fuses ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3652 of 6020

Battery Page 6D1-3–12

9 Lock the doors and activate the theft deterrent system to arm the vehicle.

10 If the multimeter contains fuses, check they are serviceable.

Test Procedure

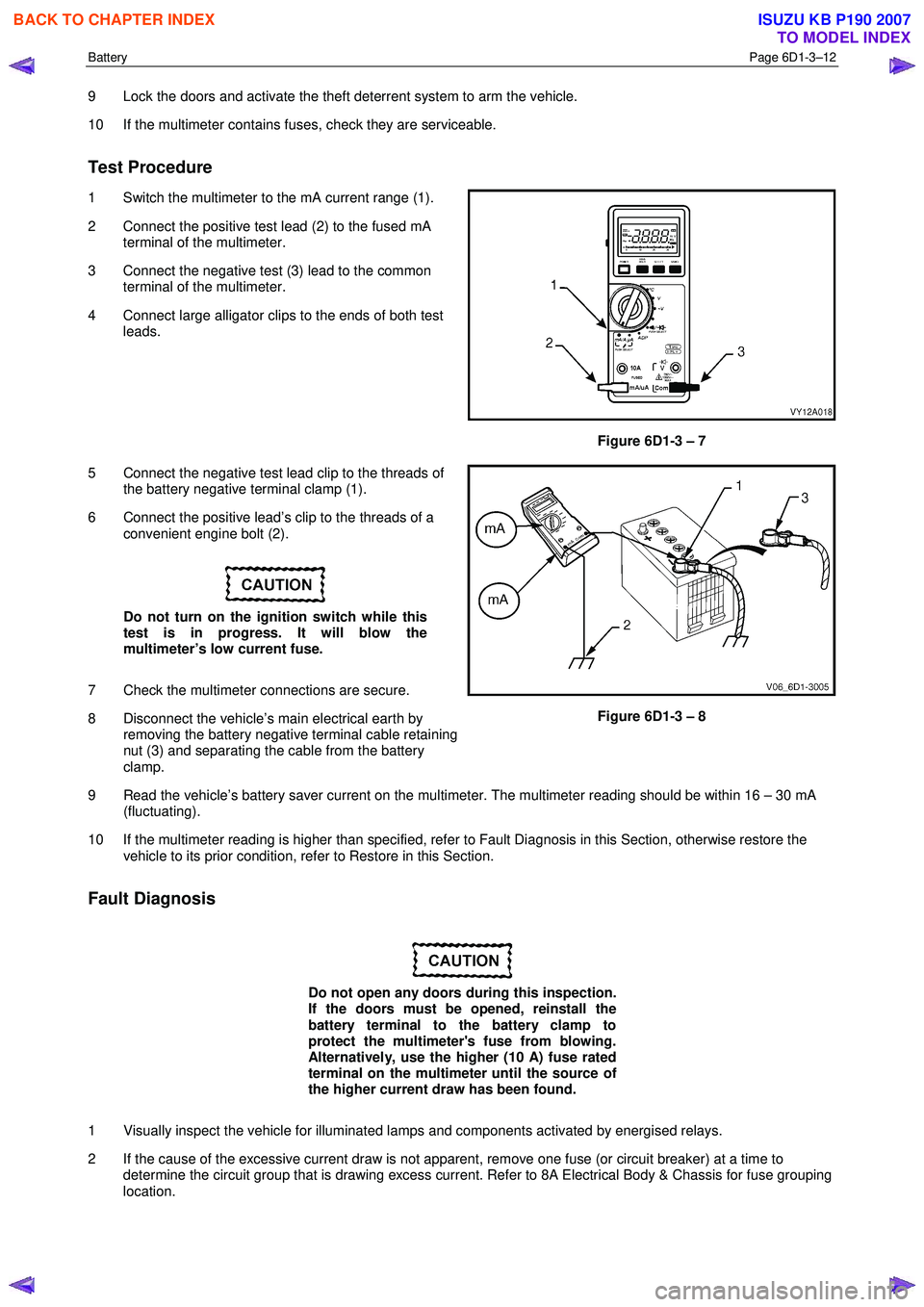

1 Switch the multimeter to the mA current range (1).

2 Connect the positive test lead (2) to the fused mA terminal of the multimeter.

3 Connect the negative test (3) lead to the common terminal of the multimeter.

4 Connect large alligator clips to the ends of both test leads.

Figure 6D1-3 – 7

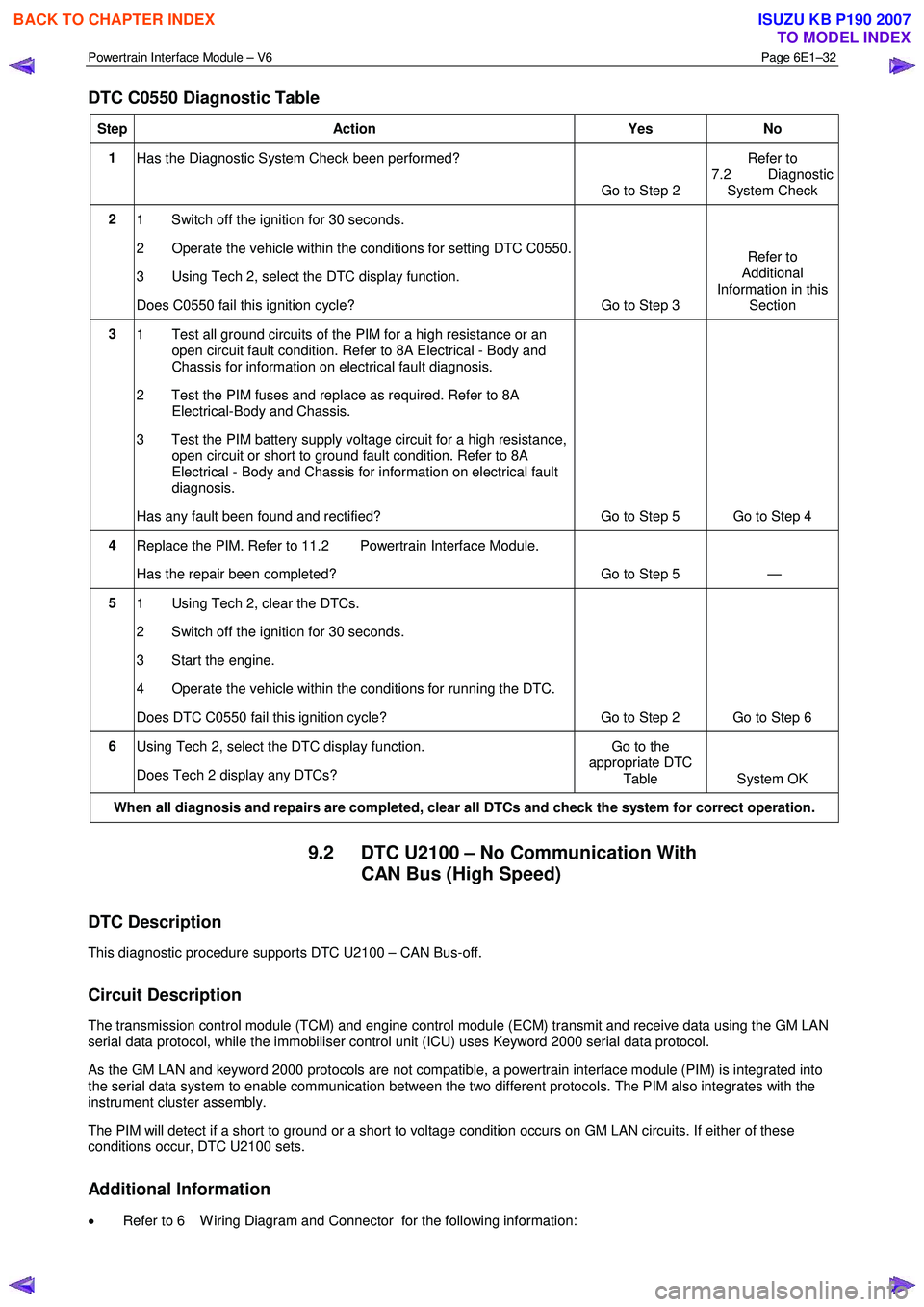

5 Connect the negative test lead clip to the threads of the battery negative terminal clamp (1).

6 Connect the positive lead’s clip to the threads of a convenient engine bolt (2).

Do not turn on the ignition switch while this

test is in progress. It will blow the

multimeter’s low current fuse.

7 Check the multimeter connections are secure.

8 Disconnect the vehicle’s main electrical earth by removing the battery negative terminal cable retaining

nut (3) and separating the cable from the battery

clamp.

Figure 6D1-3 – 8

9 Read the vehicle’s battery saver current on the multimeter. The multimeter reading should be within 16 – 30 mA (fluctuating).

10 If the multimeter reading is higher than specified, refer to Fault Diagnosis in this Section, otherwise restore the vehicle to its prior condition, refer to Restore in this Section.

Fault Diagnosis

Do not open any doors during this inspection.

If the doors must be opened, reinstall the

battery terminal to the battery clamp to

protect the multimeter's fuse from blowing.

Alternatively, use the higher (10 A) fuse rated

terminal on the multimeter until the source of

the higher current draw has been found.

1 Visually inspect the vehicle for illuminated lamps and components activated by energised relays.

2 If the cause of the excessive current draw is not apparent, remove one fuse (or circuit breaker) at a time to determine the circuit group that is drawing excess current. Refer to 8A Electrical Body & Chassis for fuse grouping

location.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3653 of 6020

Battery Page 6D1-3–13

3 W hen the circuit group is determined, install the fuse / circuit breaker and identify the specific circuit within this

group that is drawing the excess current. Disconnect the wiring harness connectors in this circuit group one at a

time. Refer to 8A Electrical Body & Chassis.

4 W hen the cause is disconnected, the multimeter reading should drop to the correct reading as outlined in Step 9 of the Test Procedure in this Section.

5 If required, remove the components in this circuit one at a time to determine the cause of the excessive standing current. Refer to 8A Electrical Body & Chassis.

6 Repair the fault, refer to 8A Electrical Body & Chassis.

7 Ensure any fuses, circuit breakers and connectors that have been removed are secure.

Restore

1 Reconnect the electrical earth cable to the battery terminal and tighten the nut to the correct torque specification.

Battery terminal nut

torque specification .....................................2.0 – 5.0 Nm

2 Disconnect the multimeter connections.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3693 of 6020

Powertrain Interface Module – V6 Page 6E1–32

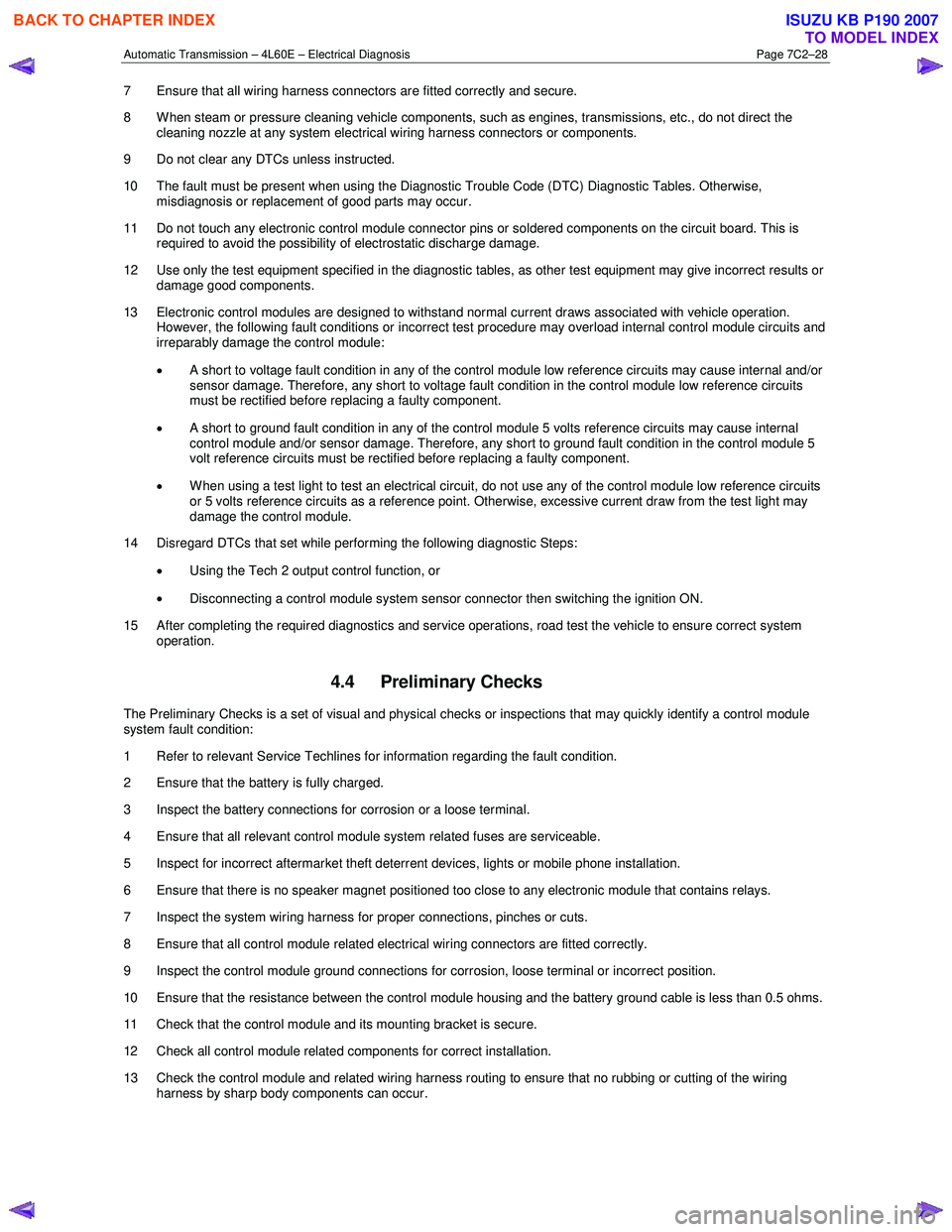

DTC C0550 Diagnostic Table

Step Action Yes No

1

Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

7.2 Diagnostic System Check

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for setting DTC C0550.

3 Using Tech 2, select the DTC display function.

Does C0550 fail this ignition cycle? Go to Step 3 Refer to

Additional

Information in this Section

3 1 Test all ground circuits of the PIM for a high resistance or an

open circuit fault condition. Refer to 8A Electrical - Body and

Chassis for information on electrical fault diagnosis.

2 Test the PIM fuses and replace as required. Refer to 8A Electrical-Body and Chassis.

3 Test the PIM battery supply voltage circuit for a high resistance, open circuit or short to ground fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

Has any fault been found and rectified? Go to Step 5 Go to Step 4

4 Replace the PIM. Refer to 11.2 Powertrain Interface Module.

Has the repair been completed? Go to Step 5 —

5 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does DTC C0550 fail this ignition cycle? Go to Step 2 Go to Step 6

6 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table System OK

When all diagnosis and repairs are completed, clear all DTCs and check the system for correct operation.

9.2 DTC U2100 – No Communication With CAN Bus (High Speed)

DTC Description

This diagnostic procedure supports DTC U2100 – CAN Bus-off.

Circuit Description

The transmission control module (TCM) and engine control module (ECM) transmit and receive data using the GM LAN

serial data protocol, while the immobiliser control unit (ICU) uses Keyword 2000 serial data protocol.

As the GM LAN and keyword 2000 protocols are not compatible, a powertrain interface module (PIM) is integrated into

the serial data system to enable communication between the two different protocols. The PIM also integrates with the

instrument cluster assembly.

The PIM will detect if a short to ground or a short to voltage condition occurs on GM LAN circuits. If either of these

conditions occur, DTC U2100 sets.

Additional Information

• Refer to 6 W iring Diagram and Connector for the following information:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3814 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–28

7 Ensure that all wiring harness connectors are fitted correctly and secure.

8 W hen steam or pressure cleaning vehicle components, such as engines, transmissions, etc., do not direct the cleaning nozzle at any system electrical wiring harness connectors or components.

9 Do not clear any DTCs unless instructed.

10 The fault must be present when using the Diagnostic Trouble Code (DTC) Diagnostic Tables. Otherwise, misdiagnosis or replacement of good parts may occur.

11 Do not touch any electronic control module connector pins or soldered components on the circuit board. This is required to avoid the possibility of electrostatic discharge damage.

12 Use only the test equipment specified in the diagnostic tables, as other test equipment may give incorrect results or damage good components.

13 Electronic control modules are designed to withstand normal current draws associated with vehicle operation. However, the following fault conditions or incorrect test procedure may overload internal control module circuits and

irreparably damage the control module:

• A short to voltage fault condition in any of the control module low reference circuits may cause internal and/or

sensor damage. Therefore, any short to voltage fault condition in the control module low reference circuits

must be rectified before replacing a faulty component.

• A short to ground fault condition in any of the control module 5 volts reference circuits may cause internal

control module and/or sensor damage. Therefore, any short to ground fault condition in the control module 5

volt reference circuits must be rectified before replacing a faulty component.

• W hen using a test light to test an electrical circuit, do not use any of the control module low reference circuits

or 5 volts reference circuits as a reference point. Otherwise, excessive current draw from the test light may

damage the control module.

14 Disregard DTCs that set while performing the following diagnostic Steps:

• Using the Tech 2 output control function, or

• Disconnecting a control module system sensor connector then switching the ignition ON.

15 After completing the required diagnostics and service operations, road test the vehicle to ensure correct system operation.

4.4 Preliminary Checks

The Preliminary Checks is a set of visual and physical checks or inspections that may quickly identify a control module

system fault condition:

1 Refer to relevant Service Techlines for information regarding the fault condition.

2 Ensure that the battery is fully charged.

3 Inspect the battery connections for corrosion or a loose terminal.

4 Ensure that all relevant control module system related fuses are serviceable.

5 Inspect for incorrect aftermarket theft deterrent devices, lights or mobile phone installation.

6 Ensure that there is no speaker magnet positioned too close to any electronic module that contains relays.

7 Inspect the system wiring harness for proper connections, pinches or cuts.

8 Ensure that all control module related electrical wiring connectors are fitted correctly.

9 Inspect the control module ground connections for corrosion, loose terminal or incorrect position.

10 Ensure that the resistance between the control module housing and the battery ground cable is less than 0.5 ohms.

11 Check that the control module and its mounting bracket is secure.

12 Check all control module related components for correct installation.

13 Check the control module and related wiring harness routing to ensure that no rubbing or cutting of the wiring harness by sharp body components can occur.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3823 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–37

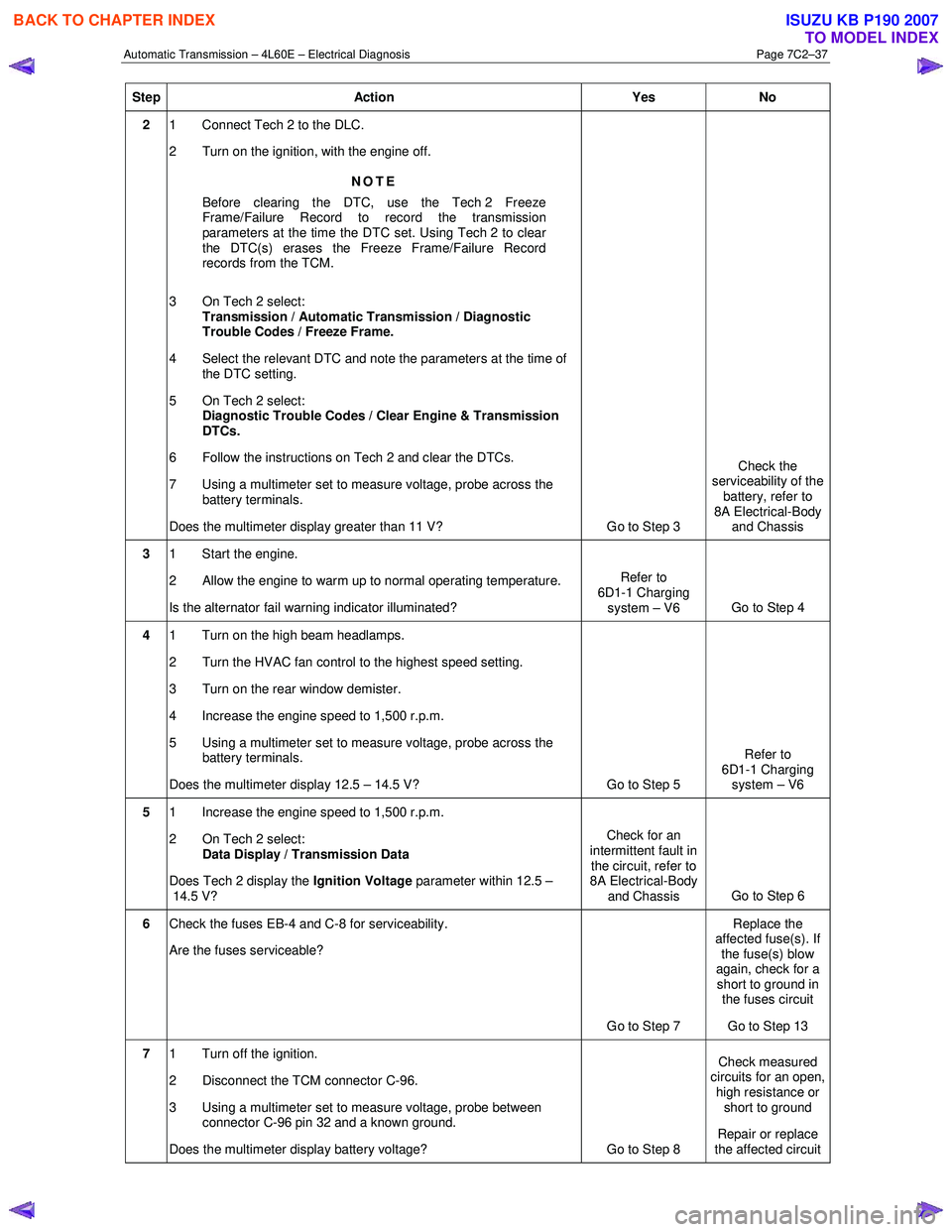

Step Action Yes No

2 1 Connect Tech 2 to the DLC.

2 Turn on the ignition, with the engine off.

NOTE

Before clearing the DTC, use the Tech 2 Freeze

Frame/Failure Record to record the transmission

parameters at the time the DTC set. Using Tech 2 to clear

the DTC(s) erases the Freeze Frame/Failure Record

records from the TCM.

3 On Tech 2 select: Transmission / Automatic Transmission / Diagnostic

Trouble Codes / Freeze Frame.

4 Select the relevant DTC and note the parameters at the time of the DTC setting.

5 On Tech 2 select:

Diagnostic Trouble Codes / Clear Engine & Transmission

DTCs.

6 Follow the instructions on Tech 2 and clear the DTCs.

7 Using a multimeter set to measure voltage, probe across the battery terminals.

Does the multimeter display greater than 11 V? Go to Step 3 Check the

serviceability of the battery, refer to

8A Electrical-Body and Chassis

3 1 Start the engine.

2 Allow the engine to warm up to normal operating temperature.

Is the alternator fail warning indicator illuminated? Refer to

6D1-1 Charging system – V6 Go to Step 4

4 1 Turn on the high beam headlamps.

2 Turn the HVAC fan control to the highest speed setting.

3 Turn on the rear window demister.

4 Increase the engine speed to 1,500 r.p.m.

5 Using a multimeter set to measure voltage, probe across the battery terminals.

Does the multimeter display 12.5 – 14.5 V? Go to Step 5 Refer to

6D1-1 Charging system – V6

5 1 Increase the engine speed to 1,500 r.p.m.

2 On Tech 2 select: Data Display / Transmission Data

Does Tech 2 display the Ignition Voltage parameter within 12.5 –

14.5 V? Check for an

intermittent fault in the circuit, refer to

8A Electrical-Body

and Chassis Go to Step 6

6

Check the fuses EB-4 and C-8 for serviceability.

Are the fuses serviceable?

Go to Step 7 Replace the

affected fuse(s). If the fuse(s) blow

again, check for a short to ground in the fuses circuit

Go to Step 13

7 1 Turn off the ignition.

2 Disconnect the TCM connector C-96.

3 Using a multimeter set to measure voltage, probe between connector C-96 pin 32 and a known ground.

Does the multimeter display battery voltage? Go to Step 8 Check measured

circuits for an open,

high resistance or short to ground

Repair or replace

the affected circuit

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3832 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–46

Step Action Yes No

3 Inspect the transmission and related components for the following:

• transmission fluid level,

• transmission fluid cooling system restrictions / blockages,

• debris in the transmission fluid,

• incorrect line pressure,

• torque converter stator operation, and

• transmission overload.

W as a fault found and rectified? Go to Step 10 Check for an

intermittent fault in

the circuit, refer to

8A Electrical-Body and Chassis

4 1 Switch off the ignition.

2 Disconnect connector E-95 from the transmission.

3 Using a multimeter set to measure voltage, probe between harness connector E-95 pin 16 and a known ground.

Does the multimeter display 4.8 – 5.2 V? Go to Step 6 Go to Step 5

5 Test the TFT sensor signal circuit (between connectors E-95 pin 16

and C-96 pin 35) for a high resistance, open circuit, short to ground or

short to voltage fault condition.

Did you find and correct the condition? Go to Step 10 Go to Step 9

6 1 Switch off the ignition.

2 Remove the TCM fuses C-8 and EB-4, refer to 8A Electrical- Body and Chassis.

3 Using a multimeter set to measure resistance, probe between connector E95 pin 15 and a known ground.

Does the multimeter display less than 5 Ω? Go to Step 8 Go to Step 7

7 Using a multimeter, test between E-95 pin 15 and C-96 pin 30 for high

resistance, open circuit, short to ground or short to voltage fault

condition.

W as any fault found and rectified? Go to Step 10 —

8 Replace the TFT sensor, refer to 7C4 Automatic Transmission –

4L60E – On-vehicle Servicing.

NOTE

Check for damaged wiring (short to ground, short to

voltage, high resistance or open circuit) or poor

connections inside the transmission assembly before

replacing the TFT sensor.

Was the repair complete? Go to Step 10 —

9 Replace the TCM, refer to 7C4 Automatic Transmission – 4L60E –

On-vehicle Servicing

Was the repair completed? Go to Step 10

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3957 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–44

b Starter motor, refer to 6D1-2 Starting System.

b Rear propeller shaft and for 4WD front propeller shaft, refer to 4A Propeller Shaft.

6 On 4WD vehicle, disconnect the harness two clips from the upper side of the transfer case.

7 From within the starter motor access hole, remove the three bolts (2) attaching the torque converter to the flexplate and discard, refer to Figure 7C4 – 62.

8 Remove the transmission support, refer to 3.7 Transmission Support and Mount.

9 Disconnect the fuel and EVAP pipes three brackets and clips, refer to 6C Fuel System – V6.

Before lowering the transmission take care of

the following:

• Do not strain the harness and connector

as the connector pins could be

permanently damaged.

• Ensure the inlet manifold does not hit the

firewall.

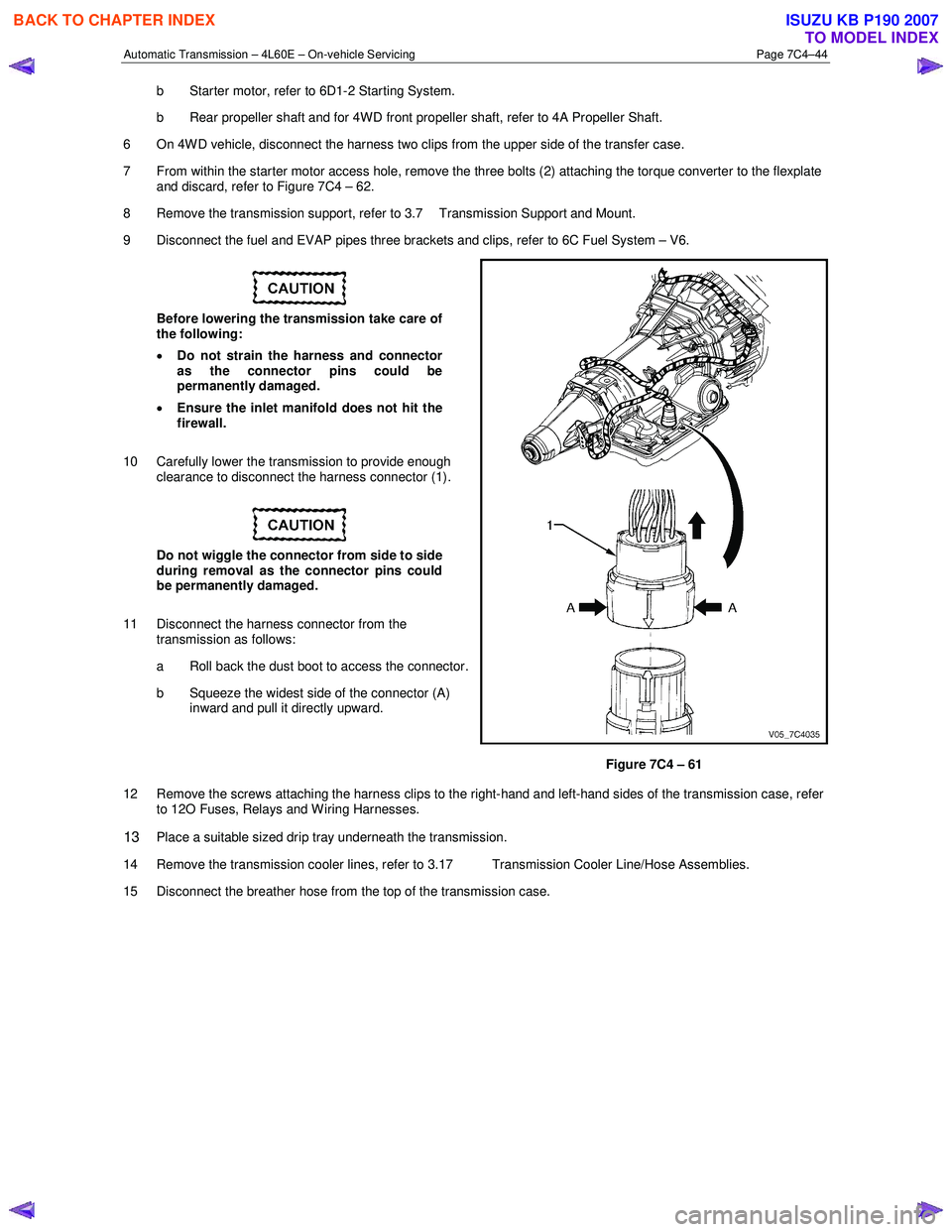

10 Carefully lower the transmission to provide enough clearance to disconnect the harness connector (1).

Do not wiggle the connector from side to side

during removal as the connector pins could

be permanently damaged.

11 Disconnect the harness connector from the transmission as follows:

a Roll back the dust boot to access the connector.

b Squeeze the widest side of the connector (A) inward and pull it directly upward.

Figure 7C4 – 61

12 Remove the screws attaching the harness clips to the right-hand and left-hand sides of the transmission case, refer to 12O Fuses, Relays and W iring Harnesses.

13 Place a suitable sized drip tray underneath the transmission.

14 Remove the transmission cooler lines, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

15 Disconnect the breather hose from the top of the transmission case.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3959 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–46

Reinstall

1 If required on 4W D vehicle, reinstall the transfer case, refer to 7D Transfer Case and Adaptor Housing.

2 Ensure the transmission and the engine mating surfaces are clean and free of burrs.

3 Lubricate the torque converter spigot (7) with a small amount of high temperature wheel bearing grease, refer to Figure 7C4 – 62.

4 Install a new filler tube seal into the transmission case.

Support the transmission while installing the

attaching bolts to avoid damage to the torque

converter and flexplate. Do not have the

transmission hanging.

5 Bring the transmission up to the engine, inserting the filler tube and ensuring the locating dowels completely enter the torque converter housing.

6 Reconnect the breather hose to the top of the transmission case.

NOTE

The bolts attaching the torque converter housing

are facing forward except for the bolt in position ℑ

which is facing rearward.

7 With the transmission supported, install the bolt (1), nine places, attaching the torque converter housing to the engine and tighten to the correct torque specification following the sequence shown in

within Figure 7C4 – 62.

Torque converter housing attaching

bolt torque specification .......................... 52.0 – 66.0 Nm

8 Remove the access hole cover plate from the lower surface of the housing and push the torque converter forward to meet the flexplate, then hand start three new bolts (2) before tightening to the correct torque specification.

Reinstall the access hole cover plate.

Torque converter to flexplate attaching

bolt torque specification .......................... 60.0 – 70.0 Nm

9 Reinstall the bolt (3) and torque converter cover (4) on the transmission right-hand side and the bolt (5) and torque converter cover (6) on the transmission left-hand side, tighten the bolts to the correct torque specification.

Torque converter cover attaching

bolt torque specification .......................... 12.0 – 16.0 Nm

10 Reinstall the transmission fluid lines, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

Prior to connecting the harness connector to

the transmission, check that all pins and

seals are in sound condition and the dust

boot is not torn or damaged.

11 Reconnect the transmission harness connector to the transmission as follows: a Push straight down on the connector body until a click is heard.

b Reinstall the dust boot ensuring it is correctly located.

12 Attach the harness clips to the right-hand and left-hand sides of the transmission case, refer to 12O Fuses, Relays and Wiring Harnesses.

13 On 4WD vehicle, connect the harness two clips from the upper side of the transfer case.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4377 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-93

Intermittent Conditions

ChecksAction

Definition:

The problem is not currently present but is indicated in DTC History.

OR

There is a customer complaint, but the symptom cannot currently be duplicated, if the problem is not DTC related.

Preliminary Checks • Refer to Symptoms - Transmission Controls before starting.

Harness/ Connector Many intermittent open or shorted circuits are affected by harness/ connector

movement that is caused by vibration, engine torque, bumps/ rough pavement, etc.

Test for this type of condition by performing the applicable procedure from the

following list:

• Move related connectors and wiring while monitoring the appropriate scan tool data.

• Move related connectors and wiring with the component commanded ON, and OFF, with the scan tool. Observe the component operation.

• With the engine running, move related connectors and wiring while monitoring engine operation.

If harness or connector movement affects the data displayed, component/ system

operation, or engine operation, inspect and repair the harness/ connections as

necessary.

Electrical Connections or Wiring Poor electrical connections, terminal tension or wiring problems cause most intermittent. To perform the following inspections:

• Poor mating of the connector halves, or terminals improperly seated in the connector body.

• Improperly formed or damaged terminals. Test for poor terminal tension.

• Poor terminal to wire connections including terminals crimped over insulation. This requires removing the terminal from the connector body.

• Corrosion/ water intrusion. Pierced or damaged insulation can allow moisture to enter the wiring. The conductor can corrode inside the insulation, with little

visible evidence. Look for swollen and stiff sections of wire in the suspect

circuits.

• Wires that are broken inside the insulation.

• Harness for pinched, cut or rubbed through wiring.

• Ensure that the wiring does not come in contact with hot exhaust components.

Control Module Power and Grounds

Component Power and Grounds Poor power or ground connections can cause widely varying symptoms.

• Test all control module power supply circuits. Many vehicles have multiple circuits supplying power to the control module. Other components in the system

may have separate power supply circuits that may also need to be tested.

Inspect connections at the module/ component connectors, fuses, and any

intermediate connections between the power source and the module/

component. A test lamp or a DMM may indicate that voltage is present, but

neither tests the ability of the circuit to carry sufficient current. Ensure that the

circuit can carry the current necessary to operate the component.

• Test all control module ground and system ground circuits. The control module may have multiple ground circuits. Other components in the system may have

separate grounds that may also need to be tested. Inspect grounds for clean

and tight connections at the grounding point. Inspect the connections at the

component and in splice packs, where applicable. Ensure that the circuit can

carry the current necessary to operate the component.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4942 of 6020

8A-4 ELECTRICAL-BODY AND CHASSIS

GENERAL INFORMATION

The body and chassis electrical system operates on a twelve volt power supply with negative ground polarity.

The main harness consists of the engine harness, the instrument harness, the body harness, and the chassis

harness.

The harnesses use a split corrugated tube to protect the wires from the elements.

W ire size is determined by current flow, circuit length, and voltage drop.

All wires have color-coded insulation.

W ire color-codes are shown in the circuit diagrams.

This makes it easier to trace circuits and to make the proper connections.

Each circuit consists of the following:

5. Power source – The battery and the alternator

5. W ires – To carry electrical current through the circuit

5. Fuses – To protect the circuit against current overload

5. Relays – To protect voltage drop between the battery and the circuit parts and to protect the switch points against burning

5. Switches – To open and close the circuit

5. Load – Any device, such as a light or motor, which converts the electrical current into useful work

5. Ground – To allow the current to flow back to the power source

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007