CIRCUIT IMMOBILISER ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2388 of 6020

6E–218 ENGINE DRIVEABILITY AND EMISSIONS

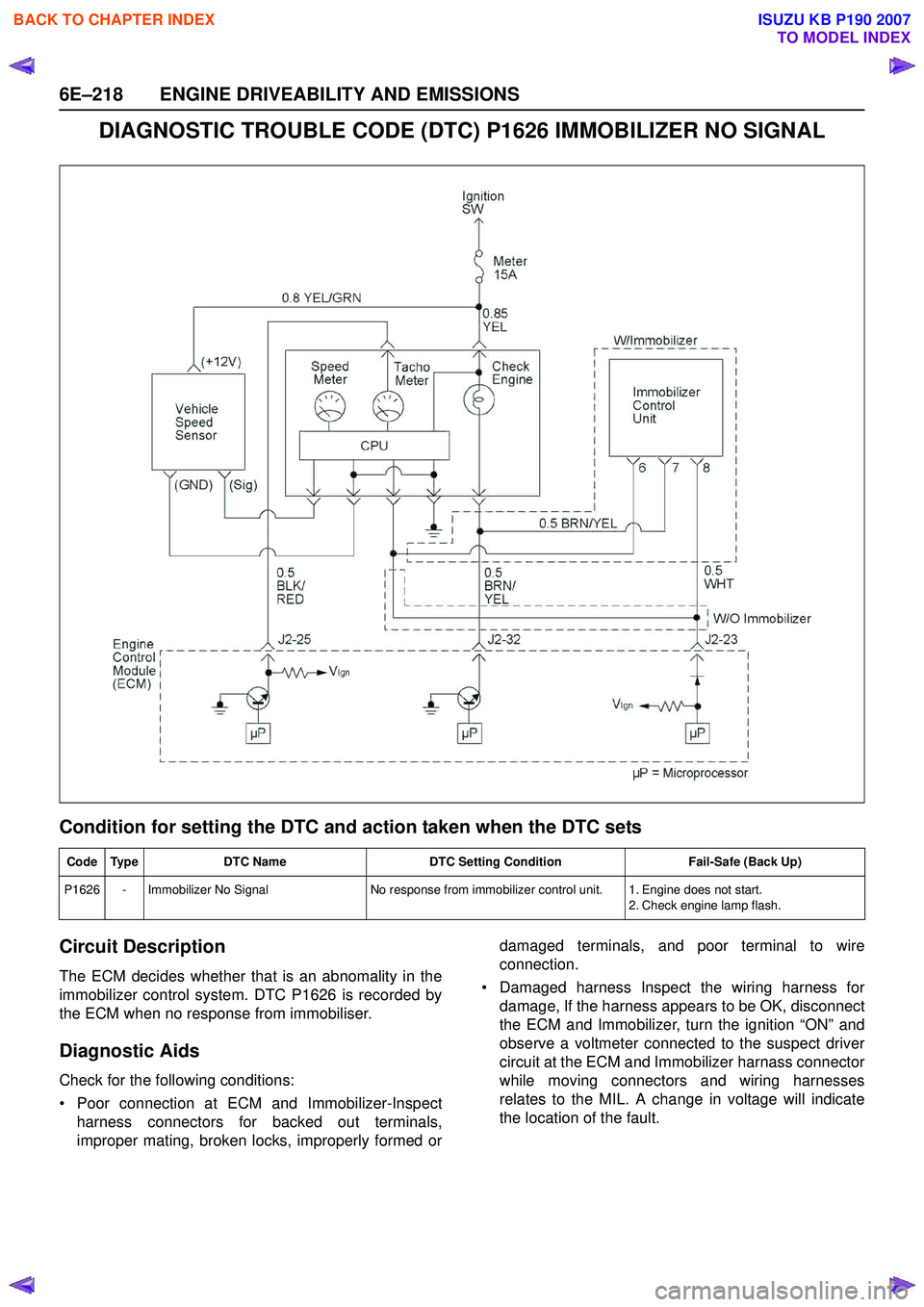

DIAGNOSTIC TROUBLE CODE (DTC) P1626 IMMOBILIZER NO SIGNAL

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The ECM decides whether that is an abnomality in the

immobilizer control system. DTC P1626 is recorded by

the ECM when no response from immobiliser.

Diagnostic Aids

Check for the following conditions:

• Poor connection at ECM and Immobilizer-Inspect harness connectors for backed out terminals,

improper mating, broken locks, improperly formed or damaged terminals, and poor terminal to wire

connection.

• Damaged harness Inspect the wiring harness for damage, If the harness appears to be OK, disconnect

the ECM and Immobilizer, turn the ignition “ON” and

observe a voltmeter connected to the suspect driver

circuit at the ECM and Immobilizer harnass connector

while moving connectors and wiring harnesses

relates to the MIL. A change in voltage will indicate

the location of the fault.

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P1626 - Immobilizer No Signal No response from immobilizer control unit. 1. Engine does not start.

2. Check engine lamp flash.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3254 of 6020

Engine Management – V6 – General Information Page 6C1-1–12

Battery Voltage Correction Mode

The ECM monitors the battery voltage circuit to ensure the voltage available to the engine management system stays

within the specified range. A low system voltage changes the voltage across the fuel injectors, which affects the fuel

injector flow rate. In addition, a low system voltage fault condition may cause other engine management system

components to malfunction.

The ECM switches to battery voltage correction mode when the ECM detects a low battery voltage fault condition. W hile

in battery voltage correction mode, the ECM performs the following functions to compensate for the low system voltage:

• Increases the injector on-time to maintain the correct amount of fuel being delivered, and

• Increases the idle speed to increase the generator output.

Limp Mode

The programming in the ECM software allows the engine to run in a back-up fuel strategy or limp mode when the ECM

fails to receive signal inputs from critical sensors or when a critical engine management fault condition exists.

The ECM switches to limp mode to enable the vehicle to be driven until service operations can be performed.

Engine Protection Mode

Engine protection mode is engaged to protect engine components from friction damage in the event of an engine over-

temperature condition being detected by the ECM.

W hen the ECM is in engine protection mode, fuel injectors are systematically disabled and re-activated. The injectors

that have been shut down allow the air being drawn into the engine to assist with engine cooling.

Clear Flood Mode

If the engine is flooded with fuel during starting and will not start, the clear flood mode can be manually selected by

depressing the accelerator pedal to wide open throttle (W OT). In this mode, the ECM will completely disable the fuel

injectors, and will maintain this state during engine cranking as long as the ECM detects a W OT condition with engine

speed less than 1,000 rpm.

3.3 Ignition Control System

The electronic ignition system provides a spark to ignite the compressed air / fuel mixture at the correct time. The ECM

maintains correct spark timing and dwell for all engine operating conditions. The ECM calculates the optimum spark

parameters from information received from the various sensors and triggers the appropriate ignition module / coil to fire

the spark plug.

3.4 Starter Motor Operation

The engine control module controls the activation of the start relay in response to inputs from:

• Ignition switch,

• Battery,

• Immobiliser system, and

• Automatic transmission gear selector position / clutch pedal position switch for vehicles with manual transmissions.

3.5 Throttle Actuator Control System

Description

The throttle actuator control (TAC) system is used to improve emissions, fuel economy and driveability. The TAC system

eliminates the mechanical link between the accelerator pedal and the throttle plate and eliminates the need for a cruise

control module and idle air control motor. The TAC system comprises of:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3299 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–21

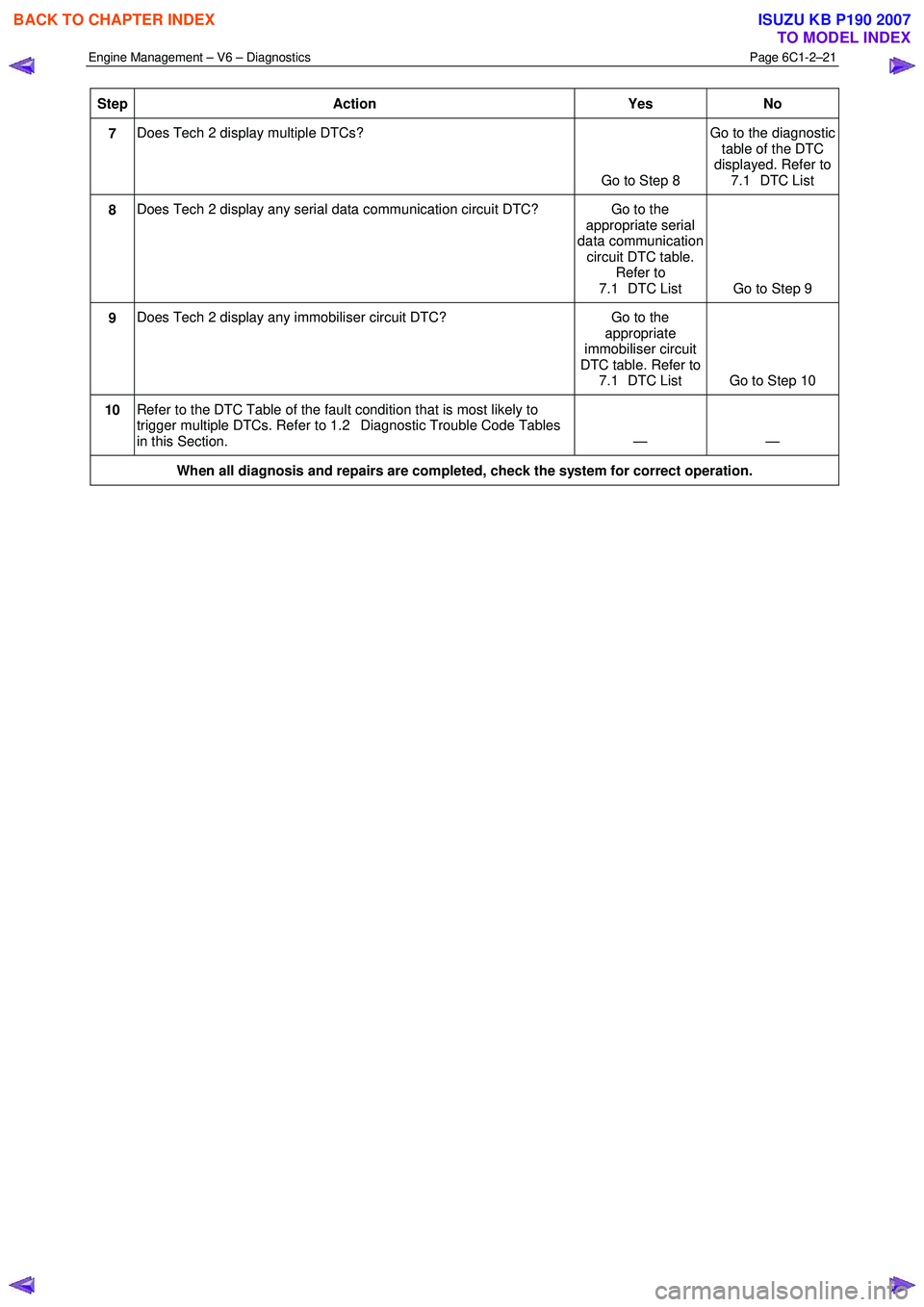

Step Action Yes No

7 Does Tech 2 display multiple DTCs?

Go to Step 8 Go to the diagnostic

table of the DTC

displayed. Refer to 7.1 DTC List

8 Does Tech 2 display any serial data communication circuit DTC? Go to the

appropriate serial

data communication circuit DTC table. Refer to

7.1 DTC List Go to Step 9

9 Does Tech 2 display any immobiliser circuit DTC? Go to the

appropriate

immobiliser circuit

DTC table. Refer to 7.1 DTC List Go to Step 10

10 Refer to the DTC Table of the fault condition that is most likely to

trigger multiple DTCs. Refer to 1.2 Diagnostic Trouble Code Tables

in this Section. — —

When all diagnosis and repairs are completed, check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3301 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–23

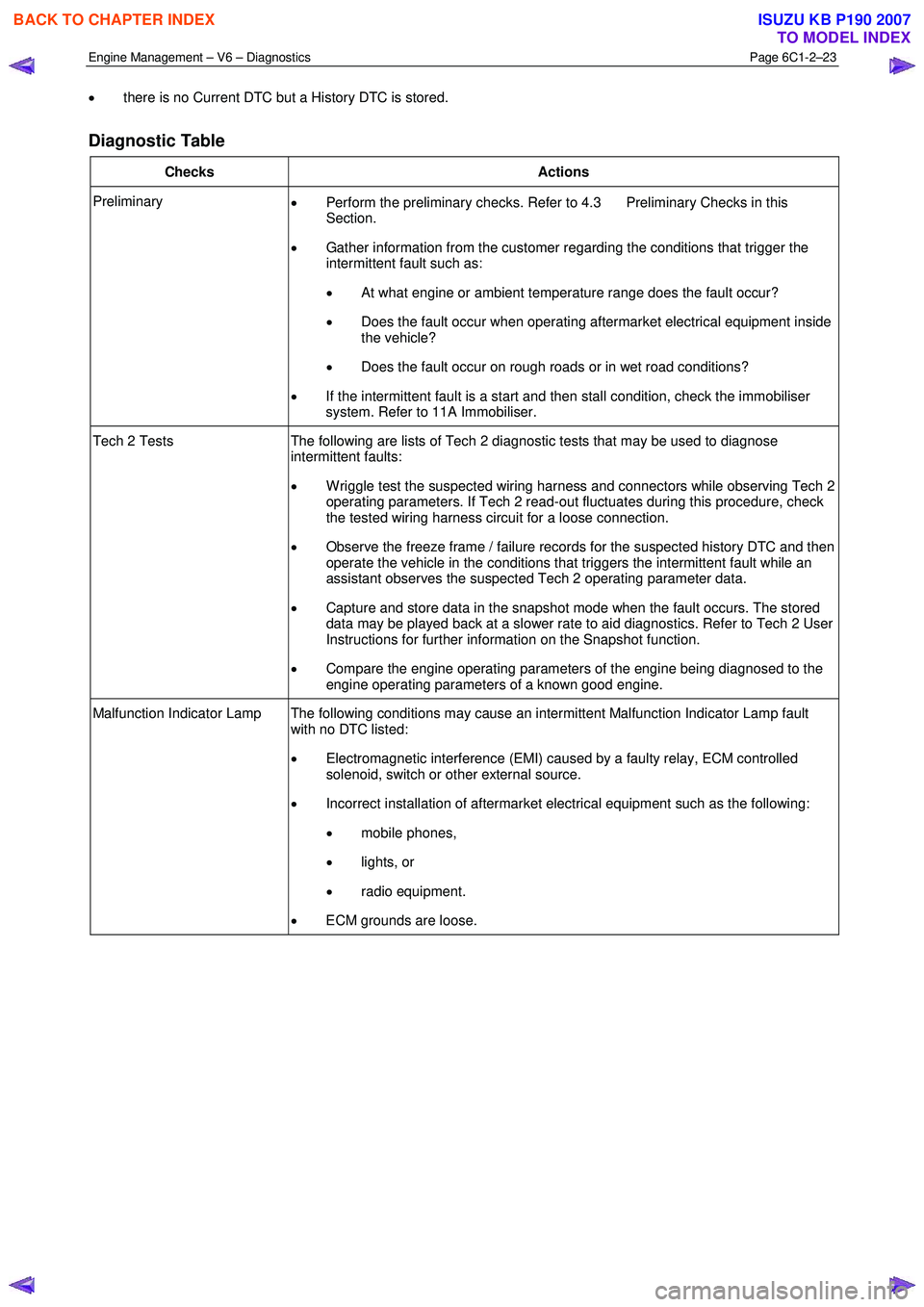

• there is no Current DTC but a History DTC is stored.

Diagnostic Table

Checks Actions

Preliminary

• Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

• Gather information from the customer regarding the conditions that trigger the

intermittent fault such as:

• At what engine or ambient temperature range does the fault occur?

• Does the fault occur when operating aftermarket electrical equipment inside

the vehicle?

• Does the fault occur on rough roads or in wet road conditions?

• If the intermittent fault is a start and then stall condition, check the immobiliser

system. Refer to 11A Immobiliser.

Tech 2 Tests The following are lists of Tech 2 diagnostic tests that may be used to diagnose

intermittent faults:

• W riggle test the suspected wiring harness and connectors while observing Tech 2

operating parameters. If Tech 2 read-out fluctuates during this procedure, check

the tested wiring harness circuit for a loose connection.

• Observe the freeze frame / failure records for the suspected history DTC and then

operate the vehicle in the conditions that triggers the intermittent fault while an

assistant observes the suspected Tech 2 operating parameter data.

• Capture and store data in the snapshot mode when the fault occurs. The stored

data may be played back at a slower rate to aid diagnostics. Refer to Tech 2 User

Instructions for further information on the Snapshot function.

• Compare the engine operating parameters of the engine being diagnosed to the

engine operating parameters of a known good engine.

Malfunction Indicator Lamp The following conditions may cause an intermittent Malfunction Indicator Lamp fault with no DTC listed:

• Electromagnetic interference (EMI) caused by a faulty relay, ECM controlled

solenoid, switch or other external source.

• Incorrect installation of aftermarket electrical equipment such as the following:

• mobile phones,

• lights, or

• radio equipment.

• ECM grounds are loose.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3304 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–26

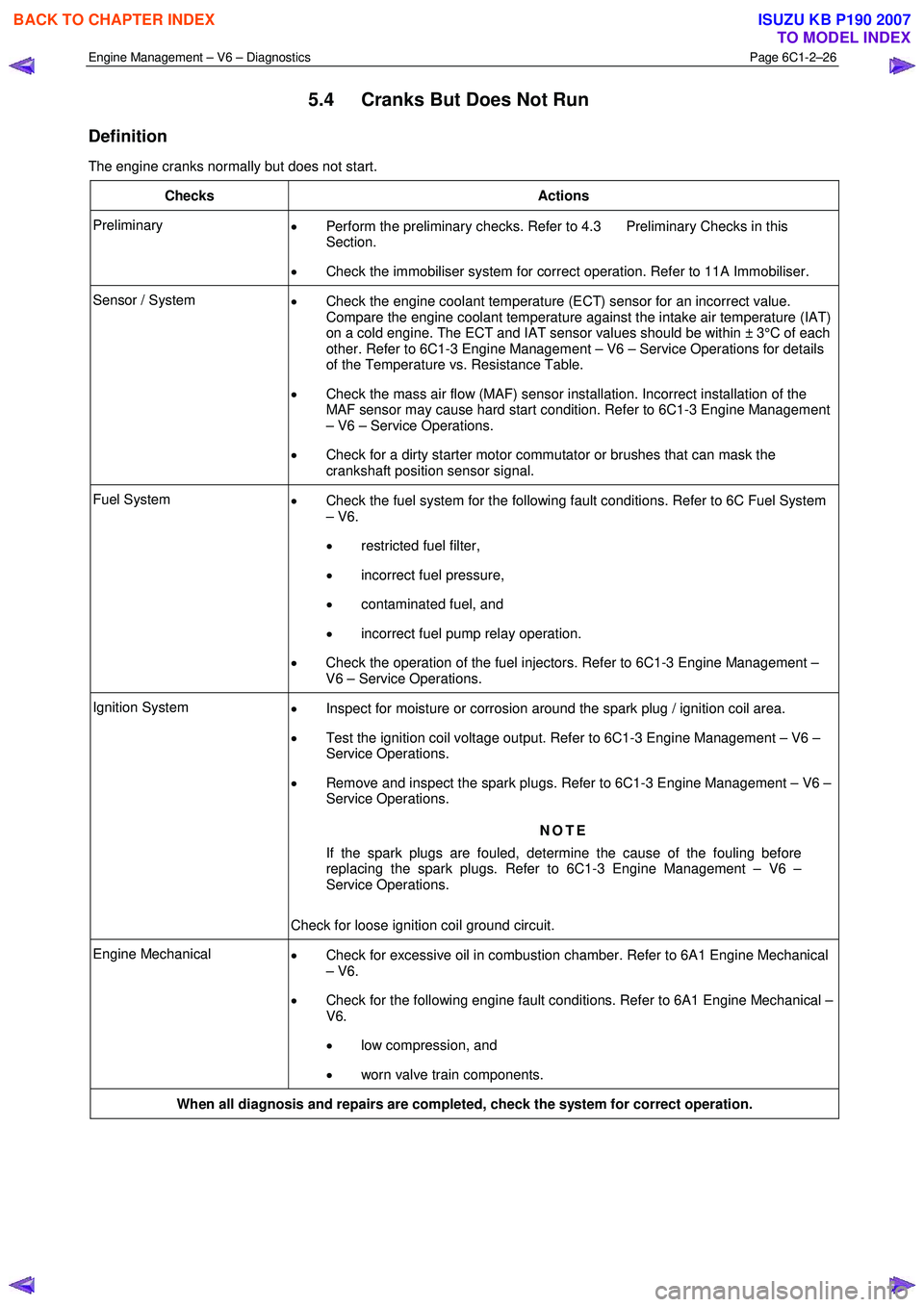

5.4 Cranks But Does Not Run

Definition

The engine cranks normally but does not start.

Checks Actions

Preliminary • Perform the preliminary checks. Refer to 4.3 Preliminary Checks in this

Section.

• Check the immobiliser system for correct operation. Refer to 11A Immobiliser.

Sensor / System

• Check the engine coolant temperature (ECT) sensor for an incorrect value.

Compare the engine coolant temperature against the intake air temperature (IAT)

on a cold engine. The ECT and IAT sensor values should be within ± 3°C of each

other. Refer to 6C1-3 Engine Management – V6 – Service Operations for details

of the Temperature vs. Resistance Table.

• Check the mass air flow (MAF) sensor installation. Incorrect installation of the

MAF sensor may cause hard start condition. Refer to 6C1-3 Engine Management

– V6 – Service Operations.

• Check for a dirty starter motor commutator or brushes that can mask the

crankshaft position sensor signal.

Fuel System • Check the fuel system for the following fault conditions. Refer to 6C Fuel System

– V6.

• restricted fuel filter,

• incorrect fuel pressure,

• contaminated fuel, and

• incorrect fuel pump relay operation.

• Check the operation of the fuel injectors. Refer to 6C1-3 Engine Management –

V6 – Service Operations.

Ignition System • Inspect for moisture or corrosion around the spark plug / ignition coil area.

• Test the ignition coil voltage output. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

• Remove and inspect the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

NOTE

If the spark plugs are fouled, determine the cause of the fouling before

replacing the spark plugs. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

Check for loose ignition coil ground circuit.

Engine Mechanical • Check for excessive oil in combustion chamber. Refer to 6A1 Engine Mechanical

– V6.

• Check for the following engine fault conditions. Refer to 6A1 Engine Mechanical –

V6.

• low compression, and

• worn valve train components.

When all diagnosis and repairs are completed, check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3334 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–56

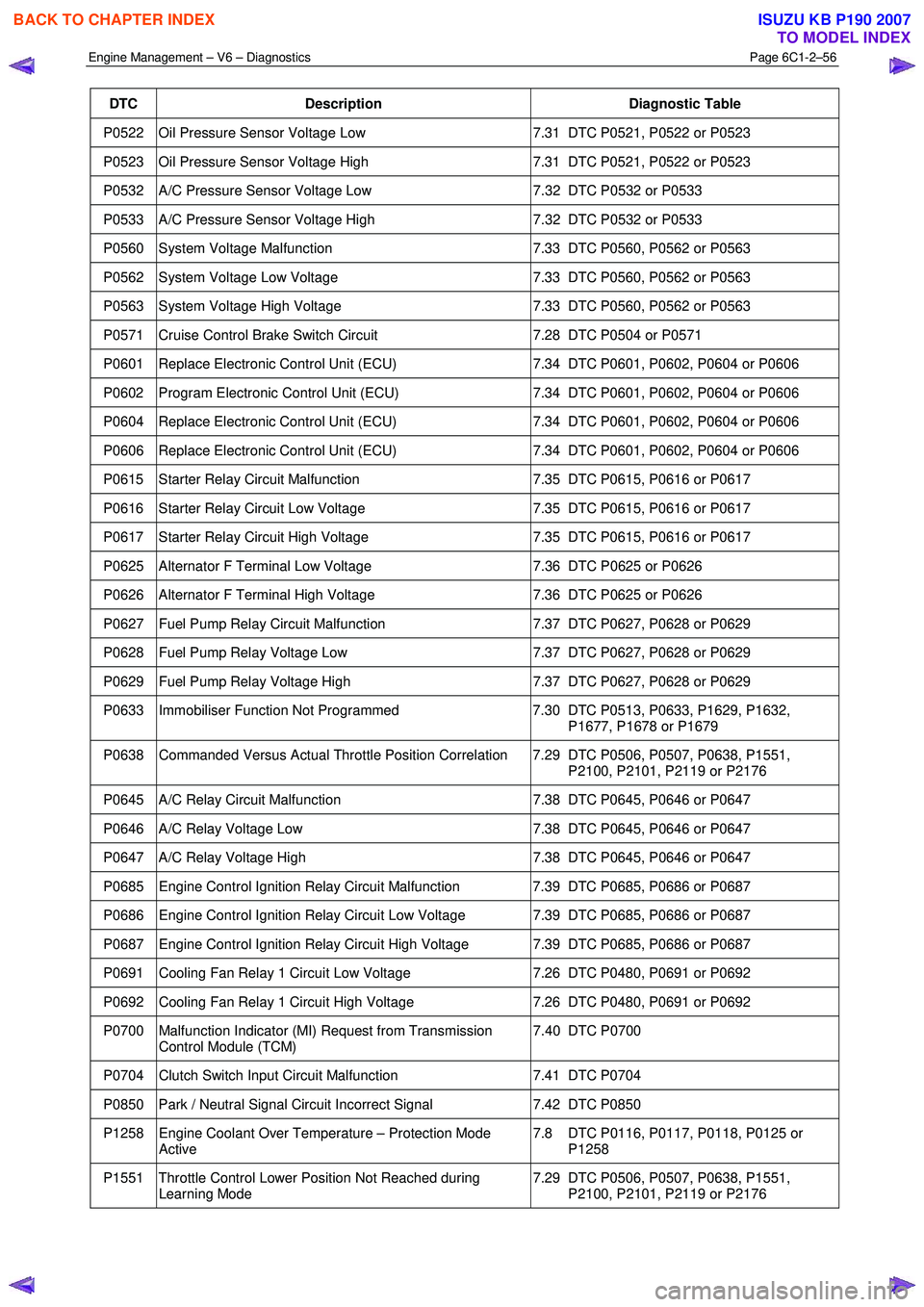

DTC Description Diagnostic Table

P0522 Oil Pressure Sensor Voltage Low 7.31 DTC P0521, P0522 or P0523

P0523 Oil Pressure Sensor Voltage High 7.31 DTC P0521, P0522 or P0523

P0532 A/C Pressure Sensor Voltage Low 7.32 DTC P0532 or P0533

P0533 A/C Pressure Sensor Voltage High 7.32 DTC P0532 or P0533

P0560 System Voltage Malfunction 7.33 DTC P0560, P0562 or P0563

P0562 System Voltage Low Voltage 7.33 DTC P0560, P0562 or P0563

P0563 System Voltage High Voltage 7.33 DTC P0560, P0562 or P0563

P0571 Cruise Control Brake Switch Circuit 7.28 DTC P0504 or P0571

P0601 Replace Electronic Control Unit (ECU) 7.34 DTC P0601, P0602, P0604 or P0606

P0602 Program Electronic Control Unit (ECU) 7.34 DTC P0601, P0602, P0604 or P0606

P0604 Replace Electronic Control Unit (ECU) 7.34 DTC P0601, P0602, P0604 or P0606

P0606 Replace Electronic Control Unit (ECU) 7.34 DTC P0601, P0602, P0604 or P0606

P0615 Starter Relay Circuit Malfunction 7.35 DTC P0615, P0616 or P0617

P0616 Starter Relay Circuit Low Voltage 7.35 DTC P0615, P0616 or P0617

P0617 Starter Relay Circuit High Voltage 7.35 DTC P0615, P0616 or P0617

P0625 Alternator F Terminal Low Voltage 7.36 DTC P0625 or P0626

P0626 Alternator F Terminal High Voltage 7.36 DTC P0625 or P0626

P0627 Fuel Pump Relay Circuit Malfunction 7.37 DTC P0627, P0628 or P0629

P0628 Fuel Pump Relay Voltage Low 7.37 DTC P0627, P0628 or P0629

P0629 Fuel Pump Relay Voltage High 7.37 DTC P0627, P0628 or P0629

P0633 Immobiliser Function Not Programmed 7.30 DTC P0513, P0633, P1629, P1632,

P1677, P1678 or P1679

P0638 Commanded Versus Actual Throttle Position Correlation 7.29 DTC P0506, P0507, P0638, P1551, P2100, P2101, P2119 or P2176

P0645 A/C Relay Circuit Malfunction 7.38 DTC P0645, P0646 or P0647

P0646 A/C Relay Voltage Low 7.38 DTC P0645, P0646 or P0647

P0647 A/C Relay Voltage High 7.38 DTC P0645, P0646 or P0647

P0685 Engine Control Ignition Relay Circuit Malfunction 7.39 DTC P0685, P0686 or P0687

P0686 Engine Control Ignition Relay Circuit Low Voltage 7.39 DTC P0685, P0686 or P0687

P0687 Engine Control Ignition Relay Circuit High Voltage 7.39 DTC P0685, P0686 or P0687

P0691 Cooling Fan Relay 1 Circuit Low Voltage 7.26 DTC P0480, P0691 or P0692

P0692 Cooling Fan Relay 1 Circuit High Voltage 7.26 DTC P0480, P0691 or P0692

P0700 Malfunction Indicator (MI) Request from Transmission

Control Module (TCM) 7.40 DTC P0700

P0704 Clutch Switch Input Circuit Malfunction

7.41 DTC P0704

P0850 Park / Neutral Signal Circuit Incorrect Signal 7.42 DTC P0850

P1258 Engine Coolant Over Temperature – Protection Mode

Active 7.8 DTC P0116, P0117, P0118, P0125 or

P1258

P1551 Throttle Control Lower Position Not Reached during Learning Mode 7.29 DTC P0506, P0507, P0638, P1551,

P2100, P2101, P2119 or P2176

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3335 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–57

DTC Description Diagnostic Table

P1629 Immobiliser Fuel Enable Signal Not Received 7.30 DTC P0513, P0633, P1629, P1632,

P1677, P1678 or P1679

P1632 Immobiliser Fuel Disable Signal Received 7.30 DTC P0513, P0633, P1629, P1632,

P1677, P1678 or P1679

P1648 W rong Security Code Entered 7.43 DTC P1648

P1668 Alternator L Terminal Circuit Malfunction 7.44 DTC P1668, P2500 or P2501

P1677 Immobiliser Function not Enabled 7.30 DTC P0513, P0633, P1629, P1632,

P1677, P1678 or P1679

P1678 Engine Control Module Identification Failed 7.30 DTC P0513, P0633, P1629, P1632,

P1677, P1678 or P1679

P1679 Immobiliser Environment Identification Failed 7.30 DTC P0513, P0633, P1629, P1632,

P1677, P1678 or P1679

P1845 Engine Torque Reduction Malfunction 7.45 DTC P1845

P2096 Post Catalyst O2 Sensor Fuel Trim Below Lower Limit

(Bank 1) 7.46 DTC P2096 or P2098

P2097 Post Catalyst O2 Sensor Fuel Trim Above Upper Limit

(Bank 1) 7.47 DTC P2097 or P2099

P2098 Post Catalyst O2 Sensor Fuel Trim Below Lower Limit

(Bank 2) 7.46 DTC P2096 or P2098

P2099 Post Catalyst O2 Sensor Fuel Trim Above Upper Limit

(Bank 2) 7.47 DTC P2097 or P2099

P2100 Throttle Control Motor Malfunction

7.29 DTC P0506, P0507, P0638, P1551,

P2100, P2101, P2119 or P2176

P2101 Throttle Control Position Range / Performance 7.29 DTC P0506, P0507, P0638, P1551,

P2100, P2101, P2119 or P2176

P2105 Throttle Control Forced Engine Shutdown 7.48 DTC P2105

P2107 Throttle Control Malfunction 7.49 DTC P2107

P2119 Closed Throttle Position Range / Performance 7.29 DTC P0506, P0507, P0638, P1551,

P2100, P2101, P2119 or P2176

P2122 Accelerator Pedal Position Sensor 1 Voltage Low 7.50 DTC P2122, P2123, P2127, P2128 or P2138

P2123 Accelerator Pedal Position Sensor 1 Voltage High 7.50 DTC P2122, P2123, P2127, P2128 or P2138

P2127 Accelerator Pedal Position Sensor 2 Voltage Low 7.50 DTC P2122, P2123, P2127, P2128 or P2138

P2128 Accelerator Pedal Position Sensor 2 Voltage High 7.50 DTC P2122, P2123, P2127, P2128 or P2138

P2138 Accelerator Pedal Position Sensor 1-2 Correlation 7.50 DTC P2122, P2123, P2127, P2128 or P2138

P2176 Throttle Control Lower Position not Learned 7.29 DTC P0506, P0507, P0638, P1551,

P2100, P2101, P2119 or P2176

P2177 Fuel Trim Lean during Cruising/Acceleration (Bank 1) 7.51 DTC P2177 or P2179

P2178 Fuel Trim Rich during Cruising/Acceleration (Bank 1) 7.52 DTC P2178 or P2180

P2179 Fuel Trim Lean during Cruising/Acceleration (Bank 2) 7.51 DTC P2177 or P2179

P2180 Fuel Trim Rich during Cruising/Acceleration (Bank 2 7.52 DTC P2178 or P2180

P2187 Fuel Trim Lean during Idling/Deceleration (Bank 1) 7.53 DTC P2187 or P2189

P2188 Fuel Trim Rich during Idling/Deceleration (Bank 1) 7.54 DTC P2188 or P2190

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3417 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–139

Step Action Yes

No

8 1 Switch off the ignition.

2 Connect Tool No. J34730-405 injector test lamp between the positive and negative control circuit of the TAC.

3 Switch on the ignition for about 5 seconds then switch off while observing the test lamp.

Does the test lamp illuminate briefly each time the ignition cycles? Go to Step 11 Go to Step 10

9 Test the TAC control circuit that measured outside the specified value

for a high resistance, open circuit, short to ground or short to voltage

fault condition. Refer to 8A Electrical - Body and Chassis for

information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 13 Go to Step 12

10 Test the positive and negative control circuits of the TAC for a shorted

together fault condition. Refer to 8A Electrical - Body and Chassis for

information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 13 Go to Step 12

11 Replace the throttle body assembly. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

W as the repair completed? Go to Step 13 —

12 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 13 —

13 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the TAC motor control circuit DTCs fail this ignition

cycle? Go to Step 2 Go to Step 14

14 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.30 DTC P0513, P0633, P1629, P1632, P1677,

P1678 or P1679

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P0513 – W rong Transponder Key

• DTC P0633 – Immobiliser Function Not Programmed

• DTC P1629 – Immobiliser Fuel Enable Signal Not Received

• DTC P1632 – Immobiliser Fuel Disable Signal Received

• DTC P1677 – Immobiliser Function Not Enabled

• DTC P1678 – Engine Control Module Identification Failed

• DTC P1679 – Immobiliser Environment Identification Failed

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3418 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–140

Circuit Description

The engine control module (ECM), the powertrain interface module (PIM) and the immobiliser control unit (ICU) are

integral parts of the vehicle immobiliser system. The immobiliser system authenticates the security code programmed

into each of these modules to prevent unauthorised vehicle operation. This authentication process includes the following

steps:

1 At predetermined situations, the ICU sends a security code to the PIM.

2 W hen the ignition is switched ON, the PIM receives and compares this security code from the ICU against the security code programmed into the PIM.

3 Once the PIM receives the correct security code from the ICU, it sends a security code to the ECM.

4 The ECM receives and compares this security code from the PIM against the security code programmed into the ECM.

5 The authentication process is complete once the ECM receives the correct security code from the PIM within the specified time frame.

6 The ECM allows normal vehicle operation.

NOTE

If any of these authentication processes fail, the

vehicle will not start and DTCs will set. For further

information on the immobiliser system, refer to

11A Immobiliser.

Conditions for Running the DTC

Conditions for running the DTC are:

• The ignition is switched on.

• The ignition voltage is 10.0 – 16.0 V.

Conditions for Setting the DTC

P0513

The ECM receives an incorrect response from the PIM during the immobiliser authentication process.

P0633

An attempt is made to start the engine before the immobiliser function has been programmed into a new PIM.

P1629

The ECM has not received a fuel enable password from the ICU.

P1632

The ECM receives an incorrect response from the PIM during the immobiliser authentication process.

P1677

An attempt is made to start the vehicle after the ECM was reset.

P1678

The ECM does not receive a valid response from the PIM when an attempt is made to start the engine.

P1679

The ECM receives a message from the PIM stating that it can't authenticate to the ICU.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3419 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–141

Conditions for Clearing the DTC

Refer to 1.4 Diagnostic Trouble Codes in this Section, for action taken when a Type B DTC sets and conditions for

clearing Type B DTCs.

Additional Information

• Refer to 6C1-1 Engine Management –V6 – General Information for details of the ECM operation.

• Refer to 11A Immobiliser for the following information:

• ICU link to PIM, and

• Immobiliser System.

• Since a fault condition in a wiring connector may trigger DTCs, always test the connectors related to this

diagnostic procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A

Electrical - Body and Chassis for information on electrical fault diagnosis.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

DTC P0513, P0633, P1629, P1632, P0633, P1677, P1678, P1679 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for setting the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC P0513, P1629, P1632, P0633, P1677, P1678 or P1679 fail

this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 Using Tech 2, perform the ICU Link to ECM / PIM procedure. Refer to

6E1 Powertrain Interface Module – V6.

Has the linking procedure been performed correctly? Go to Step 7 Go to Step 4

4 Test the Immobiliser system. Refer to 11A Immobiliser.

Has any fault been found and rectified? Go to Step 7 Go to Step 5

5 1 Test all ground circuits of the PIM for a high resistance or an

open circuit fault condition. Refer to 8A Electrical - Body and

Chassis for information on electrical fault diagnosis.

2 Test the PIM ignition supply voltage circuit for a high resistance, open circuit or short to ground fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

Has any fault been found and rectified? Go to Step 7 Go to Step 6

6 Replace the PIM. Refer to 6E1 Powertrain Interface Module – V6.

Has the repair been completed? Go to Step 7 —

7 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Do any of the immobiliser DTCs fail this ignition cycle? Go to Step 2 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007