DTC CHECK ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4396 of 6020

7A2-112 TRANSMISSION CONTROL SYSTEM (JR405E)

D3: Gearshift Point is Low or High at All Points

D4: Gearshift Point is Low or High at Limited Area

D5: No Kick-down

E1: No Gearshift

Checks Action

Definition: • Gearshift point is deviated from the shift speed chart.

• Gear is not shifted up properly, even though the vehicle is accelerating.

• Gear is not shifted immediately and enough acceleration cannot be obtained, even though the accelerator pedal is being stepped on.

Diagnosis Hints • Inspect the output shaft speed (OSS) sensor for faulty operation.

• Incorrect accelerator pedal position signal is suspected. Observe the Accelerator Pedal Position (APP). APP parameter should change linearly

from 0 to 99 or 100% according to the accelerator pedal operation.

Checks Action

Definition:

The engine speeds up but the vehicle speed does not increase when the accelerator pedal is being stepped on at starting.

Diagnosis Hints Incorrect accelerator pedal position signal is suspected. Observe the

Accelerator Pedal Position (APP). APP parameter should change linearly from

0 to 99 or 100% according to the accelerator pedal operation.

Checks Action

Definition: • Gear is fixed, such as no gearshift from 1st to 2nd, 2nd to 3rd, and 3rd to 4th.

• Sometimes the gear is shifted, and sometimes it is not possible.

Diagnosis Hints • Fixing at same gear speed, a signal error from the accelerator pedal

position (APP) sensor or trouble in the transmission main unit are

suspected.

• Slipping of the clutch is suspected. Gear ratio error DTC might be set.

Transmission Range Switch & Selector Lever

Cable Checks Inspect the transmission range switch and selector lever cable for misadjusting

or disordering. Refer to On-Vehicle Service section.

Transmission Fluid Checks Inspect the transmission fluid for the following conditions. If the transmission

fluid is extremely blacked, contaminated or smells burnt, slipping of clutch is

suspected.

• Low quantity

• Contamination

•Smell

Line Pressure Checks Inspect the line pressure in forward ranges for a possible dropped pressure.

Refer to Line Pressure Test in Test Instruction section.

Stall Speed Checks Inspect the stall speed in forward ranges. Refer to Stall Test in Test Instruction

section.

Control Valve Body Checks Inspect the valve body for the following conditions.

• Faulty operation

• Sticking spool valve

• Sticking shift solenoid valve. Perform function check. Refer to On-Vehicle Service section.

• Clogged hydraulic circuit

Clutch and Brake Checks Inspect the low clutch, high clutch or low & reverse brake for slipping.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4399 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-115

F3: Noise or Vibration Occurs During in R, D, 3, 2 or L Range

F4: Engine Brake Does Not Apply in L Range

F5: Engine Stalls Before Vehicle Stops from Running

G1: Vehicle Moves in P Range or Parking is Not Disengaged in Other Than P Range

Diagnosis Hints The same causes as in category No. “C1 - C8: Engine Race Up (Slipping)”

are suspected. When the condition of No. C1 - C8 grows worse, No. F2

results.

Checks Action

Definition:

Noise or vibration occurs in the vicinity of the transmission during running.

Diagnosis Hints Cause other than transmission is suspected. Reproduce the running

condition using a lift up, chassis dynamo, etc. to investigate the origin of the

noise and vibration.

Additional Checks • Inspect the differential gear noise.

• Inspect the propeller shaft noise.

• Inspect the tires for unbalanced or poor uniformity.

Checks

Action

Checks Action

Definition:

The engine brake does not apply, allowing the vehicle to run freely when the accelerator pedal is released at low speed in L

range.

Diagnosis Hints • Slipping of the clutch is suspected. Gear ratio error DTC might be set.

Line Pressure Checks Inspect the line pressure in forward ranges for a possible dropped pressure.

Refer to Line Pressure Test in Test Instruction section.

Control Valve Body Checks Inspect the valve body for the following conditions.

• Faulty operation

• Sticking spool valve

• Sticking shift solenoid valve. Perform function check. Refer to On- Vehicle Service section.

• Clogged hydraulic circuit

Clutch and Brake Checks Inspect the low & reverse brake for slipping.

Sensor Checks Inspect the input shaft speed (ISS) sensor and output shaft speed (OSS)

sensor for faulty operation.

Checks Action

Definition:

The engine stalls simultaneously with the vehicle when the brake pedal is stepped on to stop the vehicle during running.

Diagnosis Hints The same causes as in category No. “B5: Engine Stalls When Selector Lever

is Changed from N to R, D, 3, 2 or L Range” is suspected.

Checks Action

Definition:

Vehicle moves even though it stops on a slope and P range is selected.

Vehicle does not move even though a position other than P range is selected, and the accelerator pedal is being stepped on.

Diagnosis Hints If the vehicle moves in N range, refer to category No. “B1: Vehicle Runs in

N Range”.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4402 of 6020

7A2-118 TRANSMISSION CONTROL SYSTEM (JR405E)

J1: Transmission Fluid Leaks from Breather

J2: Transmission Fluid Leaks Between Engine and Converter Housing

J3: Transmission Fluid Leaks Between Converter Housing and Transmission Case

J4: Transmission Fluid Leaks Between Transmission Case and Extension Housing

J3: Transmission Fluid Leaks from Oil Pan

J3: Transmission Fluid Leaks from Manual Shaft Oil Seal

J3: Transmission Fluid Leaks from Oil Cooler Pipe Joint

Z1: Transmission Overheat

Transmission Fluid Checks Inspect the transmission fluid for the following conditions. If the transmission

fluid is extremely blacked, contaminated or smells burnt, slipping of clutch is

suspected.

• Low quantity

• Contamination

• Smell

Control Valve Body Checks Inspect the valve body for the following conditions.

• Faulty operation

• Sticking spool valve

• Sticking TCC solenoid valve. Perform function check. Refer to On- Vehicle Service section.

• Clogged hydraulic circuit

Sensor Checks Inspect the TFT sensor. Use the Temperature vs. Resistance table to test

the TFT sensor at various temperature levels to evaluate the possibility of a

skewed sensor.

Checks

Action

Checks Action

Definition:

Transmission fluid leaks from breather.

Diagnosis Hints Transmission fluid quantity is excessively high.

Checks Action

Definition:

Transmission fluid leaks between engine and converter housing.

Transmission fluid leaks between converter housing and transmission case.

Transmission fluid leaks between transmission case and extension housing.

Transmission fluid leaks from oil pan.

Transmission fluid leaks from manual shaft oil seal.

Transmission fluid leaks from oil cooler pipe joint.

Diagnosis Hints Faulty oil seal or contact surface is suspected.

Checks Action

Definition:

Smells burnt or smoke from transmission.

Diagnosis Hints • Transmission fluid quantity is excessively high.

• Slipping of the clutch is suspected. Gear ratio error DTC might be set.

• Clogged oil cooler.

• Faulty operation of oil pump.

• Faulty torque converter clutch (TCC) piston.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4409 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-125

Road Test

Road Test Procedure

*1: Shifting at high vehicle speed, the transmission may

hold the gear position until vehicle speed gets down to

prevent engine overruning.

Notice: Perform this test at the normal transmission

fluid temperature between 50 to 80 °C (122 to 176 °F).

Drive the vehicle on level ground so as not to change to

up slope mode and down slope mode.

1. D range road test in normal and power drive mode. • Select into the D range and hold the accelerator pedal constant at the 50% and 100% accelerator

pedal position.

• 1 to 2, 2 to 3, 3 to 4 upshift and lock up should take place, and shift points should match those shown

in the shift speed chart.

• Also check to see that downshift is made from 4 to 3, 3 to 2 and 2 to 1 point is within the limits shown

in the shift speed chart.

2. 3 range road test in normal and power drive mode. • Select into the 3 range and hold the accelerator pedal constant at the 50% and 100% accelerator

pedal position.

• 1 to 2, 2 to 3 upshift and lock up should take place, and shift points should match those shown in the

shift speed chart.

• While running in the 3 range, does not upshift from 3 to 4.

3. 2 range road test in normal mode. • Select into the 2 range and hold the accelerator

pedal constant at the 50% and 100% accelerator

pedal position.

• 1 to 2 upshift should take place, and shift points should match those shown in the shift speed chart.

• While running in the 2 range, does not upshift from 2 to 3 or 3 to 4, and lock-up does not operate.

4. L range road test in normal mode.

• While running in the L range, does not upshift from 1 to 2, 2 to 3 or 3 to 4, and lock-up does not

operate.

5. R range road test. • Select into the R range and check for slipping.

6. P range road test. • Stop the vehicle on a grade and release the park brake after selecting into the P range. Then check

to see that the parking lock pawl holds the vehicle

in place.

Diagnosis 1. If there is no 1 to 2 upshift.• Faulty operation of 2-4 brake

• Faulty operation of 2-4 brake hydraulic circuits

• Sticking of 2-4 brake solenoid valve

• Refer to symptom diagnosis No. D1: Faulty Gear Shifting or DTC P0731 - P0734 Incorrect Gear

Ratio diagnosis.

2. If there is no 2 to 3 upshift.

• Faulty operation of high clutch

• Faulty operation of high clutch hydraulic circuits

• Sticking of high clutch solenoid valve

• Refer to symptom diagnosis No. D1: Faulty Gear Shifting or DTC P0731 - P0734 Incorrect Gear

Ratio diagnosis.

3. If there is no 3 to 4 upshift.

• Faulty operation of 2-4 brake

• Faulty operation of 2-4 brake hydraulic circuits

• Sticking of 2-4 brake solenoid valve

• Refer to symptom diagnosis No. D1: Faulty Gear Shifting or DTC P0731 - P0734 Incorrect Gear

Ratio diagnosis.

4. If there is no lock up in 2nd, 3rd and 4th. • Faulty operation of torque converter clutch (TCC) piston

• Faulty operation of lock up hydraulic circuit

• Sticking of TCC solenoid valve

• Refer to symptom diagnosis No. I1: No Lock-up

5. If there is no reverse. • Faulty operation of reverse clutch

• Faulty operation of reverse clutch hydraulic circuits

• Faulty operation of low & reverse brake hydraulic circuits

Selector lever

position GearshiftSelected gear

position

P

R

N

D

3

2

L 1st

2nd 3rd4th1st

2nd 3rd

4th(*1) 1st

2nd

3rd(*1) 4th(*1) 1st

2nd(*1) 3rd(*1)4th(*1)

Reverse

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4436 of 6020

7A2-152 TRANSMISSION CONTROL SYSTEM (JR405E)

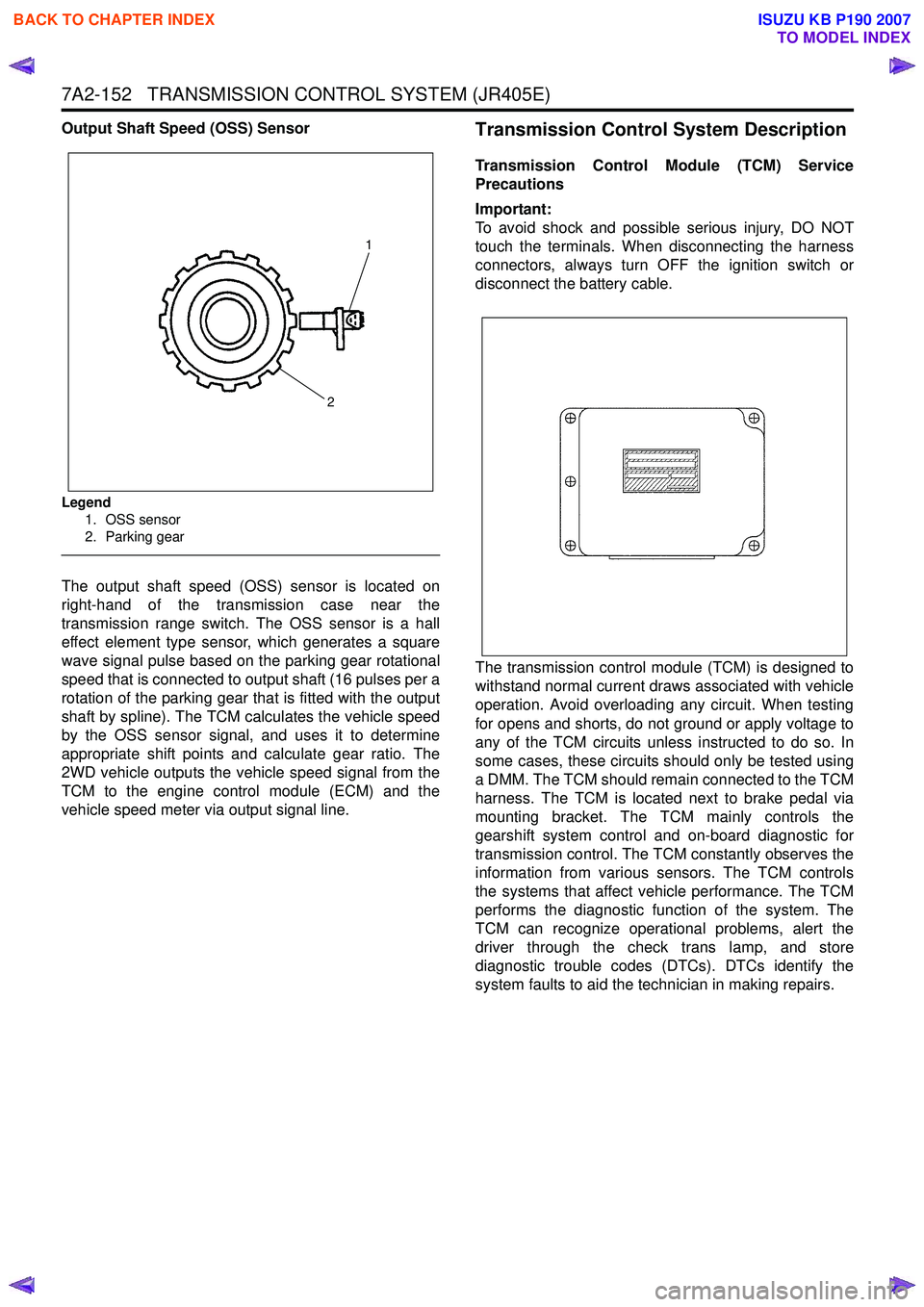

Output Shaft Speed (OSS) Sensor

Legend1. OSS sensor

2. Parking gear

The output shaft speed (OSS) sensor is located on

right-hand of the transmission case near the

transmission range switch. The OSS sensor is a hall

effect element type sensor, which generates a square

wave signal pulse based on the parking gear rotational

speed that is connected to output shaft (16 pulses per a

rotation of the parking gear that is fitted with the output

shaft by spline). The TCM calculates the vehicle speed

by the OSS sensor signal, and uses it to determine

appropriate shift points and calculate gear ratio. The

2WD vehicle outputs the vehicle speed signal from the

TCM to the engine control module (ECM) and the

vehicle speed meter via output signal line.

Transmission Control System Description

Transmission Control Module (TCM) Service

Precautions

Important:

To avoid shock and possible serious injury, DO NOT

touch the terminals. When disconnecting the harness

connectors, always turn OFF the ignition switch or

disconnect the battery cable.

The transmission control module (TCM) is designed to

withstand normal current draws associated with vehicle

operation. Avoid overloading any circuit. When testing

for opens and shorts, do not ground or apply voltage to

any of the TCM circuits unless instructed to do so. In

some cases, these circuits should only be tested using

a DMM. The TCM should remain connected to the TCM

harness. The TCM is located next to brake pedal via

mounting bracket. The TCM mainly controls the

gearshift system control and on-board diagnostic for

transmission control. The TCM constantly observes the

information from various sensors. The TCM controls

the systems that affect vehicle performance. The TCM

performs the diagnostic function of the system. The

TCM can recognize operational problems, alert the

driver through the check trans lamp, and store

diagnostic trouble codes (DTCs). DTCs identify the

system faults to aid the technician in making repairs.

1

2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4438 of 6020

7A2-154 TRANSMISSION CONTROL SYSTEM (JR405E)

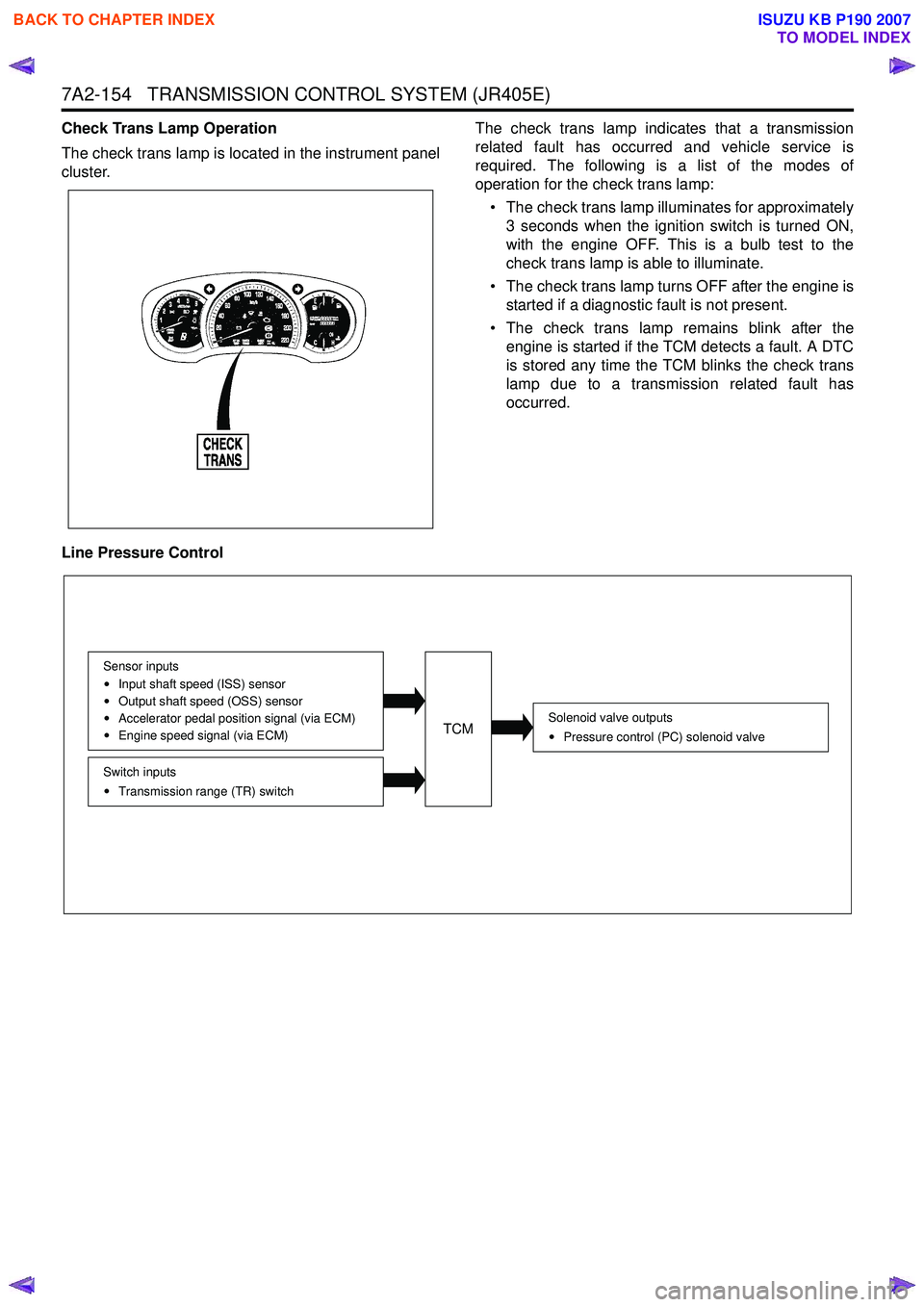

Check Trans Lamp Operation

The check trans lamp is located in the instrument panel

cluster. The check trans lamp indicates that a transmission

related fault has occurred and vehicle service is

required. The following is a list of the modes of

operation for the check trans lamp:

• The check trans lamp illuminates for approximately 3 seconds when the ignition switch is turned ON,

with the engine OFF. This is a bulb test to the

check trans lamp is able to illuminate.

• The check trans lamp turns OFF after the engine is started if a diagnostic fault is not present.

• The check trans lamp remains blink after the engine is started if the TCM detects a fault. A DTC

is stored any time the TCM blinks the check trans

lamp due to a transmission related fault has

occurred.

Line Pressure Control

Solenoid valve outputs Pressure control (PC) solenoid valve

Switch inputsTransmission range (TR) switch

Sensor inputs

Input shaft speed (ISS) sensor

Output shaft speed (OSS) sensor

Accelerator pedal position signal (via ECM)

Engine speed signal (via ECM)TCM

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5522 of 6020

8A-584 ELECTRICAL-BODY AND CHASSIS

RTW 38DLH000101

Menu

The left table shows witch functions are used for the

available equipment versions.

NOTE: Marked items are not applied for keyless entry

system.

DTC

On OBD has three options available in the Tech-2

DTC mode to display the enhanced information

available.

• Read DTC Info Ordered By Priority.

• Read DTC Info As Stored By ECU.

• Clear DTC and Alarm Code Info.

Clear DTC Information

To clear Diagnostic Trouble Codes (DTCs), Use the

diagnostic scan tool “Clear DTC Information” function.

Tech-2 Data Display

The Tech-2 data values represent values that would

be seen on a normally-keyless entry system.

RTW 38DSH001601

Actuator Test

Unlock/Lock Test

Check whether opening and closing of a door lock

can be performed by operation of Tech-2.

1. Turn the key “OFF”.

2. Turn the key “ON”.

3. Check the display and test menu.

4. Operate the Tech-2.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5588 of 6020

Cruise Control – HFV6 Page 8C–10

Tech 2 Data List

The Tech 2 displays the status of certain cruise control system input parameters.

To view the data list:

1 Connect Tech 2 to the data link connector (DLC) and turn on the ignition.

2 On Tech 2 select Body / Powertrain Interface Module / Diagnostic Data Display / Data List .

Tech 2 Parameter Units Displayed Typical Display Values

Cruise Cancel Switch Inactive / Active Inactive

Cruise Resume Switch Off / Enabled Off

Cruise Set Switch Inactive / Active Inactive

Cruise Main Switch Inactive / Active Inactive

Cruise Control Set Lamp Off / On Off

Cruise Control On Lamp Off / On Off

3 On Tech 2 select Engine / V6 Engine / Data Display / Data List / Cruise Control Data.

Tech 2 Parameter Units Displayed Typical Display Values

Brake Lamp Switch Inactive / Active Inactive

Initial Brake Apply Sig Inactive / Active Inactive

Cruise Set / Decel Swit Inactive / Active Inactive

Cruise Resume / Accelerat Inactive / Active Inactive

Cruise Control Disengag Engine Speed / Brake Engine Speed

4 On Tech 2 select Engine / V6 Engine / Data Display / Data List / Engine Data 1.

Tech 2 Parameter Units Displayed Typical Display Values

Clutch Pedal Switch Inactive / Active Inactive

2.2 Diagnostic Systems Check

Diagnostic Systems Check

Refer to 2.3 Wiring Diagram to aid in the diagnosis of the cruise control system.

For the cruise control system to work effectively the following systems / components need to be serviceable:

Step Action Yes No

1 Is the fault specifically isolated to this system / module?

Go to Step 2 Go to 6E1

Powertrain Interface Module – V6

2 1 Connect Tech 2 to the DLC.

2 Ignition ON, engine OFF.

3 On Tech 2 select Body / Powertrain Interface Module / Diagnostic Trouble

codes / Read DTCs’.

Are there any set DTC’s? Go to the

appropriate DTC table in 6E1

Powertrain Interface Module – V6. Go to Step 3

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5589 of 6020

Cruise Control – HFV6 Page 8C–11

Step Action Yes No

3 On Tech 2 select

Engine / V6 Engine / Diagnostic Trouble codes / Read DTCs’.

Are there any set DTC’s? Go to the

appropriate DTC table in 6C1-2 Engine

Management – V6 – Diagnostics Go to Step 4

4 Is the instrument cluster assembly functioning correctly? Go to 2.4

Cruise

Control Inoperative / Malfunctioning Refer to 8A

Electrical – Body

and Chassis.

When all diagnosis and repairs are completed, clear all DTCs and check the system for correct operation.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5597 of 6020

Cruise Control – HFV6 Page 8C–19

Step Action Yes No

28 1 Disconnect the ECM connector C – 56.

2 Using a multimeter set to measure voltage, back probe between the harness connector C – 56 pin 53 and ground.

3 W ith the aid of an assistant, monitor the voltage on the multimeter and press and release the clutch pedal.

• With the clutch pedal in the rest position, the multimeter

should display battery voltage

• W ith the clutch pedal pressed, the multimeter should

display 0 V

Does the multimeter display as described? Go to Step 31 Check for a blown

fuse C-4.

Check for short to ground or open circuit

Repair as required (refer to Note 2).

Go to Step 32

29 Check all associated circuits and connectors for the following:

• Loose or damaged connections

• Intermittent faults.

Refer to the Wiring Diagrams in this Section and repair as required.

W as the repair completed? Go to Step 32 —

30 Replace the PIM, refer to 6E1 Powertrain Interface Module – V6.

W as the repair completed? Go to Step 32 —

31 Replace the ECM module, refer to 6C1-3 Engine Management – V6

Service Operations.

W as the repair completed? Go to Step 32 —

32 Operate the system in order to verify the repair.

Did you correct the condition? System OK Go to Step 1

When all diagnosis and repairs are completed, clear all DTCs and check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007