedures in this Section contain both general and specific W ARNING, CAUTION and NOTE

statements. HOLDEN LTD is dedicated to the presentation of service information that helps the technician to diagnose

and repair the systems necessary for proper operation of the vehicle. Certain procedures may present a hazard to the

technician if they are not followed in the recommended manner. W ARNING, CAUTION and NOTE statements are

designed to help prevent these hazards from occurring, but not all hazards can be foreseen.

WARNING defined

A W ARNING statement immediately precedes an operating procedure or maintenance practice which, if not correctly

followed, could result in death or injury. A W ARNING statement alerts you to take necessary action or not to take a

prohibited action. If a W ARNING statement is ignored, the following consequences may occur:

• Death or injury to the technician or other personnel working on the vehicle,

• Death or injury to other people in or near the workplace area, and / or

• Death or injury to the driver / or passenger(s) of the vehicle or other people, if the vehicle has been improperly

repaired.

CAUTION defined

A CAUTION statement immediately precedes an operating procedure or maintenance practice which, if not correctly

followed, could result in damage to or destruction of equipment, or corruption of data. If a CAUTION statement is

ignored, the following consequences may occur:

• Damage to the vehicle,

• Unnecessary vehicle repairs or component replacement,

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3772 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–12

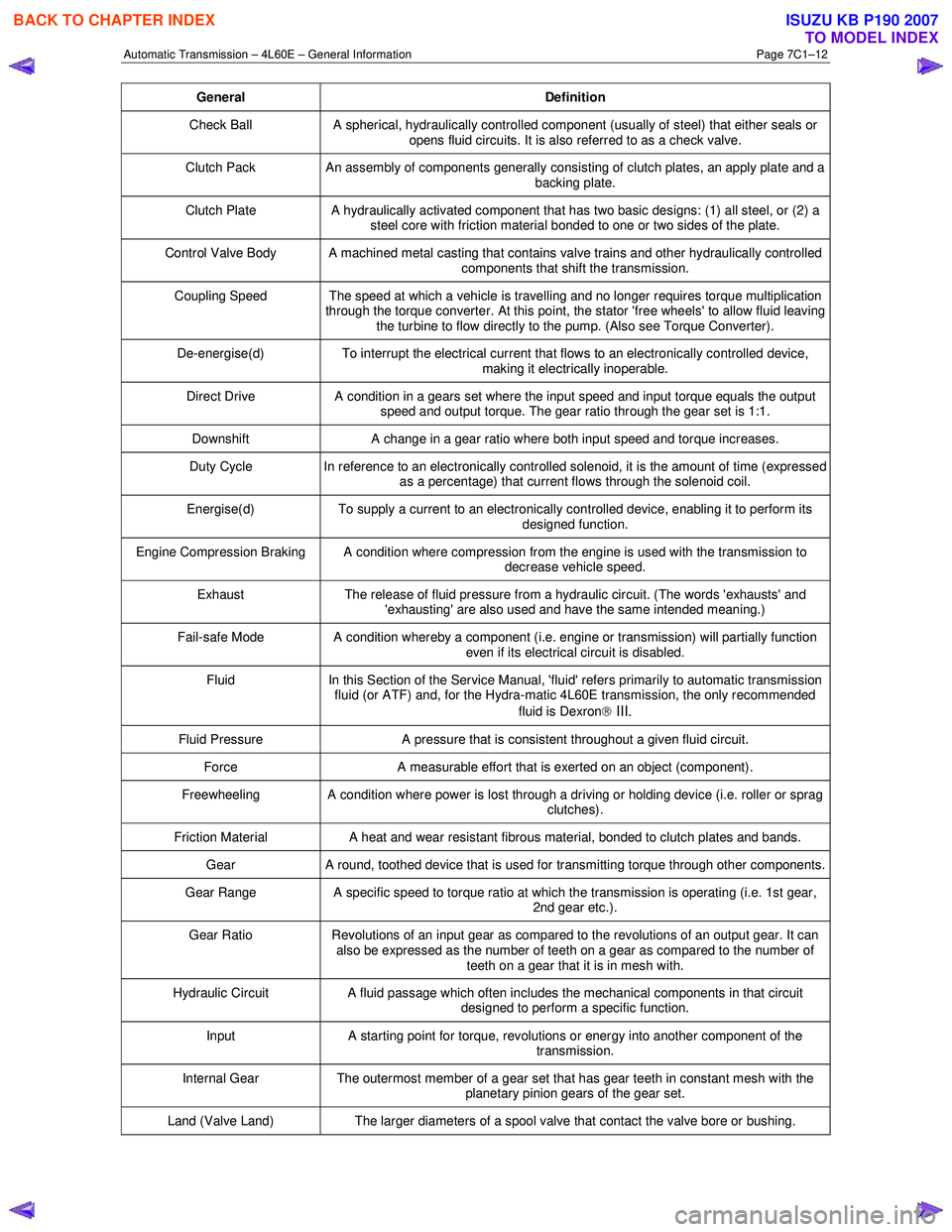

General Definition

Check Ball A spherical, hydraulically controlled component (usually of steel) that either seals or

opens fluid circuits. It is also referred to as a check valve.

Clutch Pack An assembly of components generally consisting of clutch plates, an apply plate and a

backing plate.

Clutch Plate A hydraulically activated component that has two basic designs: (1) all steel, or (2) a

steel core with friction material bonded to one or two sides of the plate.

Control Valve Body A machined metal casting that contains valve trains and other hydraulically controlled components that shift the transmission.

Coupling Speed The speed at which a vehicle is travelling and no longer requires torque multiplication through the torque converter. At this point, the stator 'free wheels' to allow fluid leaving

the turbine to flow directly to the pump. (Also see Torque Converter).

De-energise(d) To interrupt the electrical current that flows to an electronically controlled device,

making it electrically inoperable.

Direct Drive A condition in a gears set where the input speed and input torque equals the output

speed and output torque. The gear ratio through the gear set is 1:1.

Downshift A change in a gear ratio where both input speed and torque increases.

Duty Cycle In reference to an electronically controlled solenoid, it is the amount of time (expressed

as a percentage) that current flows through the solenoid coil.

Energise(d) To supply a current to an electronically controlled device, enabling it to perform its

designed function.

Engine Compression Braking A condition where compression from the engine is used with the transmission to decrease vehicle speed.

Exhaust The release of fluid pressure from a hydraulic circuit. (The words 'exhausts' and

'exhausting' are also used and have the same intended meaning.)

Fail-safe Mode A condition whereby a component (i.e. engine or transmission) will partially function even if its electrical circuit is disabled.

Fluid In this Section of the Service Manual, 'fluid' refers primarily to automatic transmission

fluid (or ATF) and, for the Hydra-matic 4L60E transmission, the only recommended

fluid is Dexron

III.

Fluid Pressure A pressure that is consistent throughout a given fluid circuit.

Force A measurable effort that is exerted on an object (component).

Freewheeling A condition where power is lost through a driving or holding device (i.e. roller or sprag

clutches).

Friction Material A heat and wear resistant fibrous material, bonded to clutch plates and bands.

Gear A round, toothed device that is used for transmitting torque through other components.

Gear Range A specific speed to torque ratio at which the transmission is operating (i.e. 1st gear,

2nd gear etc.).

Gear Ratio Revolutions of an input gear as compared to the revolutions of an output gear. It can

also be expressed as the number of teeth on a gear as compared to the number of

teeth on a gear that it is in mesh with.

Hydraulic Circuit A fluid passage which often includes the mechanical components in that circuit

designed to perform a specific function.

Input A starting point for torque, revolutions or energy into another component of the

transmission.

Internal Gear The outermost member of a gear set that has gear teeth in constant mesh with the

planetary pinion gears of the gear set.

Land (Valve Land) The larger diameters of a spool valve that contact the valve bore or bushing.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007