compression ratio ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1467 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-107

LNW 21BSH010401

12. Measure the bearing oil clearance.

• Install the bearing to the connecting rod big

end.

• Tighten the bearing cap to the two step o

f

angular tightening method.

• Use an inside dial indicator to measure the

connecting rod bearing inside diameter.

Connecting rod bearing cap bolt torque:

N ⋅m (kg ⋅m / lb ft)

1st step 29.4 (3.0 / 22)

2nd step 45 deg

If the clearance between the measured bearing

inside diameter and the crankpin exceeds the

specified limit, the bearing and/or the crankshaft

must be replaced.

Crankpin and bearing clearance mm (in)

Standard 0.029 - 0.083 (0.0011 - 0.0033)

Limit 0.10 (0.0039)

Reassembly

1. Install the piston.

2. Install the connecting rod. • Install it so that the front mark of the head o

f

the piston, and the connecting rod forging mark

(projecting) on the connecting rod, both face in

the same direction.

• Install the snap ring of one side.

LNW 46ASH004601

Legend

1. Front Mark

2. Forging Mark (Projecting)

4. Apply enough engine oil on the piston pin, push it

in the piston and the connecting rod small edge.

5. Use snap ring pliers to install the snap ring.

Note:

Make sure that the snap ring is installed in the ring

groove properly. Make sure that the connecting rod

moves smoothly.

015R100001

6. Use ring pliers to install the piston ring.

• Install the piston rings in the order shown in the

illustration.

• Install 2nd and 1st compression rings in this

order so that the marks “2N” and “N” face

upward.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1946 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-329

Air Intake System ChecksInspect the air intake system for the following conditions.

• Air cleaner, air intake ducts and charge air cooler for a restriction, holes, or leaks.

• A restriction in the turbocharger inlet duct.

• Intake throttle valve for a stuck condition.

• A restriction or leak in the intake manifold.

Exhaust System Checks Inspect the exhaust system for a possible restriction. Refer to the Exhaust System

section.

Engine Mechanical Checks Inspect the engine mechanical for the following conditions. Refer to the Engine

Mechanical section.

• Poor cylinder compression.

• Improper mechanical timing (timing gear and timing chain).

• Improper valve gap.

• Broken or weak valve springs.

• Worn camshaft lobes.

Electrical System Checks Inspect the engine electrical for the following conditions. Refer to the Engine Electrical

section.

• Glow plug control system operation. Refer to Glow Control System Check in this section.

• Slow cranking speed.

• Weakened batteries.

Checks

Action

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1948 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-331

Air Intake System ChecksInspect the air intake system for the following conditions.

• Air cleaner, air intake ducts and charge air cooler for a restriction, holes, or leaks.

• A restriction in the turbocharger inlet duct.

• Intake throttle valve for a stuck condition.

• A restriction or leak in the intake manifold.

Exhaust System Checks Inspect the exhaust system for a possible restriction. Refer to the Exhaust System

section.

Engine Mechanical Checks Inspect the engine mechanical for the following conditions. Refer to the Engine

Mechanical section.

• Poor cylinder compression.

• Improper mechanical timing (timing gear and timing chain).

• Improper valve gap.

• Broken or weak valve springs.

• Worn camshaft lobes.

• Incorrect basic engine parts such as camshaft, cylinder head, pistons, etc..

Additional Checks • Electromagnetic interference (EMI) on the reference circuit can cause an engine

miss condition. The scan tool can usually detect EMI by monitoring the engine

speed. A sudden increase in speed with little change in actual engine speed change

indicates that EMI is present. If a problem exists, check routing of high voltage

components, such as fuel injector solenoid valve wiring, near the sensor circuits.

• Faulty engine mounts.

• Faulty crank pulley.

• Faulty generator & A/C compressor.

• Generator output voltage.

• EGR system operating correctly. Refer to EGR Control System Check in this section.

• A/C operation.

Checks

Action

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1954 of 6020

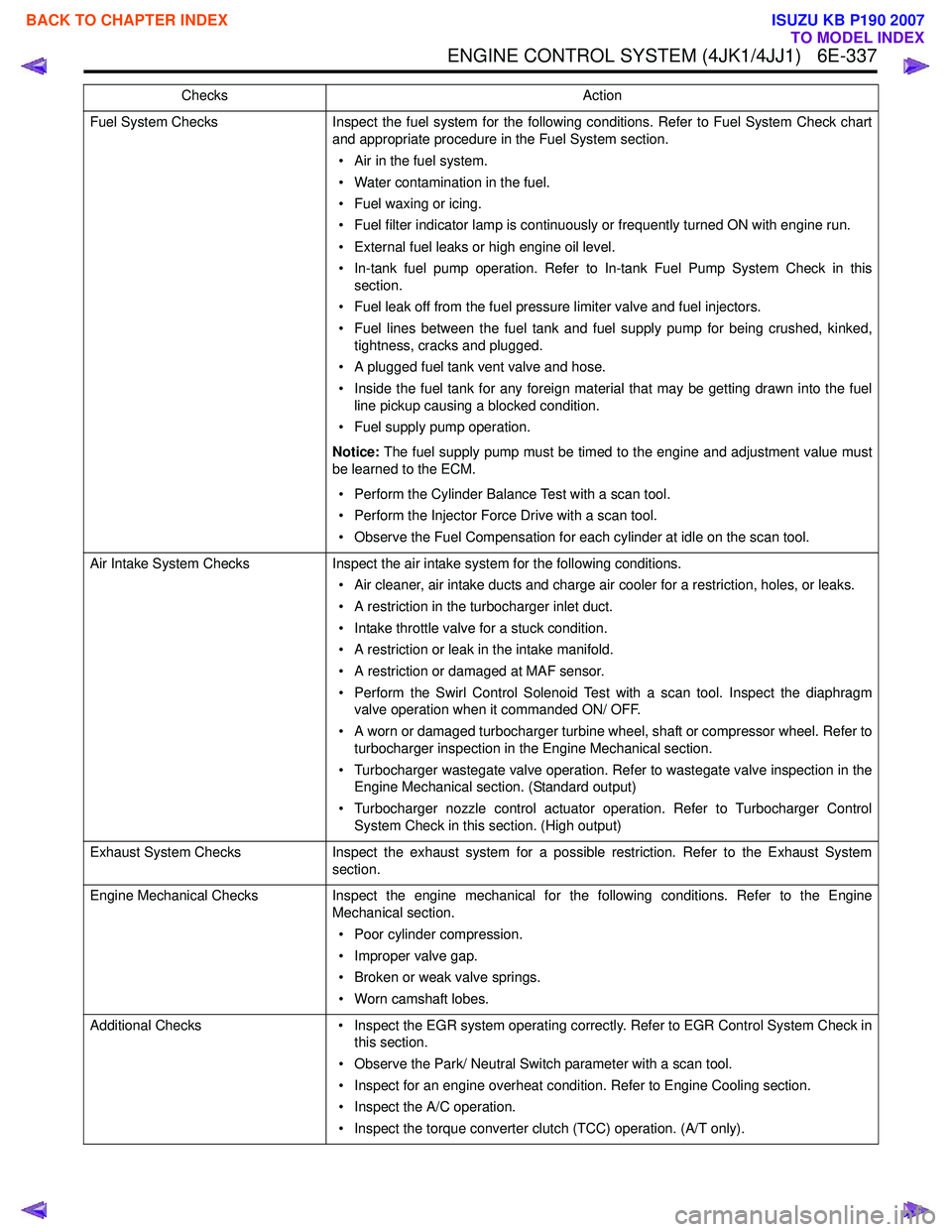

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-337

Fuel System ChecksInspect the fuel system for the following conditions. Refer to Fuel System Check chart

and appropriate procedure in the Fuel System section.

• Air in the fuel system.

• Water contamination in the fuel.

• Fuel waxing or icing.

• Fuel filter indicator lamp is continuously or frequently turned ON with engine run.

• External fuel leaks or high engine oil level.

• In-tank fuel pump operation. Refer to In-tank Fuel Pump System Check in this section.

• Fuel leak off from the fuel pressure limiter valve and fuel injectors.

• Fuel lines between the fuel tank and fuel supply pump for being crushed, kinked, tightness, cracks and plugged.

• A plugged fuel tank vent valve and hose.

• Inside the fuel tank for any foreign material that may be getting drawn into the fuel line pickup causing a blocked condition.

• Fuel supply pump operation.

Notice: The fuel supply pump must be timed to the engine and adjustment value must

be learned to the ECM.

• Perform the Cylinder Balance Test with a scan tool.

• Perform the Injector Force Drive with a scan tool.

• Observe the Fuel Compensation for each cylinder at idle on the scan tool.

Air Intake System Checks Inspect the air intake system for the following conditions.

• Air cleaner, air intake ducts and charge air cooler for a restriction, holes, or leaks.

• A restriction in the turbocharger inlet duct.

• Intake throttle valve for a stuck condition.

• A restriction or leak in the intake manifold.

• A restriction or damaged at MAF sensor.

• Perform the Swirl Control Solenoid Test with a scan tool. Inspect the diaphragm valve operation when it commanded ON/ OFF.

• A worn or damaged turbocharger turbine wheel, shaft or compressor wheel. Refer to turbocharger inspection in the Engine Mechanical section.

• Turbocharger wastegate valve operation. Refer to wastegate valve inspection in the Engine Mechanical section. (Standard output)

• Turbocharger nozzle control actuator operation. Refer to Turbocharger Control System Check in this section. (High output)

Exhaust System Checks Inspect the exhaust system for a possible restriction. Refer to the Exhaust System

section.

Engine Mechanical Checks Inspect the engine mechanical for the following conditions. Refer to the Engine

Mechanical section.

• Poor cylinder compression.

• Improper valve gap.

• Broken or weak valve springs.

• Worn camshaft lobes.

Additional Checks • Inspect the EGR system operating correctly. Refer to EGR Control System Check in

this section.

• Observe the Park/ Neutral Switch parameter with a scan tool.

• Inspect for an engine overheat condition. Refer to Engine Cooling section.

• Inspect the A/C operation.

• Inspect the torque converter clutch (TCC) operation. (A/T only).

Checks

Action

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1956 of 6020

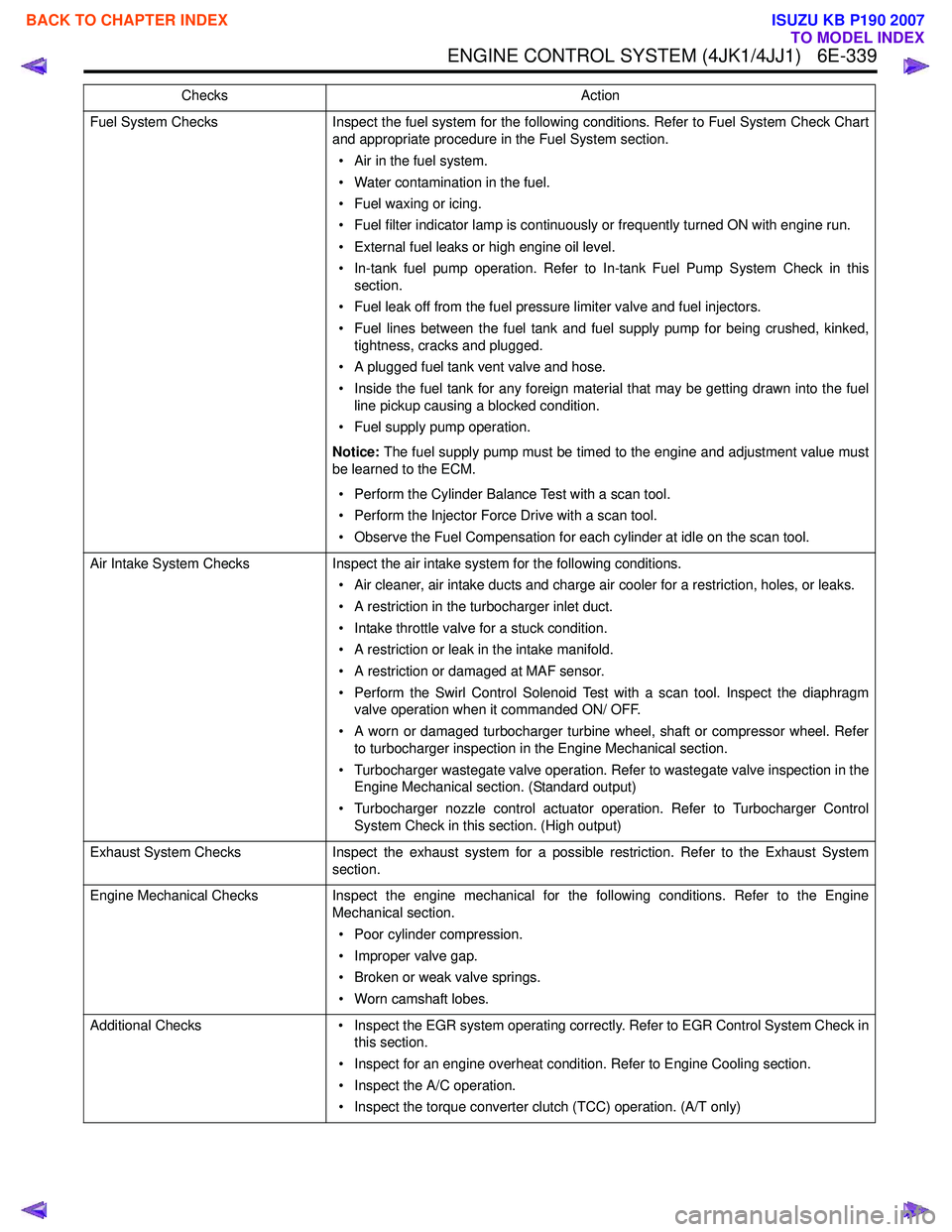

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-339

Fuel System ChecksInspect the fuel system for the following conditions. Refer to Fuel System Check Chart

and appropriate procedure in the Fuel System section.

• Air in the fuel system.

• Water contamination in the fuel.

• Fuel waxing or icing.

• Fuel filter indicator lamp is continuously or frequently turned ON with engine run.

• External fuel leaks or high engine oil level.

• In-tank fuel pump operation. Refer to In-tank Fuel Pump System Check in this section.

• Fuel leak off from the fuel pressure limiter valve and fuel injectors.

• Fuel lines between the fuel tank and fuel supply pump for being crushed, kinked, tightness, cracks and plugged.

• A plugged fuel tank vent valve and hose.

• Inside the fuel tank for any foreign material that may be getting drawn into the fuel line pickup causing a blocked condition.

• Fuel supply pump operation.

Notice: The fuel supply pump must be timed to the engine and adjustment value must

be learned to the ECM.

• Perform the Cylinder Balance Test with a scan tool.

• Perform the Injector Force Drive with a scan tool.

• Observe the Fuel Compensation for each cylinder at idle on the scan tool.

Air Intake System Checks Inspect the air intake system for the following conditions.

• Air cleaner, air intake ducts and charge air cooler for a restriction, holes, or leaks.

• A restriction in the turbocharger inlet duct.

• Intake throttle valve for a stuck condition.

• A restriction or leak in the intake manifold.

• A restriction or damaged at MAF sensor.

• Perform the Swirl Control Solenoid Test with a scan tool. Inspect the diaphragm valve operation when it commanded ON/ OFF.

• A worn or damaged turbocharger turbine wheel, shaft or compressor wheel. Refer to turbocharger inspection in the Engine Mechanical section.

• Turbocharger wastegate valve operation. Refer to wastegate valve inspection in the Engine Mechanical section. (Standard output)

• Turbocharger nozzle control actuator operation. Refer to Turbocharger Control System Check in this section. (High output)

Exhaust System Checks Inspect the exhaust system for a possible restriction. Refer to the Exhaust System

section.

Engine Mechanical Checks Inspect the engine mechanical for the following conditions. Refer to the Engine

Mechanical section.

• Poor cylinder compression.

• Improper valve gap.

• Broken or weak valve springs.

• Worn camshaft lobes.

Additional Checks • Inspect the EGR system operating correctly. Refer to EGR Control System Check in

this section.

• Inspect for an engine overheat condition. Refer to Engine Cooling section.

• Inspect the A/C operation.

• Inspect the torque converter clutch (TCC) operation. (A/T only)

Checks

Action

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1957 of 6020

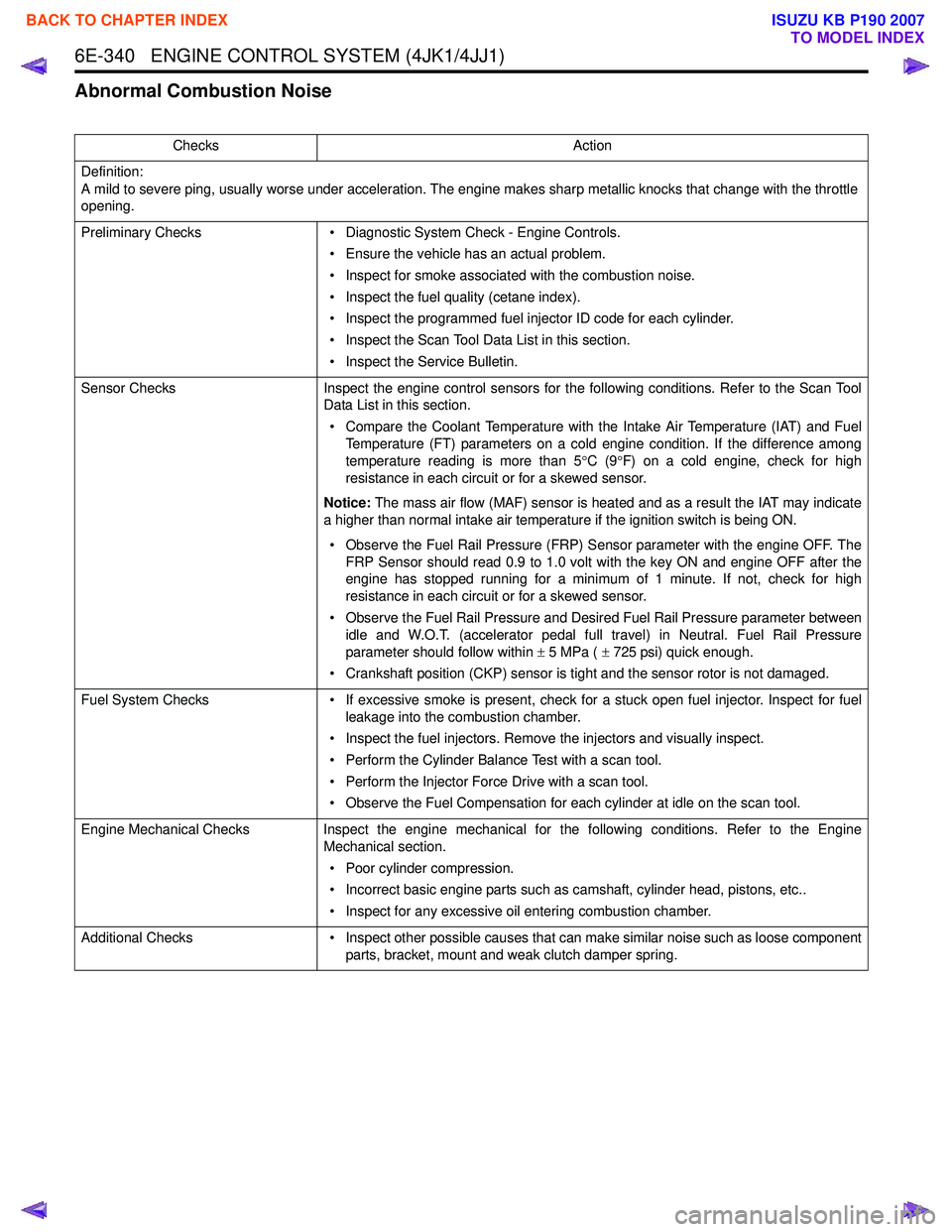

6E-340 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Abnormal Combustion Noise

ChecksAction

Definition:

A mild to severe ping, usually worse under acceleration. The engine makes sharp metallic knocks that change with the throttle

opening.

Preliminary Checks • Diagnostic System Check - Engine Controls.

• Ensure the vehicle has an actual problem.

• Inspect for smoke associated with the combustion noise.

• Inspect the fuel quality (cetane index).

• Inspect the programmed fuel injector ID code for each cylinder.

• Inspect the Scan Tool Data List in this section.

• Inspect the Service Bulletin.

Sensor Checks Inspect the engine control sensors for the following conditions. Refer to the Scan Tool

Data List in this section.

• Compare the Coolant Temperature with the Intake Air Temperature (IAT) and Fuel Temperature (FT) parameters on a cold engine condition. If the difference among

temperature reading is more than 5 °C (9 °F) on a cold engine, check for high

resistance in each circuit or for a skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT may indicate

a higher than normal intake air temperature if the ignition switch is being ON.

• Observe the Fuel Rail Pressure (FRP) Sensor parameter with the engine OFF. The FRP Sensor should read 0.9 to 1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1 minute. If not, check for high

resistance in each circuit or for a skewed sensor.

• Observe the Fuel Rail Pressure and Desired Fuel Rail Pressure parameter between idle and W.O.T. (accelerator pedal full travel) in Neutral. Fuel Rail Pressure

parameter should follow within ± 5 MPa ( ± 725 psi) quick enough.

• Crankshaft position (CKP) sensor is tight and the sensor rotor is not damaged.

Fuel System Checks • If excessive smoke is present, check for a stuck open fuel injector. Inspect for fuel

leakage into the combustion chamber.

• Inspect the fuel injectors. Remove the injectors and visually inspect.

• Perform the Cylinder Balance Test with a scan tool.

• Perform the Injector Force Drive with a scan tool.

• Observe the Fuel Compensation for each cylinder at idle on the scan tool.

Engine Mechanical Checks Inspect the engine mechanical for the following conditions. Refer to the Engine

Mechanical section.

• Poor cylinder compression.

• Incorrect basic engine parts such as camshaft, cylinder head, pistons, etc..

• Inspect for any excessive oil entering combustion chamber.

Additional Checks • Inspect other possible causes that can make similar noise such as loose component

parts, bracket, mount and weak clutch damper spring.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1959 of 6020

6E-342 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Air Intake System ChecksInspect the air intake system for the following conditions.

• Air cleaner, air intake ducts and charge air cooler for a restriction, holes, or leaks.

• A restriction in the turbocharger inlet duct.

• Intake throttle valve for a stuck condition.

• A restriction or leak in the intake manifold.

• A restriction or damaged at MAF sensor.

• Perform the Swirl Control Solenoid Test with a scan tool. Inspect the diaphragm valve operation when it commanded ON/ OFF.

• A worn or damaged turbocharger turbine wheel, shaft or compressor wheel. Refer to turbocharger inspection in the Engine Mechanical section.

• Turbocharger wastegate valve operation. Refer to wastegate valve inspection in the Engine Mechanical section. (Standard output)

• Turbocharger nozzle control actuator operation. Refer to Turbocharger Control System Check in this section. (High output)

Exhaust System Checks Inspect the exhaust system for a possible restriction. Refer to the Exhaust System

section.

Engine Mechanical Checks Inspect the engine mechanical for the following conditions. Refer to the Engine

Mechanical section.

• Poor cylinder compression.

• Improper valve gap.

• Broken or weak valve springs.

• Worn camshaft lobes.

Checks

Action

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1963 of 6020

6E-346 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Engine Mechanical ChecksInspect the engine mechanical for the following conditions. Refer to the Engine

Mechanical section.

• Poor cylinder compression.

• Improper mechanical timing (timing gear and timing chain).

• Improper valve gap.

• Broken or weak valve springs.

• Worn camshaft lobes.

• Thermostat working (open stuck).

• Any excessive oil entering combustion chamber.

Electrical System Checks • Glow plug control (preheating) system operation. Refer to Glow Control System

Check in this section.

Checks

Action

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2026 of 6020

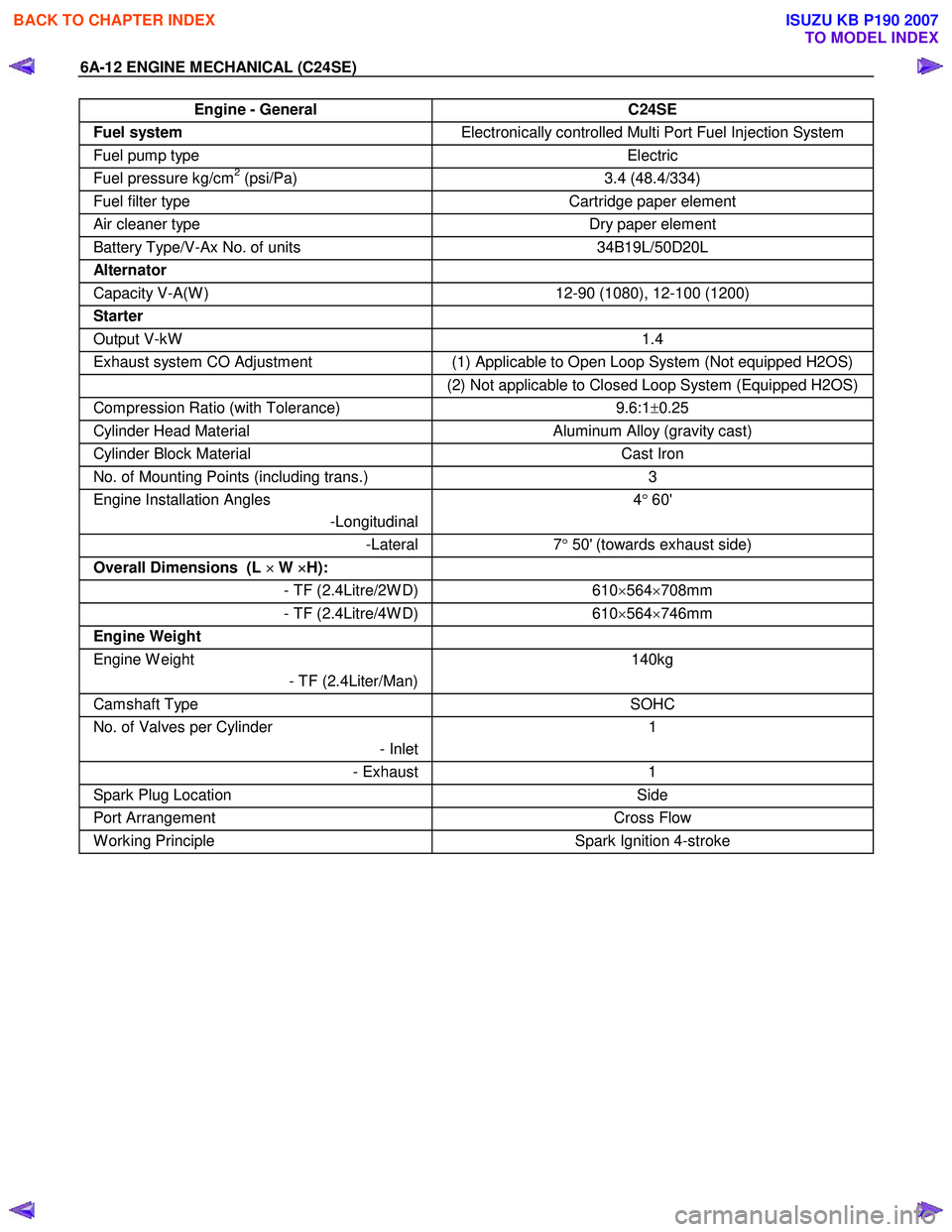

6A-12 ENGINE MECHANICAL (C24SE)

Engine - General C24SE

Fuel system Electronically controlled Multi Port Fuel Injection System

Fuel pump type Electric

Fuel pressure kg/cm2 (psi/Pa) 3.4 (48.4/334)

Fuel filter type Cartridge paper element

Air cleaner type Dry paper element

Battery Type/V-Ax No. of units 34B19L/50D20L

Alternator

Capacity V-A(W ) 12-90 (1080), 12-100 (1200)

Starter

Output V-kW 1.4

Exhaust system CO Adjustment (1) Applicable to Open Loop System (Not equipped H2OS)

(2) Not applicable to Closed Loop System (Equipped H2OS)

Compression Ratio (with Tolerance) 9.6:1±0.25

Cylinder Head Material Aluminum Alloy (gravity cast)

Cylinder Block Material Cast Iron

No. of Mounting Points (including trans.) 3

Engine Installation Angles

-Longitudinal 4

° 60'

-Lateral 7° 50' (towards exhaust side)

Overall Dimensions (L ×

××

×

W ×

××

×

H):

- TF (2.4Litre/2W D)610×564 ×708mm

- TF (2.4Litre/4W D) 610×564 ×746mm

Engine Weight

Engine W eight

- TF (2.4Liter/Man) 140kg

Camshaft Type

SOHC

No. of Valves per Cylinder

- Inlet1

- Exhaust

1

Spark Plug Location Side

Port Arrangement Cross Flow

W orking Principle Spark Ignition 4-stroke

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2029 of 6020

ENGINE MECHANICAL (C24SE) 6A-15

Engine Specification Matrix for destination

04 HEO FOR TF MODEL:

VEHICLE MODEL TFR/S 2.4L

Major Description

AUSTRALIA, CHILE,

GULF, NEW

ZEALAND, SAUDI ARABIA, SOUTH AFRICA COLOMBIA, COSTA

RICA, EQUADOR, GUATEMALA BOLIVIA, GENERAL

EXPORT, PERU, VENEZUELA

VEHICLE TYPE 4× 2 4x4 4 ×2 4 ×4 4 ×2

VEHICLE IDENT. CODE TX TY TX TY TX

ENGINE TYPE C24SE ← ←

FUEL CONTROL SYSYTEM CLOSE LOOP CLOSED LOOP OPEN LOOP

COMPRESSION RATIO 9.6:1 ← ←

FUEL OCTANE(ROD) 91RON 85RON 80RON

FUEL TYPE UN-LEADED UN-LEADED LEADED

HO2 YES YES YES NO

EVAP CANISTER YES YES YES YES

PURGE CONTROL

SOLENOID YES

YES YES YES

CHECK & RELIEF VALVE YES YES YES YES

ECM YES YES YES YES

EXHAUST SYSTEM

FRONT PIPE

SILENCER

TW C YES YES YES NO

CO ADJUSTMENT NO NO NO YES

Refer to 6A-77 Refer to 6A-77 Refer to 6A-77

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007