check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2560 of 6020

Engine Mechanical – V6 Page 6A1–81

14 Remove the bolt (1), 13 places, attaching the camshaft

cover (2) to the cylinder head (3).

15 Remove the cover and discard the seal.

Figure 6A1 – 66

16 Install Tool No. EN-46101 (1) to the spark plug tubes of the cylinder head to prevent entry of dirt into the

combustion chamber.

Figure 6A1 – 67

Clean and Inspect

Safety glasses must be worn when using

compressed air.

1 Clean the camshaft cover with suitable cleaning solvent and blow dry with compressed air.

2 Inspect the cover for cracking and distortion.

3 Check the spark plug tube seals for damage.

4 If the camshaft cover is damaged in any way that will affect it’s performance to seal and stop the ingress of dirt, replace the camshaft cover.

Reinstall

Reinstallation of the camshaft cover assembly is the reverse of the removal procedure, noting the following:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2576 of 6020

Engine Mechanical – V6 Page 6A1–97

5 After aligning the crankshaft sprocket timing mark,

check that the camshaft flats (1) at the rear of the

right-hand cylinder head are parallel with the

camshaft cover rail (2).

6 If the camshaft flats are not as shown, rotate the crankshaft 360 °.

Figure 6A1 – 103

7 Install Tool No. EN 46105-1 (1) onto the rear of the right-hand cylinder head camshafts (2).

Figure 6A1 – 104

8 Install Tool No. EN 46105-2 (1) onto the rear of the left-hand cylinder head camshafts (2), and tool No

Figure 6A1 – 105

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2626 of 6020

Engine Mechanical – V6 Page 6A1–147

2 Inspect the back of each sprocket for the following:

• Sprocket damage (1),

• Camshaft locating pin damage (2) and,

• Camshaft seating/sealing inner hub flange

damage (3),

NOTE

These checks apply to both the inlet and

exhaust camshaft sprockets.

Figure 6A1 – 237

Reinstall

Reinstallation of the camshaft sprockets is the reverse of the removal procedure, noting the following:

1 Align the sprockets and timing chain with the marks made during removal.

2 Tighten the camshaft sprocket bolts to the correct torque specification.

Camshaft sprocket attaching

bolt torque specification ..........................49.0 – 67.0 Nm

3 Remove the timing chain retention tools.

3.19 Camshaft

Remove

Right-hand Side

1 Remove the right-hand cylinder head camshaft sprockets, refer to 3.18 Camshaft Sprocket.

2 Remove the Tool No. EN-46105 – 1 (1) from the right- hand cylinder head camshafts (2).

NOTE

Tool No. EN-46105 was installed as part of the

right-hand cylinder head camshaft sprocket

removal procedure.

Figure 6A1 – 238

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2650 of 6020

Engine Mechanical – V6 Page 6A1–171

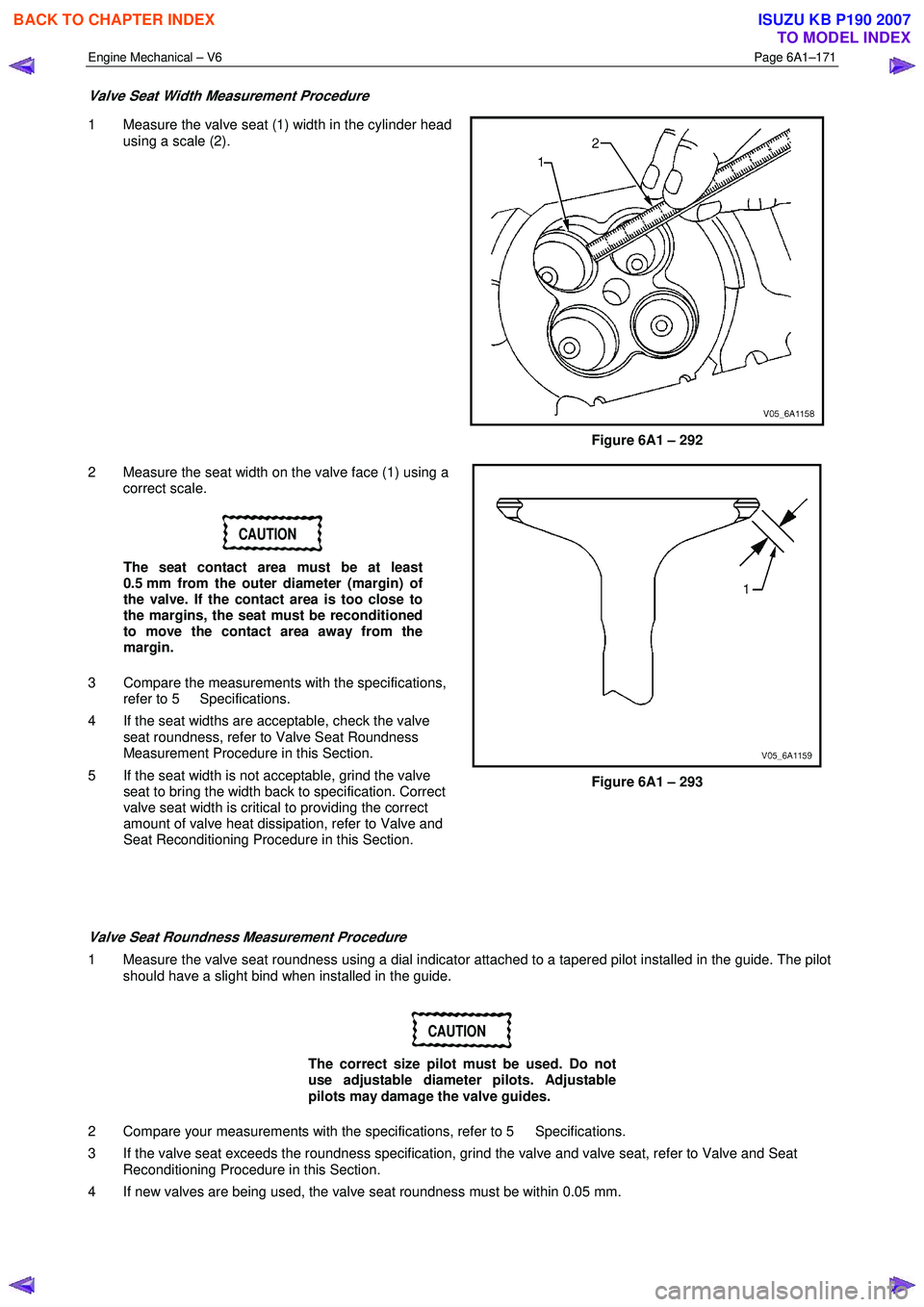

Valve Seat Width Measurement Procedure

1 Measure the valve seat (1) width in the cylinder head

using a scale (2).

Figure 6A1 – 292

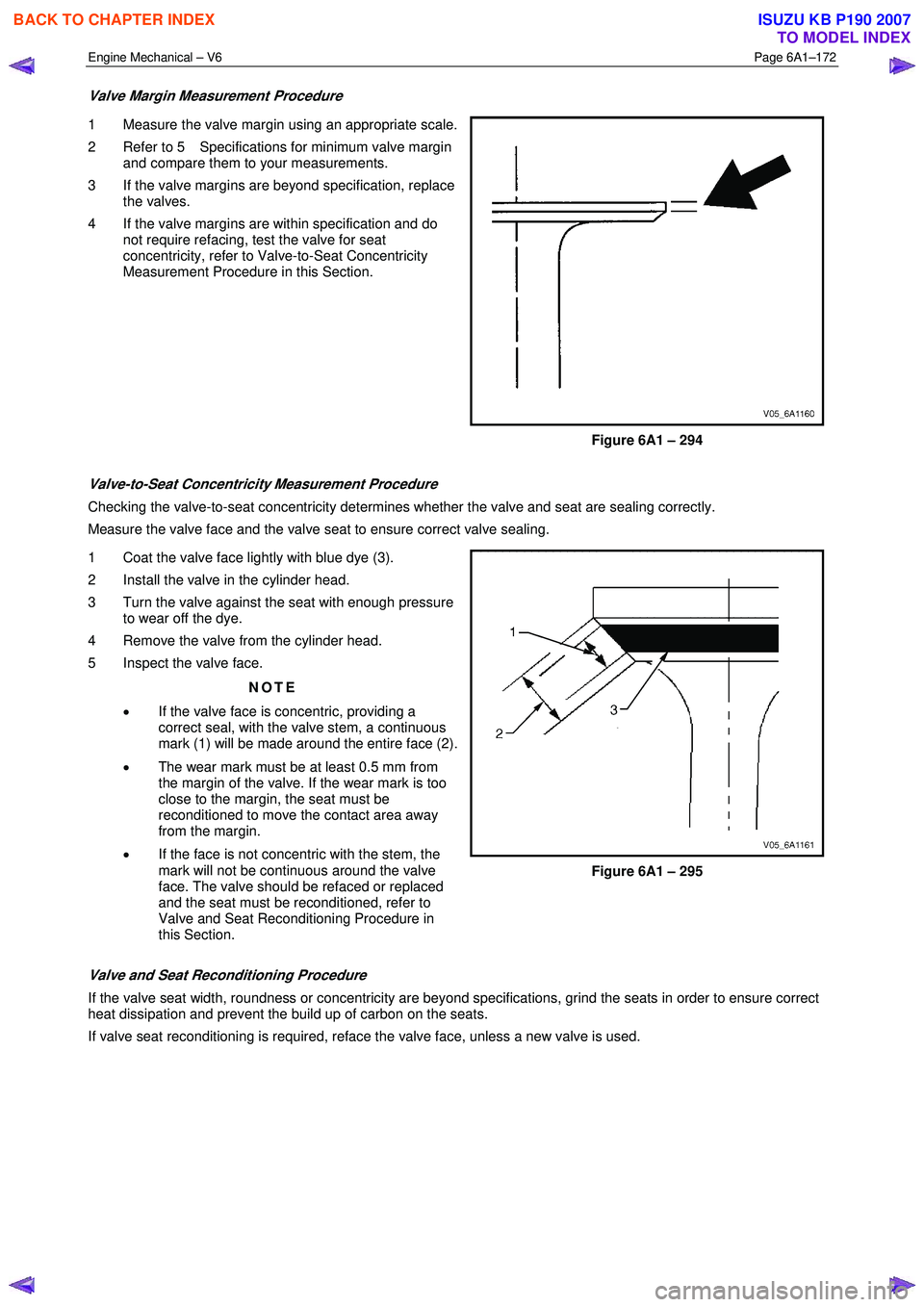

2 Measure the seat width on the valve face (1) using a correct scale.

CAUTION

The seat contact area must be at least

0.5 mm from the outer diameter (margin) of

the valve. If the contact area is too close to

the margins, the seat must be reconditioned

to move the contact area away from the

margin.

3 Compare the measurements with the specifications, refer to 5 Specifications.

4 If the seat widths are acceptable, check the valve seat roundness, refer to Valve Seat Roundness

Measurement Procedure in this Section.

5 If the seat width is not acceptable, grind the valve seat to bring the width back to specification. Correct

valve seat width is critical to providing the correct

amount of valve heat dissipation, refer to Valve and

Seat Reconditioning Procedure in this Section.

Figure 6A1 – 293

Valve Seat Roundness Measurement Procedure

1 Measure the valve seat roundness using a dial indicator attached to a tapered pilot installed in the guide. The pilot should have a slight bind when installed in the guide.

CAUTION

The correct size pilot must be used. Do not

use adjustable diameter pilots. Adjustable

pilots may damage the valve guides.

2 Compare your measurements with the specifications, refer to 5 Specifications.

3 If the valve seat exceeds the roundness specification, grind the valve and valve seat, refer to Valve and Seat Reconditioning Procedure in this Section.

4 If new valves are being used, the valve seat roundness must be within 0.05 mm.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2651 of 6020

Engine Mechanical – V6 Page 6A1–172

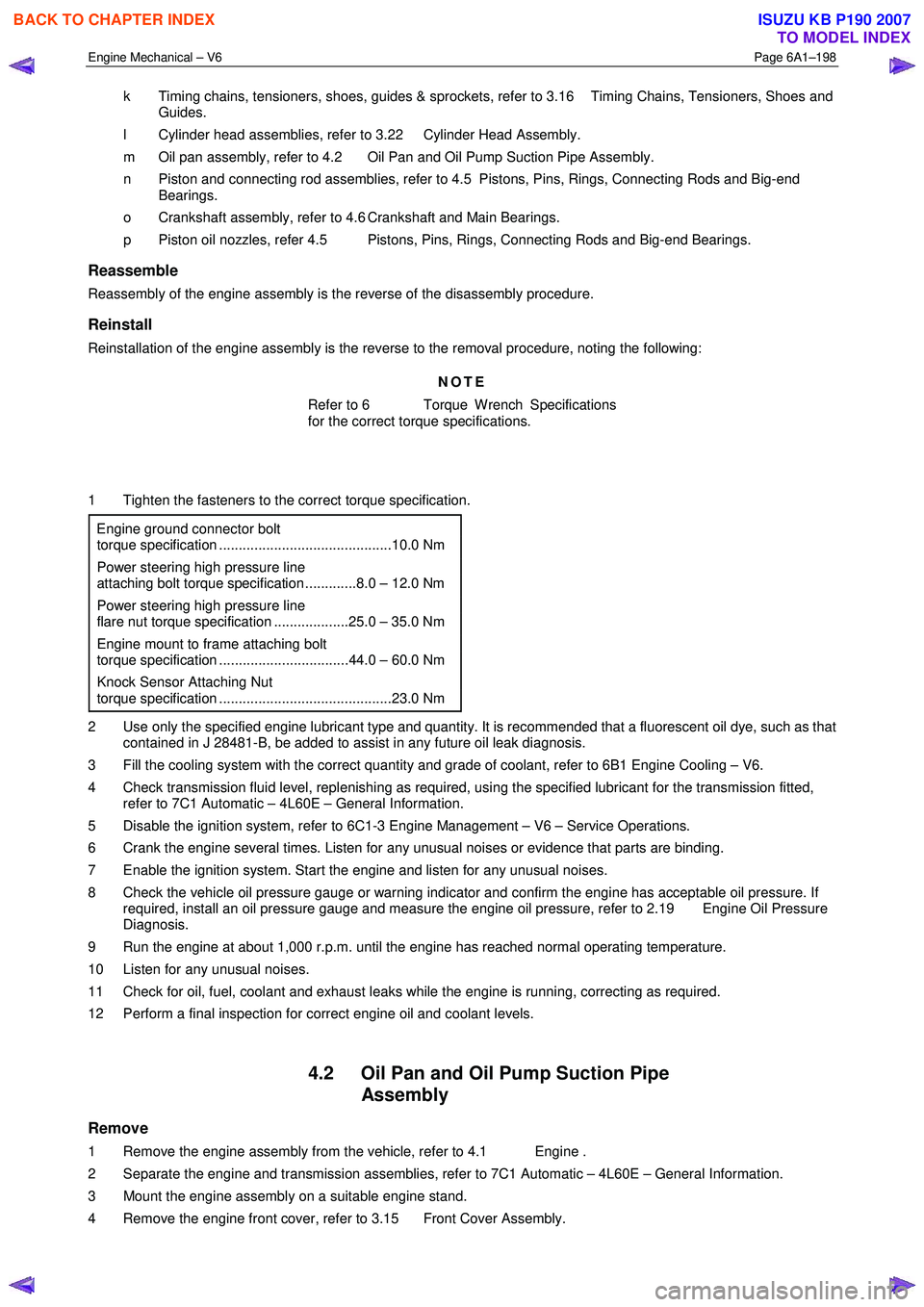

Valve Margin Measurement Procedure

1 Measure the valve margin using an appropriate scale.

2 Refer to 5 Specifications for minimum valve margin and compare them to your measurements.

3 If the valve margins are beyond specification, replace the valves.

4 If the valve margins are within specification and do not require refacing, test the valve for seat

concentricity, refer to Valve-to-Seat Concentricity

Measurement Procedure in this Section.

Figure 6A1 – 294

Valve-to-Seat Concentricity Measurement Procedure

Checking the valve-to-seat concentricity determines whether the valve and seat are sealing correctly.

Measure the valve face and the valve seat to ensure correct valve sealing.

1 Coat the valve face lightly with blue dye (3).

2 Install the valve in the cylinder head.

3 Turn the valve against the seat with enough pressure to wear off the dye.

4 Remove the valve from the cylinder head.

5 Inspect the valve face.

NOTE

• If the valve face is concentric, providing a

correct seal, with the valve stem, a continuous

mark (1) will be made around the entire face (2).

• The wear mark must be at least 0.5 mm from

the margin of the valve. If the wear mark is too

close to the margin, the seat must be

reconditioned to move the contact area away

from the margin.

• If the face is not concentric with the stem, the

mark will not be continuous around the valve

face. The valve should be refaced or replaced

and the seat must be reconditioned, refer to

Valve and Seat Reconditioning Procedure in

this Section.

Figure 6A1 – 295

Valve and Seat Reconditioning Procedure

If the valve seat width, roundness or concentricity are beyond specifications, grind the seats in order to ensure correct

heat dissipation and prevent the build up of carbon on the seats.

If valve seat reconditioning is required, reface the valve face, unless a new valve is used.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2662 of 6020

Engine Mechanical – V6 Page 6A1–183

• The hard rubber surface is covered with heat check cracks,

• The rubber is split through the centre of the engine mount, or

• The rubber is separated from the metal plate portion of the engine mount.

5 Remove the engine lift brackets, Tool No. EN-46114 from the engine.

Reinstall

The reinstallation procedure for the engine mounts is the reverse of the removal procedure, noting the following:

Ensure all fasteners are tightened to the correct torque specification.

Engine mount bracket to

cylinder block attaching bolt

torque specification

................................................................43.0 – 57.0 Nm

Engine mount to bracket attaching nut

torque specification

................................................................70.0 – 90.0 Nm

Engine mount to frame attaching nut

torque specification

................................................................44.0 – 60.0 Nm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2677 of 6020

Engine Mechanical – V6 Page 6A1–198

k Timing chains, tensioners, shoes, guides & sprockets, refer to 3.16 Timing Chains, Tensioners, Shoes and

Guides.

l Cylinder head assemblies, refer to 3.22 Cylinder Head Assembly.

m Oil pan assembly, refer to 4.2 Oil Pan and Oil Pump Suction Pipe Assembly.

n Piston and connecting rod assemblies, refer to 4.5 Pistons, Pins, Rings, Connecting Rods and Big-end Bearings.

o Crankshaft assembly, refer to 4.6 Crankshaft and Main Bearings.

p Piston oil nozzles, refer 4.5 Pistons, Pins, Rings, Connecting Rods and Big-end Bearings.

Reassemble

Reassembly of the engine assembly is the reverse of the disassembly procedure.

Reinstall

Reinstallation of the engine assembly is the reverse to the removal procedure, noting the following:

NOTE

Refer to 6 Torque Wrench Specifications

for the correct torque specifications.

1 Tighten the fasteners to the correct torque specification.

Engine ground connector bolt

torque specification ............................................10.0 Nm

Power steering high pressure line

attaching bolt torque specification .............8.0 – 12.0 Nm

Power steering high pressure line

flare nut torque specification ...................25.0 – 35.0 Nm

Engine mount to frame attaching bolt

torque specification .................................44.0 – 60.0 Nm

Knock Sensor Attaching Nut

torque specification ............................................23.0 Nm

2 Use only the specified engine lubricant type and quantity. It is recommended that a fluorescent oil dye, such as that contained in J 28481-B, be added to assist in any future oil leak diagnosis.

3 Fill the cooling system with the correct quantity and grade of coolant, refer to 6B1 Engine Cooling – V6.

4 Check transmission fluid level, replenishing as required, using the specified lubricant for the transmission fitted, refer to 7C1 Automatic – 4L60E – General Information.

5 Disable the ignition system, refer to 6C1-3 Engine Management – V6 – Service Operations.

6 Crank the engine several times. Listen for any unusual noises or evidence that parts are binding.

7 Enable the ignition system. Start the engine and listen for any unusual noises.

8 Check the vehicle oil pressure gauge or warning indicator and confirm the engine has acceptable oil pressure. If required, install an oil pressure gauge and measure the engine oil pressure, refer to 2.19 Engine Oil Pressure

Diagnosis.

9 Run the engine at about 1,000 r.p.m. until the engine has reached normal operating temperature.

10 Listen for any unusual noises.

11 Check for oil, fuel, coolant and exhaust leaks while the engine is running, correcting as required.

12 Perform a final inspection for correct engine oil and coolant levels.

4.2 Oil Pan and Oil Pump Suction Pipe Assembly

Remove

1 Remove the engine assembly from the vehicle, refer to 4.1 Engine .

2 Separate the engine and transmission assemblies, refer to 7C1 Automatic – 4L60E – General Information.

3 Mount the engine assembly on a suitable engine stand.

4 Remove the engine front cover, refer to 3.15 Front Cover Assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2687 of 6020

Engine Mechanical – V6 Page 6A1–208

5 Install the crankshaft rear oil seal housing attaching

bolts (1) to the cylinder block (2) and tighten to the

correct torque specification.

Crankshaft rear oil seal housing

attaching bolt torque specification .............8.0 – 12.0 Nm

Figure 6A1 – 373

4.5 Pistons, Pins, Rings, Connecting Rods and Big-end Bearings

Remove

1 Remove the engine assembly, refer to 4.1 Engine .

2 Remove both cylinder head assemblies, refer to 3.22 Cylinder Head Assembly.

3 Remove the oil pan assembly, refer to 4.2 Oil Pan and Oil Pump Suction Pipe Assembly.

4 Mark the top of the piston being removed to identify its specific bore.

5 Install Tool No. EN-46111 (1) onto the crankshaft (2).

6 Rotate the crankshaft until the piston being removed is at the bottom of its stroke; bottom dead centre

(BDC).

Figure 6A1 – 374

CAUTION

If the connecting rod bearings have been

used in a running engine, they must be

replaced with new connecting rod bearings

for reassembly.

7 Before removing the connecting rods, check the connecting rod side clearance using the following procedure: a Tap the connecting rod to one end of the crankshaft journal with a dead blow or wooden hammer.

b Using feeler gauges, measure the clearance between the crankshaft counterweight and the connecting rod.

c The connecting rod side clearance should not exceed specifications, refer to 5 Specifications.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2692 of 6020

Engine Mechanical – V6 Page 6A1–213

Piston Inspection Procedure

1 Inspect the pistons for the following conditions:

• eroded areas at the top of the piston (1),

• piston pin retainer grooves for burrs (2),

• worn piston pin bores or worn piston pins (3),

• scuffed or damaged skirt coating (4),

• ring grooves for cracks, nicks or burrs that may

cause binding (5), and

• warped or worn ring lands.

2 Replace pistons that show any signs of damage or excessive wear.

Figure 6A1 – 384

Piston Measurement

1 Measure piston width using the following procedure:

a Using an outside micrometer, measure the width of the piston at 30 mm below the crown

top (1), at the thrust surfaces of the piston,

perpendicular to the piston pin centreline.

b Compare the measurement of the piston to its original cylinder by subtracting the piston width

from the cylinder diameter.

c Check your measurements with specifications, refer to 5 Specifications.

d If the clearance obtained through measurement is greater than the provided specifications and

the cylinder bores are within specification,

replace the piston.

Figure 6A1 – 385

2 Measure the piston pin bore to piston pin (2) clearances using the following procedure:

a Piston pin bores and pins must be free of varnish or scuffing.

b Use an outside micrometer (1) to measure the piston pin in the piston contact areas.

Figure 6A1 – 386

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2693 of 6020

Engine Mechanical – V6 Page 6A1–214

3 Using an inside micrometer, measure the piston pin

bore (1). Compare the result with the piston pin

diameter and piston pin to piston pin bore clearance

listed in the specifications, refer to 5 Specifications.

4 If the clearance is excessive, determine which piece is out of specification and replace as required.

5 Replace the piston if any of its dimensions are out of specification.

6 If the new piston does not meet clearance specifications, the cylinder block may need to be

oversized to 0.25 mm. There is only one size of

oversized pistons and rings available for service.

Figure 6A1 – 387

Piston Ring Measurement

1 Measure the piston ring end gap using the following procedure:

a Place the piston ring (1) in the area of the bore where the piston ring will travel, approximately 25 mm below

the deck surface. Ensure the ring is square with the

cylinder bore by positioning the ring with the piston

head.

b Measure the end gap of the piston ring with feeler gauges (2), refer to 5 Specifications.

c If the clearance exceeds the provided specifications, the piston rings must be replaced.

d Repeat the procedure for all piston rings.

Figure 6A1 – 388

2 Measure the piston ring side clearance using the following procedure:

a Roll the piston ring (1) entirely around the piston ring groove. If any binding is caused by the ring groove,

dress the groove with a fine file. If any binding is

caused by a distorted piston ring, replace the ring.

b W ith the piston ring on the piston, use feeler gauges (2) to check clearance at multiple locations.

c Compare the measurements with piston ring side clearance listed in the specifications, refer to 5

Specifications.

d If the clearance is greater than specifications, replace the piston rings.

Figure 6A1 – 389

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007