wiring diagram ISUZU TF SERIES 2004 Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 1779 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–407

EXCESSIVE WHITE SMOKE

Step Action Value(s) Yes No

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2Go to On Board

Diagnostic

(OBD) System

Check

2 1. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?—Verify repair Go to Step 3

3 Was a visually/physical check performed?

—Go to Step 4Go to Visual /

physical Check

4 Is the customer using the incorrect fuel type? Diesel fuel

onlyReplace with

diesel fuel Go to Step 5

5 Check the engine coolant consumption to verify that it

leaks to combustion chamber or ex haust through the

gasket.

Was a problem found?—Verify repair Go to Step 6

6 Check the ECM & PSG grounds to verify that they are

clean and tight. Refer to the ECM wiring diagrams.

Was a problem found?—Verify repair Go to Step 7

7 1. Using the Tech 2, display the ECT sensor and IAT

sensor value.

2. Check the displayed value.

Does the Tech 2 indicate correct temperature

depending on engine condition?

If a problem is found, repair as necessary.

Was the problem found?—Verify repair Go to Step 8

8 1. Using the Tech 2, display the FT sensor value.

2. Check the displayed value.

Does the Tech 2 indicate correct temperature

depending on engine condition?

If a problem is found, repair as necessary.

Was the problem found?—Go to Step 30Go to Step 9

9 1. Using the Tech 2, ignition “On” and engine “Run”.

2. Monitor the “Mass Air Flow” in the data display.

Does the Tech 2 indicate correct “Mass Air Flow”

depending on accelerator pedal operation? —Go to Step 14Go to Step 10

10 Remove the MAF & IAT sensor assembly and check

for the following conditions.

Objects blocking at the MAF sensor element.

If a problem is found, repair as necessary.

Was the problem found?—Verify repair Go to Step 11

11 Check the MAF sensor harness for the following

conditions.

Check for poor connector connection.

Check for misrouted harness.

Check for any accessory parts which may cause

electric interference.

If a problem is found, repair as necessary.

Was a problem found? —Verify repair Go to Step 12

Page 1785 of 4264

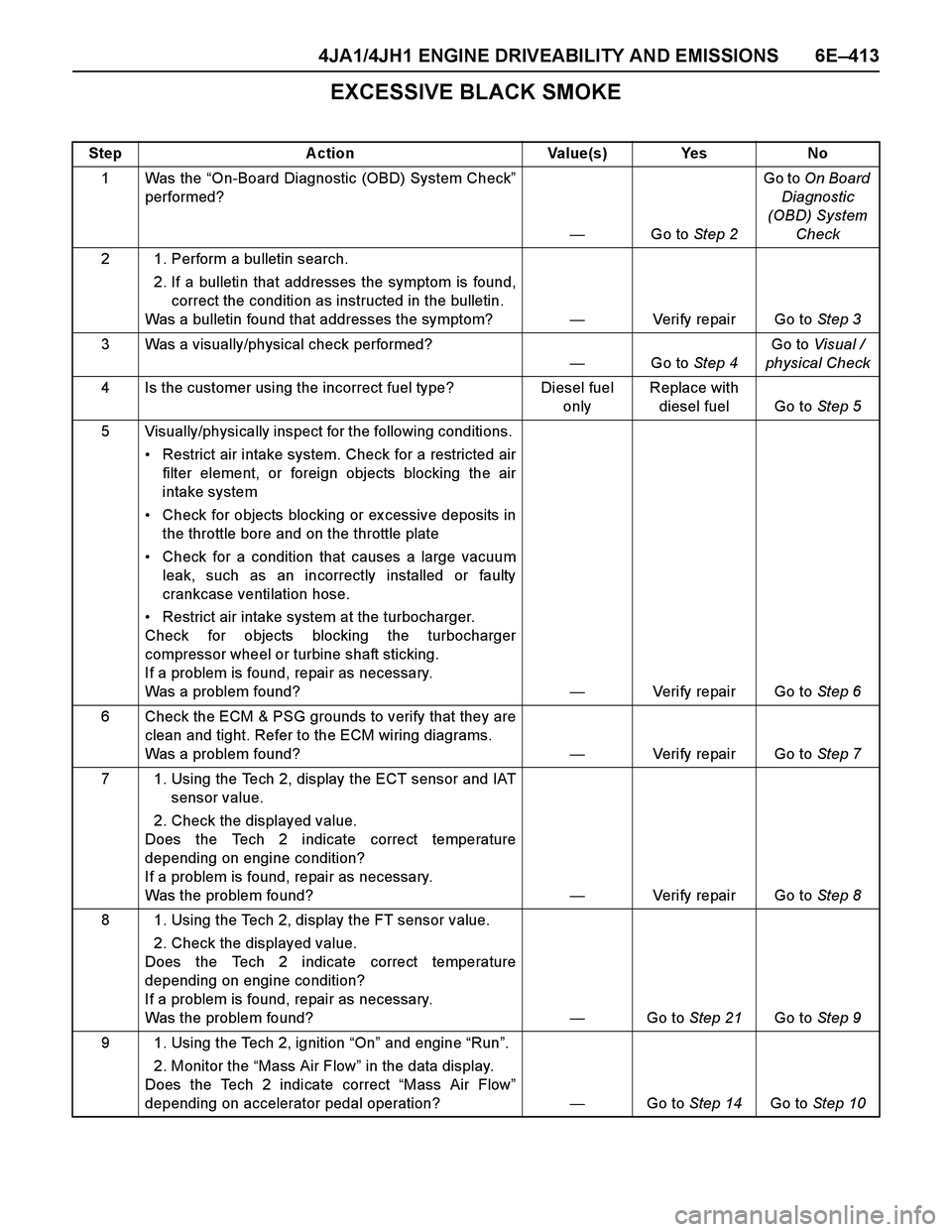

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–413

EXCESSIVE BLACK SMOKE

Step Action Value(s) Yes No

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2Go to On Board

Diagnostic

(OBD) System

Check

2 1. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?—Verify repair Go to Step 3

3 Was a visually/physical check performed?

—Go to Step 4Go to Visual /

physical Check

4 Is the customer using the incorrect fuel type? Diesel fuel

onlyReplace with

diesel fuel Go to Step 5

5 Visually/physically inspect for the following conditions.

Restrict air intake system. Check for a restricted air

filter element, or foreign objects blocking the air

intake system

Check for objects blocking or ex cessive deposits in

the throttle bore and on the throttle plate

Check for a condition that causes a large vacuum

leak, such as an incorrectly installed or faulty

crankcase ventilation hose.

Restrict air intake system at the turbocharger.

Check for objects blocking the turbocharger

compressor wheel or turbine shaft sticking.

If a problem is found, repair as necessary.

Was a problem found?—Verify repair Go to Step 6

6 Check the ECM & PSG grounds to verify that they are

clean and tight. Refer to the ECM wiring diagrams.

Was a problem found?—Verify repair Go to Step 7

7 1. Using the Tech 2, display the ECT sensor and IAT

sensor value.

2. Check the displayed value.

Does the Tech 2 indicate correct temperature

depending on engine condition?

If a problem is found, repair as necessary.

Was the problem found?—Verify repair Go to Step 8

8 1. Using the Tech 2, display the FT sensor value.

2. Check the displayed value.

Does the Tech 2 indicate correct temperature

depending on engine condition?

If a problem is found, repair as necessary.

Was the problem found?—Go to Step 21Go to Step 9

9 1. Using the Tech 2, ignition “On” and engine “Run”.

2. Monitor the “Mass Air Flow” in the data display.

Does the Tech 2 indicate correct “Mass Air Flow”

depending on accelerator pedal operation? —Go to Step 14Go to Step 10

Page 1997 of 4264

3.5L ENGINE DRIVEABILITY AND EMISSIONS 6E-1

ENGINE

3.5L ENGINE DRIVEABILITY AND EMISSIONS

CONTENTS

ABBREVIATION CHARTS ................................ 6E-5

COMPONENT LOCATOR ................................. 6E-6

ENGINE COMPONENT LOCATOR TABLE .. 6E-6

ECM CIRCUIT DIAGRAM ................................. 6E-10

GROUND POINT CHART G.EXP (LHD)

WITHOUT EUROPE, ISRAEL, TURKEY (1/4). 6E-13

GROUND POINT CHART G.EXP (LHD) (2/4) .. 6E-14

GROUND POINT CHART G.EXP (LHD) (3/4) .. 6E-15

GROUND POINT CHART G.EXP (LHD) (4/4) .. 6E-16

GROUND POINT CHART G.EXP (RHD) (1/4) . 6E-17

GROUND POINT CHART G.EXP (RHD) (2/4) . 6E-18

GROUND POINT CHART G.EXP (RHD) (3/4) . 6E-19

GROUND POINT CHART G.EXP (RHD) (4/4) . 6E-20

LOCATION ........................................................ 6E-21

CABLE HARNESS & CONNECTOR

LOCATION ....................................................... 6E-22

CONNECTOR LIST ........................................... 6E-27

RELAY AND FUSE ............................................ 6E-30

RELAY AND FUSE BOX LOCATION

(LHD&RHD) ................................................... 6E-30

RELAY AND FUSE BOX LOCATION

(LHD&RHD) ................................................... 6E-31

FUSE AND RELAY LOCATION

(LHD&RHD) ................................................... 6E-32

ECM WIRING DIAGRAM (1/10) ........................ 6E-33

ECM WIRING DIAGRAM (2/10) ........................ 6E-34

ECM WIRING DIAGRAM (3/10) ........................ 6E-35

ECM WIRING DIAGRAM (4/10) ........................ 6E-36

ECM WIRING DIAGRAM (5/10) ........................ 6E-37

ECM WIRING DIAGRAM (6/10) ........................ 6E-38

ECM WIRING DIAGRAM (7/10) ........................ 6E-39

ECM WIRING DIAGRAM (8/10) ........................ 6E-40

ECM WIRING DIAGRAM (9/10) ........................ 6E-41

ECM WIRING DIAGRAM (10/10) ...................... 6E-42

ECM CONNECTOR PIN ASSIGNMENT

& OUTPUT SIGNAL ......................................... 6E-43

GENERAL DESCRIPTION FOR ECM AND

SENSORS ........................................................ 6E-51

Mass Air Flow (MAF) Sensor & Intake Air

Temperature (IAT) Sensor ............................. 6E-52

Throttle Position Sensor (TPS)....................... 6E-52

Idle Air Control (IAC) Valve ............................ 6E-53

Camshaft Position (CMP) Sensor .................. 6E-53

Crankshaft Position (CKP) Sensor ................. 6E-54

Engine Coolant Temperature (ECT) Sensor .. 6E-54

Vehicle Speed Sensor (VSS) ......................... 6E-55

Heated Oxygen (O

2) Sensor........................... 6E-55

GENERAL DESCRIPTION FOR FUEL

METERING....................................................... 6E-56

GENERAL DESCRIPTION FOR ELECTRONIC

IGNITION SYSTEM IGNITION

COILS & CONTROL ......................................... 6E-58

GENERAL DESCRIPTION FOR EVAPORATIVE

EMISSION SYSTEM ........................................ 6E-61

GENERAL DESCRIPRION FOR EXHAUST

GAS RECIRCULATION (EGR) SYSTEM......... 6E-62

ISUZU STRATEGY BASED DIAGNOSTICS .... 6E-63

Diagnostic Thought Process .......................... 6E-64

1. Verify the Complaint ................................... 6E-64

2. Perform Preliminary Checks....................... 6E-64

3. Check Bulletins and Troubleshooting

Hints ........................................................... 6E-65

4. Perform Service Manual Diagnostic

Checks ....................................................... 6E-65

5a and 5b. Perform Service Manual

Diagnostic Procedures ............................... 6E-65

5c. Technician Self Diagnoses ....................... 6E-65

5d. Intermittent Diagnosis............................ 6E-66

Symptom Simulation Tests.......................... 6E-67

5e. Vehicle Operates as Designed ................. 6E-68

6. Re-Examine the Complaint ........................ 6E-68

7. Repair and Verify Fix .................................. 6E-68

GENERAL SERVICE INFORMATION .............. 6E-69

Aftermarket Electrical and Vacuum

Equipment ..................................................... 6E-69

Electrostatic Discharge Damage .................... 6E-69

Page 2029 of 4264

3.5L ENGINE DRIVEABILITY AND EMISSIONS 6E-33

ECM WIRING DIAGRAM (1/10)

RTW46EMF000401

Page 2030 of 4264

6E-34 3.5L ENGINE DRIVEABILITY AND EMISSIONS

ECM WIRING DIAGRAM (2/10)

RUW46EMF000101

Page 2031 of 4264

3.5L ENGINE DRIVEABILITY AND EMISSIONS 6E-35

ECM WIRING DIAGRAM (3/10)

RUW46EMF000201

Page 2032 of 4264

6E-36 3.5L ENGINE DRIVEABILITY AND EMISSIONS

ECM WIRING DIAGRAM (4/10)

RTW46EMF000301

Page 2033 of 4264

3.5L ENGINE DRIVEABILITY AND EMISSIONS 6E-37

ECM WIRING DIAGRAM (5/10)

RTW36EMF000901

Page 2034 of 4264

6E-38 3.5L ENGINE DRIVEABILITY AND EMISSIONS

ECM WIRING DIAGRAM (6/10)

RTW46ELF001001

Page 2035 of 4264

3.5L ENGINE DRIVEABILITY AND EMISSIONS 6E-39

ECM WIRING DIAGRAM (7/10)

RTW36EMF000201