ISUZU TFS SERIES 1997 User Guide

TFS SERIES 1997

ISUZU

ISUZU

https://www.carmanualsonline.info/img/61/57182/w960_57182-0.png

ISUZU TFS SERIES 1997 User Guide

Trending: low beam, wheel bolt torque, door lock, center console, transmission oil, rear view mirror, steering wheel

Page 11 of 1600

REAR AXLE 4B-15

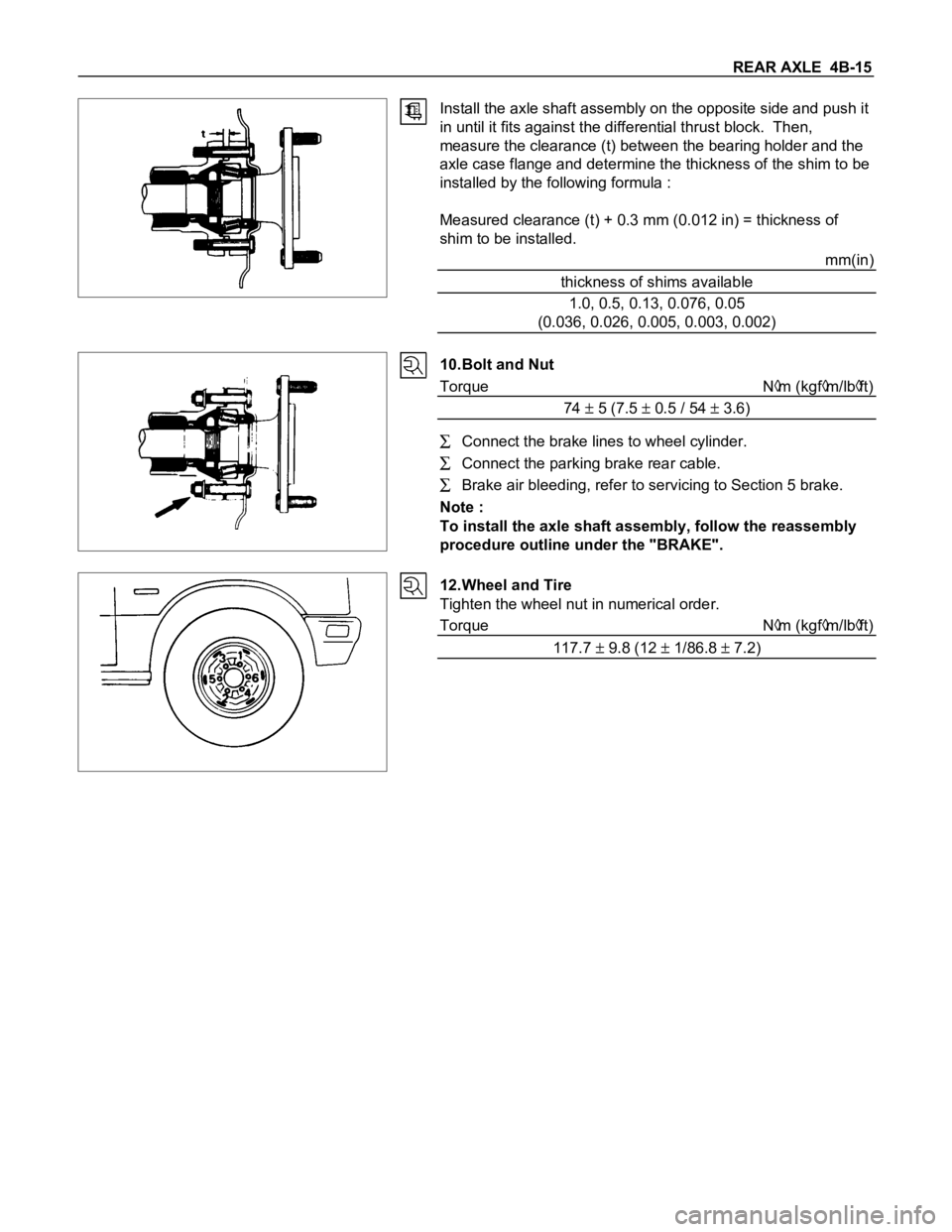

Install the axle shaft assembly on the opposite side and push it

in until it fits against the differential thrust block. Then,

measure the clearance (t) between the bearing holder and the

axle case flange and determine the thickness of the shim to be

installed by the following formula :

Measured clearance (t) + 0.3 mm (0.012 in) = thickness of

shim to be installed.

mm(in)

thickness of shims available

1.0, 0.5, 0.13, 0.076, 0.05

(0.036, 0.026, 0.005, 0.003, 0.002)

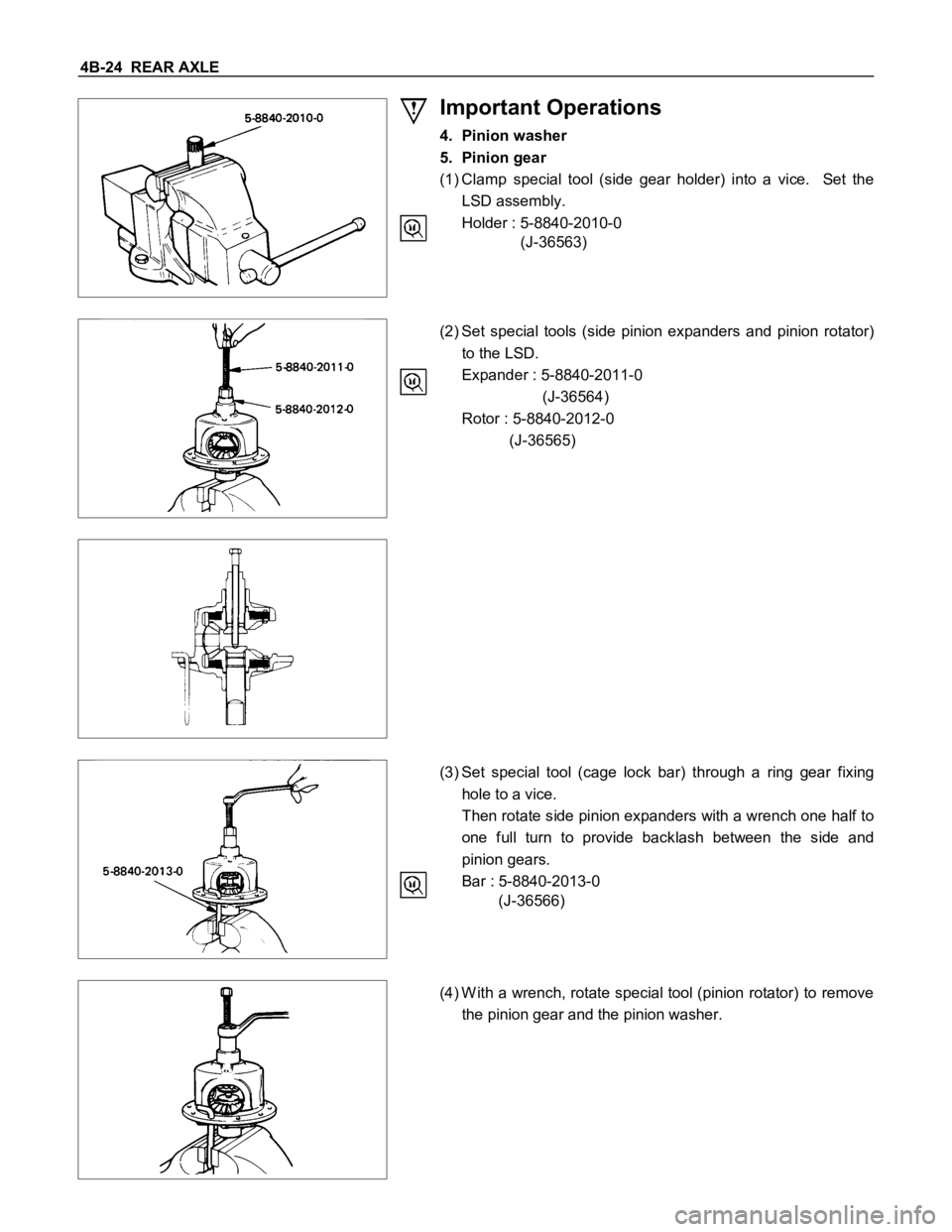

10.Bolt and Nut

Torque N

m (kgfm/lbft)

74

5 (7.5 0.5 / 54 3.6)

Connect the brake lines to wheel cylinder.

Connect the parking brake rear cable.

Brake air bleeding, refer to servicing to Section 5 brake.

Note :

To install the axle shaft assembly, follow the reassembly

procedure outline under the "BRAKE".

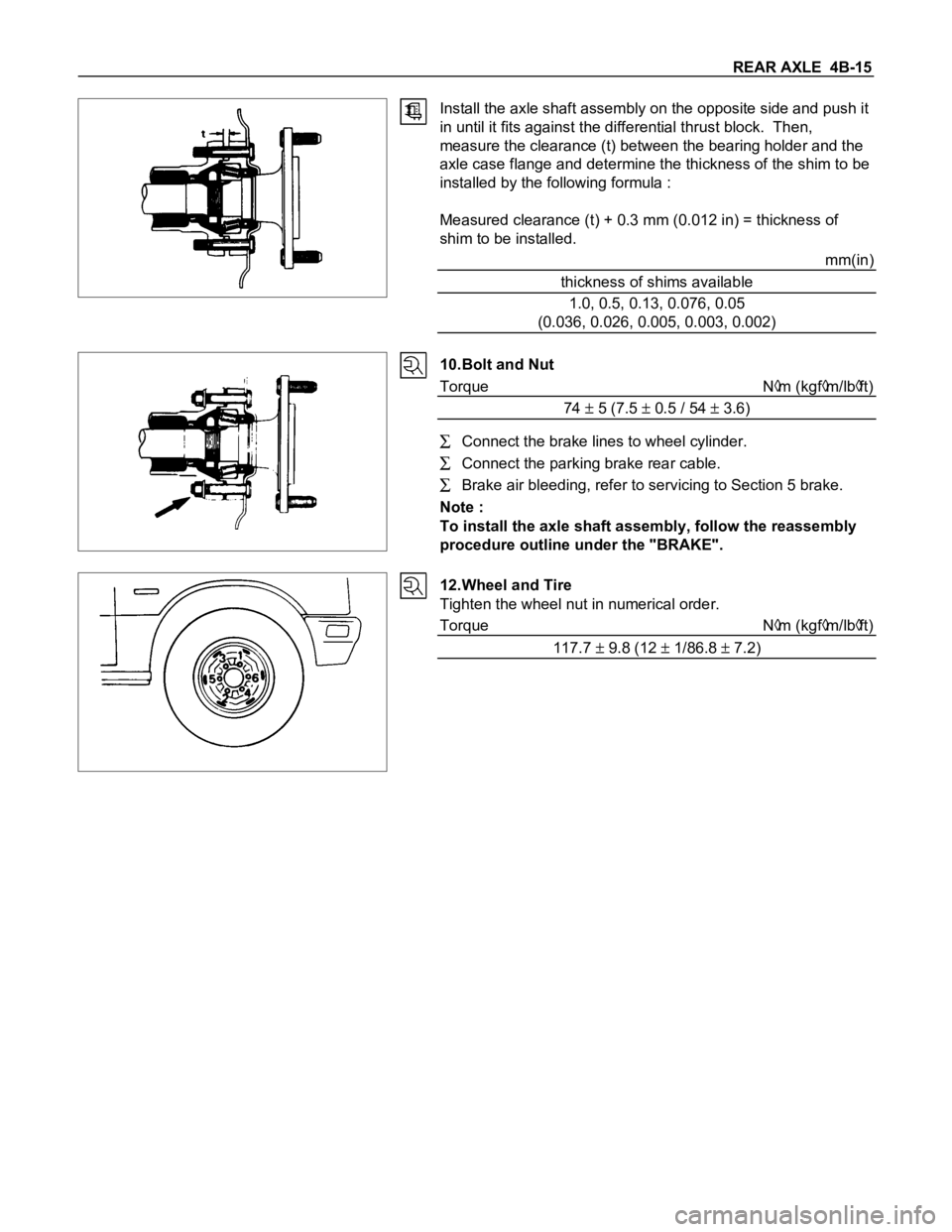

12.Wheel and Tire

Tighten the wheel nut in numerical order.

Torque N

m (kgfm/lbft)

117.7

9.8 (12 1/86.8 7.2)

Page 12 of 1600

4B-16 REAR AXLE

DIFFERENTIAL

REMOVAL AND INSTALLATION

Removal Steps

1. Propeller shaft

2. Axle shaft

3. Differential assembly

Installation Steps

3. Differential assembly

2. Axle shaft

1. Propeller shaft

To remove the axle shaft assembly,

follow the disassembly procedure outline

in this Section “Axle shaft”

Important Operation - Removal

2. Axle Shaft

Disengage the axle shafts from the carrier assembly and

partially withdraw the shafts from the axle tube.

It is not necessary to completely remove the axle shafts.

Move them only enough to allow the differential to be removed.

To remove the axle shaft assembly, follow the disassembly

procedure outline in this Section "Axle shaft".

Page 13 of 1600

REAR AXLE 4B-17

Important Operations - Installation

3. Differential Assembly

(194 mm)

Torque N

m (kgfm/lbft)

NUT 37.3

3.9 (3.8 0.4/27 2.9)

BOLT 24.5 5 (2.5 0.5/18 3.6)

(220 mm)

Torque N

m (kgfm/lbft)

NUT 44

14.7 (4.5 1.5/32.5 10.8)

BOLT 63.8 5 (6.5 0.5/47 3.6)

Apply the recommended liquid gasket or its equivalent to the

sealing side of the axle case and the carrier.

To install the axle shaft assembly, follow

the reassembly procedure outline in the

“Rear axle shaft” section.

2. Axle Shaft

Torque N

m (kgfm/lbft)

73.6

5 (7.5 0.5/54.2 3.6)

1. Propeller Shaft

Torque N

m (kgfm/lbft)

194 mm 35.3

2.9 (3.6 0.3/26 2.2)

220 mm 62.8 3.9 (6.4 0.4/46.3 2.9)

Page 14 of 1600

4B-18 REAR AXLE

DISASSEMBLY

MAJOR COMPONENTS

Disassembly Steps

1. Side bearing cap

2. Side bearing outer race

3. Differential cage assembly and ring gear

4. Side bearing

5. Backlash and side bearing preload

adjusting shim

6. Flange nut and washer

7. Flange assembly

8. Drive pinion shaft assembly

9. Inner bearing

10. Pinion depth adjusting shim

11. Drive pinion shaft

12. Collapsible spacer

13. Oil seal

14. Outer bearing

15. Inner bearing outer race

16. Outer bearing outer race

Page 15 of 1600

REAR AXLE 4B-19

Important Operations

Before disassembling, make a pattern check using the method

described later in this section under "Gear Tooth Contact

Pattern Check and Adjustments". This check will help

determine what service should be performaed on the

differential components.

On some bench operations, it may be advantageous to use a

holding fixture and a holding fixture base.

Tool 5-8840-0275-0 (J-37264) and 5-8840-0003-0 (J-3289-20)

are available tools that work well for this purpose.

1. Bearing Cap

Apply an alignment mark to the side bearing cap and

differential carrier.

2. Side Bearing Outer Race

After removal, keep the right and left side bearing assemblies

separate to maintain inner and outer race combinations.

4. Side Bearing

5. Backlash and Side Bearing Preload Adjusting Shim

Remover : 5-8840-0013-0 (J-22888)

Adapter : 9-8521-1743-0 (J-8107-2) (194 mm)

5-8840-2196-0 (J-8107-4) (220 mm)

Carefully record the thickness of each side bearing and each

shim pack. Keep them separated and in order for later

reassembly.

6. Flange nut and washer (194 mm)

Holder : 5-8840-0133-0

(J-8614-01)

Page 16 of 1600

4B-20 REAR AXLE

Flange Nut and Washer (220 mm)

Holder : 5-8840-2157-0

(J-37221)

8. Drive Pinion Shaft Assembly

Hold a soft metal rod against the end of the drive pinion. Drive

out the pinion from the carrier by tapping the hammer against

the metal rod.

Installer : 9-8521-5032-0

9. Inner Bearing

Remove the pinion bearing using a separator and a press.

Separator : 5-8840-0015-0 (194 mm)

(J-22912-01)

: 5-8840-2197-0 (220 mm)

(J-37452)

Inner bearing outer

race15.Inner Bearing Outer Race

16.Outer Bearing Outer Race

Remove the inner bearing outer race and the outer bearing

outer race by using a brass bar and a hammer.

Other bearing outer

race

Page 17 of 1600

REAR AXLE 4B-21

MINOR COMPONENTS

DIFFERENTIAL ASSEMBLY

Disassembly Steps

1. Ring gear

2. Lock pin

3. Cross pin

4. Pinion gear

5. Thrust block6. Side gear

7. Thrust washer

8. Differential cage

Page 18 of 1600

4B-22 REAR AXLE

Important Operations

1. Ring Gear

Take care not to damage the ring gear or the differential case

when removing the ring gear. Never try to wedge a tool

between the two faces.

2. Lock Pin

Drive out the pinion shaft lock pin with a long drift punch. It

may be necessary to first remove the stakes in the lock pin with

a 5 mm drill.

3. Cross Pin

(1) Check the amount of backlash before removal.

Backlash mm(in)

194 mm 0.03 - 0.08 (0.001 - 0.003)

220 mm 0.13 - 0.18 (0.005-0.007)

(2) Remove the cross pin with a brass drift punch, and take out

the pinion gears, side gears, thrust block and thrust

washers from the differential cage.

Page 19 of 1600

REAR AXLE 4B-23

LIMITED SLIP DIFFERENTIAL (LSD)

(FOR RING SIZE 194 mm)

Disassembly Steps

1. Spring pin

2. Pinion spider

3. Thrust block

4. Pinion washer

5. Pinion gear

6. Side gear

7. Friction disc and plate assembly8. Side gear

9. Friction disc and plate assembly

10. Differential cage

11. Sleeve

12. Spring plate

13. Disc spring

14. Disc and plate

Page 20 of 1600

4B-24 REAR AXLE

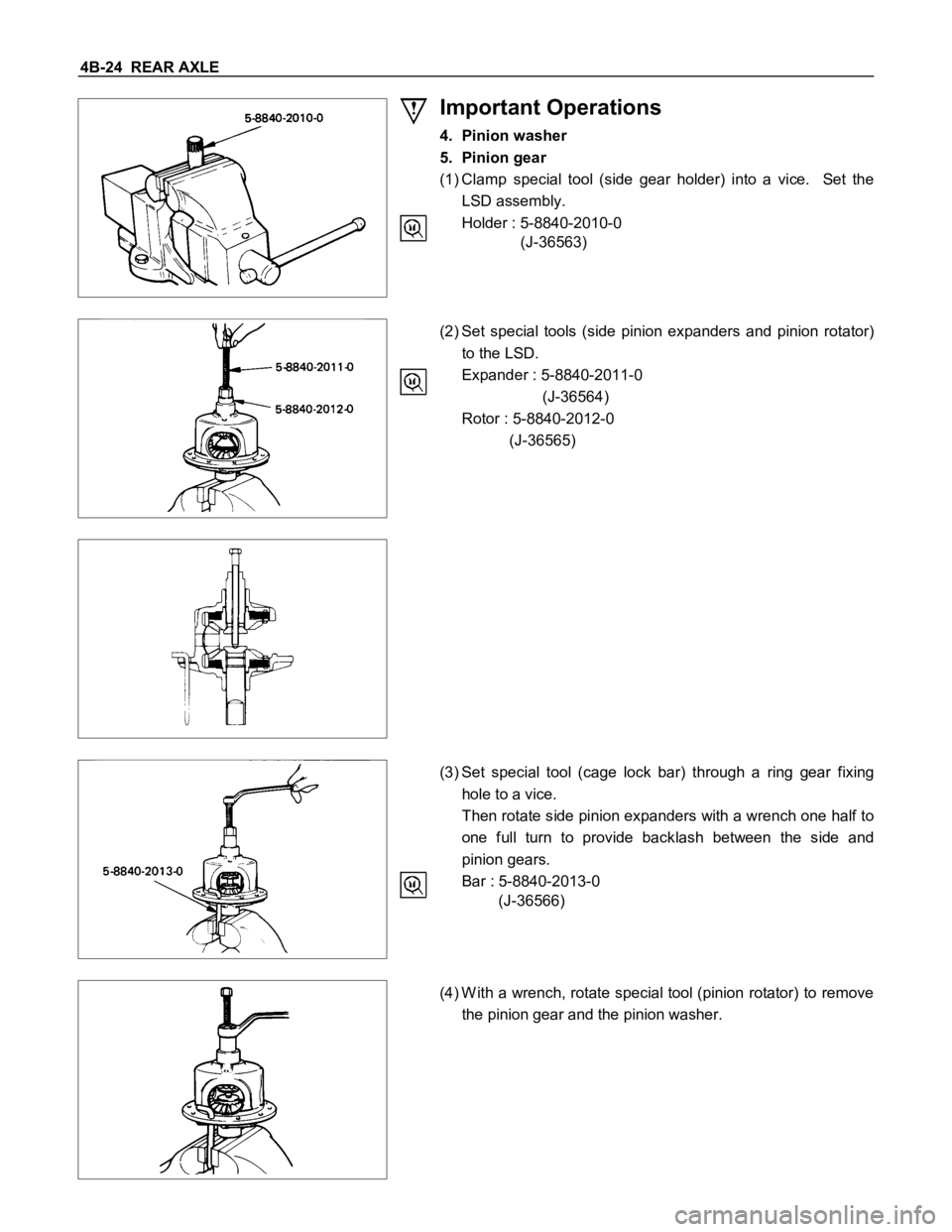

Important Operations

4. Pinion washer

5. Pinion gear

(1) Clamp special tool (side gear holder) into a vice. Set the

LSD assembly.

Holder : 5-8840-2010-0

(J-36563)

(2) Set special tools (side pinion expanders and pinion rotator)

to the LSD.

Expander : 5-8840-2011-0

(J-36564)

Rotor : 5-8840-2012-0

(J-36565)

(3) Set special tool (cage lock bar) through a ring gear fixing

hole to a vice.

Then rotate side pinion expanders with a wrench one half to

one full turn to provide backlash between the side and

pinion gears.

Bar : 5-8840-2013-0

(J-36566)

(4) W ith a wrench, rotate special tool (pinion rotator) to remove

the pinion gear and the pinion washer.

Trending: wiring, clock, dashboard, instrument panel, glove box, automatic transmission, window