oil pressure ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 22 of 6020

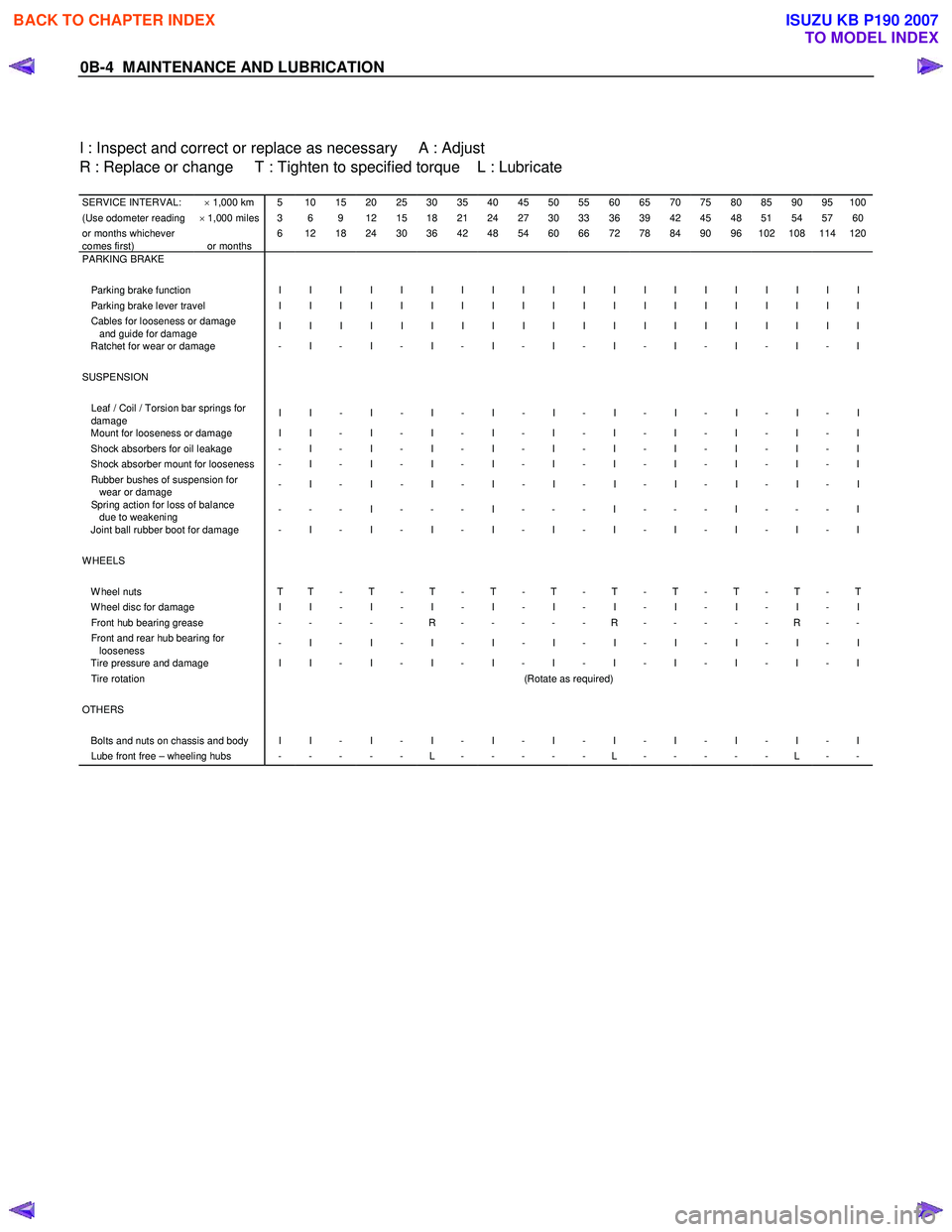

0B-4 MAINTENANCE AND LUBRICATION

I : Inspect and correct or replace as necessary A : Adjust

R : Replace or change T : Tighten to specified torque L : Lubricate

SERVICE INTERVAL: × 1,000 km 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100(Use odometer reading × 1,000 miles 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60or months whichever

comes first)

or months 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

PARKING BRAKE

Parking brake function I I I I I I I I I I I I I I I I I I I I Parking brake lever travel I I I I I I I I I I I I I I I I I I I I Cables for looseness or damage

and guide for damage I I I I I I I I I I I I I I I I I I I I

Ratchet for wear or damage - I - I - I - I - I - I - I - I - I - I

SUSPENSION Leaf / Coil / Torsion bar springs for

damage I I - I - I - I - I - I - I - I - I - I

Mount for looseness or damage I I - I - I - I - I - I - I - I - I - I Shock absorbers for oil leakage - I - I - I - I - I - I - I - I - I - I Shock absorber mount for looseness - I - I - I - I - I - I - I - I - I - I Rubber bushes of suspension for

wear or damage - I - I - I - I - I - I - I - I - I - I

Spring action for loss of balance

due to weakening - - - I - - - I - - - I - - - I - - - I

Joint ball rubber boot for damage - I - I - I - I - I - I - I - I - I - I

WHEELS W heel nuts T T - T - T - T - T - T - T - T - T - T W heel disc for damage I I - I - I - I - I - I - I - I - I - I Front hub bearing grease - - - - - R - - - - - R - - - - - R - - Front and rear hub bearing for

looseness - I - I - I - I - I - I - I - I - I - I

Tire pressure and damage I I - I - I - I - I - I - I - I - I - I Tire rotation

(Rotate as required) OTHERS Bolts and nuts on chassis and body I I - I - I - I - I - I - I - I - I - I Lube front free – wheeling hubs - - - - - L - - - - - L - - - - - L - -

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 24 of 6020

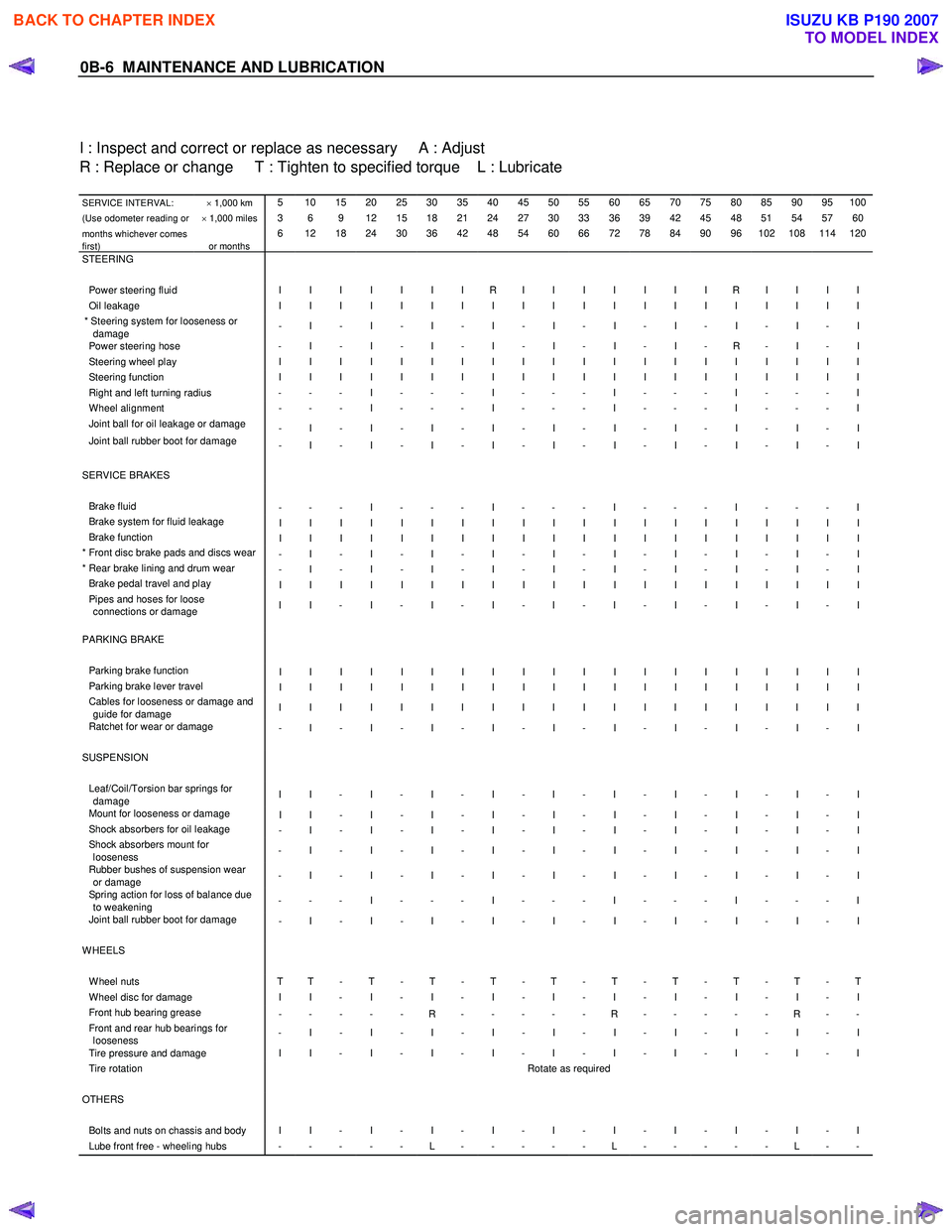

0B-6 MAINTENANCE AND LUBRICATION

I : Inspect and correct or replace as necessary A : Adjust

R : Replace or change T : Tighten to specified torque L : Lubricate

SERVICE INTERVAL: × 1,000 km 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

(Use odometer reading or × 1,000 miles 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60

months whichever comes

first)

or months 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

STEERING Power steering fluid I I I I I I I R I I I I I I I R I I I I Oil leakage I I I I I I I I I I I I I I I I I I I I * Steering system for looseness or

damage - I - I - I - I - I - I - I - I - I - I

Power steering hose

- I - I - I - I - I - I - I - R - I - I Steering wheel play I I I I I I I I I I I I I I I I I I I I Steering function I I I I I I I I I I I I I I I I I I I I Right and left turning radius - - - I - - - I - - - I - - - I - - - I W heel alignment - - - I - - - I - - - I - - - I - - - I Joint ball for oil leakage or damage

- I - I - I - I - I - I - I - I - I - I

Joint ball rubber boot for damage - I - I - I - I - I - I - I - I - I - I

SERVICE BRAKES Brake fluid - - - I - - - I - - - I - - - I - - - I Brake system for fluid leakage I I I I I I I I I I I I I I I I I I I I Brake function I I I I I I I I I I I I I I I I I I I I * Front disc brake pads and discs wear - I - I - I - I - I - I - I - I - I - I * Rear brake lining and drum wear - I - I - I - I - I - I - I - I - I - I Brake pedal travel and play I I I I I I I I I I I I I I I I I I I I Pipes and hoses for loose

connections or damage I I - I - I - I - I - I - I - I - I - I

PARKING BRAKE Parking brake function I I I I I I I I I I I I I I I I I I I I Parking brake lever travel I I I I I I I I I I I I I I I I I I I I Cables for looseness or damage and

guide for damage I I I I I I I I I I I I I I I I I I I I

Ratchet for wear or damage

- I - I - I - I - I - I - I - I - I - I SUSPENSION Leaf/Coil/Torsion bar springs for

damage I I - I - I - I - I - I - I - I - I - I

Mount for looseness or damage

I I - I - I - I - I - I - I - I - I - I Shock absorbers for oil leakage - I - I - I - I - I - I - I - I - I - I Shock absorbers mount for

looseness - I - I - I - I - I - I - I - I - I - I

Rubber bushes of suspension wear

or damage - I - I - I - I - I - I - I - I - I - I

Spring action for loss of balance due

to weakening - - - I - - - I - - - I - - - I - - - I

Joint ball rubber boot for damage

- I - I - I - I - I - I - I - I - I - I WHEELS W heel nuts T T - T - T - T - T - T - T - T - T - T W heel disc for damage I I - I - I - I - I - I - I - I - I - I Front hub bearing grease

- - - - - R - - - - - R - - - - - R - - Front and rear hub bearings for

looseness - I - I - I - I - I - I - I - I - I - I

Tire pressure and damage I I - I - I - I - I - I - I - I - I - I Tire rotation

Rotate as required OTHERS Bolts and nuts on chassis and body I I - I - I - I - I - I - I - I - I - I Lube front free - wheeling hubs - - - - - L - - - - - L - - - - - L - -

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 26 of 6020

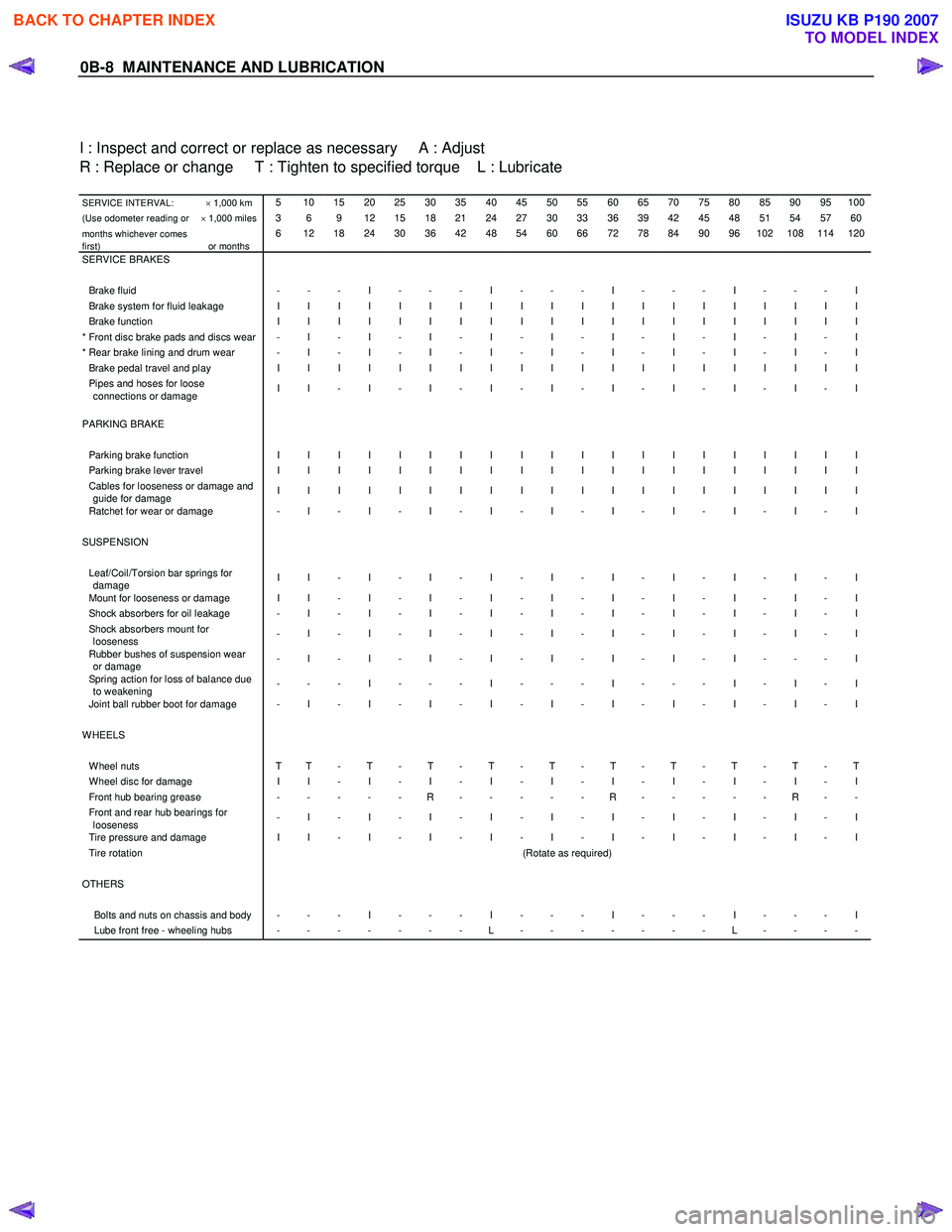

0B-8 MAINTENANCE AND LUBRICATION

I : Inspect and correct or replace as necessary A : Adjust

R : Replace or change T : Tighten to specified torque L : Lubricate

SERVICE INTERVAL: × 1,000 km 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

(Use odometer reading or × 1,000 miles 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60

months whichever comes

first)

or months 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

SERVICE BRAKES Brake fluid - - - I - - - I - - - I - - - I - - - I Brake system for fluid leakage I I I I I I I I I I I I I I I I I I I I Brake function I I I I I I I I I I I I I I I I I I I I * Front disc brake pads and discs wear - I - I - I - I - I - I - I - I - I - I * Rear brake lining and drum wear - I - I - I - I - I - I - I - I - I - I Brake pedal travel and play I I I I I I I I I I I I I I I I I I I I Pipes and hoses for loose

connections or damage I I - I - I - I - I - I - I - I - I - I

PARKING BRAKE Parking brake function I I I I I I I I I I I I I I I I I I I I Parking brake lever travel I I I I I I I I I I I I I I I I I I I I Cables for looseness or damage and

guide for damage I I I I I I I I I I I I I I I I I I I I

Ratchet for wear or damage - I - I - I - I - I - I - I - I - I - I

SUSPENSION Leaf/Coil/Torsion bar springs for

damage I I - I - I - I - I - I - I - I - I - I

Mount for looseness or damage I I - I - I - I - I - I - I - I - I - I Shock absorbers for oil leakage - I - I - I - I - I - I - I - I - I - I Shock absorbers mount for

looseness - I - I - I - I - I - I - I - I - I - I

Rubber bushes of suspension wear

or damage - I - I - I - I - I - I - I - I - - - I

Spring action for loss of balance due

to weakening - - - I - - - I - - - I - - - I - I - I

Joint ball rubber boot for damage - I - I - I - I - I - I - I - I - I - I

WHEELS W heel nuts T T - T - T - T - T - T - T - T - T - T W heel disc for damage I I - I - I - I - I - I - I - I - I - I Front hub bearing grease - - - - - R - - - - - R - - - - - R - - Front and rear hub bearings for

looseness - I - I - I - I - I - I - I - I - I - I

Tire pressure and damage I I - I - I - I - I - I - I - I - I - I Tire rotation

(Rotate as required) OTHERS Bolts and nuts on chassis and body - - - I - - - I - - - I - - - I - - - I Lube front free - wheeling hubs - - - - - - - L - - - - - - - L - - - -

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 55 of 6020

HEATER AND AIR CONDITIONING 1-21

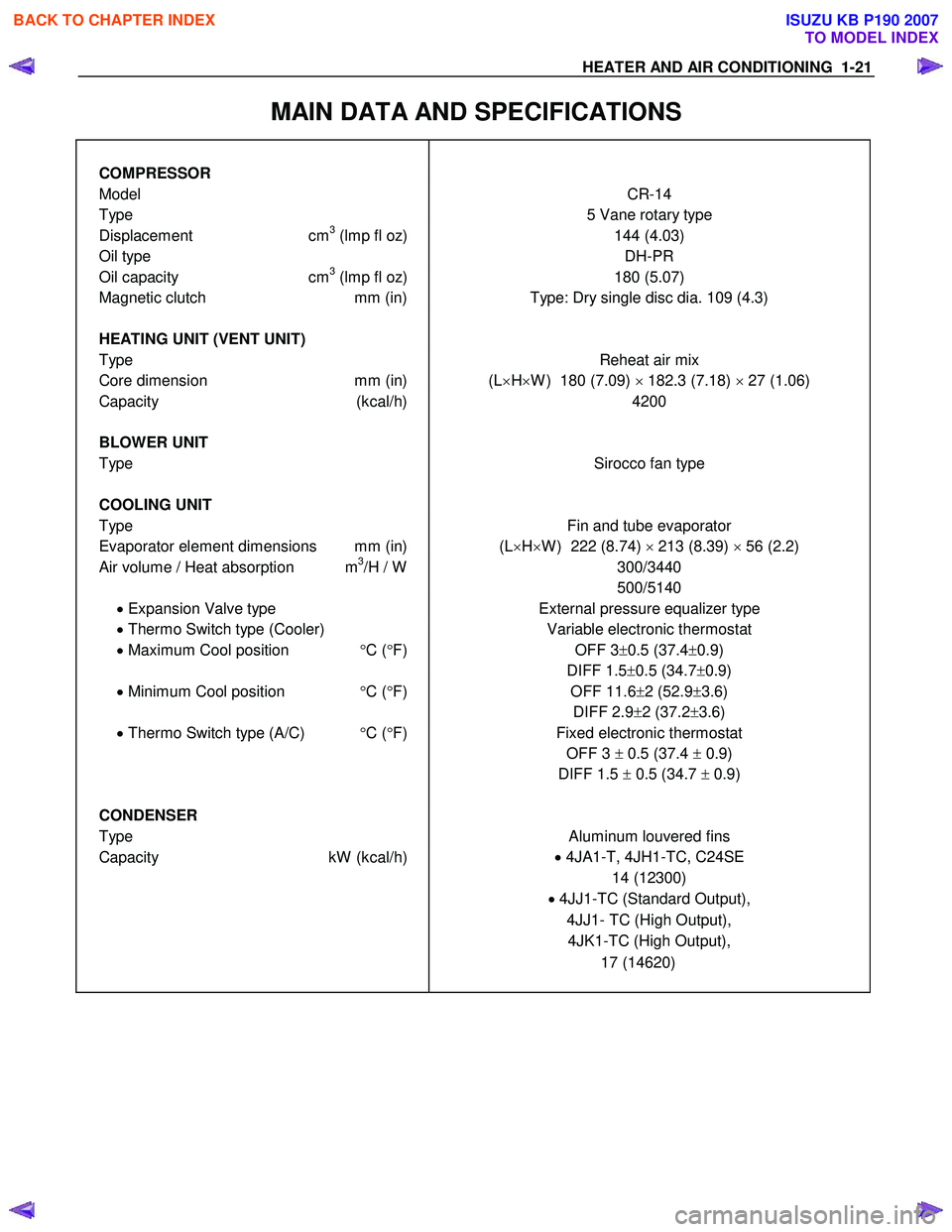

MAIN DATA AND SPECIFICATIONS

COMPRESSOR

Model CR-14

Type 5 Vane rotary type

Displacement cm3 (lmp fl oz) 144 (4.03)

Oil type DH-PR

Oil capacity cm3 (lmp fl oz) 180 (5.07)

Magnetic clutch mm (in) Type: Dry single disc dia. 109 (4.3)

HEATING UNIT (VENT UNIT)

Type Reheat air mix

Core dimension mm (in) (L×H ×W ) 180 (7.09) × 182.3 (7.18) × 27 (1.06)

Capacity (kcal/h) 4200

BLOWER UNIT

Type Sirocco fan type

COOLING UNIT

Type Fin and tube evaporator

Evaporator element dimensions mm (in) (L×H ×W ) 222 (8.74) × 213 (8.39) × 56 (2.2)

Air volume / Heat absorption m3/H / W

300/3440

500/5140

• Expansion Valve type External pressure equalizer type

• Thermo Switch type (Cooler) Variable electronic thermostat

• Maximum Cool position °C ( °F) OFF 3± 0.5 (37.4 ±0.9)

DIFF 1.5 ±0.5 (34.7 ±0.9)

• Minimum Cool position °C ( °F)

OFF 11.6

±2 (52.9 ±3.6)

DIFF 2.9 ±2 (37.2 ±3.6)

• Thermo Switch type (A/C) °C ( °F) Fixed electronic thermostat

OFF 3 ± 0.5 (37.4 ± 0.9)

DIFF 1.5 ± 0.5 (34.7 ± 0.9)

CONDENSER

Type Aluminum louvered fins

Capacity kW (kcal/h) •

4JA1-T, 4JH1-TC, C24SE

14 (12300)

• 4JJ1-TC (Standard Output),

4JJ1- TC (High Output), 4JK1-TC (High Output),

17 (14620)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 265 of 6020

3B-4 POWER-ASSISTED STEERING SYSTEM

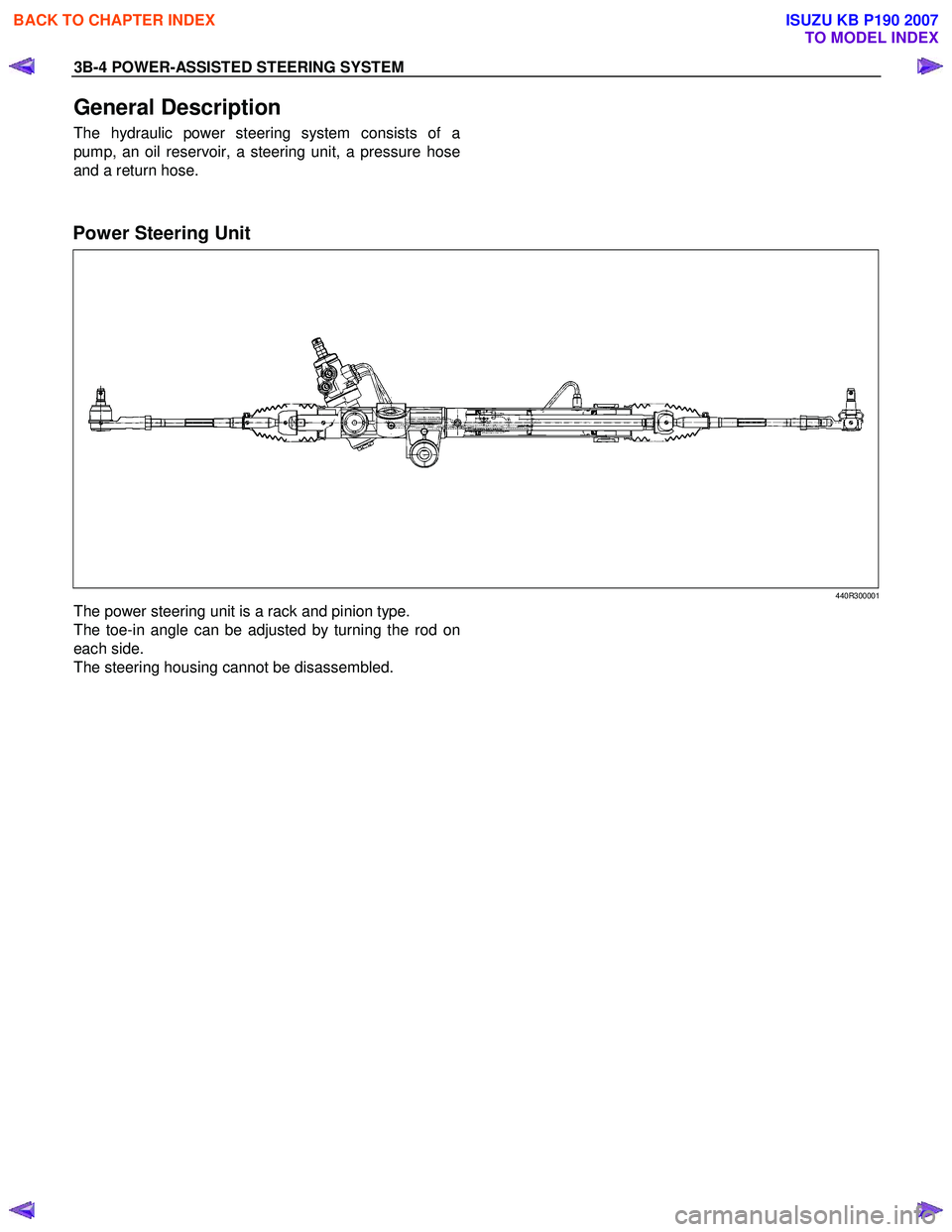

General Description

The hydraulic power steering system consists of a

pump, an oil reservoir, a steering unit, a pressure hose

and a return hose.

Power Steering Unit

440R300001

The power steering unit is a rack and pinion type.

The toe-in angle can be adjusted by turning the rod on

each side.

The steering housing cannot be disassembled.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 266 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-5

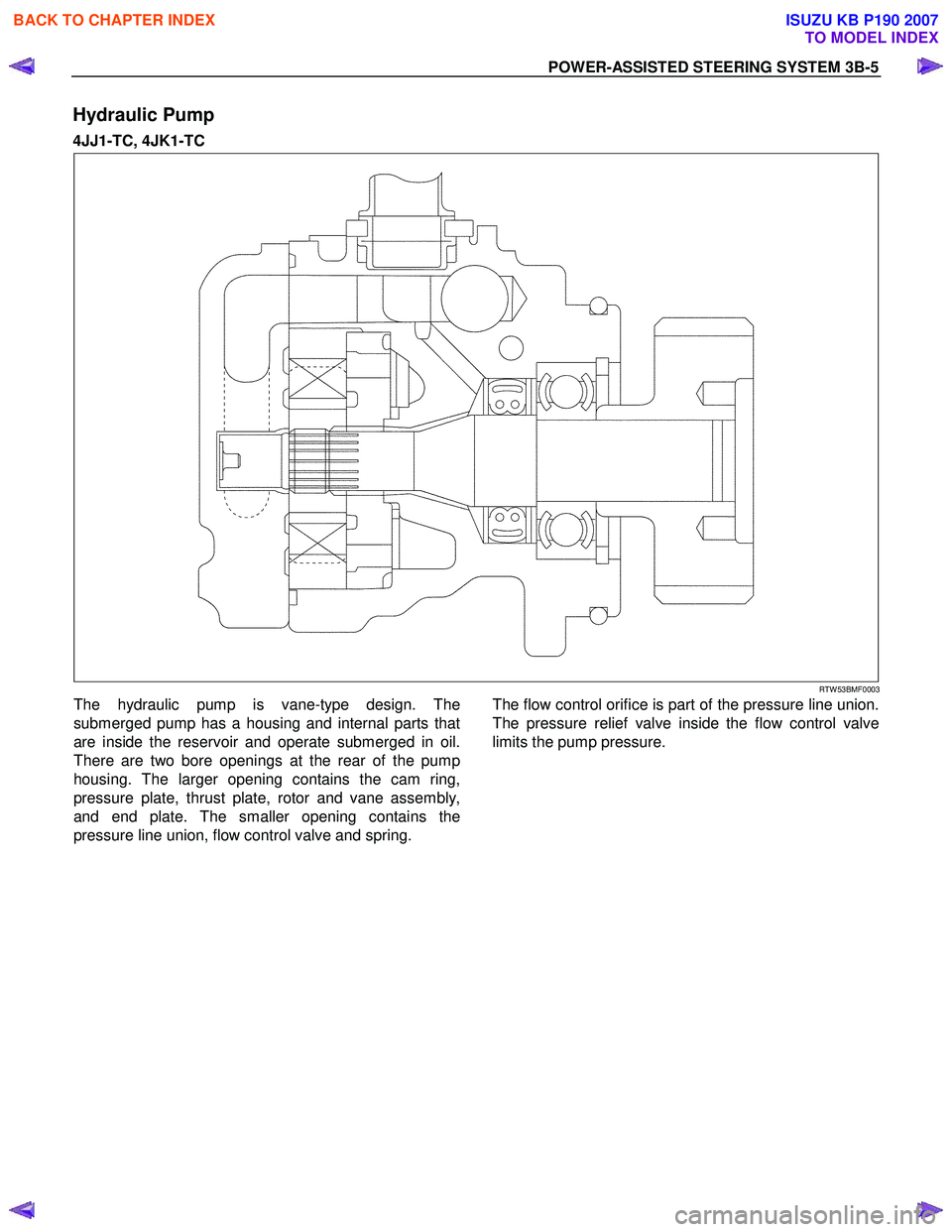

Hydraulic Pump

4JJ1-TC, 4JK1-TC

RTW 53BMF0003

The hydraulic pump is vane-type design. The

submerged pump has a housing and internal parts that

are inside the reservoir and operate submerged in oil.

There are two bore openings at the rear of the pump

housing. The larger opening contains the cam ring,

pressure plate, thrust plate, rotor and vane assembly,

and end plate. The smaller opening contains the

pressure line union, flow control valve and spring.

The flow control orifice is part of the pressure line union.

The pressure relief valve inside the flow control valve

limits the pump pressure.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 268 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-7

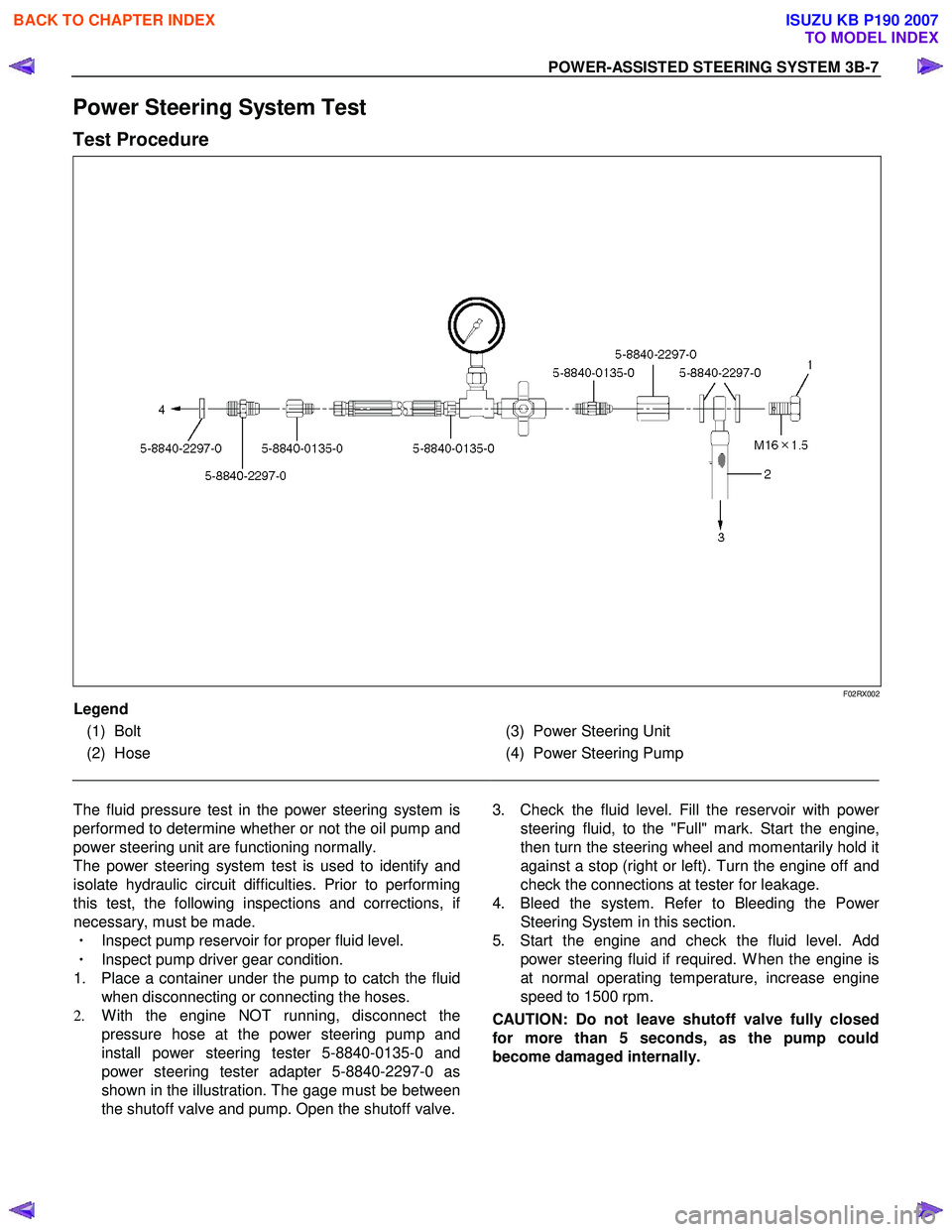

Power Steering System Test

Test Procedure

F02RX002

Legend

(1) Bolt

(2) Hose

(3) Power Steering Unit

(4) Power Steering Pump

The fluid pressure test in the power steering system is

performed to determine whether or not the oil pump and

power steering unit are functioning normally.

The power steering system test is used to identify and

isolate hydraulic circuit difficulties. Prior to performing

this test, the following inspections and corrections, i

f

necessary, must be made.

・ Inspect pump reservoir for proper fluid level.

・ Inspect pump driver gear condition.

1. Place a container under the pump to catch the fluid when disconnecting or connecting the hoses.

2. W ith the engine NOT running, disconnect the

pressure hose at the power steering pump and

install power steering tester 5-8840-0135-0 and

power steering tester adapter 5-8840-2297-0 as

shown in the illustration. The gage must be between

the shutoff valve and pump. Open the shutoff valve.

3. Check the fluid level. Fill the reservoir with powe

r

steering fluid, to the "Full" mark. Start the engine,

then turn the steering wheel and momentarily hold it

against a stop (right or left). Turn the engine off and

check the connections at tester for leakage.

4. Bleed the system. Refer to Bleeding the Powe

r

Steering System in this section.

5. Start the engine and check the fluid level. Add power steering fluid if required. W hen the engine is

at normal operating temperature, increase engine

speed to 1500 rpm.

CAUTION: Do not leave shutoff valve fully closed

for more than 5 seconds, as the pump could

become damaged internally.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 269 of 6020

3B-8 POWER-ASSISTED STEERING SYSTEM

6. Fully close the shutoff valve. Record the highest

pressures.

・ If the pressure recorded is within 9800-10300 kPa

(100-105 kg/cm

2/1422-1493psi), the pump is

functioning within its specifications.

・ If the pressure recorded is higher than 10300 kPa

(105 kg/cm

2/1493psi), the valve in the pump is

defective.

・ If the pressure recorded is lower than 9800 kPa

(100 kg/cm

2/1422psi), the valve or the rotating

assembly in the pump is defective.

7. If the pump pressures are within specifications, leave the valve open and turn (or have someone

else turn) the steering wheel fully in both directions.

Record the highest pressures and compare with the

maximum pump pressure recorded in step 6. If this

pressure cannot be built up at either side of the

power steering unit, the power steering unit is

leaking internally and must be replaced.

8. Shut the engine off, remove the testing gauge.

9. Reconnect the pressure hose, check the fluid level and make the needed repairs.

10. If the problem still exists, the steering and front suspension must be thoroughly examined.

Maintenance

The hydraulic system should be kept clean, the fluid

level in the reservoir should be checked at regula

r

intervals and fluid added when required. Refer to

Recommended Fluids and Lubricants in General

Information section for the type of fluid to be used and

the intervals for filling.

If the system contains some dirt, flush it as described in

this section. If it is exceptionally dirty, the pump must be

completely disassembled before further usage. (The

steering unit cannot be disassembled.)

All tubes, hoses, and fittings should be inspected for

leakage at regular intervals. Fittings must be tight. Make

sure the clips, clamps and supporting tubes and hoses

are in place and properly secured.

Power steering hoses and lines must not be twisted,

kinked or tightly bent. Air in the system will cause

spongy action and noisy operation. W hen a hose is

disconnected or when fluid is lost, for any reason, the

system must be bled after refilling. Refer to Bleeding the

Power Steering System in this section.

・ Inspect gear for looseness or damage.

・ Inspect hoses to insure they are not touching an

y

other parts of the vehicle.

・ Inspect fluid level and fill to the proper level.

Fluid Level

1. Run the engine until the power steering fluid

reaches normal operating temperature, about 55 °

C (130 °F), then shut the engine off.

2. Check the level of fluid in the reservoir.

3. If the fluid level is low, add power steering fluid as

specified in General Information to the proper level

and install the receiver cap.

4. W hen checking the fluid level after the steering system has been serviced, air must be bled from

the system. Refer to Bleeding the Power Steering

System in this section.

Bleeding the Power Steering System

W hen a power steering pump or unit has been installed,

or an oil line has been disconnected, the air that has

entered the system must be bled out before the vehicle

is operated. If air is allowed to remain in the powe

r

steering fluid system, noisy and unsatisfactory operation

of the system may result.

Bleeding Procedure

W hen bleeding the system, and any time fluid is added

to the power steering system, be sure to use only powe

r

steering fluid as specified in General Information.

1. Fill the pump fluid reservoir to the proper level and let the fluid settle for at least two minutes.

2. Start the engine and let it run for a few seconds. Do not turn the steering wheel. Then turn the engine

off.

3. Add fluid if necessary.

4. Repeat the above procedure until the fluid level remains constant after running the engine.

5. Raise and support the front end of the vehicle so that the wheels are off the ground.

6. Start the engine. Slowly turn the steering wheel right and left, lightly contacting the wheel stops.

7. Add power steering fluid if necessary.

8. Lower the vehicle, set the steering wheel at the straight forward position after turning it to its full

steer positions 2 or 3 times, and stop the engine.

9. Check the fluid level and refill as required.

10. If the fluid is extremely foamy, allow the vehicle to settle for a few minutes, then repeat the above

procedure.

Flushing the Power Steering System

1. Raise and support the front end of the vehicle off

the ground until the wheels are free to turn.

2. Remove the fluid return line at the pump inlet connector and plug the connector port on the pump.

Direct the line toward a large container to catch the

draining fluid.

3. W hile running the engine at idle, fill the reservoi

r

with new power steering fluid. Turn the steering

wheel in both directions. Do not contact or hold the

steering wheel to the wheel stops. This will cause

the pump to go to pressure relief mode, which ma

y

cause a sudden fluid overflow at the reservoir.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 381 of 6020

3C-60 FRONT SUSPENSION

Checkpoint Problem Countermeasure

Steering linkage and steering

gearReplaceWorn

AdjustImproper

OK

NG

NG

OKTire pressure

Continued from the previous page

Steering unit fixing bolts and

linkageRetightenLoose

Adjust or replaceIncorrect adjustment or

abrasion

OK

NG

NG

OKFront wheel bearing

Lubricating oil and grease to

steering linkageReplaceInsufficient

NG

OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 472 of 6020

4B-28 REAR AXLE

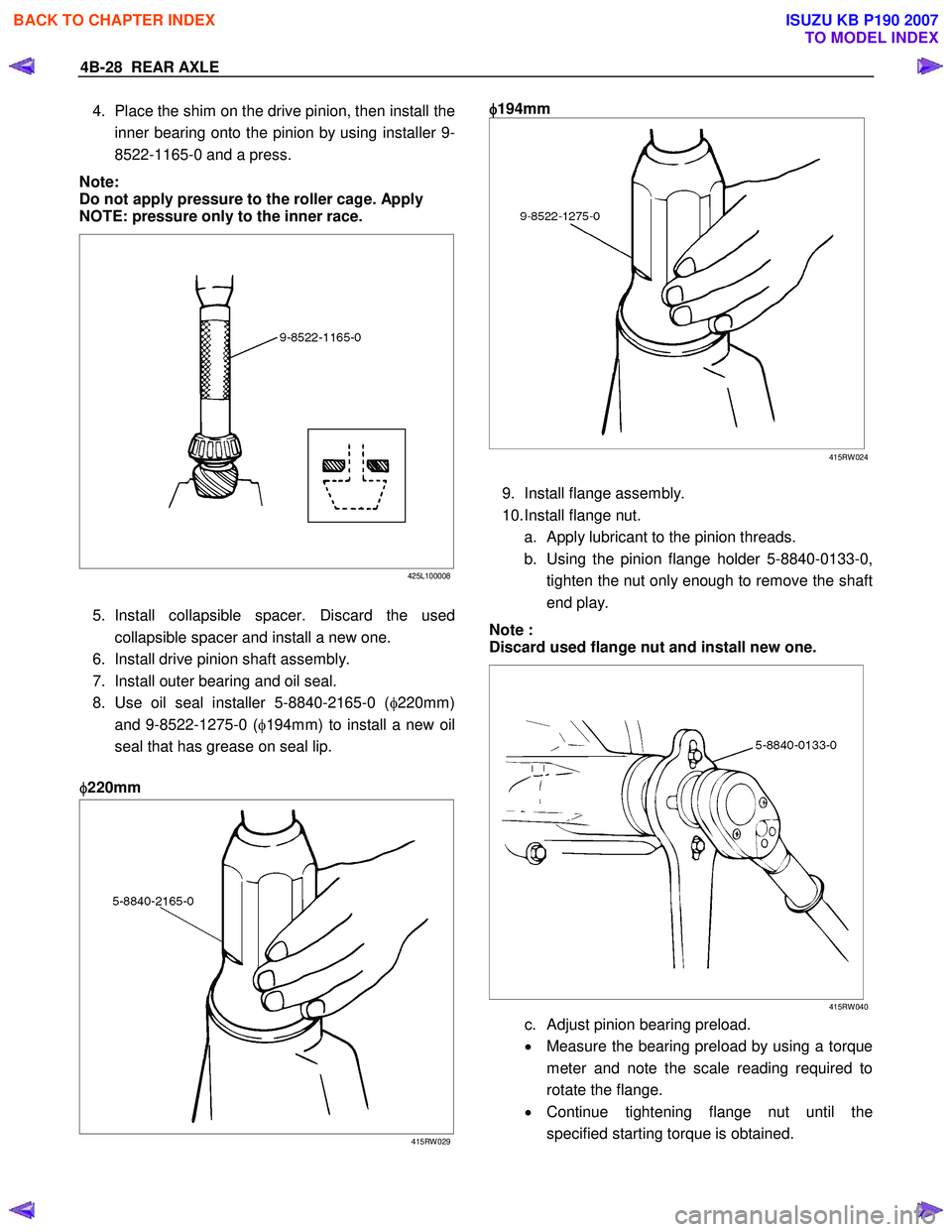

4. Place the shim on the drive pinion, then install the

inner bearing onto the pinion by using installer 9-

8522-1165-0 and a press.

Note:

Do not apply pressure to the roller cage. Apply

NOTE: pressure only to the inner race.

425L100008

5. Install collapsible spacer. Discard the used collapsible spacer and install a new one.

6. Install drive pinion shaft assembly.

7. Install outer bearing and oil seal.

8. Use oil seal installer 5-8840-2165-0 ( φ220mm)

and 9-8522-1275-0 ( φ194mm) to install a new oil

seal that has grease on seal lip.

φ

φφ

φ

220mm

415RW 029

φ

φφ

φ

194mm

415RW 024

9. Install flange assembly.

10. Install flange nut. a. Apply lubricant to the pinion threads.

b. Using the pinion flange holder 5-8840-0133-0, tighten the nut only enough to remove the shaft

end play.

Note :

Discard used flange nut and install new one.

415RW 040

c. Adjust pinion bearing preload.

• Measure the bearing preload by using a torque

meter and note the scale reading required to

rotate the flange.

• Continue tightening flange nut until the

specified starting torque is obtained.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007