ISUZU TFS SERIES 1997 Service Manual

Manufacturer: ISUZU, Model Year: 1997, Model line: TFS SERIES, Model: ISUZU TFS SERIES 1997Pages: 1600, PDF Size: 40.98 MB

Page 41 of 1600

REAR AXLE 4B-45

(6) Record the pinion depth code on the head of the drive

pinion.

The number indicates a necessary change in the pinion

mounting distance. A plus number indicates the need for a

greater mounting distance (which can be achieved by

decreasing the shim thickness). A minus number indicates

the need for a smaller mounting distance (which can be

achieved by increasing the shim thickness). If examination

reveals pinion depth code "0", the pinion is "nominal".

Page 42 of 1600

![ISUZU TFS SERIES 1997 Service Manual 4B-46 REAR AXLE

(7) Select the shim using table below.

[194 mm]mm(in)Pinion

marking

+10 +8 +6 +4 +2 0 -2 -4 -6 -8 -10Dial indicator

reading (inches)

0.0812.18 (0.0858)0.0822.18 (0.0858) 2.20 (0.0866) ISUZU TFS SERIES 1997 Service Manual 4B-46 REAR AXLE

(7) Select the shim using table below.

[194 mm]mm(in)Pinion

marking

+10 +8 +6 +4 +2 0 -2 -4 -6 -8 -10Dial indicator

reading (inches)

0.0812.18 (0.0858)0.0822.18 (0.0858) 2.20 (0.0866)](/img/61/57182/w960_57182-41.png)

4B-46 REAR AXLE

(7) Select the shim using table below.

[194 mm]mm(in)Pinion

marking

+10 +8 +6 +4 +2 0 -2 -4 -6 -8 -10Dial indicator

reading (inches)

0.0812.18 (0.0858)0.0822.18 (0.0858) 2.20 (0.0866)0.0832.18 (0.0858) 2.20 (0.0866) 2.24 (0.0882)0.0842.18 (0.0858) 2.20 (0.0866) 2.24 (0.0882) 2.26 (0.0890)0.0852.18 (0.0858) 2.20 (0.0866) 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898)0.0862.18 (0.0858) 2.20 (0.0866) 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898) 2.32 (0.0914)0.087 2.18 (0.0858) 2.20 (0.0866) 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898) 2.32 (0.0914) 2.34 (0.0921)0.088 2.18 (0.0858) 2.20 (0.0866) 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898) 2.32 (0.0914) 2.34 (0.0921) 2.36 (0.0929)0.089 2.18 (0.0858) 2.20 (0.0866) 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898) 2.32 (0.0914) 2.34 (0.0921) 2.36 (0.0929) 2.38 (0.0937)0.090 2.18 (0.0858) 2.20 (0.0866) 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898) 2.32 (0.0914) 2.34 (0.0921) 2.36 (0.0929) 2.38 (0.0937) 2.42 (0.0953)0.091 2.18 (0.0858) 2.20 (0.0866) 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898) 2.32 (0.0914) 2.34 (0.0921) 2.36 (0.0929) 2.38 (0.0937) 2.42 (0.0953) 2.44 (0.0961)0.092 2.20 (0.0866) 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898) 2.32 (0.0914) 2.34 (0.0921) 2.36 (0.0929) 2.38 (0.0937) 2.42 (0.0953) 2.44 (0.0961) 2.46 (0.0969)0.093 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898) 2.32 (0.0914) 2.34 (0.0921) 2.36 (0.0929) 2.38 (0.0937) 2.42 (0.0953) 2.44 (0.0961) 2.46 (0.0969) 2.48 (0.0977)0.094 2.26 (0.0890) 2.28 (0.0898) 2.32 (0.0914) 2.34 (0.0921) 2.36 (0.0929) 2.38 (0.0937) 2.42 (0.0953) 2.44 (0.0961) 2.46 (0.0969) 2.48 (0.0977) 2.52 (0.0992)0.095 2.28 (0.0898) 2.32 (0.0914) 2.34 (0.0921) 2.36 (0.0929) 2.38 (0.0937) 2.42 (0.0953) 2.44 (0.0961) 2.46 (0.0969) 2.48 (0.0977) 2.52 (0.0992) 2.54 (0.1000)0.096 2.32 (0.0914) 2.34 (0.0921) 2.36 (0.0929) 2.38 (0.0937) 2.42 (0.0953) 2.44 (0.0961) 2.46 (0.0969) 2.48 (0.0977) 2.52 (0.0992) 2.54 (0.1000) 2.56 (0.1008)0.097 2.34 (0.0921) 2.36 (0.0929) 2.38 (0.0937) 2.42 (0.0953) 2.44 (0.0961) 2.46 (0.0969) 2.48 (0.0977) 2.52 (0.0992) 2.54 (0.1000) 2.56 (0.1008)0.098 2.36 (0.0929) 2.38 (0.0937) 2.42 (0.0953) 2.44 (0.0961) 2.46 (0.0969) 2.48 (0.0977) 2.52 (0.0992) 2.54 (0.1000) 2.56 (0.1008)0.099 2.38 (0.0937) 2.42 (0.0953) 2.44 (0.0961) 2.46 (0.0969) 2.48 (0.0977) 2.52 (0.0992) 2.54 (0.1000) 2.56 (0.1008)0.000 2.42 (0.0953) 2.44 (0.0961) 2.46 (0.0969) 2.48 (0.0977) 2.52 (0.0992) 2.54 (0.1000) 2.56 (0.1008)0.001 2.44 (0.0961) 2.46 (0.0969) 2.48 (0.0977) 2.52 (0.0992) 2.54 (0.1000) 2.56 (0.1008)0.002 2.46 (0.0969) 2.48 (0.0977) 2.52 (0.0992) 2.54 (0.1000) 2.56 (0.1008)0.003 2.48 (0.0977) 2.52 (0.0992) 2.54 (0.1000) 2.56 (0.1008)0.004 2.52 (0.0992) 2.54 (0.1000) 2.56 (0.1008)0.005 2.54 (0.1000) 2.56 (0.1008)0.006 2.56 (0.1008)

[220 mm]mm(in)

Pinion

marking

+10 +8 +6 +4 +2 0 -2 -4 -6 -8 -10Dial indicator

reading (inches)

0.0731.94 (0.0764) 1.96 (0.0772)0.0741.94 (0.0764) 1.96 (0.0772) 1.98 (0.0779)0.0751.94 (0.0764) 1.96 (0.0772) 1.98 (0.0779) 2.00 (0.0787)0.0761.94 (0.0764) 1.96 (0.0772) 1.98 (0.0779) 2.00 (0.0787) 2.02 (0.0795) 2.04 (0.0803)0.0771.96 (0.0772) 1.98 (0.0779) 2.00 (0.0787) 2.02 (0.0787) 2.04 (0.0803) 2.06 (0.0811)0.078 1.94 (0.0764) 1.96 (0.0772) 1.98 (0.0779) 2.00 (0.0787) 2.02 (0.0787) 2.04 (0.0803) 2.06 (0.0811) 2.08 (0.0819)0.079 1.94 (0.0764) 1.96 (0.0772) 1.98 (0.0779) 2.00 (0.0787) 2.02 (0.0787) 2.04 (0.0803) 2.06 (0.0811) 2.08 (0.0819) 2.10 (0.0827)0.080 1.94 (0.0764) 1.96 (0.0772) 1.98 (0.0779) 2.00 (0.0787) 2.02 (0.0787) 2.04 (0.0803) 2.06 (0.0811) 2.08 (0.0819) 2.10 (0.0827) 2.12 (0.0835) 2.14 (0.0842)0.081 1.96 (0.0772) 1.98 (0.0779) 2.00 (0.0787) 2.02 (0.0787) 2.04 (0.0803) 2.06 (0.0811) 2.08 (0.0819) 2.10 (0.0827) 2.12 (0.0835) 2.14 (0.0842) 2.16 (0.0850)0.082 1.98 (0.0779) 2.00 (0.0787) 2.02 (0.0787) 2.04 (0.0803) 2.06 (0.0811) 2.08 (0.0819) 2.10 (0.0827) 2.12 (0.0835) 2.14 (0.0842) 2.16 (0.0850) 2.18 (0.0858)0.083 2.00 (0.0787) 2.02 (0.0787) 2.04 (0.0803) 2.06 (0.0811) 2.08 (0.0819) 2.10 (0.0827) 2.12 (0.0835) 2.14 (0.0842) 2.16 (0.0850) 2.18 (0.0858) 2.20 (0.0866)0.084 2.04 (0.0803) 2.06 (0.0811) 2.08 (0.0819) 2.10 (0.0827) 2.12 (0.0835) 2.14 (0.0842) 2.16 (0.0850) 2.18 (0.0858) 2.20 (0.0866) 2.22 (0.0874) 2.24 (0.0882)0.085 2.06 (0.0811) 2.08 (0.0819) 2.10 (0.0827) 2.12 (0.0835) 2.14 (0.0842) 2.16 (0.0850) 2.18 (0.0858) 2.20 (0.0866) 2.22 (0.0874) 2.24 (0.0882) 2.26 (0.0890)0.086 2.08 (0.0819) 2.10 (0.0827) 2.12 (0.0835) 2.14 (0.0842) 2.16 (0.0850) 2.18 (0.0858) 2.20 (0.0866) 2.22 (0.0874) 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898)0.087 2.12 (0.0835) 2.14 (0.0842) 2.16 (0.0850) 2.18 (0.0858) 2.20 (0.0866) 2.22 (0.0874) 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898) 2.30 (0.0906) 2.32 (0.0913)0.088 2.14 (0.0842) 2.16 (0.0850) 2.18 (0.0858) 2.20 (0.0866) 2.22 (0.0874) 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898) 2.30 (0.0906) 2.32 (0.0913) 2.34 (0.0921)0.089 2.16 (0.0850) 2.18 (0.0858) 2.20 (0.0866) 2.22 (0.0874) 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898) 2.30 (0.0906) 2.32 (0.0913) 2.34 (0.0921) 2.36 (0.0929)0.090 2.18 (0.0858) 2.20 (0.0866) 2.22 (0.0874) 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898) 2.30 (0.0906) 2.32 (0.0913) 2.34 (0.0921) 2.36 (0.0929)0.091 2.22 (0.0874) 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898) 2.30 (0.0906) 2.32 (0.0913) 2.34 (0.0921) 2.36 (0.0929)0.092 2.24 (0.0882) 2.26 (0.0890) 2.28 (0.0898) 2.30 (0.0906) 2.32 (0.0913) 2.34 (0.0921) 2.36 (0.0929)0.093 2.26 (0.0890) 2.28 (0.0898) 2.30 (0.0906) 2.32 (0.0913) 2.34 (0.0921) 2.36 (0.0929)0.094 2.28 (0.0898) 2.30 (0.0906) 2.32 (0.0913) 2.34 (0.0921) 2.36 (0.0929)0.095 2.32 (0.0913) 2.34 (0.0921) 2.36 (0.0929)0.096 2.34 (0.0921) 2.36 (0.0929)0.097 2.36 (0.0929)

Note :

When ordering shims, find the part number in the Parts Catalog by using the thickness of the shims listed

in the above table.

Page 43 of 1600

REAR AXLE 4B-47

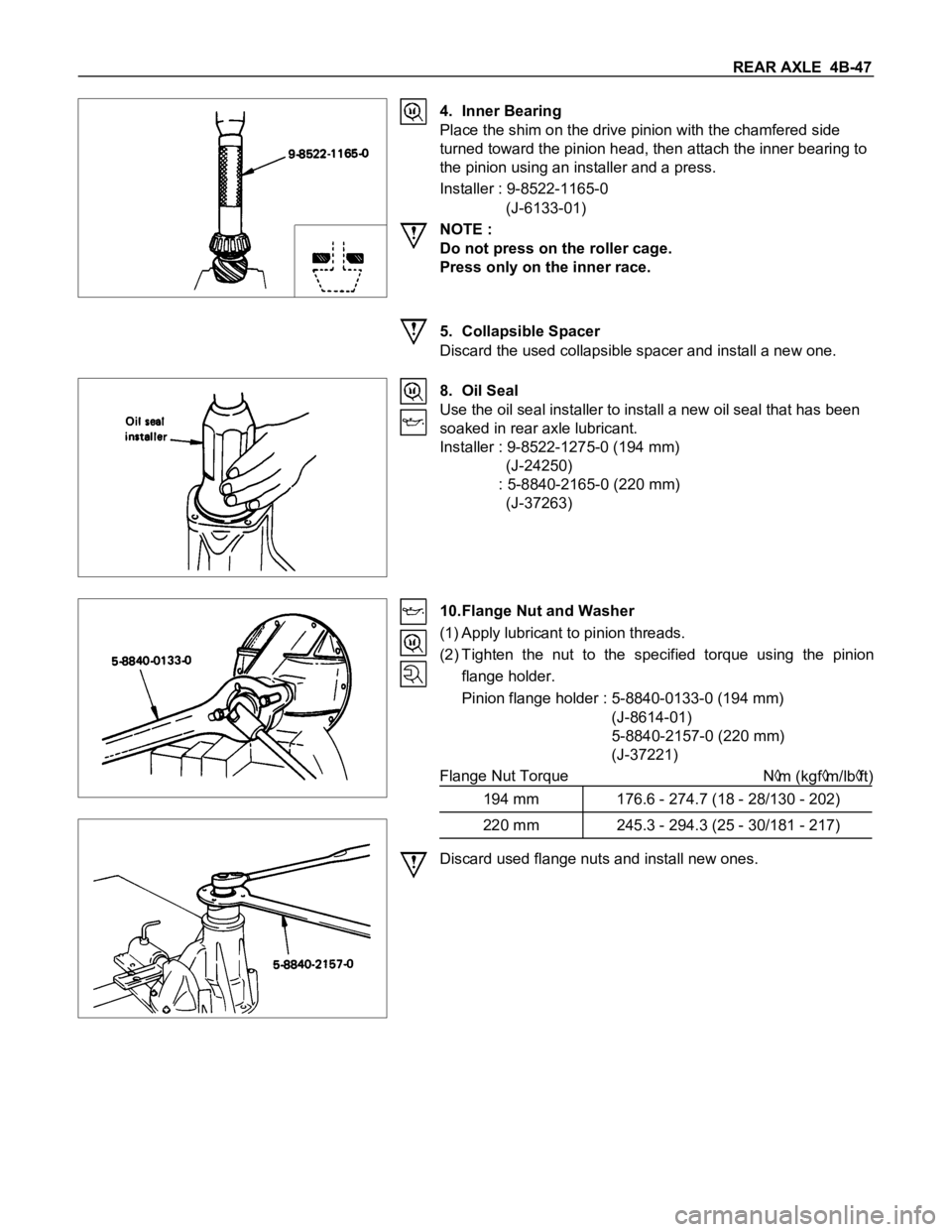

4. Inner Bearing

Place the shim on the drive pinion with the chamfered side

turned toward the pinion head, then attach the inner bearing to

the pinion using an installer and a press.

Installer : 9-8522-1165-0

(J-6133-01)

NOTE :

Do not press on the roller cage.

Press only on the inner race.

5. Collapsible Spacer

Discard the used collapsible spacer and install a new one.

8. Oil Seal

Use the oil seal installer to install a new oil seal that has been

soaked in rear axle lubricant.

Installer : 9-8522-1275-0 (194 mm)

(J-24250)

: 5-8840-2165-0 (220 mm)

(J-37263)

10.Flange Nut and Washer

(1) Apply lubricant to pinion threads.

(2) Tighten the nut to the specified torque using the pinion

flange holder.

Pinion flange holder : 5-8840-0133-0 (194 mm)

(J-8614-01)

5-8840-2157-0 (220 mm)

(J-37221)

Flange Nut Torque N

m (kgfm/lbft)

194 mm 176.6 - 274.7 (18 - 28/130 - 202)

220 mm 245.3 - 294.3 (25 - 30/181 - 217)

Discard used flange nuts and install new ones.

Page 44 of 1600

4B-48 REAR AXLE

(3) Pinion bearing preload.

(a) Measure the bearing preload by using a torque wrench.

Note the scale reading required to rotate the flange.

(b) Continue tightening until the specified starting torque is

obtained.

Pinion Bearing Preload Starting Torque N

m (kgfm/lbft)

194 mm 64 - 113 (6.5 - 11.5/47 - 72)

220 mm 69 - 127 (7 - 13/51 - 94)

11.Backlash and Pre-load Adjusting Shim

(1) Attach the side bearing to the differential assembly without

shims. Support the opposite side using a pilot to prevent

bearing damage.

1Installer : 9-8522-1164-0 (194 mm)

(J-24244)

: 5-8840-2162-0 (220 mm)

(J-37257)

2Drive handle : 5-8840-0007-0

(J-8092)

3Pilot : 9-8521-1743-0

(J-8107-2)

(2) Position the differential cage assembly with the bearing

outer races to the side bearing bores of the carrier.

(3) Using two sets of feeler gauges, insert a feeler stock of

sufficient thickness between each bearing outer race and

the carrier to remove all end play. Make certain the feeler

stock is pushed to the bottom of the bearing bores.

Mount the dial indicator on the carrier so that the indicator

stem is at right angles to a tooth on the ring gear.

Dial indicator : 5-8840-0126-0

(J-8001)

Page 45 of 1600

REAR AXLE 4B-49

(4) Adjust the feeler gauge thickness from side to side until the

ring gear backlash is in the specified range.

Backlash mm(in)

194 mm 0.13 - 0.18 (0.005 - 0.007)

220 mm 0.15 - 0.20 (0.006 - 0.008)

With zero end play and correct backlash established, remove

feeler gauge packs, determine the thickness of shims required

and add 0.05 mm (0.002 in.) to each shim pack to provide side

bearing preload. Always use new shims.

(5) Remove side bearing

Remover : 5-8840-0013-0

(J-22888)

Adapter : 9-8521-1743-0 (194 mm)

(J-8107-2)

: 5-8840-2196-0 (220 mm)

(J-8107-4)

12.Side Bearing

Install side bearings together with selected shims.

1Installer : 9-8522-1164-0 (194 mm)

(J-24244)

: 5-8840-2162-0 (220 mm)

(J-37257)

2Drive handle : 5-8840-0007-0 (J-8092)

3Pilot : 9-8521-1743-0 (J-8107-2)

15.Bearing Cap

Align the setting marks applied at the time of disassembly.

Page 46 of 1600

4B-50 REAR AXLE

16.Bolt

Cap Bolt Torque N

m (kgfm/lbft)

194 mm 98.1

9.8 (10 1/72 7.2)

220 mm 107.9 9.8 (11 1/79.5 7.2)

Measure the amount of run-out of the ring gear at its rear face.

Run-Out mm(in)

Standard Limit

194 mm

220 mm0.02 (0.001) 0.05 (0.002)

Gear Tooth Contact Pattern Check and

Adjustment

Apply a thin coat of prussian blue or equivalent to the faces of

7 - 8 teeth of the ring gear. Check the impression of contact

obtained on the ring gear teeth and make necessary

adjustment as described below if the contact is abnormal.

Page 47 of 1600

REAR AXLE 4B-51

17.Differential Assembly

(1) Clean the faces of the rear axle case and differential carrier

and apply the recommended liquid gasket or its equivalent.

(2) Mount the differential case and the carrier assembly to the

rear axle case and tighten the nuts and bolts.

Torque N

m (kgfm/lbft)

Nut 37.3

3.9 (3.8 0.4/27 2.9)

bolt 24.5 5 (2.5 0.5/18 3.6)

Nut 44 14.7 (4.5 1.5/32.5 10.8)

Bolt 68.5 5 (6.5 0.5/47 3.6)220 mm 194 mm

(3) Install the axle shaft assemblies as instructed earlier in this

section under "Axle Shaft Reassembly".

(4) Fill the axle case with hypoid gear lubricant to just below the

filler hole.

Lubricant Capacity liter (US/UK gal.)

194 mm 1.5 (0.4/0.33)

220 mm 1.8 (0.48/0.4)

Check owners manual for correct type and viscosity of gear

lubricant required.

Page 48 of 1600

4B-52 REAR AXLE

TROUBLESHOOTING

Refer to this Section to quickly diagnose and repair rear axle problems.

Each troubleshooting chart has three headings arranged from left to right.

(1) Checkpoint (2) Trouble Cause (3) Countermeasure

This Section is divided into five sub-sections:

1. Abnormal Rear Axle Noise

1) Noise when the engine is driving the vehicle

2) Noise when the vehicle is coasting

3) Intermittent noise

4) Noise when the vehicle is turning

5) Constant noise

2. Vibration

3. Oil Leakage

1) Differential carrier leakage

2) Axle case leakage

3) Axle case to inside hub leakage

4) Axle case to inside brake drum leakage

4. Power Not Being Transmitted to the Wheels (Propeller Shaft Operation is Normal)

Page 49 of 1600

REAR AXLE 4B-53

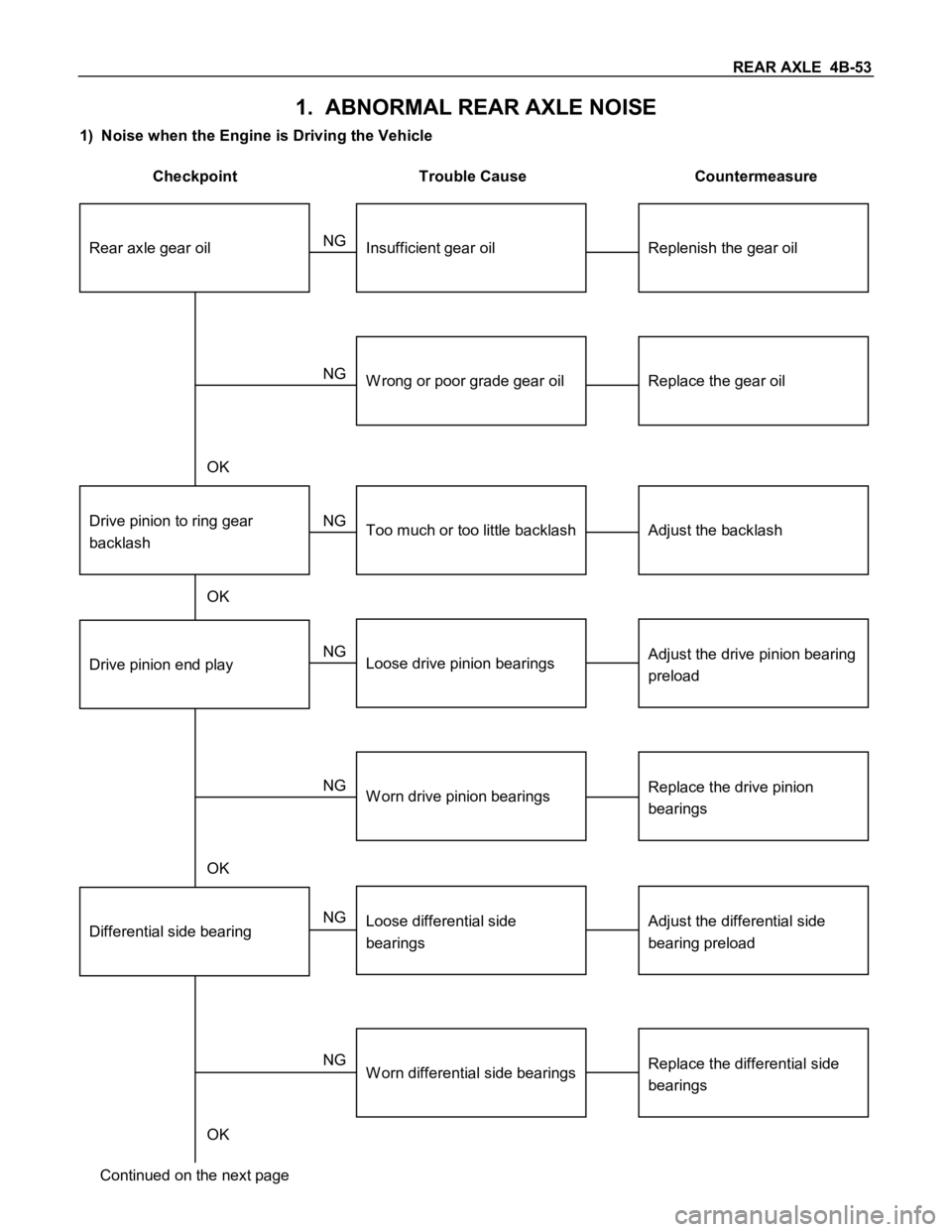

1. ABNORMAL REAR AXLE NOISE

1) Noise when the Engine is Driving the Vehicle

Checkpoint Trouble Cause Countermeasure

Replenish the gear oilInsufficient gear oil NG

Differential side bearingAdjust the differential side

bearing preload

Replace the drive pinion

bearings

Adjust the drive pinion bearing

preload

Replace the gear oil

Loose differential side

bearings

W orn drive pinion bearings

Loose drive pinion bearings

W rong or poor grade gear oil

Drive pinion to ring gear

backlash

Drive pinion end play

Adjust the backlashToo much or too little backlash

Continued on the next pageOK OK

NG NG NG NG NG

OK

OK

Rear axle gear oil

Replace the differential side

bearingsW orn differential side bearings NG

Page 50 of 1600

4B-54 REAR AXLE

Checkpoint Trouble Cause Countermeasure

Replace the drive pinion and

the ring gear as a setExcessive ring gear run-out

Replace the drive pinion and

the ring gear as a setDrive pinion and/or ring gear

damage

NG NGDrive pinion and ring gear Continued from the previous page

Replace the drive pinion and

the ring gear as a setW orn drive pinion and ring

gear NG

2) Noise when the Vehicle is Coasting

Checkpoint Trouble Cause Countermeasure

Replace the ring gear and the

pinion as a setRing gear damaged

Adjust the backlashInsufficient backlash

OK

Ring gearNG NG

Drive pinion and ring gear

backlash