service ISUZU TF SERIES 2004 Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 71 of 4264

RESTRAINT CONTROL 9A1-1

RESTRAINTS

RESTRAINT CONTROL SYSTEM

PAGE

Service Precaution .............................................................................................................9A1- 2

Diagnosis Information ..................................................................................................9A1- 3

Diagnostic Procedures .................................................................................................9A1- 3

Diagnostic Codes ..........................................................................................................9A1- 3

How To Read Trouble Codes .......................................................................................9A1- 3

How To Clear Trouble Codes .......................................................................................9A1- 3

Scan Tool Diagnostics ..................................................................................................9A1- 3

Basic Knowledge Required ..........................................................................................9A1- 3

Basic Electrical Circuits ...............................................................................................9A1- 4

"Flash Code" Diagnostics ............................................................................................9A1- 4

DATA LIST (Tech2) ........................................................................................................9A1- 5

Diagnostic Trouble Codes ............................................................................................9A1- 6

System Schematic .............................................................................................................9A1- 7

Chart A SRS control unit Integrity Check ........................................................................9A1-10

Chart B "AIR BAG" Warning Lamp Comes "ON" Steady................................................9A1-12

Chart C "AIR BAG" Warning Lamp Does Not Come "ON" Steady .................................9A1-14

DTC B0016 (Flash Code 16) Passenger Airbag Squib Circuit (Stage1) Low

Resistance ........................................................................................................................9A1-17

DTC B0017 (Flash Code 17) Passenger Airbag Squib Circuit (Stage1) High

Resistance ........................................................................................................................9A1-20

DTC B0018 (Flash Code 18) Passenger Airbag Squib Circuit (Stage1) Voltage

Range/Performance .........................................................................................................9A1-23

DTC B0022 (Flash Code 22) Driver Airbag Squib Circuit (Stage1) Low

Resistance ........................................................................................................................9A1-26

DTC B0024 (Flash Code 24) Driver Airbag Squib Circuit (Stage1) Voltage

Range/Performance ...........................................................................................................9A1-29

DTC B0026 (Flash Code 26) Driver Airbag Squib Circuit (Stage1) High

Resistance ........................................................................................................................9A1-32

DTC B0033 (Flash Code 33) ECU Connector Poor Connection .....................................9A1-35

Page 72 of 4264

9A1-2 RESTRAINT CONTROL SYSTEM

DTC B0051 (Flash Code 51) Squib Circuit Activated (Clash) .........................................9A1-37

DTC B0053 (Flash Code 53) Deployment Command Despite Present Trouble

Code ..................................................................................................................................9A1-39

DTC B0057 (Flash Code 57) Passenger Pretensioner Squib Circuit Low

Resistance ........................................................................................................................9A1-41

DTC B0058 (Flash Code 58) Passenger Pretensioner Squib Circuit High

Resistance ........................................................................................................................9A1-44

DTC B0059 (Flash Code 59) Passenger Pretensioner Squib Circuit Voltage

Range/Performance .........................................................................................................9A1-47

DTC B0064 (Flash Code 64) Driver Pretensioner Squib Circuit Low Resistance .........9A1-50

DTC B0065 (Flash Code 65) Driver Pretensioner Squib Circuit High Resistance ........9A1-53

DTC B0066 (Flash Code 66) Driver Pretensioner Squib Circuit Voltage Range/

Performance .....................................................................................................................9A1-56

DTC B0670 (Flash Code 63) Airbag Telltale Circuit Malfunction ...................................9A1-59

DTC B1000 (Flash Code 72) SDM Internal Fault ..............................................................9A1-61

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or

other corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener.

When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

Page 73 of 4264

RESTRAINT CONTROL 9A1-3

Diagnostic Information

CAUTION: When fasteners are removed, always

reinstall them at the same location from which they

were removed. if a fastener needs to be replaced,

use the correct part number fastener for that

application. if the correct part number fastener is

not available, a fastener of equal size and strength

(or stronger) may be used. fasteners that are not

reused, and those requiring thread locking

compound will be called out. the correct torque

value must be used when installing fasteners that

require it. if the above conditions are not followed,

parts or system damage could result.

Diagnostic Procedures

WARNING: TO AVOID DEPLOYMENT WHEN

TROUBLESHOOTING THE SRS, DO NOT USE

ELECTRICAL TEST EQUIPMENT SUCH AS A

BATTERY-POWERED OR AC-POWERED

VOLTMETER, OHMMETER, ETC., OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN THAT

SPECIFIED IN THIS MANUAL. DO NOT USE A NON

POWERED, PROBE-TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PERSONAL

INJURY MAY RESULT.

The diagnostic procedures used in this section are

designed to aid in finding and repairing SRS problems.

Outlined below are the steps to find and repair SRS

problems quickly and effectively. Failure to carefully

follow these procedures may result in extended

diagnostic time, incorrect diagnosis and incorrect parts

replacement.

1. Perform The “SRS Diagnostic System Check”.

The “SRS Diagnostic System Check” should always

be the starting point of any SRS diagnostics. The

“SRS Diagnostic System Check” checks for prope

r

“AIR BAG” warning lamp operation and checks for

SRS trouble codes using both “Flash Code” and

“Scan Tool” Methods.

2. Refer To The Proper Diagnostic Chart As

Directed By The “SRS Diagnostic System

Check”.

The “SRS Diagnostic System Check” will lead you to

the correct chart to diagnose any SRS problems.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis and incorrect

parts replacement.

3. Repeat The “SRS Diagnostic System Check”

After Any Repair Or Diagnostic Procedures Have

Been Performed.

Preforming the “SRS Diagnostic System Check”

after all repair or diagnostic procedures will assure

that the repair has been made correctly and that no

other conditions exist.

Diagnostic Codes

The SRS control unit maintains a history record of all

diagnostic codes that have been detected since the

SRS codes were last cleared during service.

1. Active Codes - Faults that are presently detected this

ignition cycle. Active codes are stored in RAM

(Random Access Memory).

2. History Codes - All faults detected since the last time

the history fault memory was cleared. History codes

are stored in EEPROM. (Electronically Erasable

Programmable Read only Memory)

How To Read Trouble Codes

All codes (Active and history) can be read (or cleared)

by using a scan tool or equivalent.

If a PDT is not available, have the vehicle serviced by

HOLDEN dealer.

How To Clear Trouble Codes

Trouble codes can only be cleared by using a Scan

Tool. If a “scan tool” is not available then inform the

owner of the stored codes and suggest that the codes

are cleared upon the next visit to an Isuzu dealership.

Scan Tool Diagnostics

A scan tool can be used to read current and history

codes and to clear all history codes after a repair is

complete. The scan tool must be updated to

communicate with the SRS through a replaceable

cartridge or a manufacturer's update before it can be

used for SRS diagnostics. To use the scan tool,

connect it to the DLC connector and turn the ignition

switch “ON”. Then follow the manufacturer's directions

for communication with the SRS. The scan tool reads

serial data from the SRS control unitSRS control unit

“Serial Data” output (terminal 21) to the DLC connector

(terminal 2).

Basic Knowledge Required

Before using this section of the Service Manual, there is

some basic knowledge which will be required. Without

this knowledge, you will have trouble using the

diagnostic procedures in this section. Use care to

prevent harm or unwanted deployment. Read all

Page 74 of 4264

9A1-4 RESTRAINT CONTROL SYSTEM

cautions in the service manual and on warning labels

attached to SRS components.

Basic Electrical Circuits

You should understand the basic theory of electricity

including series and parallel circuits, and understand

the voltage drops across series resistors. You should

know the meaning of voltage (volts), current (amps),

and resistance (ohms). You should understand what

happens in a circuit with an open or a shorted wire. You

should be able to read and understand a wiring

diagram.

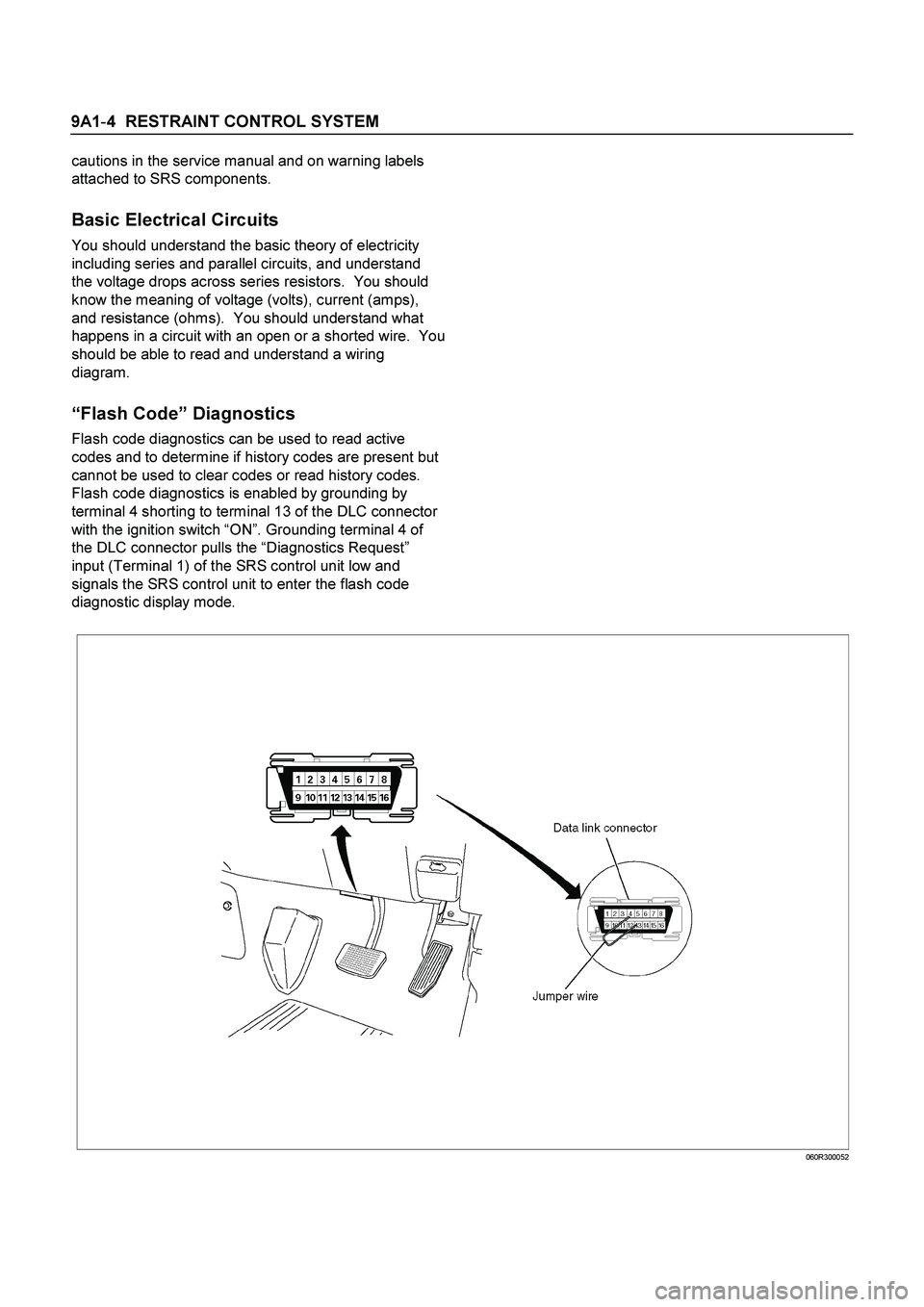

“Flash Code” Diagnostics

Flash code diagnostics can be used to read active

codes and to determine if history codes are present but

cannot be used to clear codes or read history codes.

Flash code diagnostics is enabled by grounding by

terminal 4 shorting to terminal 13 of the DLC connector

with the ignition switch “ON”. Grounding terminal 4 of

the DLC connector pulls the “Diagnostics Request”

input (Terminal 1) of the SRS control unit low and

signals the SRS control unit to enter the flash code

diagnostic display mode.

060R300052

Page 81 of 4264

RESTRAINT CONTROL 9A1-11

3.

When all circuitry outside the SRS control unit has

been found to operate properly, as indicated by the

appropriate diagnostic chart, then and only then

should the SRS control unit be replaced.

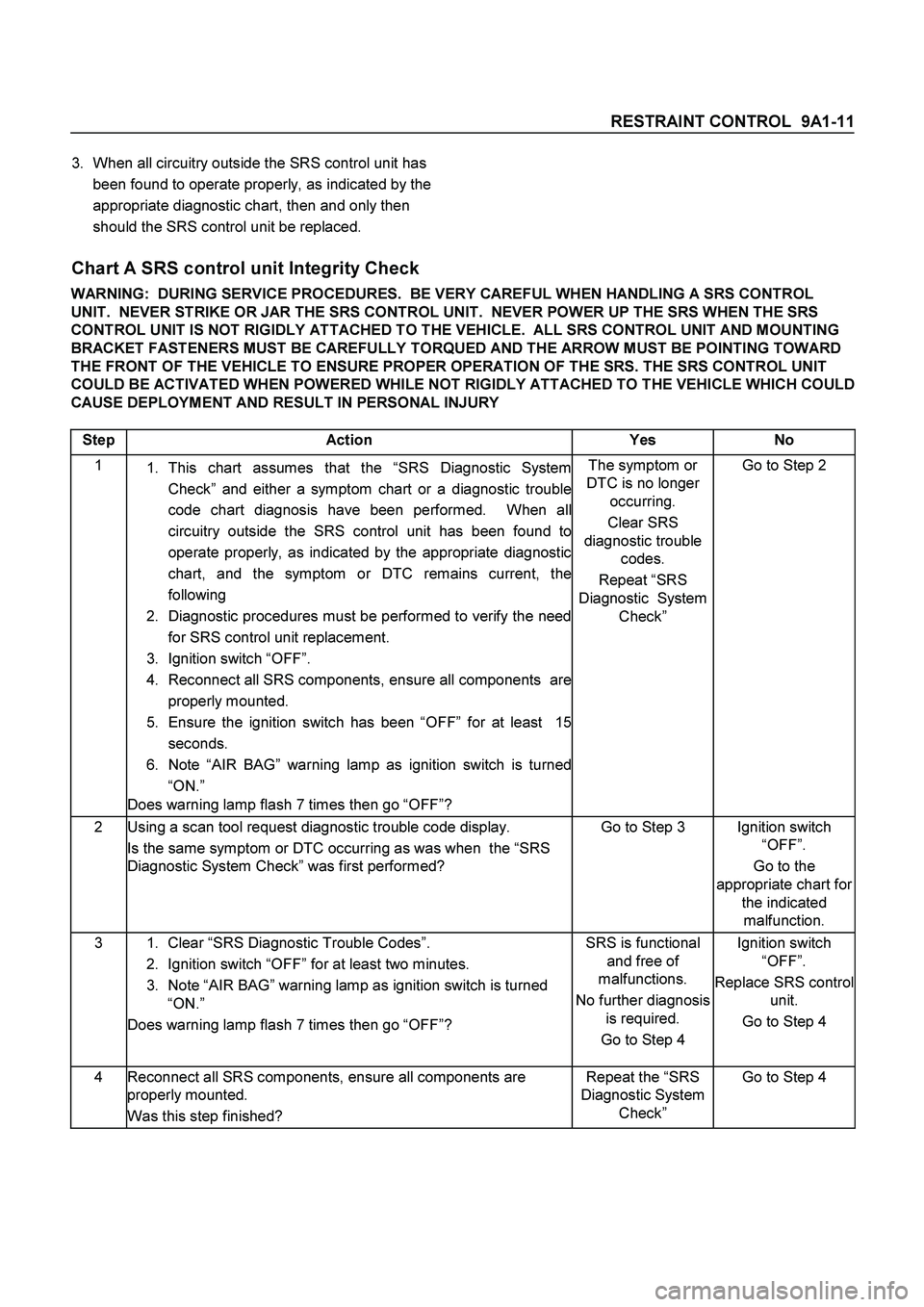

Chart A SRS control unit Integrity Check

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SRS CONTROL

UNIT. NEVER STRIKE OR JAR THE SRS CONTROL UNIT. NEVER POWER UP THE SRS WHEN THE SRS

CONTROL UNIT IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SRS CONTROL UNIT AND MOUNTING

BRACKET FASTENERS MUST BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD

THE FRONT OF THE VEHICLE TO ENSURE PROPER OPERATION OF THE SRS. THE SRS CONTROL UNIT

COULD BE ACTIVATED WHEN POWERED WHILE NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH COULD

CAUSE DEPLOYMENT AND RESULT IN PERSONAL INJURY

Step Action Yes No

1

1. This chart assumes that the “SRS Diagnostic System

Check” and either a symptom chart or a diagnostic trouble

code chart diagnosis have been performed. When all

circuitry outside the SRS control unit has been found to

operate properly, as indicated by the appropriate diagnostic

chart, and the symptom or DTC remains current, the

following

2. Diagnostic procedures must be performed to verify the need

for SRS control unit replacement.

3. Ignition switch “OFF”.

4. Reconnect all SRS components, ensure all components are

properly mounted.

5. Ensure the ignition switch has been “OFF” for at least 15

seconds.

6. Note “AIR BAG” warning lamp as ignition switch is turned

“ON.”

Does warning lamp flash 7 times then go “OFF”? The symptom or

DTC is no longer

occurring.

Clear SRS

diagnostic trouble

codes.

Repeat “SRS

Diagnostic System

Check” Go to Step 2

2 Using a scan tool request diagnostic trouble code display.

Is the same symptom or DTC occurring as was when the “SRS

Diagnostic System Check” was first performed? Go to Step 3 Ignition switch

“OFF”.

Go to the

appropriate chart for

the indicated

malfunction.

3

1. Clear “SRS Diagnostic Trouble Codes”.

2. Ignition switch “OFF” for at least two minutes.

3. Note “AIR BAG” warning lamp as ignition switch is turned

“ON.”

Does warning lamp flash 7 times then go “OFF”? SRS is functional

and free of

malfunctions.

No further diagnosis

is required.

Go to Step 4 Ignition switch

“OFF”.

Replace SRS control

unit.

Go to Step 4

4 Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished? Repeat the “SRS

Diagnostic System

Check” Go to Step 4

Page 85 of 4264

RESTRAINT CONTROL 9A1-15

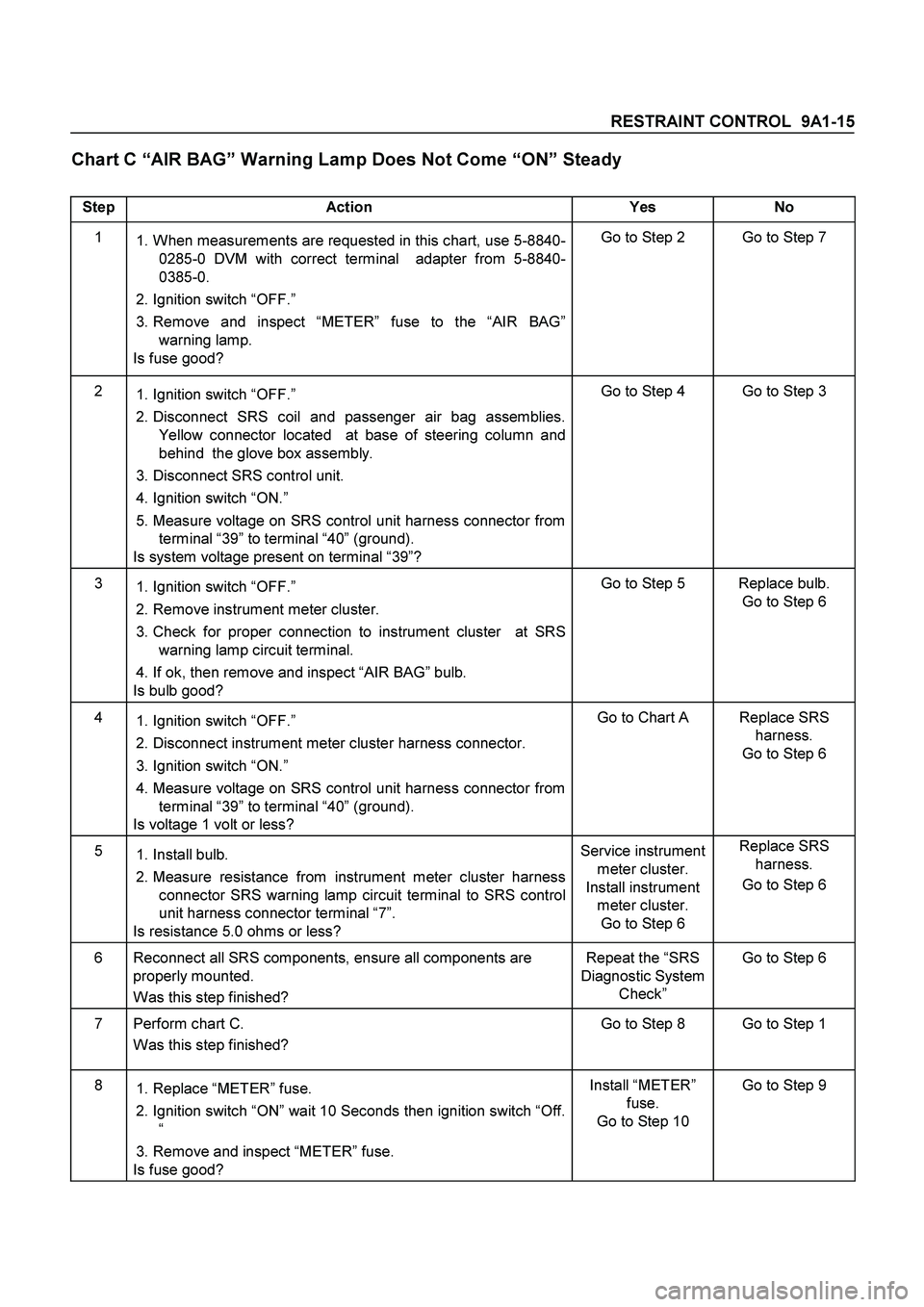

Chart C “AIR BAG” Warning Lamp Does Not Come “ON” Steady

Step Action Yes No

1

1. When measurements are requested in this chart, use 5-8840-

0285-0 DVM with correct terminal adapter from 5-8840-

0385-0.

2. Ignition switch “OFF.”

3. Remove and inspect “METER” fuse to the “AIR BAG”

warning lamp.

Is fuse good? Go to Step 2 Go to Step 7

2

1. Ignition switch “OFF.”

2. Disconnect SRS coil and passenger air bag assemblies.

Yellow connector located at base of steering column and

behind the glove box assembly.

3. Disconnect SRS control unit.

4. Ignition switch “ON.”

5. Measure voltage on SRS control unit harness connector from

terminal “39” to terminal “40” (ground).

Is system voltage present on terminal “39”? Go to Step 4 Go to Step 3

3

1. Ignition switch “OFF.”

2. Remove instrument meter cluster.

3. Check for proper connection to instrument cluster at SRS

warning lamp circuit terminal.

4. If ok, then remove and inspect “AIR BAG” bulb.

Is bulb good? Go to Step 5 Replace bulb.

Go to Step 6

4

1. Ignition switch “OFF.”

2. Disconnect instrument meter cluster harness connector.

3. Ignition switch “ON.”

4. Measure voltage on SRS control unit harness connector from

terminal “39” to terminal “40” (ground).

Is voltage 1 volt or less? Go to Chart A Replace SRS

harness.

Go to Step 6

5

1. Install bulb.

2. Measure resistance from instrument meter cluster harness

connector SRS warning lamp circuit terminal to SRS control

unit harness connector terminal “7”.

Is resistance 5.0 ohms or less? Service instrument

meter cluster.

Install instrument

meter cluster.

Go to Step 6 Replace SRS

harness.

Go to Step 6

6 Reconnect all SRS components, ensure all components are

properly mounted.

Was this step finished? Repeat the “SRS

Diagnostic System

Check” Go to Step 6

7 Perform chart C.

Was this step finished? Go to Step 8 Go to Step 1

8

1. Replace “METER” fuse.

2. Ignition switch “ON” wait 10 Seconds then ignition switch “Off.

“

3. Remove and inspect “METER” fuse.

Is fuse good? Install “METER”

fuse.

Go to Step 10 Go to Step 9

Page 108 of 4264

9A1-38 RESTRAINT CONTROL SYSTEM

DTC B0051 (Flash Code 51) Squib Circuit Activated (Crash Deteted)

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SRS CONROL UNIT.

NEVER STRIKE OR JAR THE SRS CONTROL UNIT. NEVER POWER UP THE SRS WHEN THE SRS CONTROL

UNIT IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SRS CONTROL UNIT AND MOUNTING BRACKET

FASTENERS MUST BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD THE

FRONT OF THE VEHICLE TO ENSURE PROPER OPERATION OF THE SRS. THE SRS CONTROL UNIT CAUSE

DEPLOYMENT AND RESULT IN PERSONAL INJURY.

Step Action Yes No

1 Was the “SRS Diagnostic System Check” performed? Go to Step 2. Go to the “SRS

Diagnostic System

Check”

2 Ignition switch “OFF.”

Have air bag assemblies deployed? Replace

components and

perform

inspections as

directed in

“repairs and

inspections

required after an

accident” in this

section.

clear diagnostic

trouble codes.

Repeat “SRS

Diagnostic System

Check” Go to Step 3

3 Inspect front of vehicle and undercarriage for sings of impact.

Were signs of impact found? Replace

components and

perform

inspections as

directed in

“Repairs and

Inspections

Required After An

Accident” in this

section.

Clear diagnostic

trouble codes.

Repeat “SRS

Diagnostic System

Check” Ignition switch

“OFF”.

Replace SRS

control unit.

Reconnect all SRS

system

components,

ensure all

components are

properly mounted.

Repeat “SRS

Diagnostic System

Check”

Page 110 of 4264

9A1-40 RESTRAINT CONTROL SYSTEM

DTC Chart Test Description

Number(s) below refer to step number(s) on the

diagnostic chart:

2.

If air bag assembly have not deployed, DTC B0053

may have falsely set.

3.

If DTC B0053 has set with no signs of frontal impact,

the diagnostic trouble code has falsely set.

DTC B0053 (Flash Code 53) Deployment Command Despite Present Trouble Code

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SRS CONTROL

UNIT. NEVER STRIKE OR JAR THE SRS CONTROL UNIT. NEVER POWER UP THE SRS WHEN THE SRS

CONTROL UNIT IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SRS CONTROL UNIT AND MOUNTING

BRACKET FASTENERS MUST BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD

THE FRONT OF THE VEHICLE TO ENSURE PROPER OPERATION OF THE SRS. THE SRS CONTROL UNIT

COULD BE ACTIVATED WHEN POWERED WHILE NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH

COULD CAUSE DEPLOYMENT AND RESULT IN PERSONAL INJURY.

Step Action Yes No

1 Was the “SRS Diagnostic System Check” performed? Go to Step 2 Go to the “SRS

Diagnostic System

Check”

2 Ignition switch “OFF.”

Have air bag assembles deployed? Replace

components and

perform

inspections as

directed in

“Repairs And

Inspections

Required After An

Accident” in this

section.

Clear diagnostic

trouble codes.

Repeat the “SRS

Diagnostic System

Check” Go to Step 3

3 Inspect front of vehicle and undercarriage for signs of impact.

Were signs of impact found? Replace

components and

perform

inspections as

directed in

“Repairs And

Inspections

Required After An

Accident” in this

section.

Clear diagnostic

trouble codes.

Repeat “SRS

Diagnostic System

Check” Ignition switch

“OFF.”

Replace SRS

control unit.

Reconnect all SRS

system

components,

ensure all

components are

properly mounted.

Repeat the “SRS

Diagnostic System

Check”

Page 132 of 4264

9A1-62 RESTRAINT CONTROL SYSTEM

DTC B1000 (Flash Code 72) SDM Internal Fault (SDM=SRS control unit)

WARNING: DURING SERVICE PROCEDURES. BE VERY CAREFUL WHEN HANDLING A SRS CONTROL

UNIT. NEVER STRIKE OR JAR THE SRS CONTROL UNIT. NEVER POWER UP THE SRS WHEN THE SRS

CONTROL UNIT IS NOT RIGIDLY ATTACHED TO THE VEHICLE. ALL SRS CONTROL UNIT AND MOUNTING

BRACKET FASTENERS MUST BE CAREFULLY TORQUED AND THE ARROW MUST BE POINTING TOWARD

THE FRONT OF THE VEHICLE TO ENSURE PROPER OPERATION OF THE SRS. THE SRS CONTROL UNIT

COULD BE ACTIVATED WHEN POWERED WHILE NOT RIGIDLY ATTACHED TO THE VEHICLE WHICH

COULD CAUSE DEPLOYMENT AND RESULT IN PERSONAL INJURY.

CAUTION: If DTC B1000 can not clear by Tech2, it is necessary to replace the SRS control unit.

Step Action Yes No

1 Was the “SRS Diagnostic System Check” performed? Ignition switch

“OFF.”

Replace SRS

control unit.

Repeat the “SRS

Diagnostic System

Check” Go to the “SRS

Diagnostic System

Check”

Page 138 of 4264

4A-2 PROPELLER SHAFT

Service Precaution

WARNING: THIS VEHICLE HAS A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS).

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PEREFORMING

SERVICE ON OR NEAR THE SRS COMPONENTS

OR THE SRS WIRING, REFER TO THE SRS

SERVICE INFORMATION. FAILURE TO FOLLOW

WARNING COULD RESULT IN POSSIBLE AI

R

BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS. CAUTION : Always use the correct fastener in the

proper location. When you replace a fastener,

use ONLY the exact part number for that

application. ISUZU will call out those fasteners

that require a replacement after removal. ISUZU

will also call out the fasteners that require thread

lockers or thread sealant. UNLESS OTHERWISE

SPECIFIED, do not use supplemental coatings

(Paints, greases, or other corrosion inhibitors)

on threaded fasteners or fastener joint

interfaces. Generally, such coatings adversely

affect the fastener torque and the joint clamping

force, and may damage the fastener. When you

install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts

and systems.