ISUZU TF SERIES 2004 Workshop Manual

Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 2651 of 4264

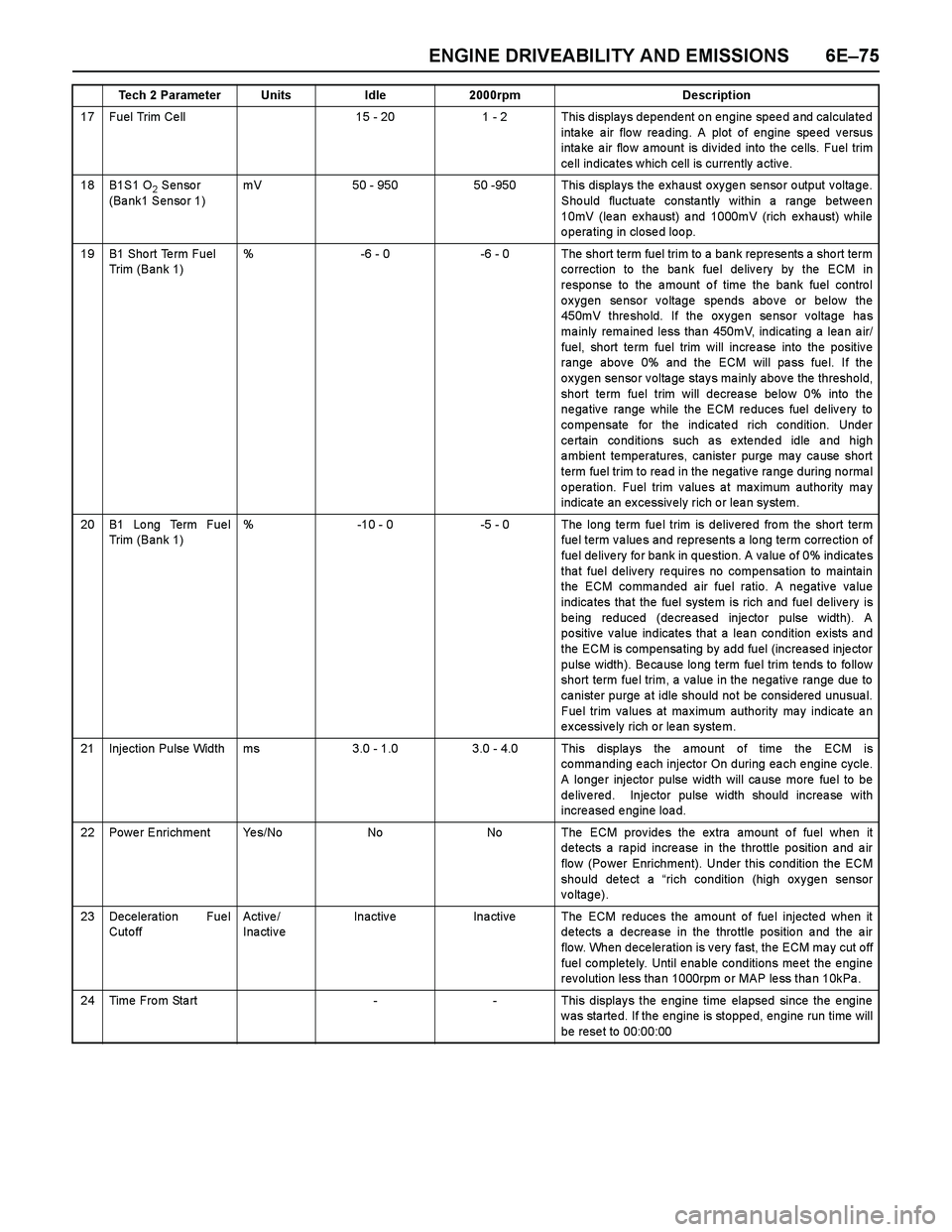

ENGINE DRIVEABILITY AND EMISSIONS 6E–75

17 Fuel Trim Ce ll15 - 201 - 2 This displays dependent on engine speed and calculated

intake air flow reading. A plot of engine speed versus

inta ke a ir flo w a mo unt is div ide d into the ce lls. Fuel trim

ce ll indica te s w hich cell is currently a ctiv e.

18B1S1 O2 Sensor

(Bank1 Sensor 1)mV50 - 95050 -950 This displays the exhaust oxygen sensor output voltage.

Should fluctuate constantly within a range between

10mV (lean exhaust) and 1000mV (rich exhaust) while

operating in closed loop.

19B1 Sho rt Te rm Fuel

Trim (Bank 1)%-6 - 0-6 - 0 The short term fuel trim to a bank represents a short term

co rrection to the ba nk fue l de liv e ry by the ECM in

response to the amount of time the bank fuel control

oxygen sensor voltage spends above or below the

450mV threshold. If the oxygen sensor voltage has

ma inly rema ine d less tha n 450mV, indicating a lea n a ir/

fue l, short te rm fuel trim will incre a se into the positiv e

range above 0% and the ECM will pass fuel. If the

oxygen sensor voltage stays mainly above the threshold,

short term fuel trim will decrease below 0% into the

negative range while the ECM reduces fuel delivery to

compensate for the indicated rich condition. Under

ce rtain co nditions such a s e xte nde d idle a nd high

ambient temperatures, canister purge may cause short

term fuel trim to rea d in the ne ga tiv e ra nge during no rma l

operation. Fuel trim values at maximum authority may

indica te an ex cessiv ely rich o r lea n sy stem.

20B1 Lo ng Term Fue l

Trim (Bank 1)%-10 - 0-5 - 0 The long te rm fue l trim is deliv ere d fro m the sho rt term

fuel term values and represents a long term correction of

fuel delivery for bank in question. A value of 0% indicates

that fuel delivery requires no compensation to maintain

the ECM commanded air fuel ratio. A negative value

indica tes tha t the fuel syste m is rich a nd fue l de live ry is

being reduced (decreased injector pulse width). A

positive value indicates that a lean condition exists and

the ECM is compensating by add fuel (increased injector

pulse width). Be ca use lo ng term fue l trim te nds to fo llow

short term fuel trim, a value in the negative range due to

canister purge at idle should not be considered unusual.

Fuel trim values at maximum authority may indicate an

excessively rich or lean system.

21Injection Pulse Widthms3.0 - 1.03.0 - 4.0 This displays the amount of time the ECM is

co mma nding e ach injecto r On during ea ch e ngine cycle.

A longer injector pulse width will cause more fuel to be

delivered. Injector pulse width should increase with

increased engine load.

22Power EnrichmentYe s / N oNoNo The ECM provides the extra amount of fuel when it

detects a rapid increase in the throttle position and air

flo w (Po wer Enrichment). Under this co ndition the ECM

should detect a “rich condition (high oxygen sensor

voltage).

23Decelera tion Fue l

Cut o ff Active /

InactiveInactiveIna ctiveThe ECM reduces the amount of fuel injected when it

detects a decrease in the throttle position and the air

flow. When deceleration is very fast, the ECM may cut off

fue l co mple te ly. Until e na ble co nditions me et the e ngine

rev olution less tha n 1000rpm o r MAP le ss tha n 10kPa .

24Time From Start--This displays the engine time elapsed since the engine

w as sta rte d. If the engine is stoppe d, engine run time will

be rese t to 00:00:00

Tech 2 ParameterUnitsIdle2000rpmDescription

Page 2652 of 4264

6E–76 ENGINE DRIVEABILITY AND EMISSIONS

MISCELLANEOUS TEST

The state of each circuit can be tested by using

miscellaneous test menus. Especially when DTC

cannot be detected, a faulty circuit can be diagnosed by

testing each circuit by means of these menus.

Even DTC has been detected, the circuit tests using

these menus could help discriminate between a

mechanical trouble and an electrical trouble.

Connect Tech 2 and select “Powertrain”, “2.XL L4

HV240” & “Miscellaneous Test”.

F0: Lamps

F0: Malfunction Indicator Lamp

When the Tech 2 is operated, “Malfunction Indicator

Lamp (Check Engine Lamp)” is turned on or off.

The circuit is normal if the “Malfunction Indicator Lamp

(Check Engine Lamp)” in the instrument panel is turned

on or off in accordance with this operation.

F1: Relays

F0: Fuel Pump Relay

When the Tech 2 is operated, fuel pump relay signal

turns ON or OFF.

The circuit is normal if fuel pump sound is generated in

accordance with this operation when key switch is

turned ON.

F1: A /C Clutch Relay

When the Tech 2 is operated, A/C clutch relay signal

turns ON or OFF.

The circuit is normal if A/C compressor clutch is

energized in accordance with this operation when the

engine is running.

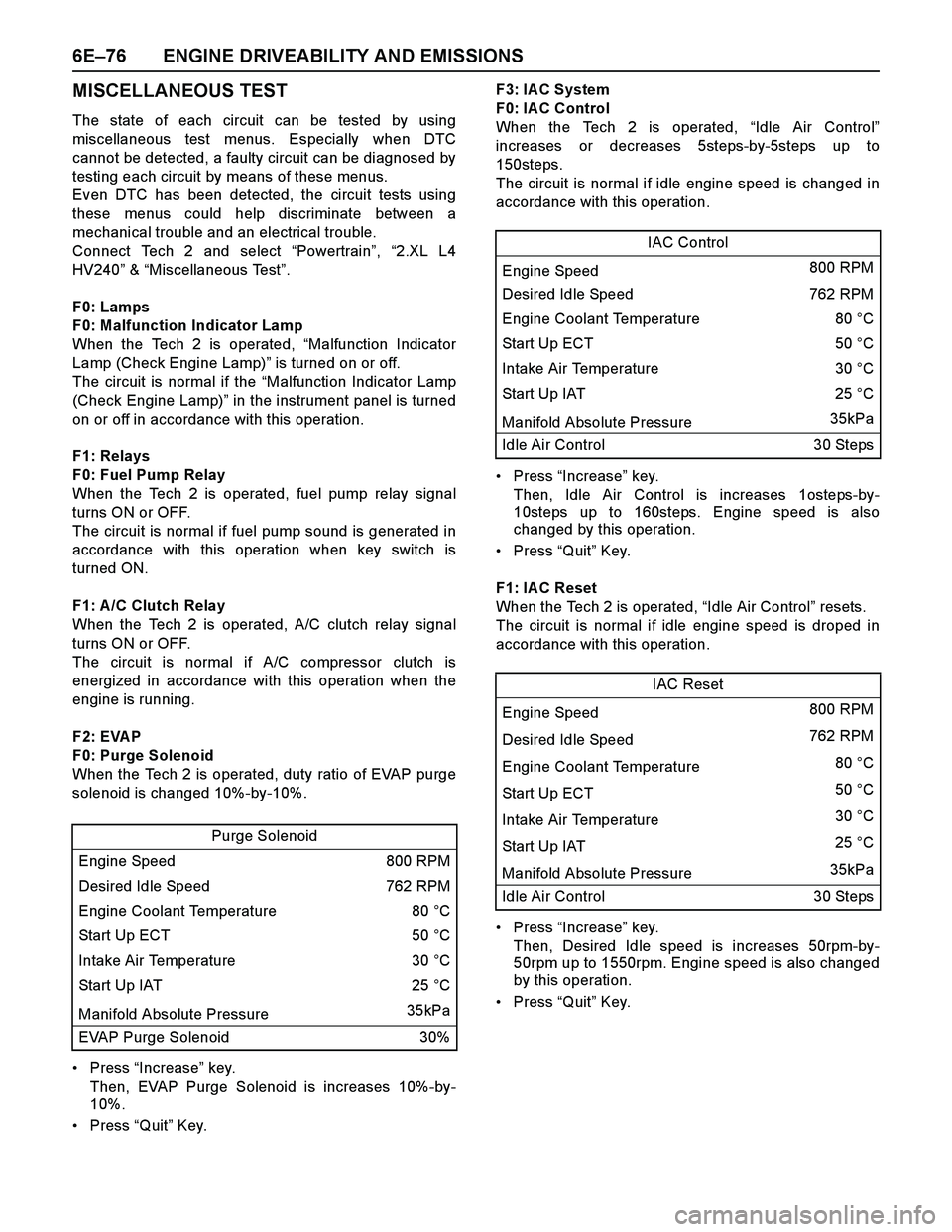

F2: EVAP

F0: Purge Solenoid

When the Tech 2 is operated, duty ratio of EVAP purge

solenoid is changed 10%-by-10%.

Press “Increase” key.

Then, EVAP Purge Solenoid is increases 10%-by-

10%.

Press “Quit” Key.F3: IAC System

F0: IA C Control

When the Tech 2 is operated, “Idle Air Control”

increases or decreases 5steps-by-5steps up to

150steps.

The circuit is normal if idle engine speed is changed in

accordance with this operation.

Press “Increase” key.

Then, Idle Air Control is increases 1osteps-by-

10steps up to 160steps. Engine speed is also

changed by this operation.

Press “Quit” Key.

F1: IA C Reset

When the Tech 2 is operated, “Idle Air Control” resets.

The circuit is normal if idle engine speed is droped in

accordance with this operation.

Press “Increase” key.

Then, Desired Idle speed is increases 50rpm-by-

50rpm up to 1550rpm. Engine speed is also changed

by this operation.

Press “Quit” Key. Purge Solenoid

Engine Speed 800 RPM

Desired Idle Speed 762 RPM

Engine Coolant Temperature 80 °C

Start Up ECT 50 °C

Intake Air Temperature 30 °C

Start Up IAT 25 °C

Manifold Absolute Pressure 35kPa

EVAP Purge Solenoid 30%

IAC Control

Engine Speed 800 RPM

Desired Idle Speed 762 RPM

Engine Coolant Temperature 80 °C

Start Up ECT 50 °C

Intake Air Temperature 30 °C

Start Up IAT25 °C

Manifold Absolute Pressure 35kPa

Idle Air Control 30 Steps

IAC Reset

Engine Speed 800 RPM

Desired Idle Speed 762 RPM

Engine Coolant Temperature 80 °C

Start Up ECT 50 °C

Intake Air Temperature 30 °C

Start Up IAT 25 °C

Manifold Absolute Pressure 35kPa

Idle Air Control 30 Steps

Page 2653 of 4264

ENGINE DRIVEABILITY AND EMISSIONS 6E–77

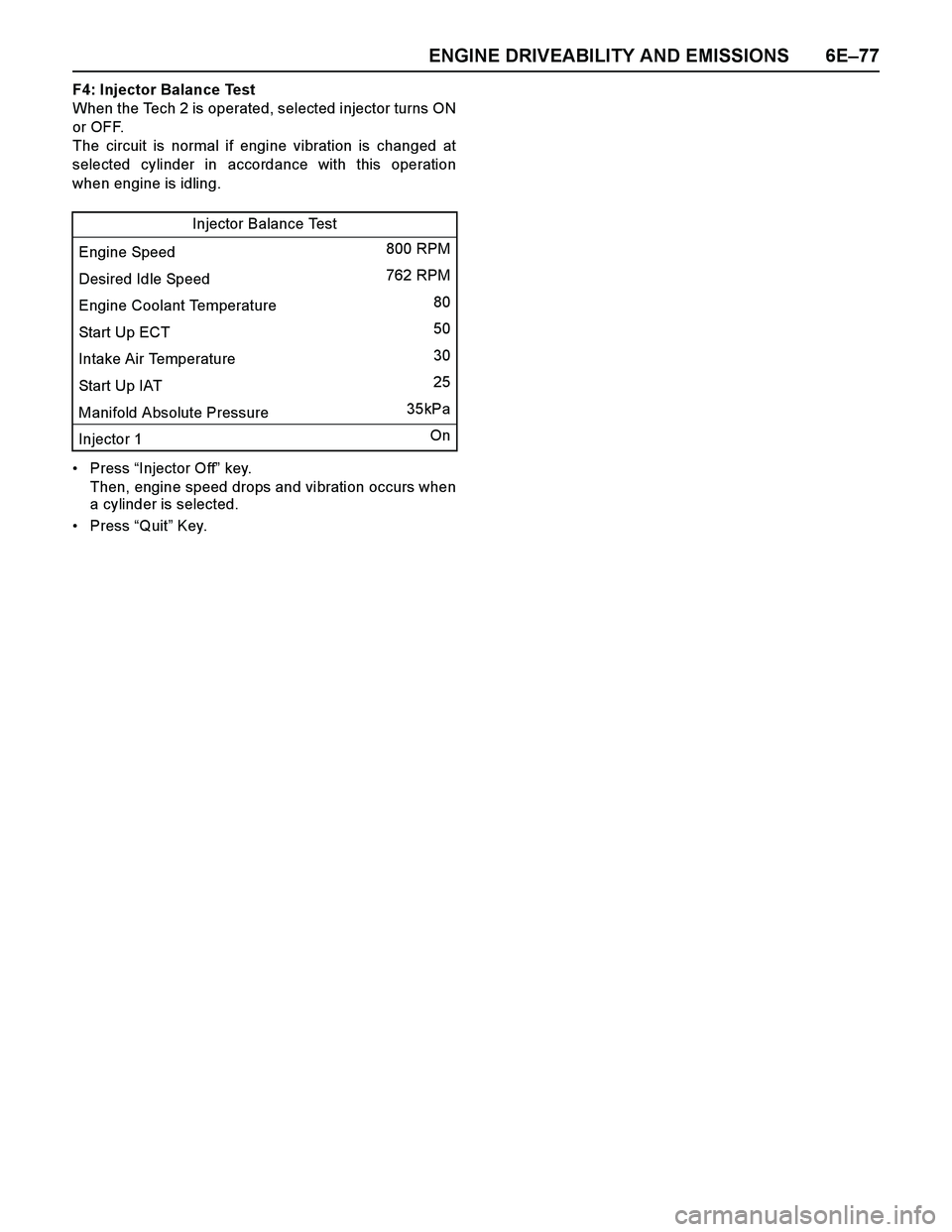

F4: Injector Balance Test

When the Tech 2 is operated, selected injector turns ON

or OFF.

The circuit is normal if engine vibration is changed at

selected cylinder in accordance with this operation

when engine is idling.

Press “Injector Off” key.

Then, engine speed drops and vibration occurs when

a cylinder is selected.

Press “Quit” Key.Injector Balance Test

Engine Speed 800 RPM

Desired Idle Speed 762 RPM

Engine Coolant Temperature 80

Start Up ECT 50

Intake Air Temperature 30

Start Up IAT 25

Manifold Absolute Pressure 35kPa

Injector 1 On

Page 2654 of 4264

6E–78 ENGINE DRIVEABILITY AND EMISSIONS

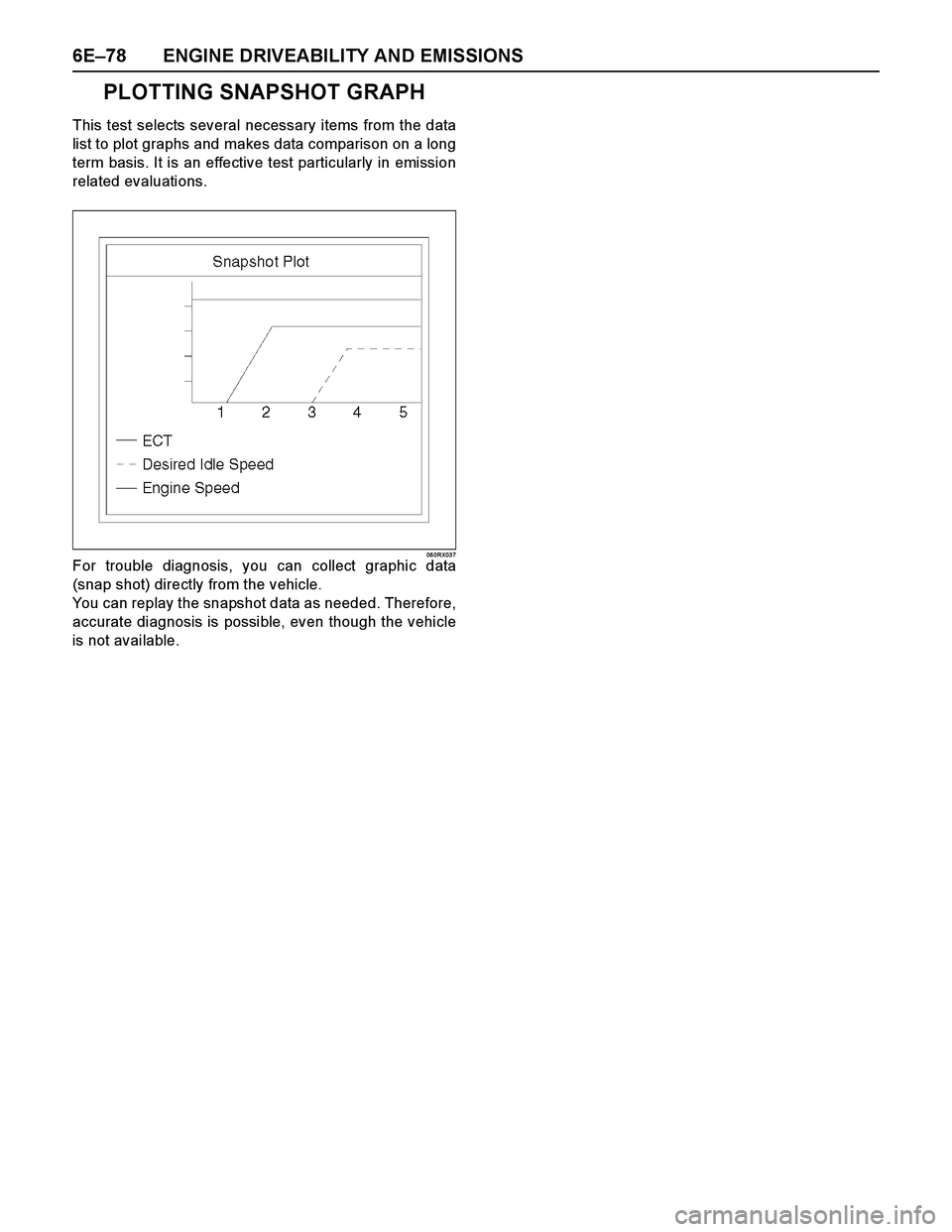

PLOTTING SNAPSHOT GRAPH

This test selects several necessary items from the data

list to plot graphs and makes data comparison on a long

term basis. It is an effective test particularly in emission

related evaluations.

06 0RX03 7For trouble diagnosis, you can collect graphic data

(snap shot) directly from the vehicle.

You can replay the snapshot data as needed. Therefore,

accurate diagnosis is possible, even though the vehicle

is not available.

Page 2655 of 4264

ENGINE DRIVEABILITY AND EMISSIONS 6E–79

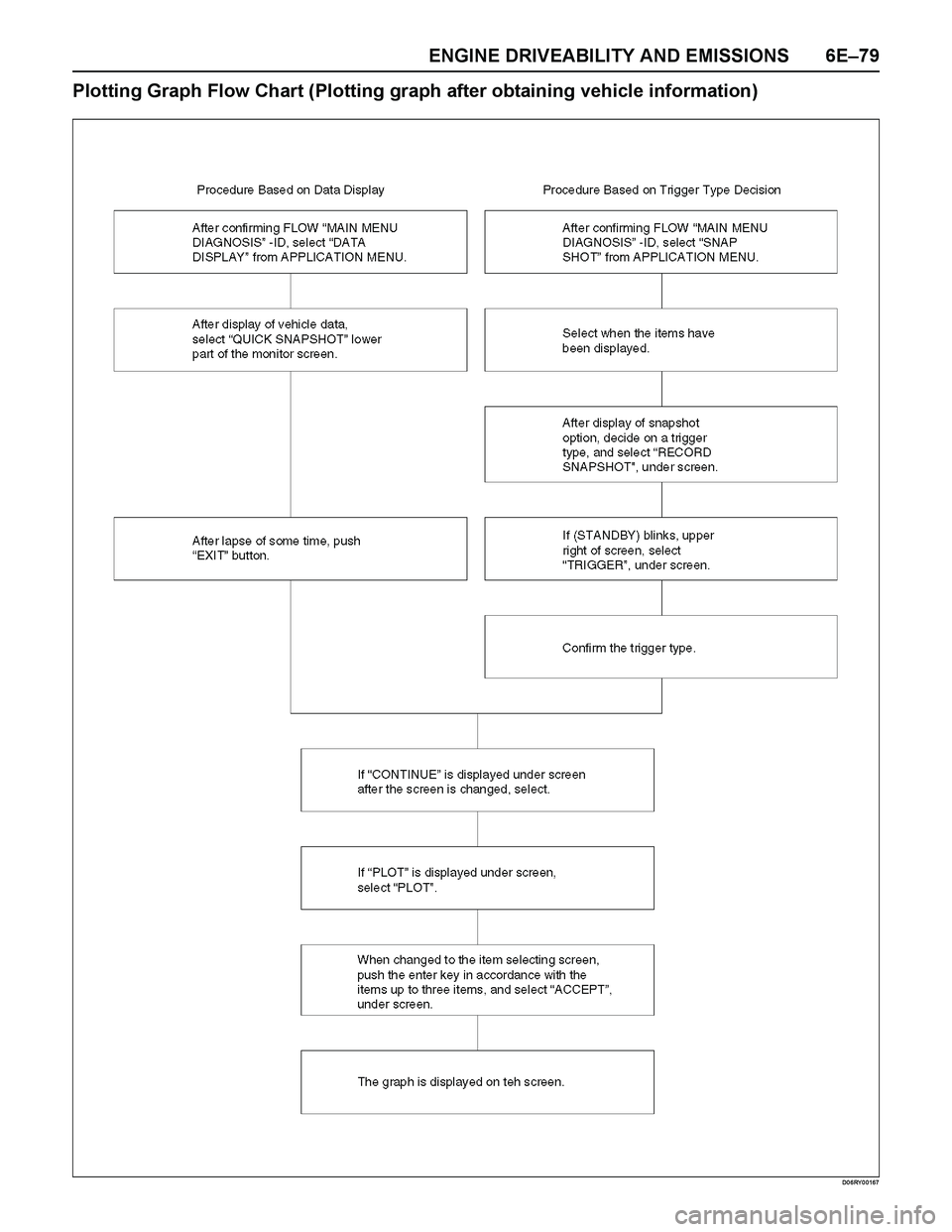

Plotting Graph Flow Chart (Plotting graph after obtaining vehicle information)

D0 6RY 0 0167

Page 2656 of 4264

6E–80 ENGINE DRIVEABILITY AND EMISSIONS

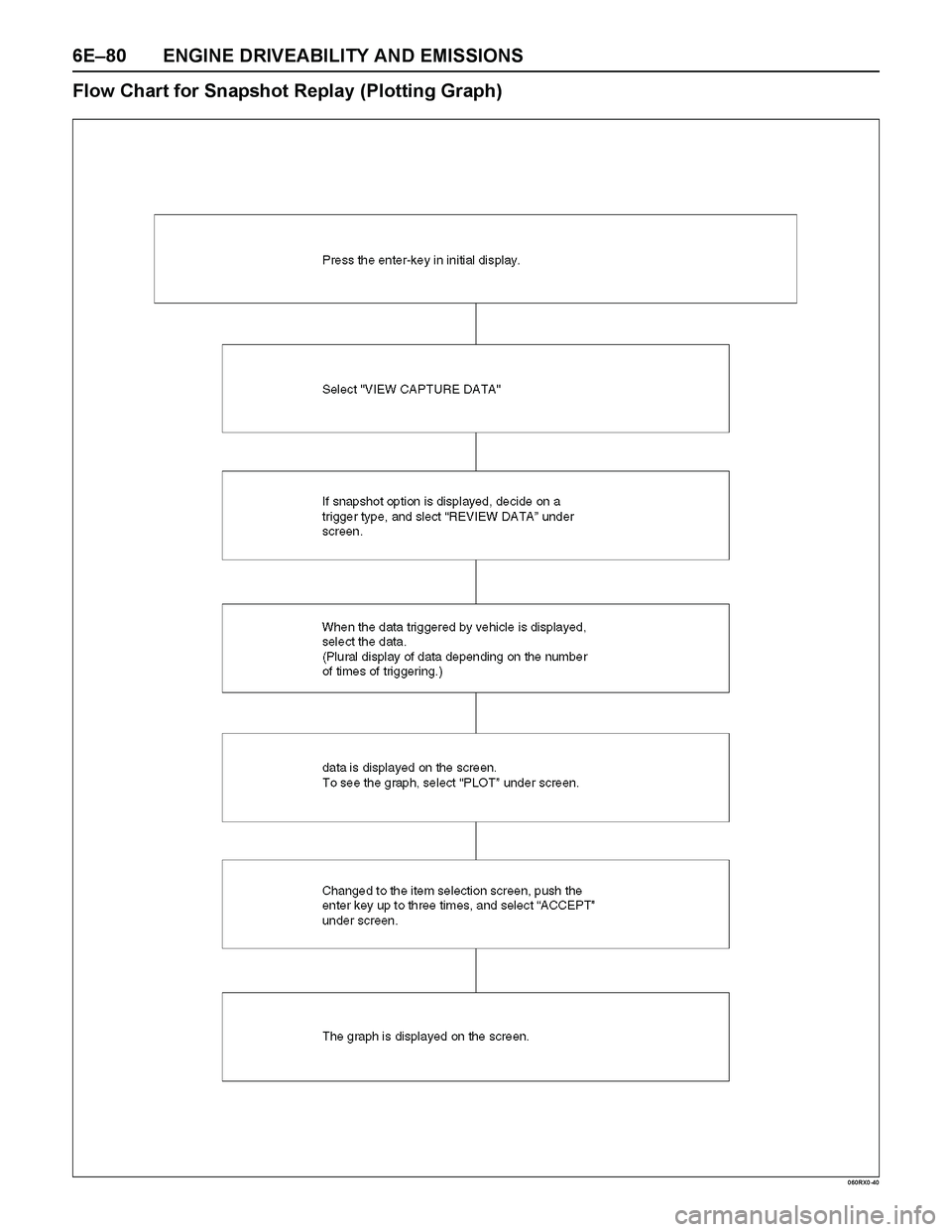

Flow Chart for Snapshot Replay (Plotting Graph)

0 60RX0 -40

Page 2657 of 4264

![ISUZU TF SERIES 2004 Workshop Manual ENGINE DRIVEABILITY AND EMISSIONS 6E–81

SNAPSHOT DISPLAY WITH TIS2000

Procedures for transferring and displaying Tech2

snapshot data by using TIS2000 [Snapshot Upload]

function is described below.

S ISUZU TF SERIES 2004 Workshop Manual ENGINE DRIVEABILITY AND EMISSIONS 6E–81

SNAPSHOT DISPLAY WITH TIS2000

Procedures for transferring and displaying Tech2

snapshot data by using TIS2000 [Snapshot Upload]

function is described below.

S](/img/61/57180/w960_57180-2656.png)

ENGINE DRIVEABILITY AND EMISSIONS 6E–81

SNAPSHOT DISPLAY WITH TIS2000

Procedures for transferring and displaying Tech2

snapshot data by using TIS2000 [Snapshot Upload]

function is described below.

Snapshot data can be displayed with [Snapshot Upload]

function included in TIS2000.

1. Record the snapshot data, in Tech2.

2. Transfer the snapshot data to PC.By analyzing these data in various methods, trouble

conditions can be checked.

Snapshot data is displayed by ex ecuting the three steps

below shown:

After recording the snapshot in Tech2, transfer the data

from Tech2 to PC by the below procedures.

1. Start TIS2000.

2. Select [Snapshot Upload] on the TIS2000 start

screen.

3. Select [Upload from trouble diagnosis tool (transfer

from diagnosis tester)] or click the corresponding

icon of the tool bar.

4. Select Tech2, and transfer the recorded snapshot

information. 5. Select the transferred snapshot.

6. After ending transfer of the snapshot, data

parameter list is displayed on the screen.

Page 2658 of 4264

![ISUZU TF SERIES 2004 Workshop Manual 6E–82 ENGINE DRIVEABILITY AND EMISSIONS

3. Snapshot data is displayed with TIS2000

[Snapshot Upload] function.

Snapshot is stored in the PC hard disk or floppy disk,

and can be displayed any time.

S ISUZU TF SERIES 2004 Workshop Manual 6E–82 ENGINE DRIVEABILITY AND EMISSIONS

3. Snapshot data is displayed with TIS2000

[Snapshot Upload] function.

Snapshot is stored in the PC hard disk or floppy disk,

and can be displayed any time.

S](/img/61/57180/w960_57180-2657.png)

6E–82 ENGINE DRIVEABILITY AND EMISSIONS

3. Snapshot data is displayed with TIS2000

[Snapshot Upload] function.

Snapshot is stored in the PC hard disk or floppy disk,

and can be displayed any time.

Stored snapshot can be displayed by the below

procedures.

1. Start TIS2000.

2. Select [Snapshot Upload] on the TIS2000 start

screen.3. Select [Open the existing files] or click the

corresponding icon of the tool bar.

4. Select the transferred snapshot.

5. Open the snapshot, to display the data parameter

list on the screen.

Graph display Values and graphs (Max. 3 graphs):

1. Click the icon for graph display. [Graph Parameter]

window opens.

2. Click the first graph icon of the window upper part,

and select one parameter from the list of the window

lower part. Selected parameter is displayed nest to

the graph icon. Graph division can be selected in

the field on the parameter right side.

3. Repeat the same procedures with the 2nd and 3rd

icons.

4. After selecting all parameters to be displayed (Max .

3 parameters), click [OK] button.

5. Parameter selected is displayed in graph form on

the right of the data parameter on the screen. 6. Graph display can be moved with the navigation

icon.

7. For displaying another parameter by graph, click the

parameter of the list, drug the mouse to the display

screen while pressing the mouse button and release

the mouse button. New parameter is displayed at

the position of the previous parameter. For

displaying the graph display screen in full size,

move the cursor upward on the screen. When the

cursor is changed to the magnifying glass form, click

the screen. Graph screen is displayed on the whole

screen.

Page 2659 of 4264

![ISUZU TF SERIES 2004 Workshop Manual ENGINE DRIVEABILITY AND EMISSIONS 6E–83

Display of graphs on one screen (Max. 6 graphs):

1. Click the 6 graph icon. [Graph Parameter] window

opens.

2. Click the graph icon, select the parameter to ISUZU TF SERIES 2004 Workshop Manual ENGINE DRIVEABILITY AND EMISSIONS 6E–83

Display of graphs on one screen (Max. 6 graphs):

1. Click the 6 graph icon. [Graph Parameter] window

opens.

2. Click the graph icon, select the parameter to](/img/61/57180/w960_57180-2658.png)

ENGINE DRIVEABILITY AND EMISSIONS 6E–83

Display of graphs on one screen (Max. 6 graphs):

1. Click the 6 graph icon. [Graph Parameter] window

opens.

2. Click the graph icon, select the parameter to be

displayed from the list and change divisions

according to necessity.

3. Repeat the same procedures with the graph icons,

from the 2nd to 6th.

4. Click the [OK] button to display.

5. In this case, parameters are displayed only in graph

form. All parameters are displayed in one graph.

6. The graph display screen can be moved with the

navigation icon.

Page 2660 of 4264

6E–84 ENGINE DRIVEABILITY AND EMISSIONS

SERVICE PROGRAMMING SYSTEM (SPS)

The procedure to program the control unit by using the

Service Programming System (SPS) software contained

in TIS2000 is ex plained below.

NOTE:

If the Engine Control Module (ECM) was

programmed, the Immobilizer System must be

linked to the ECM: Refer to section 11

“Immobilizer System-ECM replacement” for the

ECM/Immobilizer linking procedure.

Should Tech2 display "SPS Procedure was not

successful", engine will not start, but no DTCs

are present, low battery voltage or poor electrical

connections should be the primary suspects.

Perform the SPS procedure again after rectifying

the fault/s.IMPORTANT:

Perform the following checks before attempting to

program the control unit:

The Tech2 PCMCIA card is programmed with The

latest software release.

The latest release of TIS2000 is loaded on the PC.

The vehicle battery is fully charged.

The control unit to be programmed is connected

to the vehicle.

1. Preparations of TIS 2000

1. Connect Tech 2 to P/C.

2. Check to see if Hardware Key is plugged into Port.

3. Activate TIS 2000 by P/C.

4. On the activating screen of TIS2000, choose

“Service Programming System”

5. On the screen of “Diagnostic Tester and Processing

Program Selection”, choose the one that will comply

with the following.

Tech-2 in use

New programming by the ex isting module or new

programming by the replaced/new module.

Fix ing position of the control unit.6. Upon completion of the selection, push the button of

“Nex t”.