ignition ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3213 of 6020

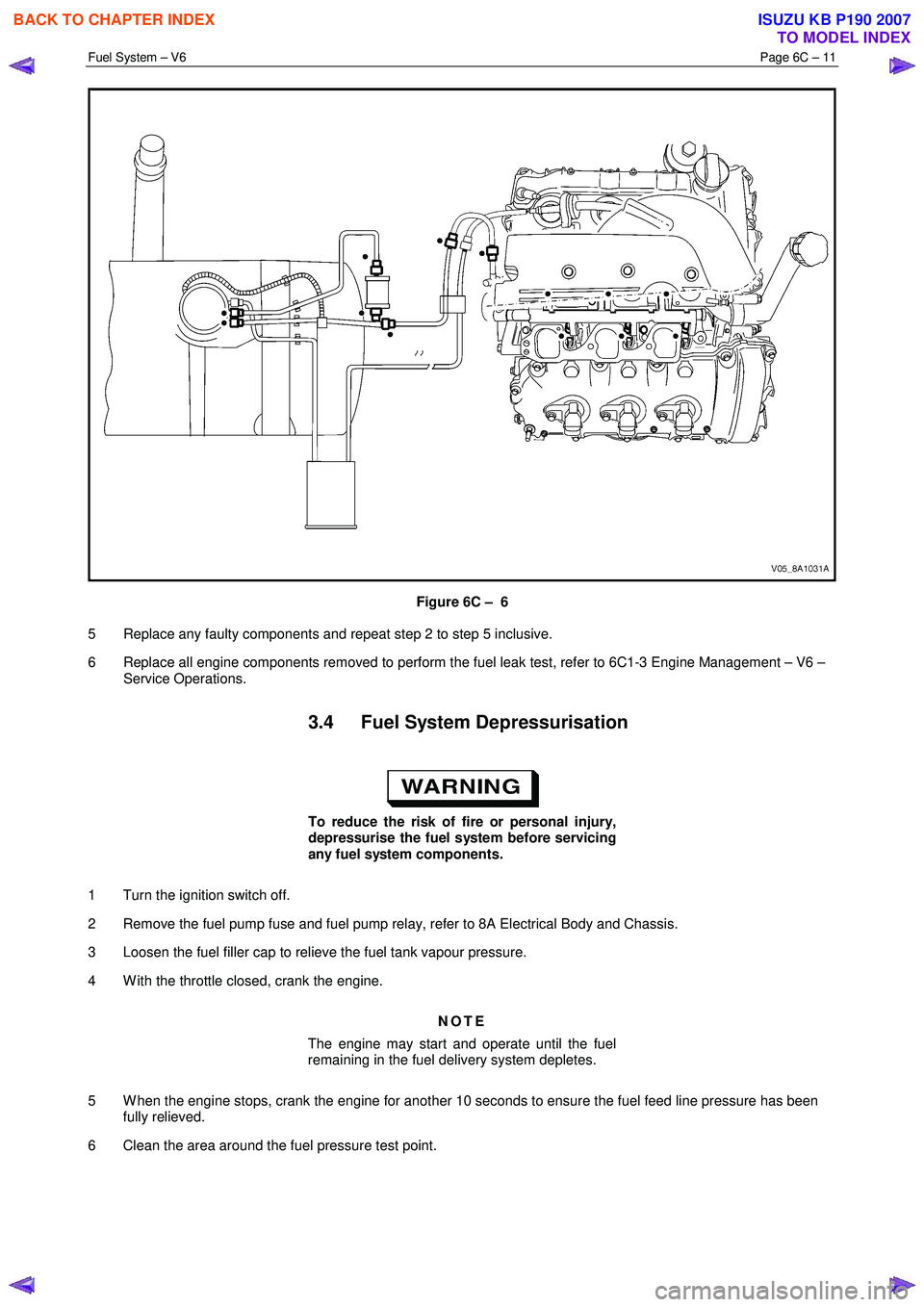

Fuel System – V6 Page 6C – 11

Figure 6C – 6

5 Replace any faulty components and repeat step 2 to step 5 inclusive.

6 Replace all engine components removed to perform the fuel leak test, refer to 6C1-3 Engine Management – V6 – Service Operations.

3.4 Fuel System Depressurisation

To reduce the risk of fire or personal injury,

depressurise the fuel system before servicing

any fuel system components.

1 Turn the ignition switch off.

2 Remove the fuel pump fuse and fuel pump relay, refer to 8A Electrical Body and Chassis.

3 Loosen the fuel filler cap to relieve the fuel tank vapour pressure.

4 W ith the throttle closed, crank the engine.

NOTE

The engine may start and operate until the fuel

remaining in the fuel delivery system depletes.

5 W hen the engine stops, crank the engine for another 10 seconds to ensure the fuel feed line pressure has been fully relieved.

6 Clean the area around the fuel pressure test point.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3214 of 6020

Fuel System – V6 Page 6C – 12

A small amount of fuel may be released when

pressing on the Schrader valve. Cover the

fitting with a shop towel to absorb any fuel

spillage before removing the Schrader valve

sealing cap. Place the soiled towel in an

approved container for disposal.

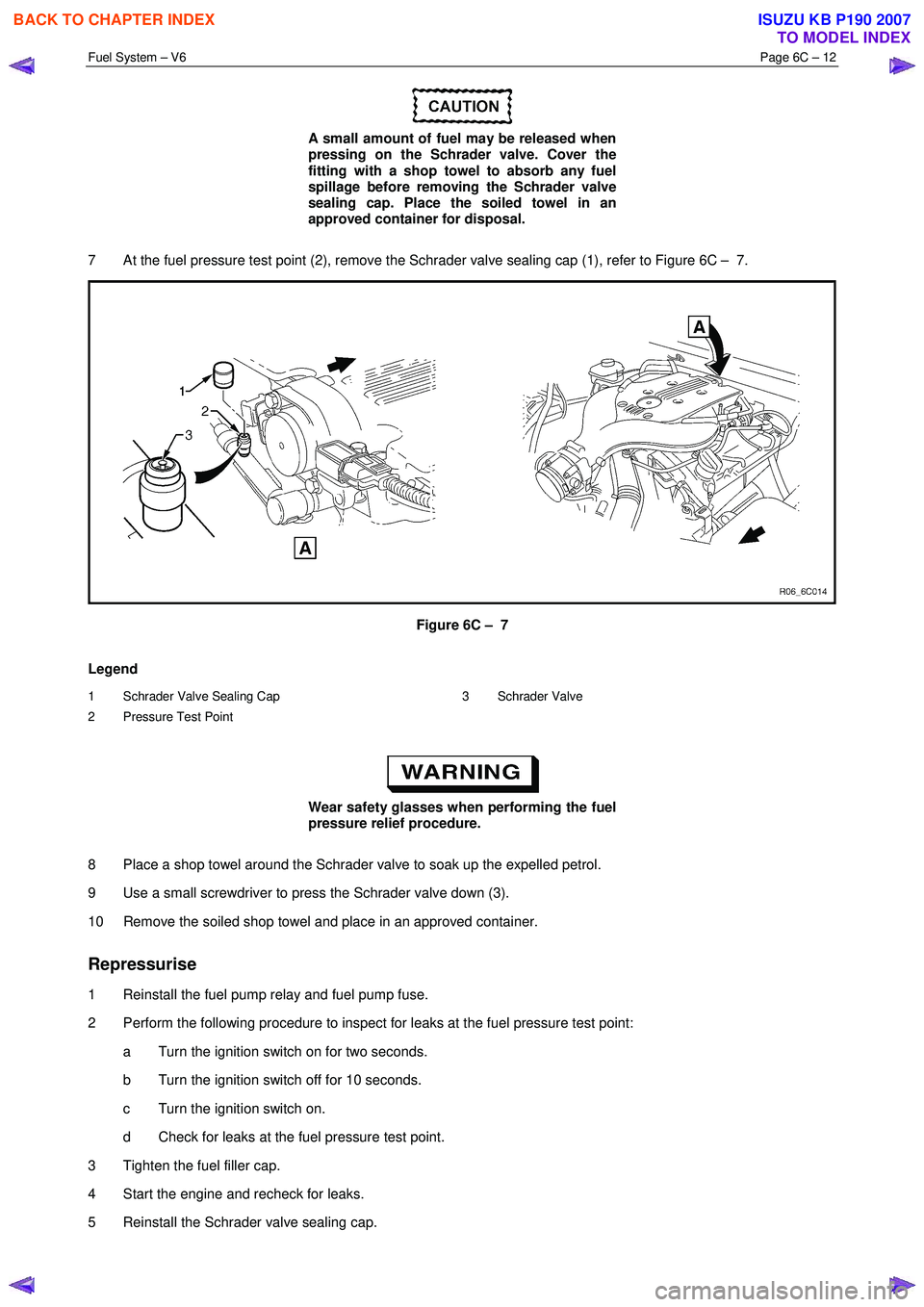

7 At the fuel pressure test point (2), remove the Schrader valve sealing cap (1), refer to Figure 6C – 7.

Figure 6C – 7

Legend

1 Schrader Valve Sealing Cap

2 Pressure Test Point 3 Schrader Valve

Wear safety glasses when performing the fuel

pressure relief procedure.

8 Place a shop towel around the Schrader valve to soak up the expelled petrol.

9 Use a small screwdriver to press the Schrader valve down (3).

10 Remove the soiled shop towel and place in an approved container.

Repressurise

1 Reinstall the fuel pump relay and fuel pump fuse.

2 Perform the following procedure to inspect for leaks at the fuel pressure test point: a Turn the ignition switch on for two seconds.

b Turn the ignition switch off for 10 seconds.

c Turn the ignition switch on.

d Check for leaks at the fuel pressure test point.

3 Tighten the fuel filler cap.

4 Start the engine and recheck for leaks.

5 Reinstall the Schrader valve sealing cap.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3215 of 6020

Fuel System – V6 Page 6C – 13

4 Service Operations

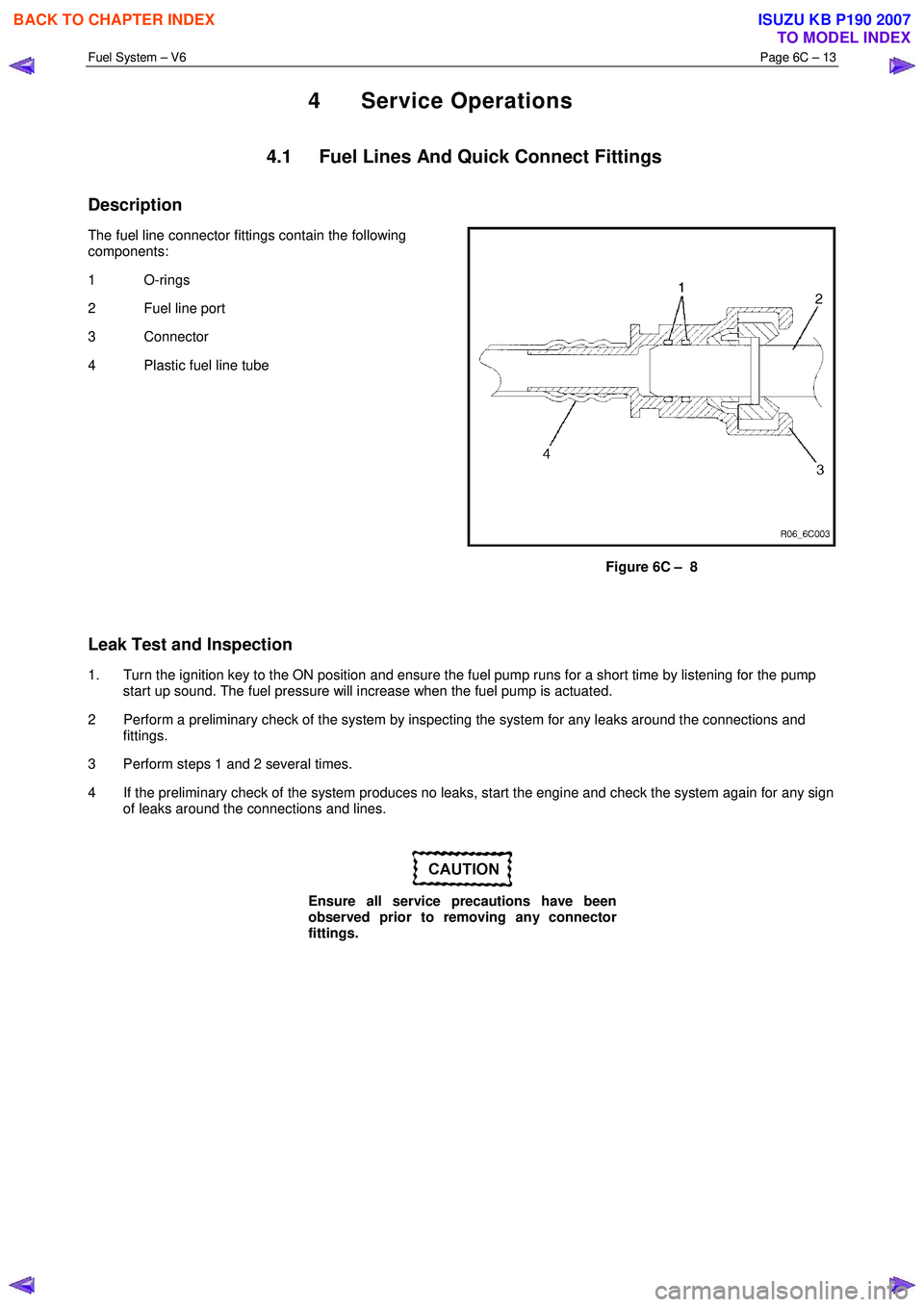

4.1 Fuel Lines And Quick Connect Fittings

Description

The fuel line connector fittings contain the following

components:

1 O-rings

2 Fuel line port

3 Connector

4 Plastic fuel line tube

Figure 6C – 8

Leak Test and Inspection

1. Turn the ignition key to the ON position and ensure the fuel pump runs for a short time by listening for the pump start up sound. The fuel pressure will increase when the fuel pump is actuated.

2 Perform a preliminary check of the system by inspecting the system for any leaks around the connections and fittings.

3 Perform steps 1 and 2 several times.

4 If the preliminary check of the system produces no leaks, start the engine and check the system again for any sign of leaks around the connections and lines.

Ensure all service precautions have been

observed prior to removing any connector

fittings.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3221 of 6020

Fuel System – V6 Page 6C – 19

Remove

• A depressurised fuel system contains fuel

in the fuel filter and fuel lines that can be

spilled during service operations.

• Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings

in the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or

other ignition sources are nearby. Ensure

all cellular phones (and transmission

devices that may cause any metal objects

to become unintentional receiving

antennas) are switched off.

• Place a dry chemical (Class B) fire

extinguisher nearby before performing any

on-vehicle service procedures. Failure to

follow these precautions may result in

personal injury.

1 Remove the fuel pump relay, refer to 8A Electrical Body and Chassis.

2 Depressurise the fuel system, refer to 3.4 Fuel System Depressurisation.

Never drain or store fuel into an open

container, due to the possibility of fire or

explosion.

3 Siphon the fuel tank, using commercially-available equipment.

Before proceeding, clean all traces of dirt and

other foreign material from the top of the fuel

tank, near the modular fuel pump and sender

assembly.

7 Place a drain tray under the fuel filter area.

Fuel can spill from the disconnected filter.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3225 of 6020

Fuel System – V6 Page 6C – 23

4.5 Modular Fuel Pump and Sender

Assembly

NOTE

If the modular fuel pump and sender assembly

develops a fault it must be replaced as a

complete unit. The only serviced parts are the

retainer locking ring and the O-ring seal.

Remove

• A depressurised fuel system contains fuel

in the fuel filter and fuel lines that can be

spilled during service operations.

• Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings

in the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or

other ignition sources are nearby. Ensure

all cellular phones (and transmission

devices that may cause any metal objects

to become unintentional receiving

antennas) are switched off.

• Place a dry chemical (Class B) fire

extinguisher nearby before performing any

on-vehicle service procedures. Failure to

follow these precautions may result in

personal injury.

• Wear safety glasses when using

compressed air. Do not blow compressed

air directly onto any body part.

1 Remove the fuel pump relay, refer to 8A Engine Body and Chassis.

2 Remove the fuel tank assembly from the vehicle, refer to 4.4 Fuel Tank.

Before proceeding, clean all traces of dirt and

other foreign material from the top of the fuel

tank, near the modular fuel pump and sender

assembly.

3 Use compressed air to ensure all dirt and foreign materials are removed from all fuel connections before disconnecting the parts.

Fuel can spill from the disconnected modular

fuel pump and sender assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3228 of 6020

Fuel System – V6 Page 6C – 26

Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings in

the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or other

ignition sources are nearby. Ensure all

cellular phones (and transmission devices

that may cause any metal objects to become

unintentional receiving antennas) are

switched off.

15 Place a suitable material over the opening in the fuel tank to prevent any foreign matter from entering the fuel system.

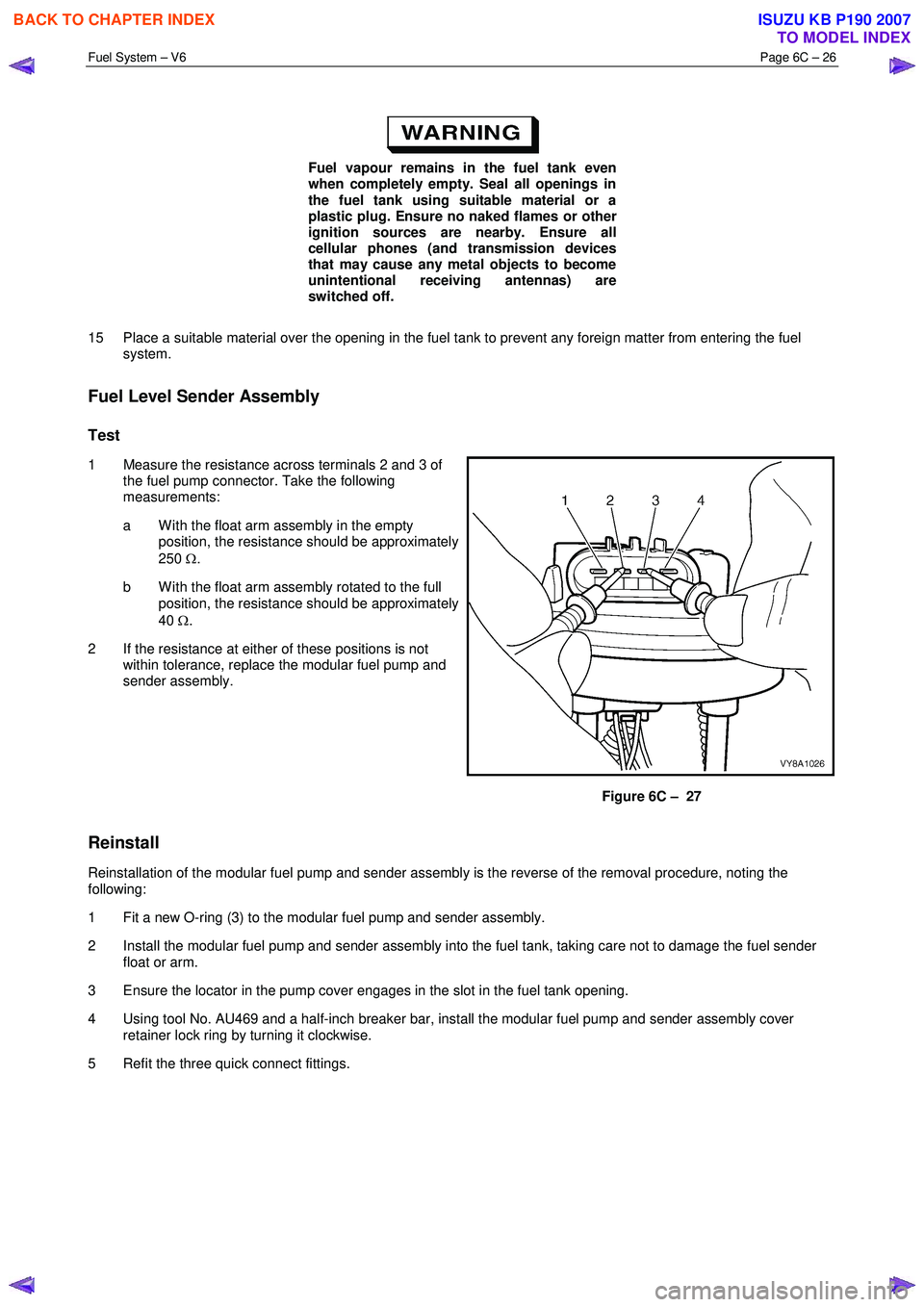

Fuel Level Sender Assembly

Test

1 Measure the resistance across terminals 2 and 3 of the fuel pump connector. Take the following

measurements:

a W ith the float arm assembly in the empty position, the resistance should be approximately

250 Ω.

b W ith the float arm assembly rotated to the full position, the resistance should be approximately

40 Ω.

2 If the resistance at either of these positions is not within tolerance, replace the modular fuel pump and

sender assembly.

Figure 6C – 27

Reinstall

Reinstallation of the modular fuel pump and sender assembly is the reverse of the removal procedure, noting the

following:

1 Fit a new O-ring (3) to the modular fuel pump and sender assembly.

2 Install the modular fuel pump and sender assembly into the fuel tank, taking care not to damage the fuel sender float or arm.

3 Ensure the locator in the pump cover engages in the slot in the fuel tank opening.

4 Using tool No. AU469 and a half-inch breaker bar, install the modular fuel pump and sender assembly cover retainer lock ring by turning it clockwise.

5 Refit the three quick connect fittings.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3232 of 6020

Fuel System – V6 Page 6C – 30

4.7 Fuel Tank Siphon Procedure

• Fuel vapour remains in the modular fuel

pump and sender assembly and fuel lines

that can be spilled during service

operations. Ensure no naked flames or

other ignition sources are nearby. Ensure

all cellular phones (and transmission

devices that may cause any metal objects

to become unintentional receiving

antennas) are switched off.

• Place a dry chemical (Class B) fire

extinguisher nearby before performing any

on-vehicle service procedures. Failure to

follow these precautions may result in

personal injury.

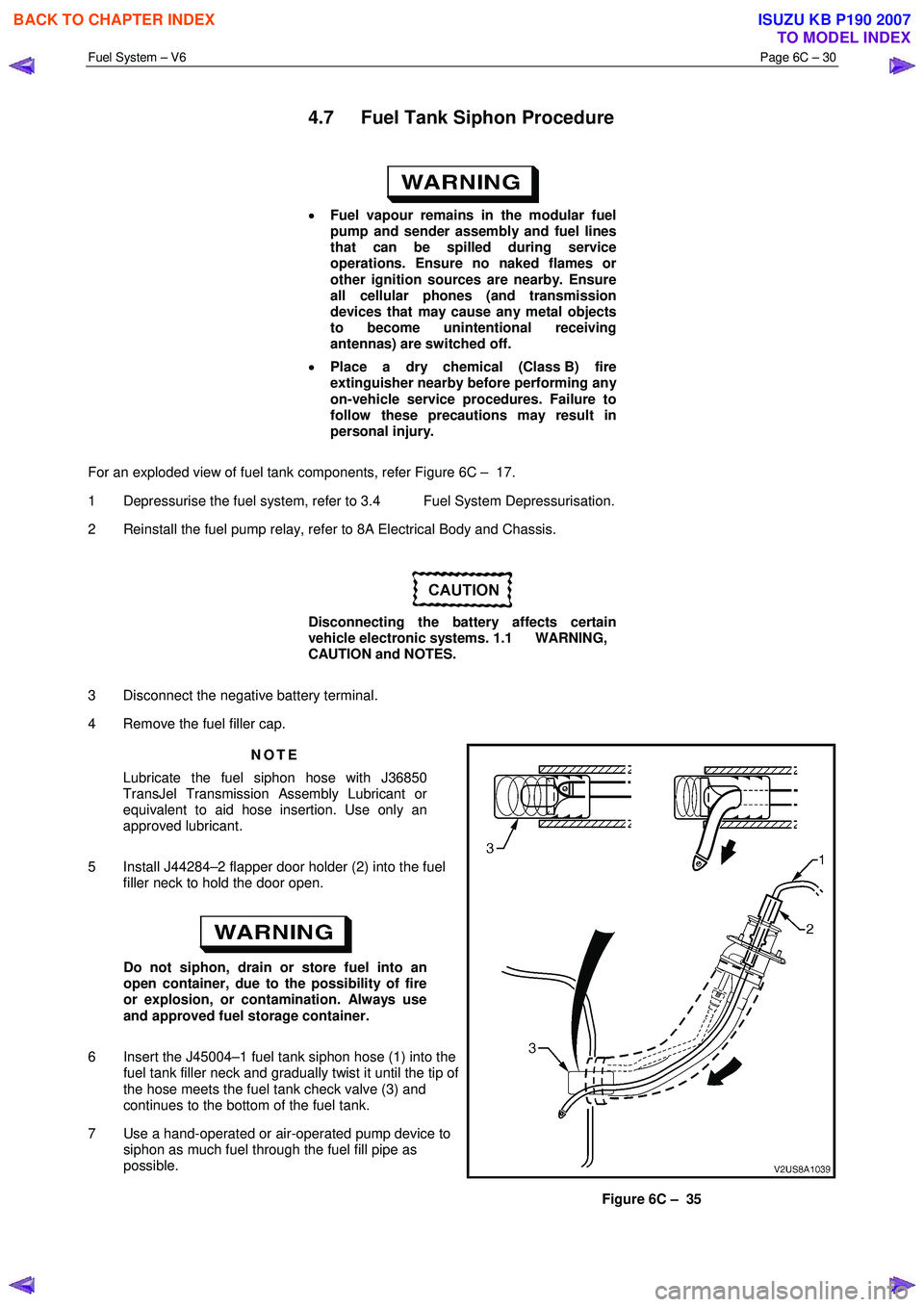

For an exploded view of fuel tank components, refer Figure 6C – 17.

1 Depressurise the fuel system, refer to 3.4 Fuel System Depressurisation.

2 Reinstall the fuel pump relay, refer to 8A Electrical Body and Chassis.

Disconnecting the battery affects certain

vehicle electronic systems. 1.1 WARNING,

CAUTION and NOTES.

3 Disconnect the negative battery terminal.

4 Remove the fuel filler cap.

NOTE

Lubricate the fuel siphon hose with J36850

TransJel Transmission Assembly Lubricant or

equivalent to aid hose insertion. Use only an

approved lubricant.

5 Install J44284–2 flapper door holder (2) into the fuel filler neck to hold the door open.

Do not siphon, drain or store fuel into an

open container, due to the possibility of fire

or explosion, or contamination. Always use

and approved fuel storage container.

6 Insert the J45004–1 fuel tank siphon hose (1) into the fuel tank filler neck and gradually twist it until the tip of

the hose meets the fuel tank check valve (3) and

continues to the bottom of the fuel tank.

7 Use a hand-operated or air-operated pump device to siphon as much fuel through the fuel fill pipe as

possible.

Figure 6C – 35

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3233 of 6020

Fuel System – V6 Page 6C – 31

Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings in

the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or other

ignition sources are nearby. Ensure all

cellular phones (and transmission devices

that may cause any metal objects to become

unintentional receiving antennas) are

switched off.

Do not use excessive force when removing

the fuel siphon hose from the fuel filler neck.

If the fuel siphon hose gets stuck upon

removal, gently twist and tug the fuel siphon

hose back and forth until it releases.

NOTE

• If fuel does not siphon from the fuel tank, the

fuel siphon hose may have entered the fuel

tank through a roof-facing check valve

opening. If required, insert the J45004–1 fuel

siphon hose (1) into the fuel tank filler neck,

refer to Figure 6C – 35, but twist the fuel

siphon hose 90° as it slides down the filler

neck. This enables the fuel siphon hose to

enter the fuel tank through a floor-facing

check valve opening.

• The siphon procedure will not remove all fuel

from the fuel tank. If required, fuel remaining

in the fuel tank may be siphoned out through

the top of the fuel tank, once the modular fuel

pump and sender assembly is removed from

the tank, refer to 4.4 Fuel Tank.

8 Remove the siphon equipment.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3235 of 6020

Fuel System – V6 Page 6C – 33

4.9 Fuel Lines

Remove

• A depressurised fuel system contains fuel

in the fuel filter and fuel lines that can be

spilled during service operations.

• Fuel vapour remains in the fuel tank even

when completely empty. Seal all openings

in the fuel tank using suitable material or a

plastic plug. Ensure no naked flames or

other ignition sources are nearby. Ensure

all cellular phones (and transmission

devices that may cause any metal objects

to become unintentional receiving

antennas) are switched off.

• Place a dry chemical (Class B) fire

extinguisher nearby before performing any

on-vehicle service procedures. Failure to

follow these precautions may result in

personal injury.

• Wear safety glasses when using

compressed air. Do not blow compressed

air onto any body part.

1 Remove the fuel pump relay, refer to 8A Electrical Body and Chassis.

2 Depressurise the fuel system, refer to 3.4 Fuel System Depressurisation.

Never drain or store fuel into an open

container, due to the possibility of fire or

explosion.

3 Raise the vehicle, preferably on a hoist, refer to 0A General Information.

Before proceeding, clean all traces of dirt and

other foreign material from the fuel lines.

4 Use compressed air to ensure that all dirt and foreign materials are removed from all fuel connections before the parts are disconnected.

5 If required, remove the stone guard, refer to Figure 6C – 17 and fuel lines. Use the following illustrations showing the fuel line layout and location of other items relating to the fuel system as a guide, also refer to 4.1 Fuel Lines

And Quick Connect Fittings and 4.6 Evaporative Emission Control Canister.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3243 of 6020

Engine Management – V6 – General Information Page 6C1-1–1

6C1-1 Engine Management – V6

General Information

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to 1.3 Warning

Caution and Notes for correct workshop practices with regard to safety and / or property damage.

1 General Information ............................................................................................................ ...................3

1.1 Introduction ............................................................................................................................................................ 3

1.2 Emission Control ................................................................................................................................................... 3

ADR 79/01 Emissions Standards .......................................................................................................................... 3

1.3 Warning Caution and Notes .................................................................................................................................. 4

Definition of WARNING, CAUTION and NOTE Statements ............................................................................. .... 4

WARNING defined ............................................................................................................................................. 4

CAUTION defined .............................................................................................................................................. 4

NOTE defined..................................................................................................................................................... 4

2 Component Locations ............................................................................................................ ...............5

2.1 Cylinder Numbering............................................................................................................................................... 5

2.2 Engine Compartment............................................................................................................................................. 5

2.3 Engine ..................................................................................................................................................................... 6

2.4 Interior..................................................................................................................................................................... 8

3 System Operation ...................................................................................................................................9

3.1 Fuel Delivery System ............................................................................................................................................. 9

Fuel System Pressure ........................................................................................................... ................................ 9

Fuel Injection System .......................................................................................................................................... 10

Short Term Fuel Trim ....................................................................................................................................... 10

Long Term Fuel Trim ........................................................................................................................................ 10

3.2 Air / Fuel Control System ...................................................................................................... .............................. 11

Starting Mode ....................................................................................................................................................... 11

Run Mode.............................................................................................................................................................. 11

Open Loop Mode................................................................................................................. ............................. 11

Closed Loop Mode ............................................................................................................... ............................ 11

Acceleration Mode .............................................................................................................. ................................. 11

Deceleration Mode ............................................................................................................................................... 11

Fuel Shut-off Mode .............................................................................................................................................. 11

Battery Voltage Correction Mode ................................................................................................ ....................... 12

Limp Mode ............................................................................................................................................................ 12

Engine Protection Mode ......................................................................................................... ............................. 12

Clear Flood Mode ................................................................................................................................................. 12

3.3 Ignition Control System........................................................................................................ ............................... 12

3.4 Starter Motor Operation....................................................................................................................................... 12

3.5 Throttle Actuator Control System ............................................................................................... ....................... 12

Description ........................................................................................................................................................... 12

Throttle Body Relearn Procedure ....................................................................................................................... 14

TAC System Default Actions / Reduce Power Modes................................................................................ ....... 14

Forced Engine Shutdown .................................................................................................................................... 14

3.6 Cruise Control System ........................................................................................................................................ 14

3.7 Brake Torque Management ........................................................................................................ ......................... 15

3.8 Emission Control Systems.................................................................................................................................. 15

Evaporative Emission Control System ............................................................................................ .................. 15

Engine Ventilation System .................................................................................................................................. 16

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007