wheel bolt torque ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4473 of 6020

ON-VEHICLE SERVICE (JR405E) 7A3-19

Install or Connect

1. Align the manual valve and the manual plate of the

transmission case.

43ASSY119

2. Install the control valve assembly and tighten the 12 fixing bolts to the specified torque.

Number of bolts Length Color

10 (A) 40 mm (1.57 in) Gold

2 (B) 30 mm (1.18 in) Gold

Bolt torque : 8 N·m (0.8 kgf·m/69 lb·in)

3. Connect the 2 harness connectors.

4. If removed, install the oil strainer.

Refer to “Solenoids, Oil Pressure Switch and Oil Temperature Sensor” previously in this section.

5. Install the new gasket and oil pan.

Bolt torque : 8 N·m (0.8 kgf·m/69 lb·in)

6. Fill with the fluid.

Refer to “ATF CHANGE” in this section.

7. Connect the negative battery cable.

8. Remove the wheel blocks.

FLUSHING THE TRANSMISSION FLUID COOLER AND LINE

The fluid cooler and lines may be flushed under the

following condition. This will help prevent more trouble

after the transmission is repaired.

1. W hen an abnormal amount of debris is found.

2. W hen an abnormal wear or chips on gears and shafts is found while overhauling.

3. W hen there is abnormal clutch facing wear and oil contamination found.

Procedures

1. Block the wheels.

2. Disconnect the negative battery cable.

3. Raise the vehicle and support it with suitable safet

y

stands.

4. Disconnect the fluid cooler lines at the transmission case and fluid cooler.

5. Flush and back-flush the fluid cooler and lines using solvent and compressed air.

Note:

DO NOT exceed (200 kPa/2.0 kgf/cm

2/28 psi) air

pressure, or damage may result to oil cooler.

6. Remove all remaining solvent from the system with

compressed air.

7. Flush the cooling system again with Automatic Transmission Fluid (ATF).

After the final flush, connect all lines.

Cooler line joint connector torque :

44 N·m (4.5 kgf·m/33 lb·ft)

8. Replenish the ATF.

9. Start the engine to test the system for the free flow o

f

fluid. If the flow is restricted, the cooler assembly o

r

lines must be replaced.

Repeated cleaning and flushing may not remove all the debris from the fluid cooler circuit.

Move the select lever through the various ranges and return to neutral.

Check for fluid level.

If the fluid level is below the specified range, ATF must be added.

10. Connect the negative battery cable.

11. Remove the safety stands.

12. Remove the wheel blocks.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4476 of 6020

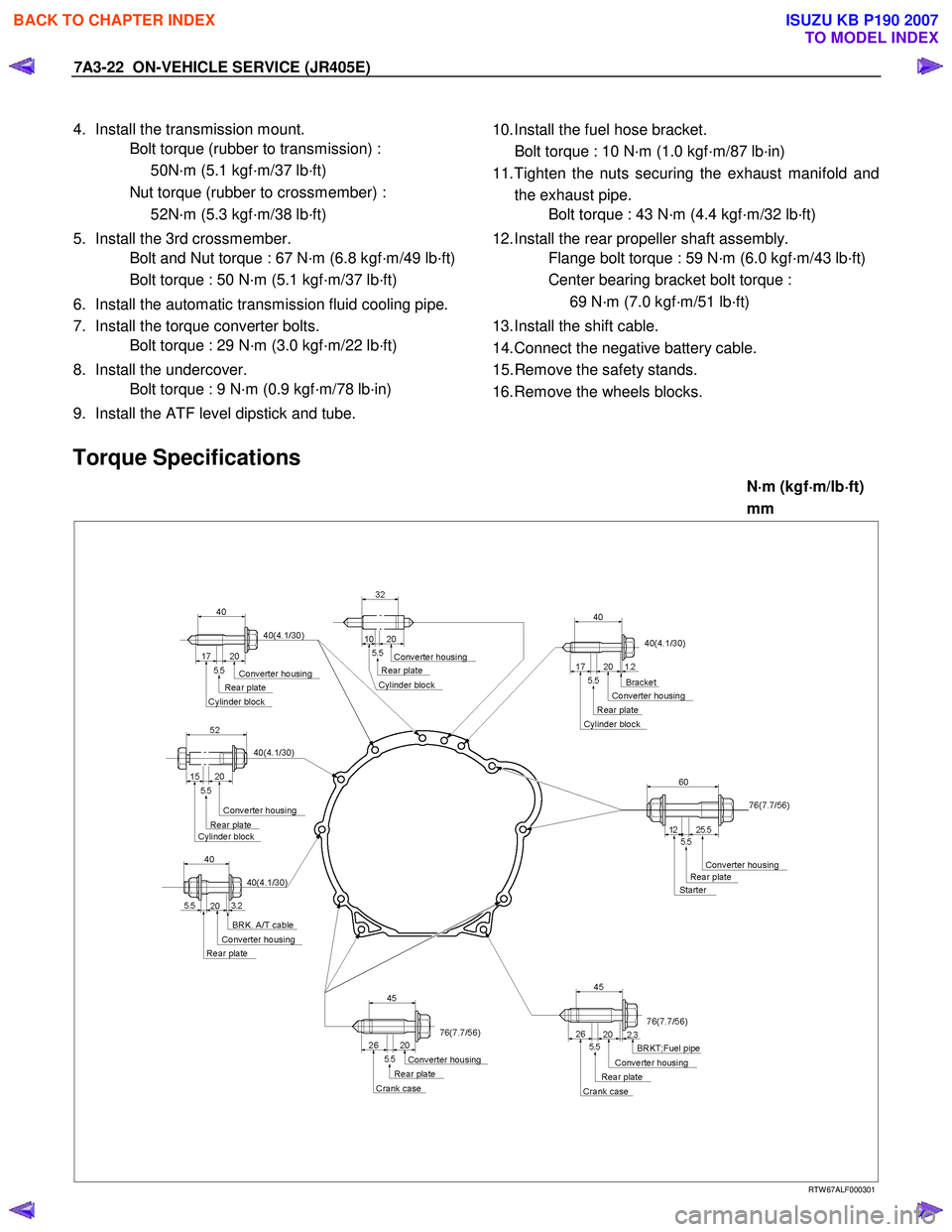

7A3-22 ON-VEHICLE SERVICE (JR405E)

4. Install the transmission mount.

Bolt torque (rubber to transmission) :

50N·m (5.1 kgf·m/37 lb·ft)

Nut torque (rubber to crossmember) :

52N·m (5.3 kgf·m/38 lb·ft)

5. Install the 3rd crossmember.

Bolt and Nut torque : 67 N·m (6.8 kgf·m/49 lb·ft)

Bolt torque : 50 N·m (5.1 kgf·m/37 lb·ft)

6. Install the automatic transmission fluid cooling pipe.

7. Install the torque converter bolts.

Bolt torque : 29 N·m (3.0 kgf·m/22 lb·ft)

8. Install the undercover.

Bolt torque : 9 N·m (0.9 kgf·m/78 lb·in)

9. Install the ATF level dipstick and tube.

10. Install the fuel hose bracket.

Bolt torque : 10 N·m (1.0 kgf·m/87 lb·in)

11. Tighten the nuts securing the exhaust manifold and the exhaust pipe.

Bolt torque : 43 N·m (4.4 kgf·m/32 lb·ft)

12. Install the rear propeller shaft assembly.

Flange bolt torque : 59 N·m (6.0 kgf·m/43 lb·ft)

Center bearing bracket bolt torque :

69 N·m (7.0 kgf·m/51 lb·ft)

13. Install the shift cable.

14. Connect the negative battery cable.

15. Remove the safety stands.

16. Remove the wheels blocks.

Torque Specifications

N ⋅

⋅⋅

⋅

m (kgf ⋅

⋅⋅

⋅

m/lb ⋅

⋅⋅

⋅

ft)

mm

RTW 67ALF000301

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4802 of 6020

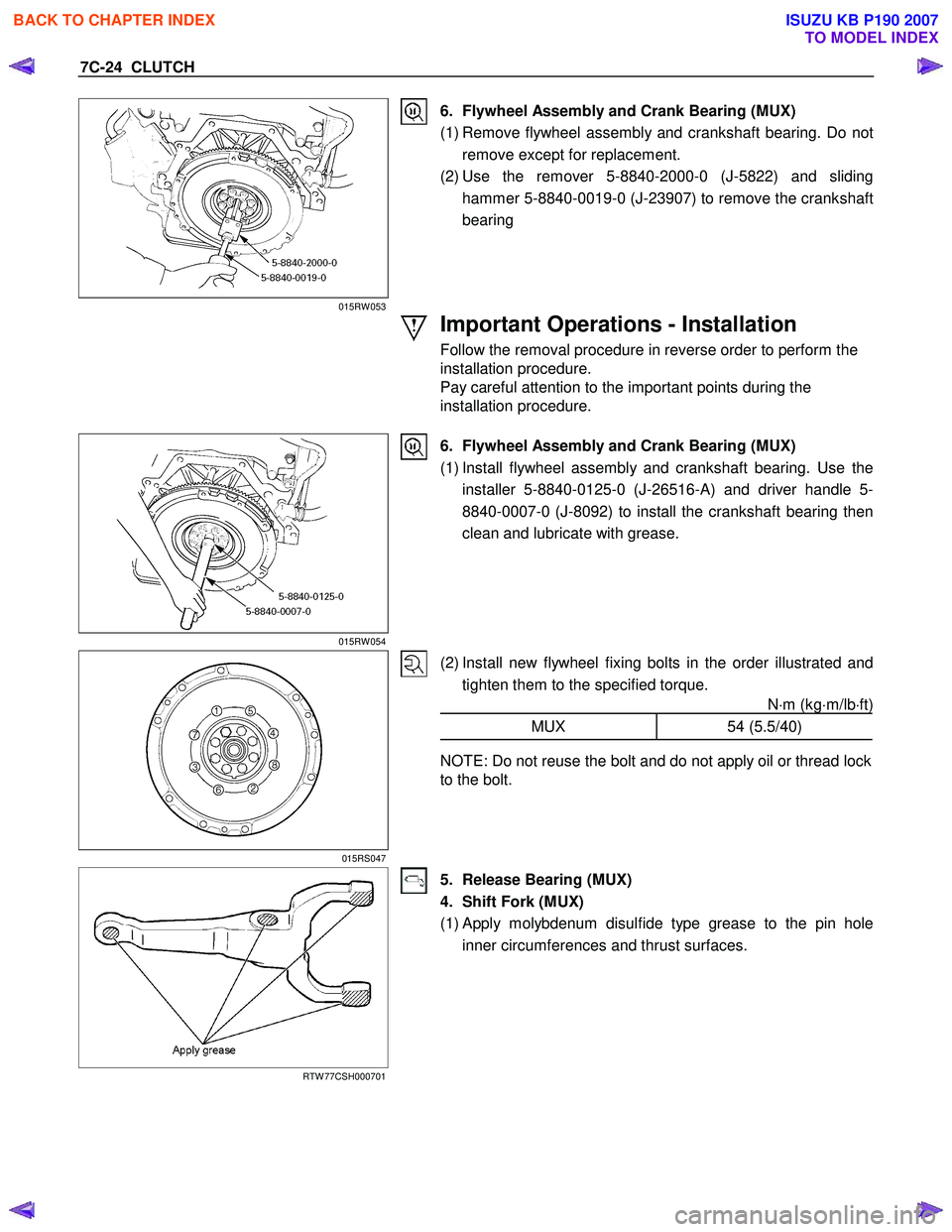

7C-24 CLUTCH

015RW 053

6. Flywheel Assembly and Crank Bearing (MUX)

(1) Remove flywheel assembly and crankshaft bearing. Do not remove except for replacement.

(2) Use the remover 5-8840-2000-0 (J-5822) and sliding hammer 5-8840-0019-0 (J-23907) to remove the crankshaft

bearing

Important Operations - Installation

Follow the removal procedure in reverse order to perform the

installation procedure.

Pay careful attention to the important points during the

installation procedure.

015RW 054

6. Flywheel Assembly and Crank Bearing (MUX)

(1) Install flywheel assembly and crankshaft bearing. Use the installer 5-8840-0125-0 (J-26516-A) and driver handle 5-

8840-0007-0 (J-8092) to install the crankshaft bearing then

clean and lubricate with grease.

015RS047

(2) Install new flywheel fixing bolts in the order illustrated and tighten them to the specified torque. N⋅m (kg ⋅m/lb ⋅ft)

MUX 54 (5.5/40)

NOTE: Do not reuse the bolt and do not apply oil or thread lock

to the bolt.

RTW 77CSH000701

5. Release Bearing (MUX)

4. Shift Fork (MUX)

(1)

Apply molybdenum disulfide type grease to the pin hole

inner circumferences and thrust surfaces.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4803 of 6020

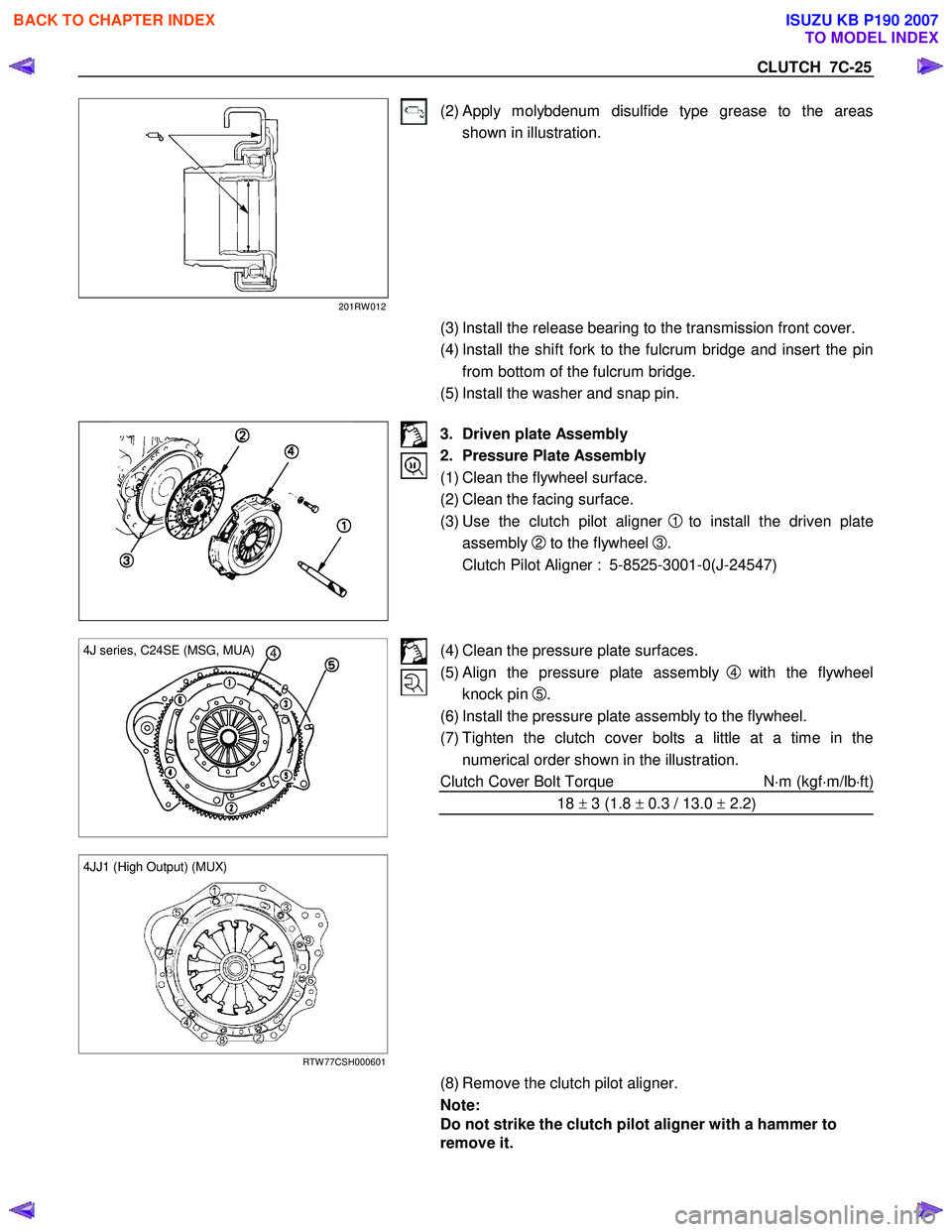

CLUTCH 7C-25

201RW 012

(2) Apply molybdenum disulfide type grease to the areas shown in illustration.

(3) Install the release bearing to the transmission front cover.

(4) Install the shift fork to the fulcrum bridge and insert the pin from bottom of the fulcrum bridge.

(5) Install the washer and snap pin.

3. Driven plate Assembly

2. Pressure Plate Assembly

(1) Clean the flywheel surface.

(2) Clean the facing surface.

(3) Use the clutch pilot aligner

1 to install the driven plate

assembly

2 to the flywheel 3.

Clutch Pilot Aligner : 5-8525-3001-0(J-24547)

4 4J series, C24SE (MSG, MUA)

(4) Clean the pressure plate surfaces.

(5) Align the pressure plate assembly

4 with the flywheel

knock pin

5.

(6) Install the pressure plate assembly to the flywheel.

(7) Tighten the clutch cover bolts a little at a time in the numerical order shown in the illustration.

Clutch Cover Bolt Torque N⋅m (kgf ⋅m/lb ⋅ft)

18 ± 3 (1.8 ± 0.3 / 13.0 ± 2.2)

4JJ1 (High Output) (MUX)

RTW 77CSH000601

(8) Remove the clutch pilot aligner.

Note:

Do not strike the clutch pilot aligner with a hammer to

remove it.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5792 of 6020

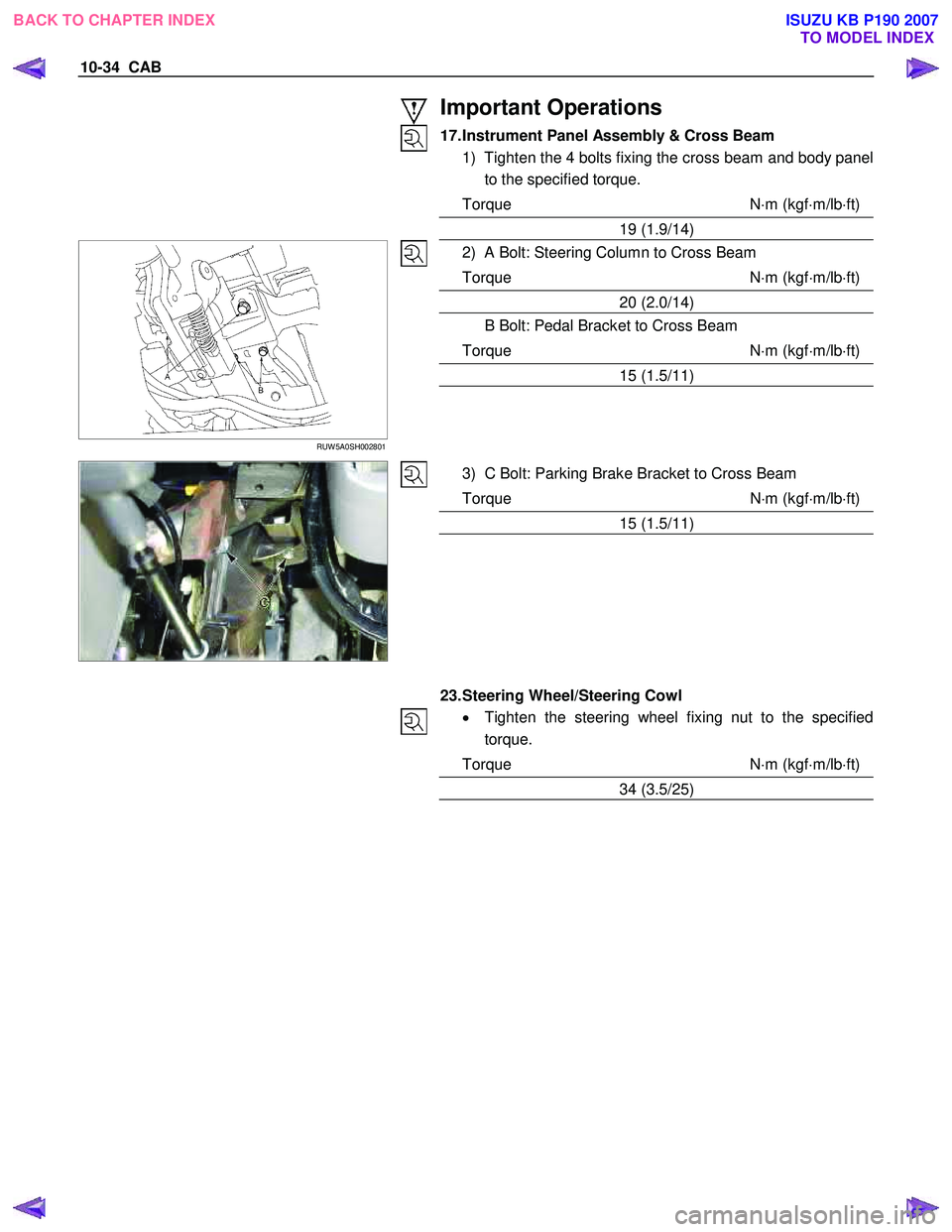

10-34 CAB

Important Operations

17. Instrument Panel Assembly & Cross Beam 1) Tighten the 4 bolts fixing the cross beam and body panel to the specified torque.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

19 (1.9/14)

RUW 5A0SH002801

2) A Bolt: Steering Column to Cross Beam

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

20 (2.0/14)

B Bolt: Pedal Bracket to Cross Beam

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

15 (1.5/11)

3) C Bolt: Parking Brake Bracket to Cross Beam

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

15 (1.5/11)

23. Steering Wheel/Steering Cowl • Tighten the steering wheel fixing nut to the specified

torque.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

34 (3.5/25)

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007