CIRCUIT IMMOBILISER ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3429 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–151

7.35 DTC P0615, P0616 or P0617

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC P0615 – Starter Relay Circuit Malfunction

• DTC P0616 – Starter Relay Circuit Low Voltage

• DTC P0617 – Starter Relay Circuit High Voltage

Circuit Description

The engine control relay applies battery voltage to the coil circuit of the starter relay through the ignition circuit. W hen

the ignition switched is turned to the Start position and all the conditions required to enable an engine cranking is met,

the ECM grounds the starter relay control circuit to activate the starter relay. W hen active, the starter relay applies

battery voltage to the starter motor solenoid control circuit to operate the starter motor. Refer to 6D1-2 Starting System –

V6 for information on the cranking system operation.

The ECM monitors the control circuit of the starter relay for conditions that are incorrect for the commanded state. A

starter relay control circuit DTC sets if the ECM detects a fault condition in the starter relay control circuit.

Conditions for Running the DTC

DTCs P0615, P0616 and P0617 run continuously once the following conditions are met:

• The ignition is switched on

• The ignition voltage is 10.0 – 16.0 V.

Conditions for Setting the DTC

The ECM detects a condition that is incorrect for the starter relay commanded state.

Conditions for Clearing the DTC

The starter relay control circuit DTCs are Type C DTCs. Refer to 1.4 Diagnostic Trouble Codes in this Section, for

action taken when Type C DTCs set and conditions for clearing Type C DTCs.

Additional Information

• Refer to 6D1-2 Starting System – V6 for information on the cranking system operation.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following number refers to the step number in the diagnostic table:

3 A fault condition in the starting system or immobiliser system may trigger this DTC.

DTC P0615, P0616 or P0617 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3430 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–152

Step Action Yes No

2 1 Switch off the ignition for 30 seconds.

2 Turn the ignition switch to the Start position or operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC P0615, P0616 and P0617 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 Check for a fault condition in the following systems which can disable

the starting system:

• Starting System, refer to 6D1-2 Starting System – V6.

• Immobiliser System, refer to 11A Immobiliser.

W as any fault found and rectified? Go to Step 10 Go to Step 4

4 1 Remove the starter relay. Refer to 8A Electrical - Body and

Chassis.

2 Connect a test lamp between the ignition circuit of the starter relay and a good ground.

3 Switch on the ignition.

Does the test lamp illuminate when the ignition switch is turned to the

on position? Go to Step 5 Go to Step 6

5 1 Connect a test lamp between the control circuit of the starter

relay and a 12 V.

2 Turn the ignition switch to the Start position and then release it back to the on position.

Does the test lamp turn on when the ignition switch is turned to the

Start position and then turn off when the ignition switch returns to the

on position? Go to Step 8 Go to Step 7

6 Repair the ignition voltage circuit of the starter relay for a high

resistance or open circuit fault condition. Refer to 8A Electrical - Body

and Chassis for information on electrical wiring repair procedures.

W as the repair completed? Go to Step 10

—

7 Test the control circuit of the starter relay for a high resistance, open

circuit, short to ground or a short to voltage fault condition. Refer to

8A Electrical - Body and Chassis for information on electrical fault

diagnosis.

W as any fault found and rectified? Go to Step 10 Go to Step 9

8 Replace the starter relay. Refer to 8A Electrical - Body and Chassis.

W as the repair completed? Go to Step 10

—

9 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 10

—

10 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does the starter relay control circuit DTCs fail this ignition cycle? Go to Step 2 Go to Step 11

11 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3443 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–165

Step Action Yes

No

10 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does DTC P0850 fail this ignition cycle? Go to Step 2 Go to Step 11

11 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.43 DTC P1648

DTC Descriptor

This diagnostic procedure supports DTC P1648 – W rong Security Code Entered.

Circuit Description

Tech 2 is used to program the engine control module (ECM). Before any programming, a security code must be entered

into Tech 2. The ECM will check if the code entered is correct before continuing. If the security code is incorrect, DTC

P1648 sets.

Conditions for Running the DTC

Conditions for running the DTC are:

• The ignition is switched on.

• The ignition voltage is 10.0 – 16.0 V.

Conditions for Setting the DTC

An incorrect security code is entered into Tech 2 when attempting to program the ECM.

Action Taken When the DTC Sets

W hen the DTC sets, the malfunction indicator lamp (MIL) is not displayed.

Conditions for Clearing the DTC

The immobiliser security code is a Type ‘C’ DTC. Refer to 1.4 Diagnostic Trouble Codes in this Section, for action

taken when a Type ‘C’ DTC sets and conditions for clearing Type ‘C’ DTCs.

Additional Information

• Refer to 6C1-1 Engine Management –V6 – General Information for details of the ECM operation.

• Refer to 6C1-3 Engine Management –V6 – Service Operations for details on resetting the ECM.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3496 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–218

6 1 Test the pump current circuit of the HO2S for an

open. Refer to 8A Electrical-Body and Chassis.

Did you find and correct the condition? —

Go to Step 11 Go to Step 8

7 1 Test for an intermittent and for a poor connection

at the appropriate HO2S. Refer to 8A Electrical-

Body and Chassis.

Did you find and correct the condition? —

Go to Step 11 Go to Step 9

8 1 Test for an intermittent and for a poor connection

at the engine control module (ECM). Refer to 8A

Electrical-Body and Chassis.

Did you find and correct the condition? —

Go to Step 11 Go to Step 10

9 1 Replace the HO2S. Refer to 6C1-3 Engine

Management – V6 – Service Operations.

Did you complete the replacement? —

Go to Step 11 —

10 1 Replace the ECM. Refer to 6C1-3 Engine

Management –V6 – Service Operations for

details on replacing the ECM.

Did you complete the replacement? —

Go to Step 11 —

11 1 Use Tech 2 to clear the DTCs.

2 Turn OFF the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you observed

from the Freeze Frame / Failure Records.

Did the DTC fail this ignition? —

Go to Step 2 Go to Step 12

12 1 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? —

Go to the

appropriate DTC Table in this Section System OK

When all diagnosis and repairs are completed, clear all DTCs and verify correct operation

7.61 DTC U0001

DTC Descriptor

This diagnostic procedure supports DTC U0001 – No Communication with CAN-Bus (High Speed).

Circuit Description

The engine control module (ECM) communicates directly with the control modules connected to the GM LAN serial data

communication circuit through the GM LAN protocol.

However, the immobiliser control unit (ICU) communicates with the ECM using the keyword 2000 protocol. Since the GM

LAN and keyword 2000 protocols are not compatible, a powertrain interface module (PIM) is integrated into the serial

data system to serve as a gateway. This gateway allows communication between the two protocols. Refer to 6E1

Powertrain Interface Module – V6 for further information on the GM LAN serial data communication circuit.

DTC U0001 sets if the ECM detects a fault condition in the serial data communication circuit.

Conditions for Running the DTC

DTC U0001 runs continuously when the following conditions are met:

The ignition voltage is 10.0 – 16.0 V.

The vehicle power mode requires serial data communication.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3497 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–219

Conditions for Setting the DTC

The ECM detects a specified number of transmitted messages are not valid.

Conditions for Clearing the DTC

The Serial Data Communication Circuit DTCs are Type ‘C’ DTCs. Refer to 1.4 Diagnostic Trouble Codes in this

Section, for action taken when a Type ‘C’ DTC sets and conditions for clearing Type ‘C’ DTCs.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the ECM operation.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following number refers to the step numbers in the diagnostic table:

1 The following tests are included in the Diagnostic System Check.

• Tests the integrity of the GM LAN serial data communication circuit.

• Tests for fault conditions on the vehicle immobiliser system stored in the ICU.

DTC U0001 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC U0001 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 4 —

4 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does DTC U0001 fail this ignition cycle? Go to Step 2 Go to Step 5

5 Using Tech 2, select the DTC display function.

Are there any DTCs displayed? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3498 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–220

7.62 DTC U0101

DTC Description

This diagnostic procedure supports the following DTC:

• DTC U0101 – CAN-Bus No Communication W ith TCM (Transmission Control Module)

Circuit Description

The Engine Control Module (ECM) communicates directly with the control modules connected to the GM LAN serial data

communication circuit through the GM LAN protocol.

However, the immobiliser control unit (ICU) communicates with the ECM using the keyword 2000 protocol. Since the GM

LAN and keyword 2000 protocols are not compatible, a powertrain interface module (PIM) is integrated into the serial

data system to serve as a gateway. This gateway allows communication between the two protocols. Refer to 6E1

Powertrain Interface Module – V6 for further information on the GM LAN serial data communication circuit.

A serial data communication circuit – TCM DTC sets if the ECM detects an invalid signal from the TCM.

Conditions for Running the DTC

DTC U0101 runs continuously when the following conditions are met:

• The ignition is on for longer than 3 seconds.

• The ignition voltage is 10.0 – 16.0 V.

Conditions for Setting the DTC

The ECM did not receive a valid signal from the TCM within the specified time frame.

Conditions for Clearing the DTC

This Serial Data Communication Circuit DTC is a Type C DTC. Refer to 1.4 Diagnostic Trouble Codes in this Section,

for action taken when a Type C DTC sets and the conditions required for clearing Type C DTCs.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the ECM operation.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following number refers to the step numbers in the diagnostic table:

1 The following tests are included in the Diagnostic System Check.

• Tests the integrity of the GM LAN serial data communication circuit.

• Tests for fault conditions on the vehicle immobiliser system stored in the ICU.

DTC P0864 and U0101 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3499 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–221

Step Action Yes No

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC U0101 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 Using Tech 2, attempt to communicate with the PIM.

Does the PIM failed to communicate? Refer to the 6E1

Powertrain Interface Module – V6 Go to Step 4

4 Are DTCs also set in the PIM? Refer to 6E1

Powertrain Interface Module – V6 Go to Step 5

5 Are DTCs that may trigger a fault condition in the serial data

communication circuit also set in the TCM? Refer to 7C2

Automatic

Transmission –

4L60E – Electrical Diagnosis Go to Step 6

6 Replace the TCM, refer to 7C4 Automatic Transmission – 4L60E –

On-vehicle Servicing.

W as the repair completed? Go to Step 7 —

7 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the serial data communication circuit – TCM DTCs fail

this ignition cycle? Go to Step 2 Go to Step 8

8 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.63 DTC U0155 or U0423

DTC Descriptors

This diagnostic procedure supports the following DTCs:

• DTC U0155 – CAN-Bus No Communication W ith Gateway

• DTC U0423 – CAN-Bus Invalid Data From Gateway

Circuit Description

The Engine Control Module (ECM) communicates directly with the control modules connected to the GM LAN serial data

communication circuit through the GM LAN protocol.

However, the immobiliser control unit (ICU) communicates with the ECM using the keyword 2000 protocol. Since the GM

LAN and keyword 2000 protocols are not compatible, a powertrain interface module (PIM) is integrated into the serial

data system to serve as a gateway. This gateway allows communication between the two protocols. Refer to 6E1

Powertrain Interface Module – V6 for further information on the GM LAN serial data communication circuit

A PIM serial data communication circuit DTC sets if the ECM detects an invalid signal from the PIM.

Conditions for Running the DTC

DTCs U0155 and U0423 run continuously when the following conditions are met:

• The engine is running.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3500 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–222

• The ignition voltage is 10.0 – 16.0 V.

Conditions for Setting the DTC

The ECM did not receive a valid signal from the PIM within the specified time frame.

Conditions for Clearing the DTC

The PIM serial data communication circuit DTCs are Type C DTCs. Refer to 1.4 Diagnostic Trouble Codes in this

Section, for action taken when a Type C DTC sets and conditions for clearing Type C DTCs.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the ECM operation.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following number refers to the step numbers in the diagnostic table:

1 The following tests are included in the Diagnostic System Check.

• Tests the integrity of the GM LAN serial data communication circuit.

• Tests for fault conditions on the vehicle immobiliser system stored in the ICU.

DTC U0155 or U0423 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC U0155, or U0423 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this Section

3 Replace the PIM. Refer to 6E1 Powertrain Interface Module – V6.

W as the repair completed? Go to Step 4 —

4 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does any of the PIM serial data communication circuit DTCs fail this

ignition cycle? Go to Step 2 Go to Step 5

5 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

When all diagnosis and repairs are completed, check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3618 of 6020

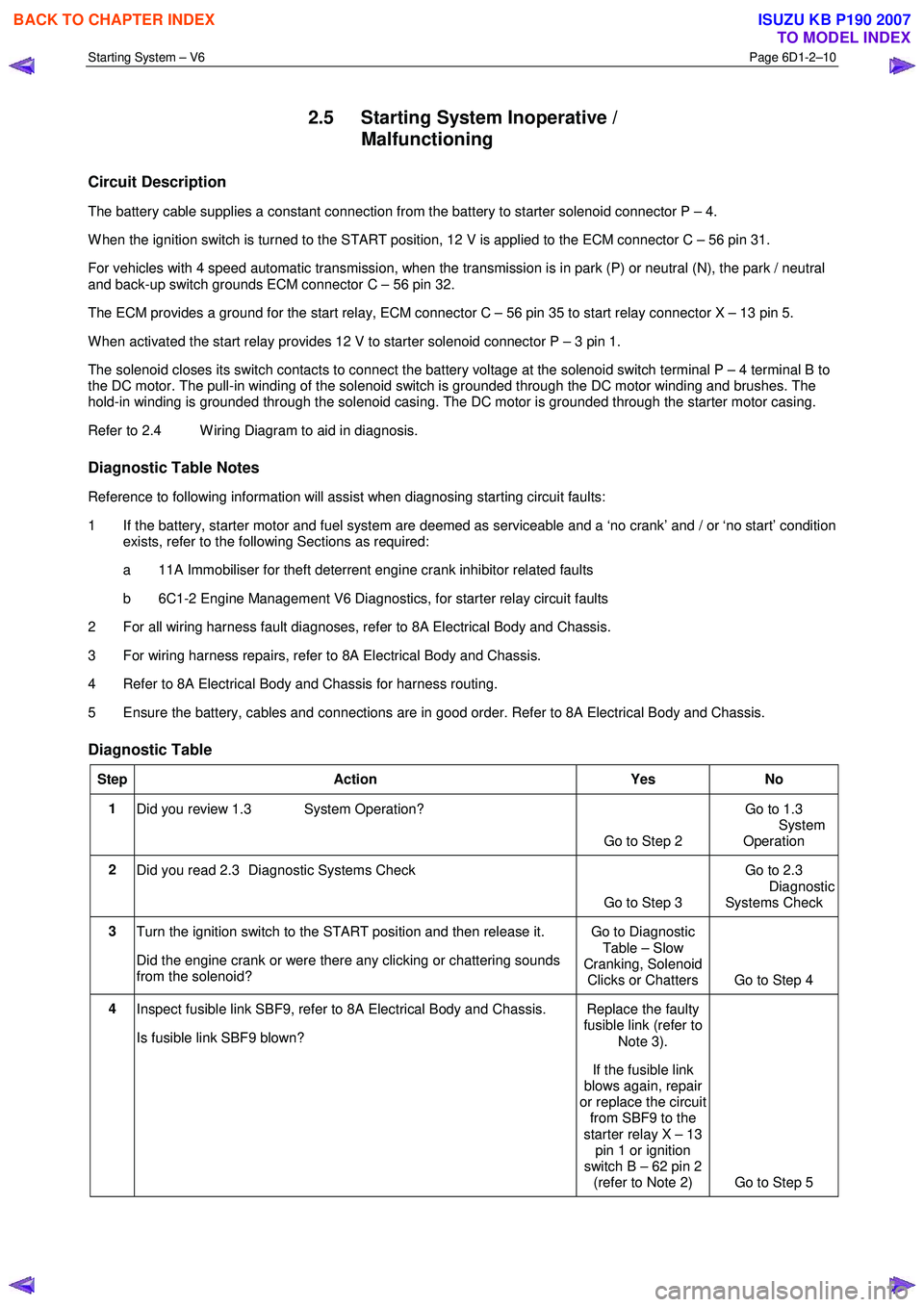

Starting System – V6 Page 6D1-2–10

2.5 Starting System Inoperative /

Malfunctioning

Circuit Description

The battery cable supplies a constant connection from the battery to starter solenoid connector P – 4.

W hen the ignition switch is turned to the START position, 12 V is applied to the ECM connector C – 56 pin 31.

For vehicles with 4 speed automatic transmission, when the transmission is in park (P) or neutral (N), the park / neutral

and back-up switch grounds ECM connector C – 56 pin 32.

The ECM provides a ground for the start relay, ECM connector C – 56 pin 35 to start relay connector X – 13 pin 5.

W hen activated the start relay provides 12 V to starter solenoid connector P – 3 pin 1.

The solenoid closes its switch contacts to connect the battery voltage at the solenoid switch terminal P – 4 terminal B to

the DC motor. The pull-in winding of the solenoid switch is grounded through the DC motor winding and brushes. The

hold-in winding is grounded through the solenoid casing. The DC motor is grounded through the starter motor casing.

Refer to 2.4 W iring Diagram to aid in diagnosis.

Diagnostic Table Notes

Reference to following information will assist when diagnosing starting circuit faults:

1 If the battery, starter motor and fuel system are deemed as serviceable and a ‘no crank’ and / or ‘no start’ condition exists, refer to the following Sections as required:

a 11A Immobiliser for theft deterrent engine crank inhibitor related faults

b 6C1-2 Engine Management V6 Diagnostics, for starter relay circuit faults

2 For all wiring harness fault diagnoses, refer to 8A Electrical Body and Chassis.

3 For wiring harness repairs, refer to 8A Electrical Body and Chassis.

4 Refer to 8A Electrical Body and Chassis for harness routing.

5 Ensure the battery, cables and connections are in good order. Refer to 8A Electrical Body and Chassis.

Diagnostic Table

Step Action Yes No

1

Did you review 1.3 System Operation?

Go to Step 2 Go to 1.3

System

Operation

2 Did you read 2.3 Diagnostic Systems Check

Go to Step 3 Go to 2.3

Diagnostic Systems Check

3 Turn the ignition switch to the START position and then release it.

Did the engine crank or were there any clicking or chattering sounds

from the solenoid? Go to Diagnostic

Table – Slow

Cranking, Solenoid Clicks or Chatters Go to Step 4

4 Inspect fusible link SBF9, refer to 8A Electrical Body and Chassis.

Is fusible link SBF9 blown? Replace the faulty

fusible link (refer to

Note 3).

If the fusible link

blows again, repair

or replace the circuit from SBF9 to the

starter relay X – 13 pin 1 or ignition

switch B – 62 pin 2 (refer to Note 2) Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3662 of 6020

Powertrain Interface Module – V6 Page 6E1–1

6E1

Powertrain Interface Module – V6

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to 1.2 Warning

Caution and Notes for correct workshop practices with regard to safety and / or property damage.

1 General Information ............................................................................................................ ...................6

1.1 General Description ............................................................................................................ ................................... 6

Serial Data Communication .................................................................................................................................. 6

Serial Data Layout.................................................................................................................................................. 8

1.2 Warning Caution and Notes .................................................................................................................................. 8

Definition of WARNING, CAUTION and NOTE Statements ............................................................................. .... 8

2 Component Location............................................................................................................................10

2.1 Engine Compartment............................................................................................................. .............................. 10

2.2 Interior................................................................................................................................................................... 11

3 Component Description and Operation ............................................................................................ .12

3.1 Powertrain Interface Module ............................................................................................................................... 12

3.2 Powertrain Interface Module Gateway Components ................................................................................. ....... 13

Engine Control Module........................................................................................................................................ 13

Immobiliser Control Unit ..................................................................................................................................... 13

Automatic Transmission Control Module .......................................................................................... ................ 13

3.3 Powertrain Interface Module Direct Input Switches.............................................................................. ............ 14

Cruise Control Switch.......................................................................................................................................... 14

Power Mode Switch – Automatic Transmission..................................................................................... ........... 14

3rd Start Switch – Automatic Transmission ....................................................................................................... 14

4 Diagnostics ...........................................................................................................................................15

4.1 Diagnostic General Descriptions................................................................................................ ........................ 15

Diagnostic Trouble Code (DTC) Tables........................................................................................... ................... 15

Diagnostic Trouble Codes (DTCs) ...................................................................................................................... 15

Tech 2 PIM Diagnostic Tests............................................................................................................................... 16

5 GM LAN Serial Communication Circuit ............................................................................................ ..17

6 Wiring Diagram and Connector Chart ................................................................................................18

6.1 Wiring Diagrams .................................................................................................................................................. 18

6.2 Connector Chart................................................................................................................................................... 20

6.3 Connector Information .......................................................................................................... .............................. 21

PIM Connector Pin Specifications ............................................................................................... ....................... 21

7 Diagnostics Starting Point ..................................................................................................................24

7.1 Diagnostic Requirements, Precautions and Preliminary Checks .................................................................... 24

Basic Knowledge Required ................................................................................................................................. 24

Basic Diagnostic Tools Required ................................................................................................ ....................... 24

Diagnostic Precautions ....................................................................................................................................... 24

Preliminary Checks.............................................................................................................................................. 25

7.2 Diagnostic System Check ........................................................................................................ ........................... 25

7.3 Powertrain Interface Module – Module Communication Check Failure Diagnostic Table............................. 27

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007