oil dipstick ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2013 of 6020

ENGINE DIAGNOSIS (C24SE) 6-13

Fuel Consumption Excessive

Condition Possible cause Correction

Trouble in fuel system Mixture too rich or too lean due to

trouble in fuel injection system Refer to "Abnormal Combustion"

Fuel cut function does not act Refer to "Abnormal Combustion"

Trouble in ignition system Misfiring or abnormal combustion

due to trouble in ignition system Refer to Hard Start or Abnormal

Combustion Troubleshooting

Guide

Others Engine idle speed too high Reset Idle Air Control Valve

Returning of accelerator control

sluggish Correct

Fuel system leakage Correct or replace

Clutch slipping Correct

Brake drag Correct

Selection of transmission gear

incorrect Caution operator of incorrect gear

selection

Oil Problems

Condition Possible cause Correction

Oil pressure too low Wrong oil in use Replace with correct engine oil

Relief valve sticking Replace

Oil pump not operating properly Correct or replace

Oil pump strainer clogged Clean or replace strainer

Oil pump worn Replace

Oil pressure gauge defective Correct or replace

Crankshaft bearing or connecting

rod bearing worn Replace

Oil contamination

Wrong oil in use Replace with new engine oil

Oil filter clogged Replace oil filter

Cylinder head gasket damage Replace gasket

Burned gases leaking Replace piston and piston rings or

rebore cylinders

Oil not reaching valve system Oil passage in cylinder head or cylinder body clogged Clean or correct

Engine Oil Pressure Check

1. Check for dirt, gasoline or water in the engine

oil.

a. Check the viscosity of the oil.

b. Change the oil if the viscosity is outside the specified standard.

c. Refer to the "Maintenance and Lubrication" section of this manual.

2. Check the engine oil level. The level should fall somewhere between the

"ADD" and the "FULL" marks on the oil level

dipstick.

If the oil level does not reach the "ADD" mark on

the oil level dipstick, engine oil must be added.

3. Remove the oil pressure unit.

4. Install an oil pressure gauge.

5. Start the engine and allow the engine to reach normal operating temperature (About 80 °C).

6. Measure the oil pressure.

Oil pressure should be:

150 kPa(21.8 psi) at idle speed.

7. Stop the engine.

8. Remove the oil pressure gauge

9. Install the oil pressure unit.

10. Start the engine and check for leaks.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2091 of 6020

ENGINE MECHANICAL (C24SE) 6A-77

TECHNICAL DATA

SOHC Gasoline Engine C24SE

Engine Oil Viscosity

The following engine oils can be used:

A = single-grade oils

B = multigrade oils

C = easy run oils

depending on the outside temperature.

Engine Oil Quality

It is important that the following API and CCMC classes are

used:

Engines Single and multigrade oils Easy run oils

Petrol API-SF/CC, SF/CD, SG/CC,

SG/CD, CCMC/G4 API-SF/CC, SF/CD, SG/CD

CCMC-G5/PD2

Important!

CD engine oils designed by manufacturers specially for diesel

engines are not suitable for petrol engines, unless a sufficient

performance class for petrol engines (e.g. API-SF/CCMC-G4)

is also indicated.

Disposal.

Observe the relevant national regulations when disposing of

used oil.

Engine Oil Filling Quantities

Engine Model Initial filling

(litres) Filling quantity

with filter change* (litres) MIN to MAX

(litres)

2.4L 4.80 4.25 1.00

*Up to mark "MAX" on oil dipstick

Oil Pump

Backlash 0.1 to 0.2mm

Gaps in gears opposite housing 0.03 to 0.1mm

Oil pressure at idle speed Engine at operating temperature (>70°C oil and

approx. 80 °C coolant)

450 - 500 kpa

Oil drain plug M14 × 1.5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3168 of 6020

Engine Cooling – V6 Engine Page 6B1–33

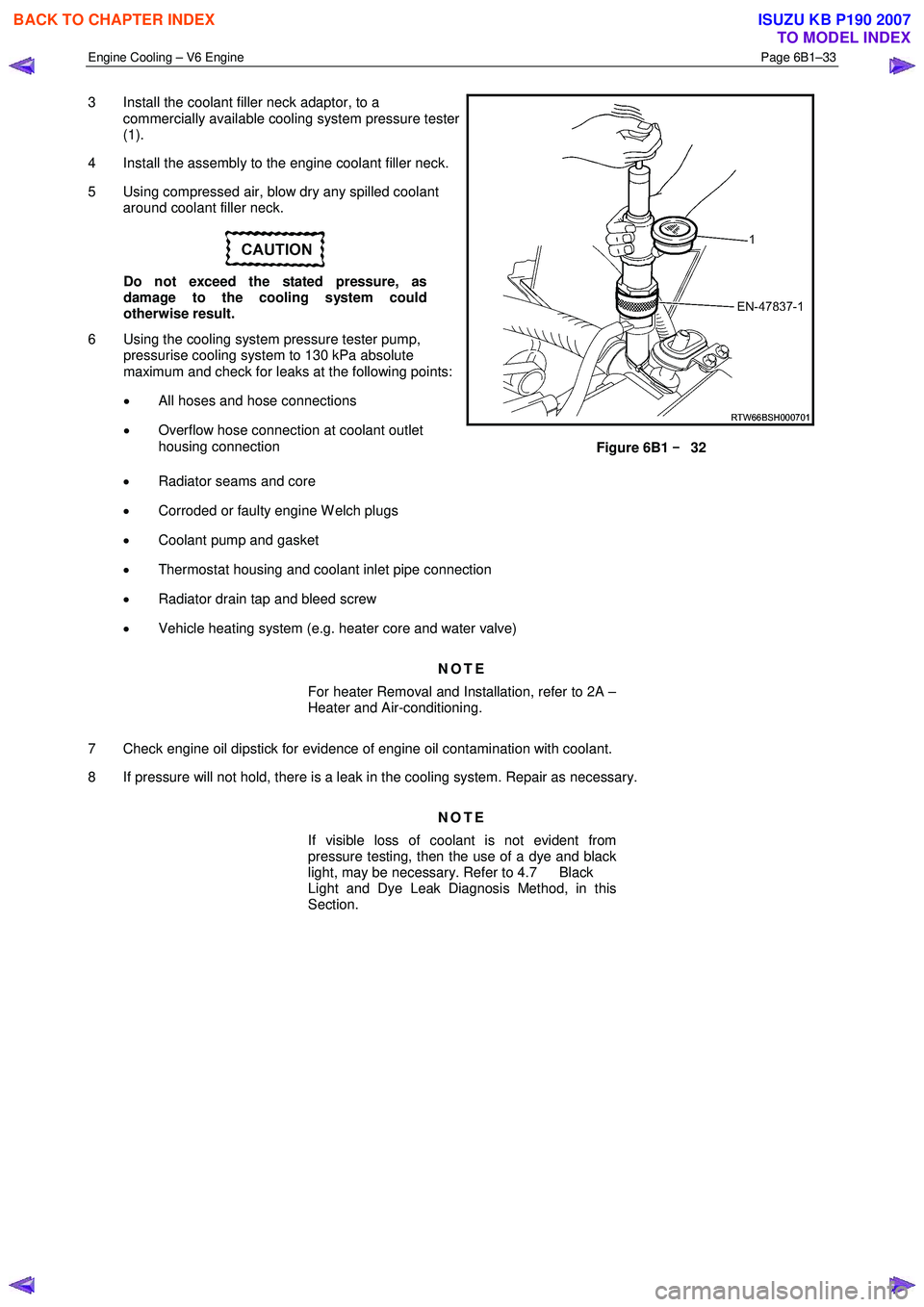

3 Install the coolant filler neck adaptor, to a

commercially available cooling system pressure tester

(1).

4 Install the assembly to the engine coolant filler neck.

5 Using compressed air, blow dry any spilled coolant around coolant filler neck.

Do not exceed the stated pressure, as

damage to the cooling system could

otherwise result.

6 Using the cooling system pressure tester pump, pressurise cooling system to 130 kPa absolute

maximum and check for leaks at the following points:

• All hoses and hose connections

• Overflow hose connection at coolant outlet

housing connection

Figure 6B1 –

––

–

32

• Radiator seams and core

• Corroded or faulty engine W elch plugs

• Coolant pump and gasket

• Thermostat housing and coolant inlet pipe connection

• Radiator drain tap and bleed screw

• Vehicle heating system (e.g. heater core and water valve)

NOTE

For heater Removal and Installation, refer to 2A –

Heater and Air-conditioning.

7 Check engine oil dipstick for evidence of engine oil contamination with coolant.

8 If pressure will not hold, there is a leak in the cooling system. Repair as necessary.

NOTE

If visible loss of coolant is not evident from

pressure testing, then the use of a dye and black

light, may be necessary. Refer to 4.7 Black

Light and Dye Leak Diagnosis Method, in this

Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3349 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–71

Step Action Yes No

3 Inspect for the following fault conditions:

• engine vacuum leak,

• air leak in the intake air duct between the MAF sensor and the

throttle body,

• plugged or collapsed intake air duct,

• objects that block the MAF sensor inlet screen,

• restricted air filter element,

• restricted throttle plate or carbon build-up around the throttle

plate,

• unseated engine oil dipstick,

• loose or missing engine oil cap, and

• over filled crankcase.

W as any fault found and rectified? Go to Step 14 Go to Step 4

4 1 Disconnect the MAF sensor wiring connector.

2 Connect a test lamp between the MAF sensor ignition voltage circuit and the ECM housing.

3 Switch on the ignition with the engine not running.

Does the test lamp illuminate? Go to Step 5 Go to Step 11

5 1 Switch on the ignition with the engine not running.

2 Using a digital multimeter, measure the voltage between the MAF sensor 5 V reference circuit and the ECM housing.

Does the multimeter display 4.8 – 5.2 V? Go to Step 6 Go to Step 8

6 1 Switch off the ignition.

2 Connect a 3 A fused jumper wire between the MAF sensor 5 V reference circuit and signal circuit.

3 Switch on the ignition with the engine not running.

4 Using Tech 2, observe the MAF sensor voltage parameter.

Does Tech 2 display 4.8 – 5.2 V? Go to Step 7 Go to Step 9

7 1 Switch off the ignition.

2 Remove ECM Fuse 29 from the engine compartment fuse and relay panel assembly.

3 Using a digital multimeter, measure the resistance between the MAF sensor low reference circuit and the ECM housing.

NOTE

Install ECM Fuse 29 to the engine compartment fuse and

relay panel assembly after completing the test.

Does the multimeter display 5 Ω? Go to Step 12 Go to Step 10

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4104 of 6020

ON-VEHICLE SERVICE (AW30–40LE) 7A3-19

ATF Replacement

Inspection

NOTE: Do not overfill.

1. Remove the drain plug from oil pan and drain the

fluid.

RUW 17ASH013401

2. Reinstall the drain plug securely.

Torque: 19 N ⋅

⋅⋅

⋅

m (1.9 kgf ⋅

⋅⋅

⋅

m/14 Ib ⋅

⋅⋅

⋅

ft)

3. W ith the engine OFF, add new fluid through the fille

r

tube.

Drain and refill 5.2 liter

Dry fill 8.7 liter

Fluid Exxon Mobil ATF-3309

4. Start the engine and shift the selector into all

position from “P" through “L", and then shift into “P".

5. W ith the engine idling, check the fluid level. Add fluid up to the “COLD" level on the dipstick.

6. The ATF level must be checked again for correct level with the “HOT" level.

NOTE: To prevent fluid leaks, the drain plug gasket

must be replaced each time this plug is removed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4457 of 6020

ON-VEHICLE SERVICE (JR405E) 7A3-3

Cold Level

The vehicle must not have been driven so that the

temperature reaches around 20 °C (68 °F) before the

cold level check is made.

1. Park the vehicle on a level surface.

2. Apply the parking brake firmly.

3. Start the engine and allow it to warm up.

The engine coolant temperature gauge needle should be midway between the “C” mark and “H”

mark.

4. Let the engine run at idle.

Move the select lever slowly through all the gea

r

ranges.

Stop in each range just long enough for the transmission to engage.

5. Return the select lever either “P” or “N”.

6. Remove the ATF level dipstick.

7. W ipe the dipstick clean with a paper towel.

8. Reinsert the dipstick and wait several seconds.

9. Remove the dipstick.

The ATF level should be inside the “C” range on the dipstick.

If the ATF level is below the “C” range, ATF must be added.

242R300002

ATF CHANGE

1. Park the vehicle on level ground and block the rear

wheels.

2. Start the engine and allow it to idle until the ATF reaches a temperature of 40-50 °C (104-122 °F).

3. Stop the engine.

4. Raise the front to the vehicle and support with suitable safety stands.

5. Remove the drain plug from the oil pan and drain the ATF (approximately 6 liters).

6. Remove the oil pan.

7. Inspect the oil pan (details written below).

8. Install the oil pan.

Note:

Use a new gasket. Clean the oil pan and magnet.

Oil pan bolt torque : 8 N ⋅m (0.8 kgf ⋅m/69 lb ⋅in)

9. Replace the gasket and install the drain plug.

Drain plug torque : 35 N ⋅m (3.6 kgf ⋅m/26 lb ⋅ft)

Note:

Do not reuse the old washer (gasket).

Clean the drain plug (especially the threaded section).

10.Remove the safety stands and wheel blocks.

11.Pour about 5 liters of new ATF.

12. Start the engine. W ith your foot on the brake, move the shift lever through each gear range, and shift to

“P” range.

13.Check the ATF level. Add more ATF carefully as necessary using the dipstick. Refer to “ATF LEVEL”

preciously in this section.

Note:

Keep the engine idle (do not stop it) during the ATF level

adjustment.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007