check engine ISUZU TF SERIES 2004 Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 1484 of 4264

6E–112 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

CHECK ENGINE LAMP (MIL) “ON” STEADY

Circuit description

The check engine lamp should always be illuminated

and steady for about five seconds with ignition “ON” and

the engine stopped. Ignition feed voltage is supplied

directly to the check engine lamp indicator. The Engine

Control Module (ECM) turns the check engine lamp

“ON” by grounding the check engine lamp driver circuit.

The check engine lamp should not remain “ON” with the

engine running and no DTC(s) set. A steady check

engine lamp with the engine running and no DTC(s)

suggests a short to ground in the check engine lamp

driver circuit.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed-through wire insulation, or a wire broken inside

the insulation. Check for the following items:

Poor connection or damaged harness – Inspect the

ECM harness and connectors for improper mating,

broken locks, improperly formed or damaged

terminals, poor terminal-to-wire connection, and

damaged harness.

Page 1485 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–11 3

Check Engine Lamp (MIL) On Steady

Step Action Value(s) Yes No

1 1. Ignition “Off”, engine “Off”.

2. Disconnect the ECM connector.

3. Ignition “On”.

Was the “CHECK ENGINE” lamp turned on?—Go to Step 2 Go to Step 4

2 Using the DVM and check the “CHECK ENGINE”

lamp circuit.

1. Ignition “Off”, engine “Off”.

2. Disconnect the meter connector and ECM

connector.

3. Check the circuit for short to ground circuit.

Was the problem found?

—Veri fy repai rGo to Step 3

3 Replace the meter assembly.

Is the action complete?—Veri fy repai r—

4 Is the ECM programmed with the latest software

release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved?—Veri fy repai rGo to Step 5

5 Replace the ECM.

Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobilizer system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobilizer System-ECM replacement” for

the ECM/Immobilizer linking procedure.—Veri fy repai r—

42

17

B-24 C-56

Page 1498 of 4264

6E–126 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

55 P1605 E ON EEPROM Defect EEPROM checksum does

not match with the read

check sum during

initialization of the ECM.EEPROM checksum match

with the read check sum

during initialization of the

ECM.ECM malfunction.

——

56 P1610 A - Security Key and Security

Code not ProgrammedImmobilizer functions are not

programmed in the ECM.1 . E n g i n e d o e s n o t s t a r t .

2. Check engine lamp flash. No recovery. ECM malfunction.

— B****

56 P1611 A - Wrong Security Code

EnteredReceived security code is not

correct.1 . E n g i n e d o e s n o t s t a r t .

2. Check engine lamp flash. N o r e c o v e r y . 1 . E C M m a l f u n c t i o n .

2. Immobilizer control unit

m a l f u n c t i o n .

3. Transponder key

malfunction.— B****

56 P1612 A - Immobilizer No or Wrong

SignalReceived challenge signal is

not correct or not received.1 . E n g i n e d o e s n o t s t a r t .

2. Check engine lamp flash. No recovery. 1. ECM and immobilizer

control unit

communication circuit

open circuit, short to

ground circuit or short to

voltage circuit.

2 . E C M m a l f u n c t i o n .

3. Immobilizer control unit

m a l f u n c t i o n .

4. Transponder key

malfunction.2 7 /

35B****

56 P1613 A - Immobilizer No or Wrong

SignalReceived response signal is

not correct or not received.1 . E n g i n e d o e s n o t s t a r t .

2. Check engine lamp flash. No recovery. 1. ECM and immobilizer

control unit

communication circuit

open circuit, short to

ground circuit or short to

voltage circuit.

2 . E C M m a l f u n c t i o n .

3. Immobilizer control unit

m a l f u n c t i o n .

4. Transponder key

malfunction.2 7 /

35B****

56 P1614 A - Wrong Transponder Key Received response signal is

not correct from the

transponder key.1 . E n g i n e d o e s n o t s t a r t .

2. Check engine lamp flash. N o r e c o v e r y . 1 . E C M m a l f u n c t i o n .

2. Immobilizer control unit

m a l f u n c t i o n .

3. Transponder key

malfunction.— B****

76 P1625 A OFF ECM Main Relay Switched

Off Too EarlyWhen ignition switch was

turned off, timing of the ECM

main relay turning off is too

early.No fail-safe function. No recovery. ECM malfunction.

3 /

58—

B OFF ECM Main Relay Switched

Off Too LateWhen ignition switch was

turned off, timing of the ECM

main relay turning off is too

late or does not off.No recovery. 1. ECM main relay

m a l f u n c t i o n .

2. ECM malfunction.3 /

58— Flash

CodeCodeSymptom

CodeMILDTC Name DTC Setting Condition Fail-Safe (Back Up) Recovery Condition Related Failure PartsRelated

ECM Pin

No.Related

Multiple

DTC4JA1-TC

(MT)4JH1-TC

(MT)4JH1-TC

(AT)

Page 1499 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–127

51 P1630 A ON Fuel Injection Quantity

Circuit MalfunctionThe PSG (pump control unit)

detects high pressure

solenoid valve control circuit

malfunction due to high

current.Fuel injection quantity is

reduced.The PSG (pump control unit)

detects correct high pressure

solenoid valve control circuit.PSG (pump control unit)

malfunction.

——

B ON Fuel Injection Quantity

Circuit MalfunctionThe PSG (pump control unit)

detects high pressure

solenoid valve control circuit

malfunction due to

continuous current.1. MAB (fuel cutoff solenoid

v a l v e ) i s o p e r a t e d .

2. Desired injection quantity

becomes 0mg/strk.No recovery. PSG (pump control unit)

malfunction.

——

44 P1650 A ON CAN Device Offline CAN controller detects Bus-

off or canceling.MAB (fuel cutoff solenoid

v a l v e ) i s o p e r a t e d . CAN controller detects

correct Bus signal.1. CAN high circuit open,

short to ground or short

t o v o l t a g e c i r c u i t .

2. CAN low circuit open,

short to ground or short

t o v o l t a g e c i r c u i t .

3. Poor connector

c o n n e c t i o n .

4. Electrical interference.

5. ECM malfunction.

6. PSG (pump control unit)

malfunction.9 9 /

100P1651(B)

B ON CAN Device Hang-up CAN controller does not

react under engine running.CAN controller reacts

correctly under engine

running.1 . E C M m a l f u n c t i o n .

2. PSG (pump control unit)

malfunction.——

45 P1651 A ON CAN Malfunction The PSG (pump control unit)

does not recognize CAN

signal from the CAN

controller.1. MAB (fuel cutoff solenoid

v a l v e ) i s o p e r a t e d .

2. Desired injection quantity

becomes 0mg/strk.The PSG (pump control unit)

recognizes CAN signal from

the CAN controller.1 . E C M m a l f u n c t i o n .

2. PSG (pump control unit)

malfunction.——

B ON CAN Malfunction The ECM does not read CAN

signal from the PSG (pump

control unit).The ECM reads CAN signal

from the PSG (pump control

unit).1. CAN high circuit open,

short to ground or short

to voltage circuit.

2. CAN low circuit open,

short to ground or short

to voltage circuit.

3. Poor connector

connection.

4. Electrical interference.

5. ECM malfunction.

6. PSG (pump control unit)

malfunction.9 9 /

100P1650(A)

77 P1690 4 OFF Check Engine Lamp (MIL)

Circuit Voltage LowCheck engine lamp circuit

open or short to ground

circuit.No fail-safe function. Check engine lamp circuit is

correct condition.1. Check engine lamp

circuit open or short to

g r o u n d c i r c u i t .

2. Check engine lamp

malfunction

3. ECM malfunction.42 B****

8 OFF Check Engine Lamp (MIL)

Circuit Voltage HighCheck engine lamp circuit

short to voltage circuit.ECM malfunction.

—— Flash

CodeCodeSymptom

CodeMILDTC Name DTC Setting Condition Fail-Safe (Back Up) Recovery Condition Related Failure PartsRelated

ECM Pin

No.Related

Multiple

DTC4JA1-TC

(MT)4JH1-TC

(MT)4JH1-TC

(AT)

Page 1501 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–129

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The mass air flow (MAF) sensor is part of the intake air

system. It is fitted between the air cleaner and

turbocharger and measure the mass air flowing into the

engine.

The mass air flow (MAF) sensor element measures the

partial air mass through a measurement duct on the

sensor housing.

The ECM monitors the MAF sensor supply voltage and

MAF sensor output voltage. The supply voltage is out of

range, DTC P0100 (Symptom Code 7) or P0100

(Symptom Code 9) will be stored. The output voltage

ex cessively high or low, DTC P0100 (Symptom Code B)

or P0100 (Symptom Code C) will be stored.

Diagnostic Aids

An intermittent may be caused by the following:

Poor connections.

Misrouted harness.

Rubbed through wire insulation.

Broken wire inside the insulation.

Check for the following conditions:

Poor connection at ECM-Inspect harness connectors

for backed out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal to wire connection.

Damaged harness-Inspect the wiring harness for

damage. If the harness appears to be OK, observe

the “Mass Air Flow” display on the Tech2 while

moving connectors and wiring harness related to the

sensor.

Diagnostic Trouble Code (DTC) P0100 (Symptom Code 7) (Flash Code 65)

Mass Air Flow (MAF) Sensor Voltage Supply Circuit High Input

Flash

CodeCodeSymptom

CodeMIL DTC Name DTC Setting Condition Fail-Safe (Back Up)

65 P0100 7 ON Ma ss Air Flo w (MAF) Senso r

Voltage Supply Circuit High

InputMAF sensor power supply

voltage is more than 5.2V.ECM uses ma ss a ir flo w

1600mg/strk & EGR 10% co n-

ditions as substitute.

9 ON Mass Air Flow (MAF) Sensor

Voltage Supply Circuit Low

InputMAF sensor power supply

voltage is below 4.6V.

B ON Mass Air Flow (MAF) Sensor

Output Circuit Low Input1. Engine speed is between

600rpm and 5000rpm.

2. MAF se nsor o utput is

below -33.7mg/strk.

C ON Mass Air Flow (MAF) Sensor

Output Circuit High Input1. Engine speed is between

600rpm and 5000rpm.

2. MAF sensor output is more

tha n 1378mg/strk (4JA1-TC)

o r 1784mg/strk (4JH1-TC).

Step Action Value(s) Yes No

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2Go to On Board

Diagnostic

(OBD) System

Check

2 1. Connect the Tech 2.

2. Review and record the failure information.

3. Select “F0: Read DTC Infor As Stored By ECU” in

“F0: Diagnostic Trouble Codes”.

Is the DTC P0100 (Symptom Code 7) stored as

“Present Failure”?—Go to Step 3Refer to

Diagnostic Aids

and Go to Step

3

Page 1502 of 4264

6E –130 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

3 1. Using the Tech 2, ignition “On ” and engine “Off ”.

2. Select “F1: Clear DTC Information ” in “F0:

Diagnostic Trouble Codes ” with the Tech 2 and

clear the DTC information.

3. Operate the vehicle and monitor the “F0: Read

DTC Infor As Stored By ECU ” in the “F0:

Diagnostic Trouble Codes ”.

Was the DTC P0100 (Symptom Code 7) stored in this

ignition cycle? —Go to Step 4 Refer to

Diagnostic Aids and Go to Step

4

4 Check for poor/faulty connection at the MAF sensor or ECM connector. If a poor/faulty connection is found,

repair as necessary.

Was the problem found?

— Verify repair Go to Step 5

5 Visually check the MAF sensor. Was the problem found? —Go to Step 11 Go to Step 6

6 Using the DVM and check the MAF sensor power supply circuit.

1. Ignition “On ”, engine “Off ”.

2. Disconnect the MAF & IAT sensor connector.

3. Check the circuit for short to battery voltage circuit.

Was the DVM indicated specified value?

Approx imately 5.0V Go to Step 11 Less than 1V:

Go to Step 7

More than

specified value: Go to Step 8

7 Repair the open circuit between the ECM and MAF sensor.

Was the problem solved?

— Verify repair Go to Step 8

Step Action Value(s) Yes No

92

88 83

2 3

4

5

C-116

C-57(B)

V

4

C-116

83

4

C-116

C-57(B)

Page 1503 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E –131

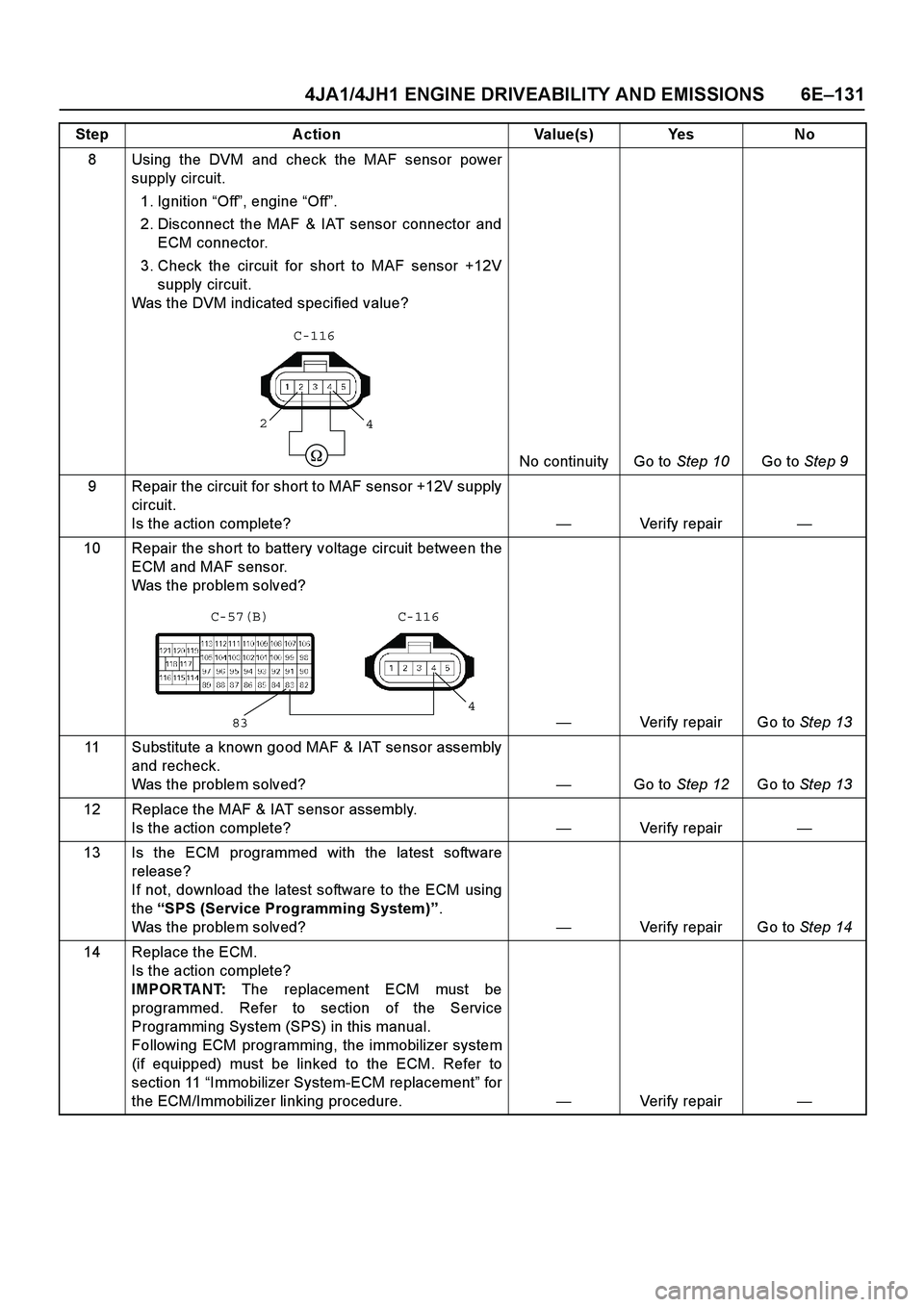

8 Using the DVM and check the MAF sensor power

supply circuit.

1. Ignition “Off ”, engine “Off ”.

2. Disconnect the MAF & IAT sensor connector and ECM connector.

3. Check the circuit for short to MAF sensor +12V supply circuit.

Was the DVM indicated specified value?

No continuity Go to Step 10Go to Step 9

9 Repair the circuit for short to MAF sensor +12V supply circuit.

Is the action complete? —Verify repair —

10 Repair the short to battery voltage circuit between the ECM and MAF sensor.

Was the problem solved?

— Verify repair Go to Step 13

11 Substitute a known good MAF & IAT sensor assembly and recheck.

Was the problem solved? —Go to Step 12 Go to Step 13

12 Replace the MAF & IAT sensor assembly. Is the action complete? —Verify repair —

13 Is the ECM programmed with the latest software release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)” .

Was the problem solved? —Verify repair Go to Step 14

14 Replace the ECM. Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobilizer system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobilizer System-ECM replacement ” for

the ECM/Immobilizer linking procedure. —Verify repair —

Step Action Value(s) Yes No

4

2

C-116

83

4

C-116

C-57(B)

Page 1504 of 4264

6E –132 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0100 (Symptom Code 9) (Flash Code 65)

Mass Air Flow (MAF) Sensor Voltage Supply Circuit Low Input

Step Action Value(s) Yes No

1Was the “On-Board Diagnostic (OBD) System Check ”

performed?

— Go to Step 2 Go to

On Board

Diagnostic

(OBD) System Check

2 1. Connect the Tech 2. 2. Review and record the failure information.

3. Select “F0: Read DTC Infor As Stored By ECU ” in

“ F0: Diagnostic Trouble Codes ”.

Is the DTC P0100 (Symptom Code 9) stored as

“ Present Failure ”? —Go to Step 3 Refer to

Diagnostic Aids and Go to Step

3

3 1. Using the Tech 2, ignition “On ” and engine “Off ”.

2. Select “F1: Clear DTC Information ” in “F0:

Diagnostic Trouble Codes ” with the Tech 2 and

clear the DTC information.

3. Operate the vehicle and monitor the “F0: Read

DTC Infor As Stored By ECU ” in the “F0:

Diagnostic Trouble Codes ”.

Was the DTC P0100 (Symptom Code 9) stored in this

ignition cycle? —Go to Step 4 Refer to

Diagnostic Aids and Go to Step

4

4 Check for poor/faulty connection at the MAF sensor or ECM connector. If a poor/faulty connection is found,

repair as necessary.

Was the problem found?

— Verify repair Go to Step 5

5 Visually check the MAF sensor. Was the problem found? —Go to Step 10 Go to Step 6

6 Using the DVM and check the MAF sensor power supply circuit.

1. Ignition “On ”, engine “Off ”.

2. Disconnect the MAF & IAT sensor connector.

3. Check the circuit for short to ground circuit.

Was the DVM indicated specified value?

Approx imately 5.0V Go to Step 10Go to Step 7

92

88 83

2 3

4

5

C-116

C-57(B)

V

4

C-116

Page 1505 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E –133

7 Using the DVM and check the MAF sensor power

supply circuit.

1. Ignition “Off ”, engine “Off ”.

2. Disconnect the MAF & IAT sensor connector and ECM connector.

3. Check the circuit for short to MAF sensor ground circuit.

Was the DVM indicated specified value?

No continuity Go to Step 9Go to Step 8

8 Repair the circuit for short to MAF sensor ground. Is the action complete? —Verify repair —

9 Repair the short to ground circuit between the ECM and MAF sensor.

Was the problem solved?

— Verify repair Go to Step 12

10 Substitute a known good MAF & IAT sensor assembly and recheck.

Was the problem solved? —Go to Step 11 Go to Step 12

11 Replace the MAF & IAT sensor assembly. Is the action complete? —Verify repair —

12 Is the ECM programmed with the latest software release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System) ”.

Was the problem solved? —Verify repair Go to Step 13

13 Replace the ECM. Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobilizer system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobilizer System-ECM replacement ” for

the ECM/Immobilizer linking procedure. —Verify repair —

Step Action Value(s) Yes No

4

3

C-116

83

4

C-116

C-57(B)

Page 1506 of 4264

6E –134 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0100 (Symptom Code B) (Flash Code 65)

Mass Air Flow (MAF) Sensor Output Circuit Low Input

Step Action Value(s) Yes No

1Was the “On-Board Diagnostic (OBD) System Check ”

performed?

— Go to Step 2 Go to

On Board

Diagnostic

(OBD) System Check

2 1. Connect the Tech 2. 2. Review and record the failure information.

3. Select “F0: Read DTC Infor As Stored By ECU ” in

“ F0: Diagnostic Trouble Codes ”.

Is the DTC P0100 (Symptom Code B) stored as

“ Present Failure ”? —Go to Step 3 Refer to

Diagnostic Aids and Go to Step

3

3 1. Using the Tech 2, ignition “On ” and engine “Off ”.

2. Select “F1: Clear DTC Information ” in “F0:

Diagnostic Trouble Codes ” with the Tech 2 and

clear the DTC information.

3. Operate the vehicle and monitor the “F0: Read

DTC Infor As Stored By ECU ” in the “F0:

Diagnostic Trouble Codes ”.

Was the DTC P0100 (Symptom Code B) stored in this

ignition cycle? —Go to Step 4 Refer to

Diagnostic Aids and Go to Step

4

4 Check for poor/faulty connection at the MAF sensor or ECM connector. If a poor/faulty connection is found,

repair as necessary.

Was the problem found?

— Verify repair Go to Step 5

5 Visually check the MAF sensor. Was the problem found? —Go to Step 11 Go to Step 6

92

88 83

2 3

4

5

C-116

C-57(B)