ISUZU TFS SERIES 1997 Owner's Guide

TFS SERIES 1997

ISUZU

ISUZU

https://www.carmanualsonline.info/img/61/57182/w960_57182-0.png

ISUZU TFS SERIES 1997 Owner's Guide

Trending: steering wheel adjustment, length, air bleeding, clock setting, compression ratio, oil pressure, low oil pressure

Page 31 of 1600

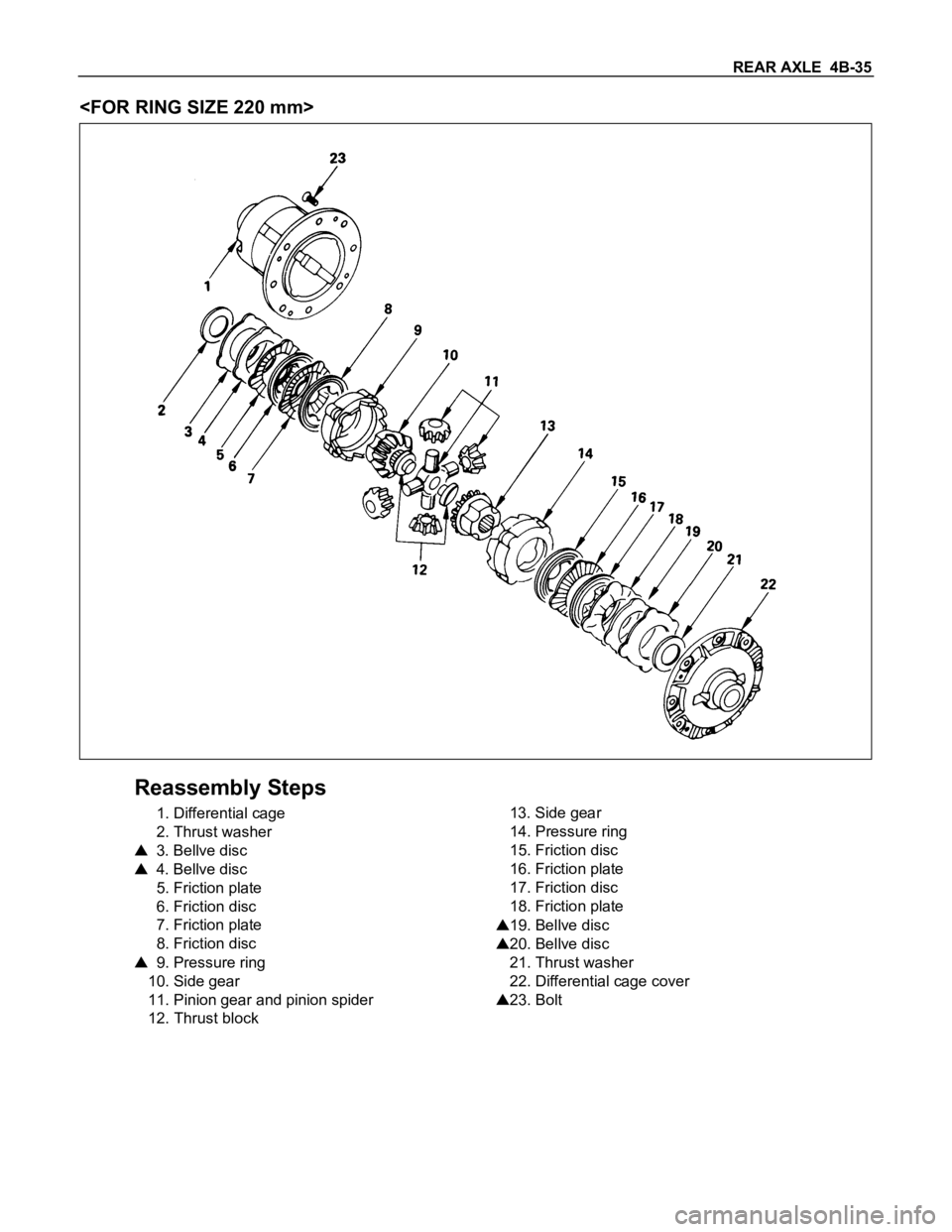

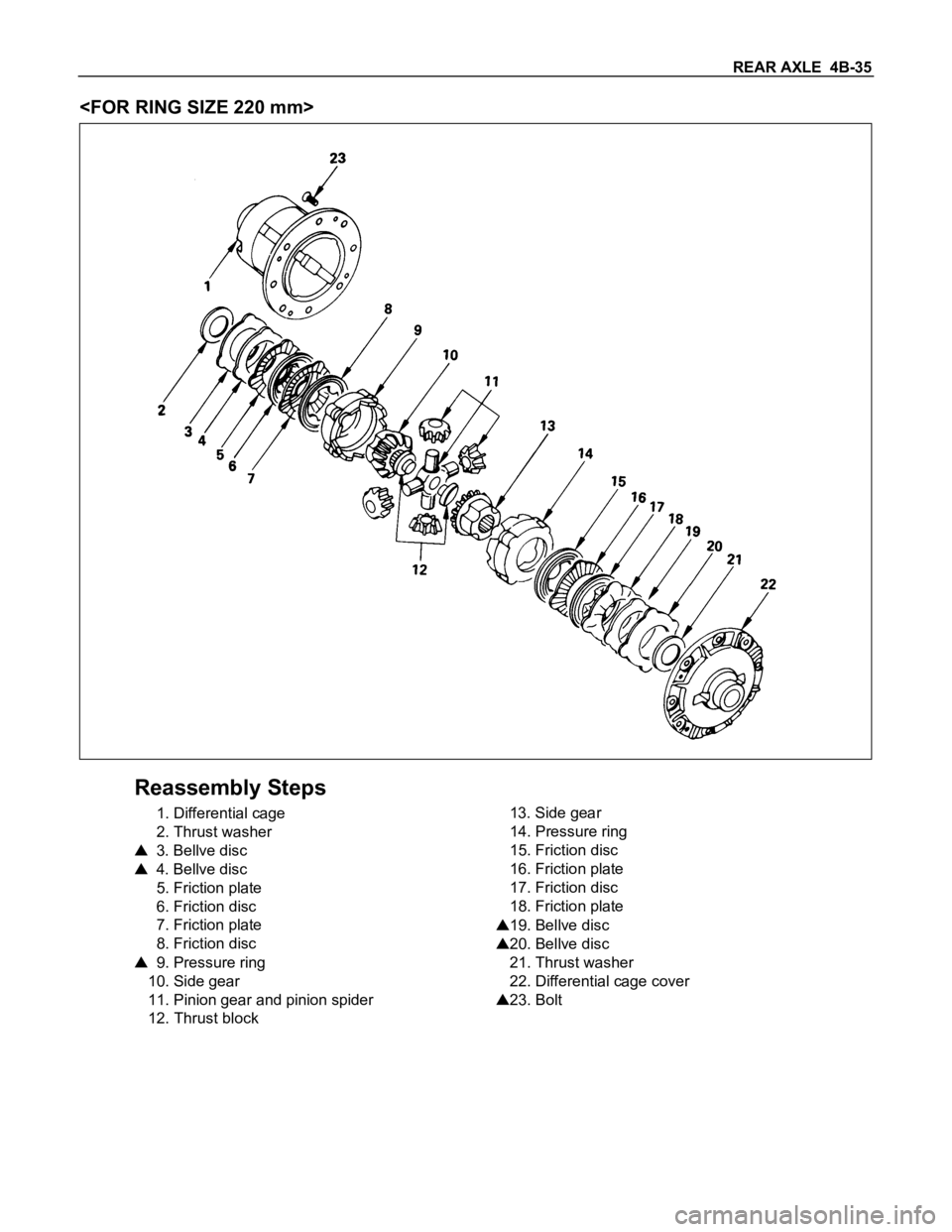

REAR AXLE 4B-35

Reassembly Steps

1. Differential cage

2. Thrust washer

3. Bellve disc

4. Bellve disc

5. Friction plate

6. Friction disc

7. Friction plate

8. Friction disc

9. Pressure ring

10. Side gear

11. Pinion gear and pinion spider

12. Thrust block13. Side gear

14. Pressure ring

15. Friction disc

16. Friction plate

17. Friction disc

18. Friction plate

19. Bellve disc

20. Bellve disc

21. Thrust washer

22. Differential cage cover

23. Bolt

Page 32 of 1600

4B-36 REAR AXLE

Adjustment of Clearance between

Friction Disc and Plate

1) Measuring depth of differential case

mm(in)

Standard (A-B) 80.58 (3.17)

(C) 10.58 (0.41)

2) Measuring overall length of pressure ring, friction disc and

plate assembly

Assembly pinion shaft with pressure ring, then friction

disc and plate.

Measure length between plates at both ends over V-

shape groove. (D)

3) After A, B, C and D dimensions are measured, perform

adjustment with the following procedure.

Measure disc spring :

1.75 mm (0.69 in)

2 pcs (E)

Measure thickness of plate spring

Standard dimension :

1.75 mm (0.069 in)

2 pcs (F)

4) Select a friction disc or plate so that ((A-B+C) - (D+E+F) =

0.06 to 0.20 mm (0.002 to 0.008 in.) and also the difference

in total dimension of friction disc and plate, plate spring and

disc spring (left/right side) does not exceed 0.05 mm (0.002

in.).

Thickness : 1.75, 1.85 mm

Adjusting Backlash of Side Gear in Axial

Direction

1) Measuring depth of differential case

mm(in.)

Standard (F-B) 82.03 (3.23)

(G) 12.03 (0.47)

Page 33 of 1600

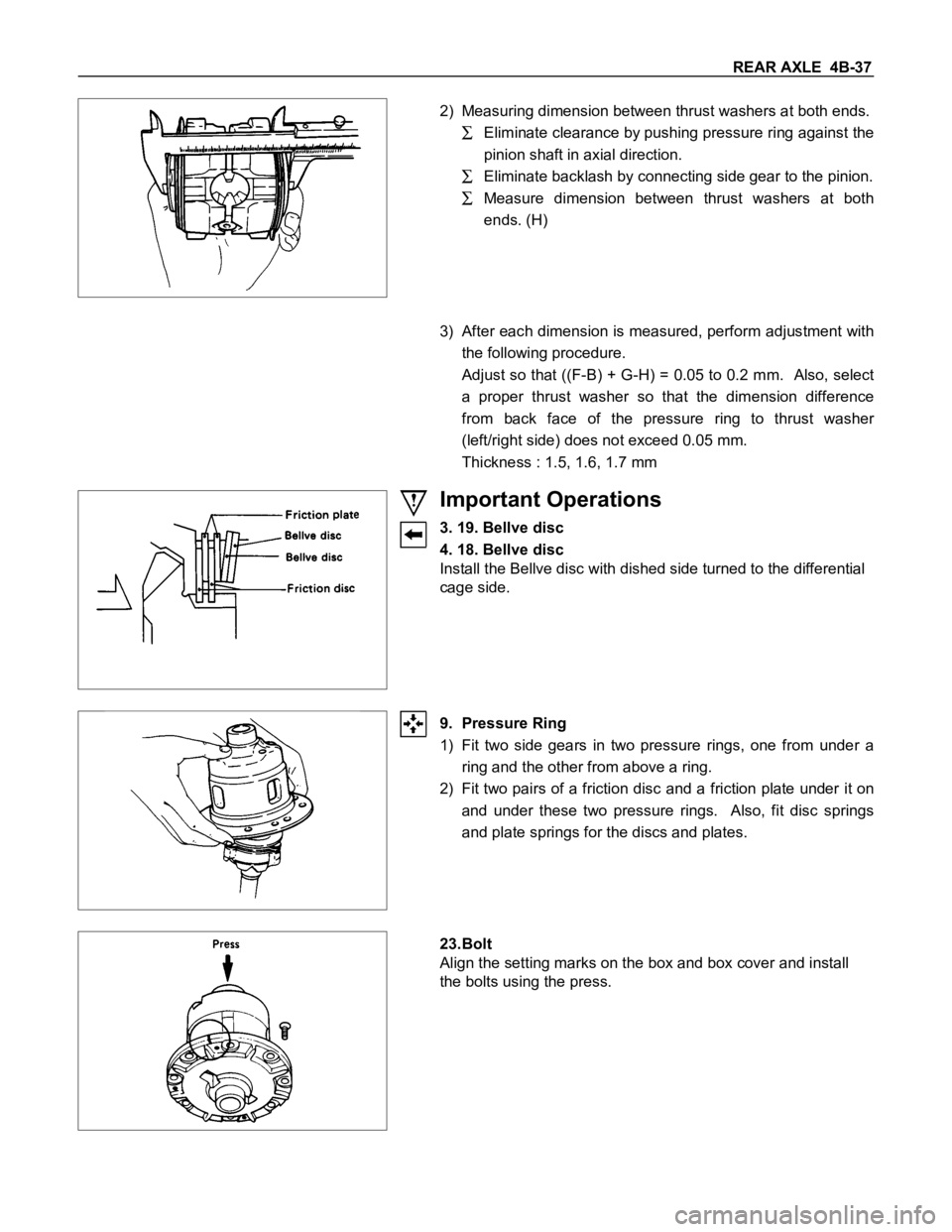

REAR AXLE 4B-37

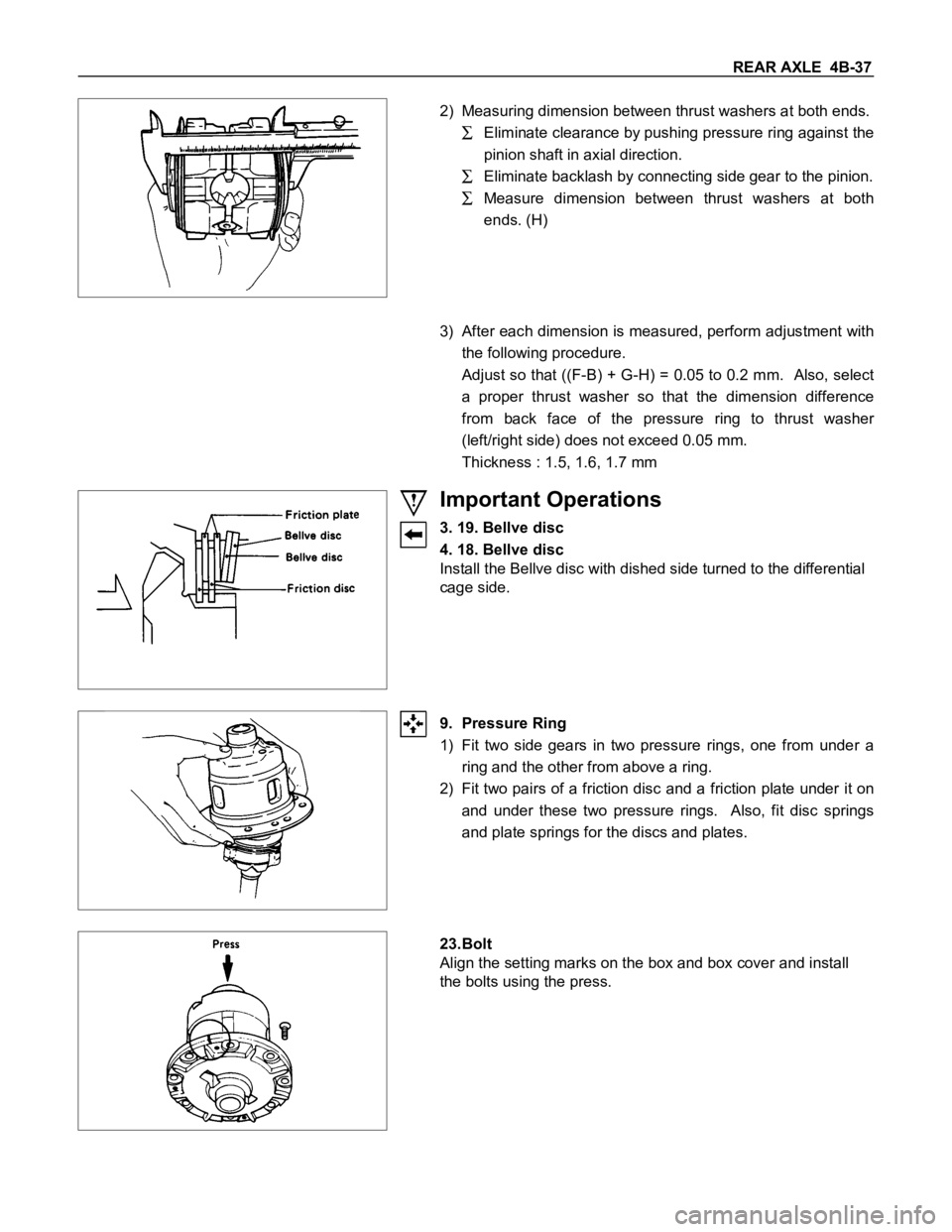

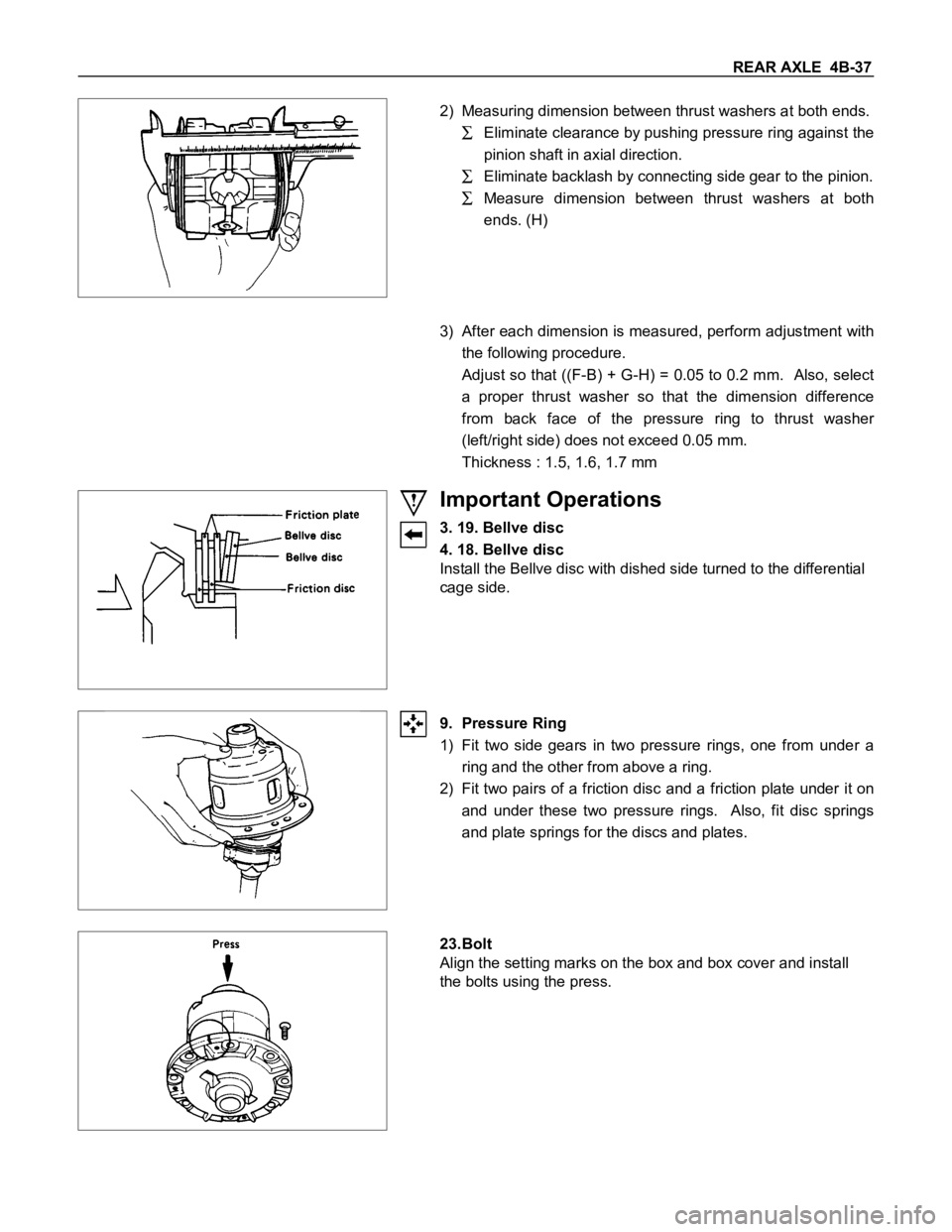

2) Measuring dimension between thrust washers at both ends.

Eliminate clearance by pushing pressure ring against the

pinion shaft in axial direction.

Eliminate backlash by connecting side gear to the pinion.

Measure dimension between thrust washers at both

ends. (H)

3) After each dimension is measured, perform adjustment with

the following procedure.

Adjust so that ((F-B) + G-H) = 0.05 to 0.2 mm. Also, select

a proper thrust washer so that the dimension difference

from back face of the pressure ring to thrust washer

(left/right side) does not exceed 0.05 mm.

Thickness : 1.5, 1.6, 1.7 mm

Important Operations

3. 19. Bellve disc

4. 18. Bellve disc

Install the Bellve disc with dished side turned to the differential

cage side.

9. Pressure Ring

1) Fit two side gears in two pressure rings, one from under a

ring and the other from above a ring.

2) Fit two pairs of a friction disc and a friction plate under it on

and under these two pressure rings. Also, fit disc springs

and plate springs for the discs and plates.

23.Bolt

Align the setting marks on the box and box cover and install

the bolts using the press.

Page 34 of 1600

4B-38 REAR AXLE

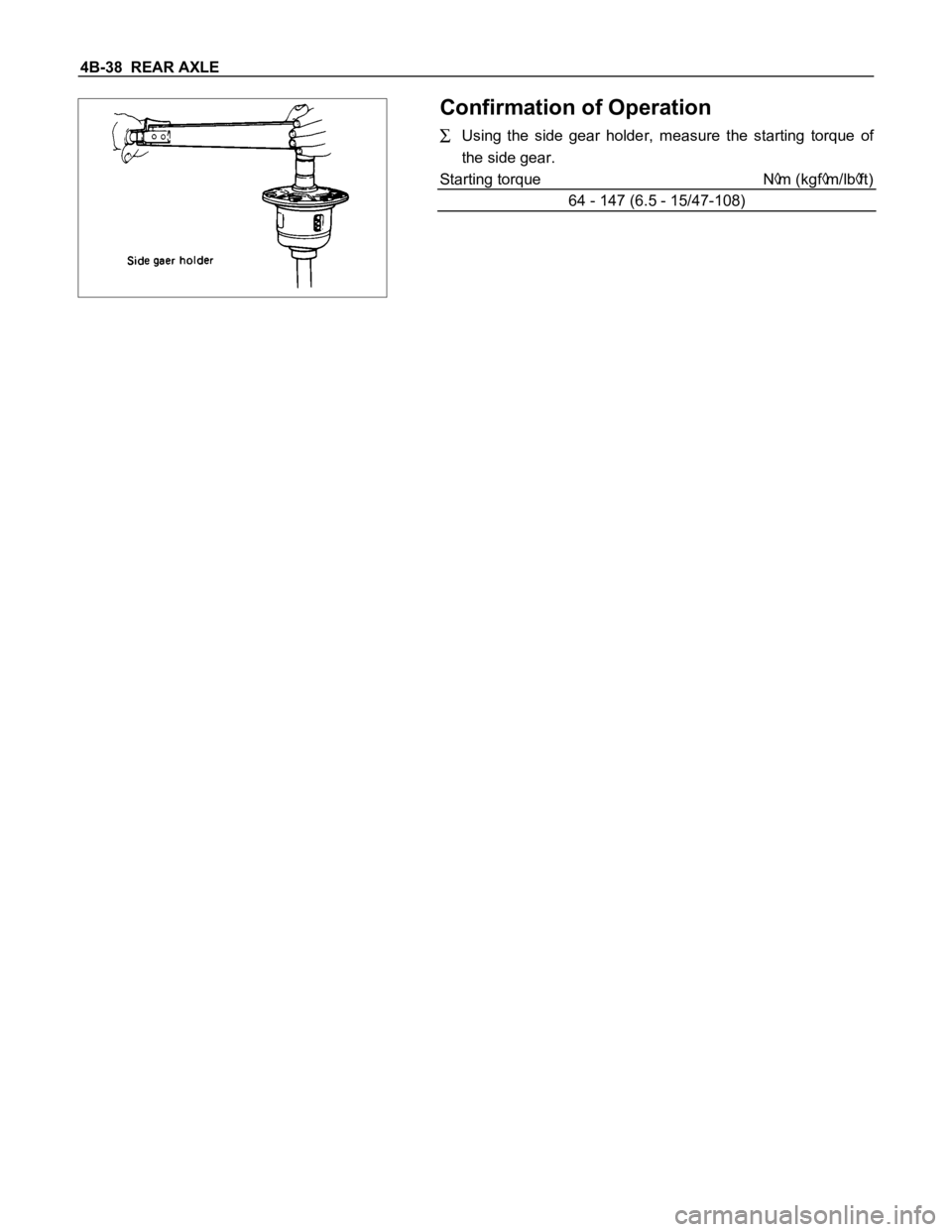

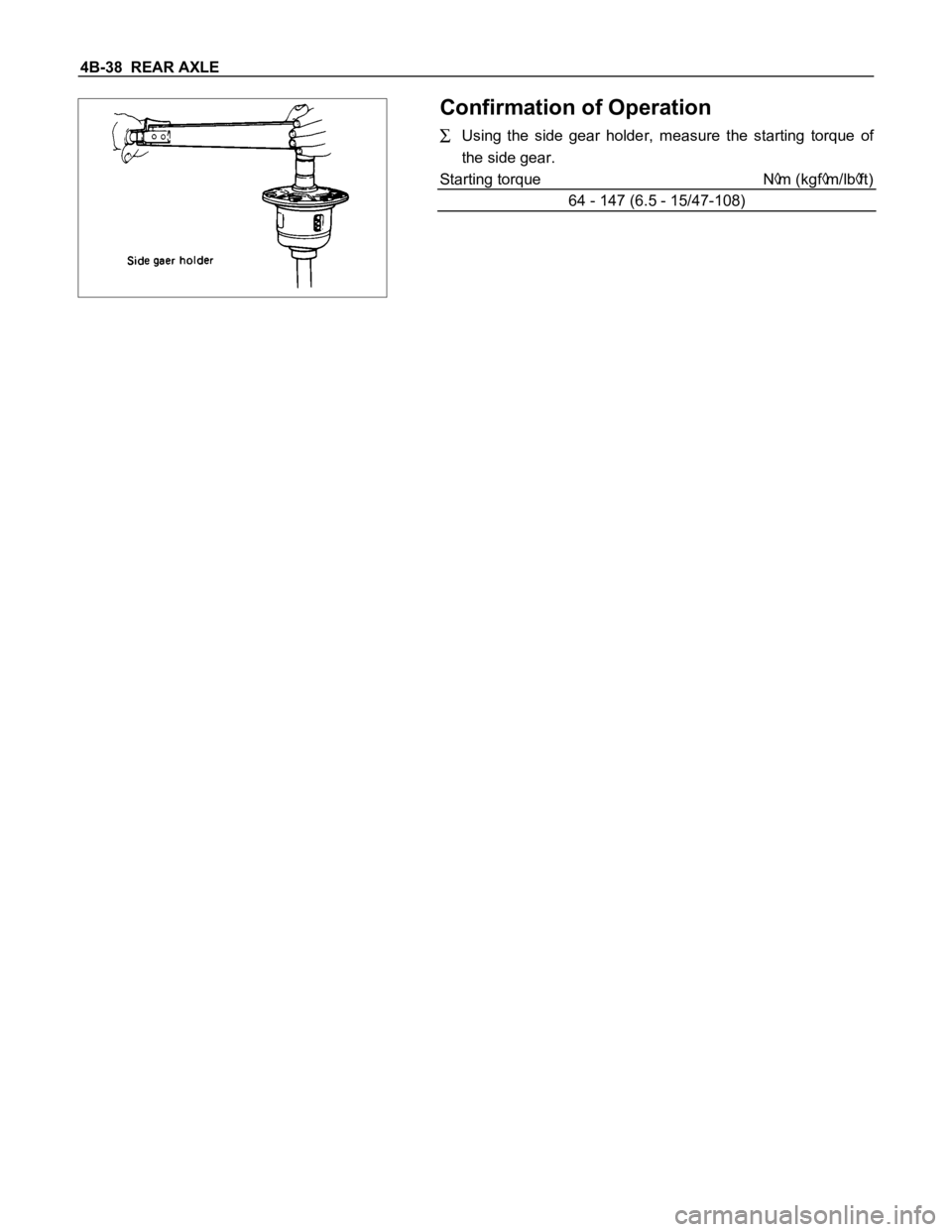

Confirmation of Operation

Using the side gear holder, measure the starting torque of

the side gear.

Starting torque N

m (kgfm/lbft)

64 - 147 (6.5 - 15/47-108)

Page 35 of 1600

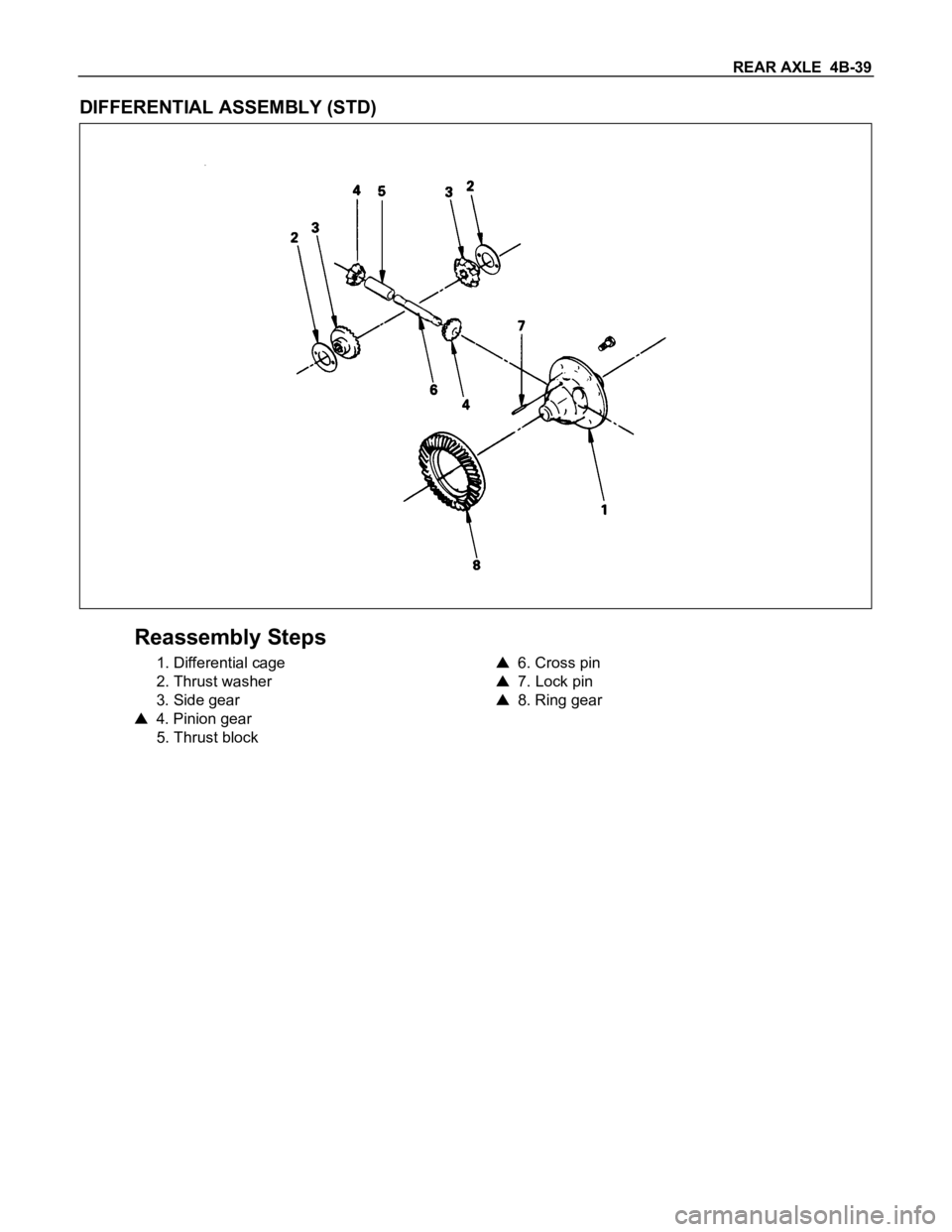

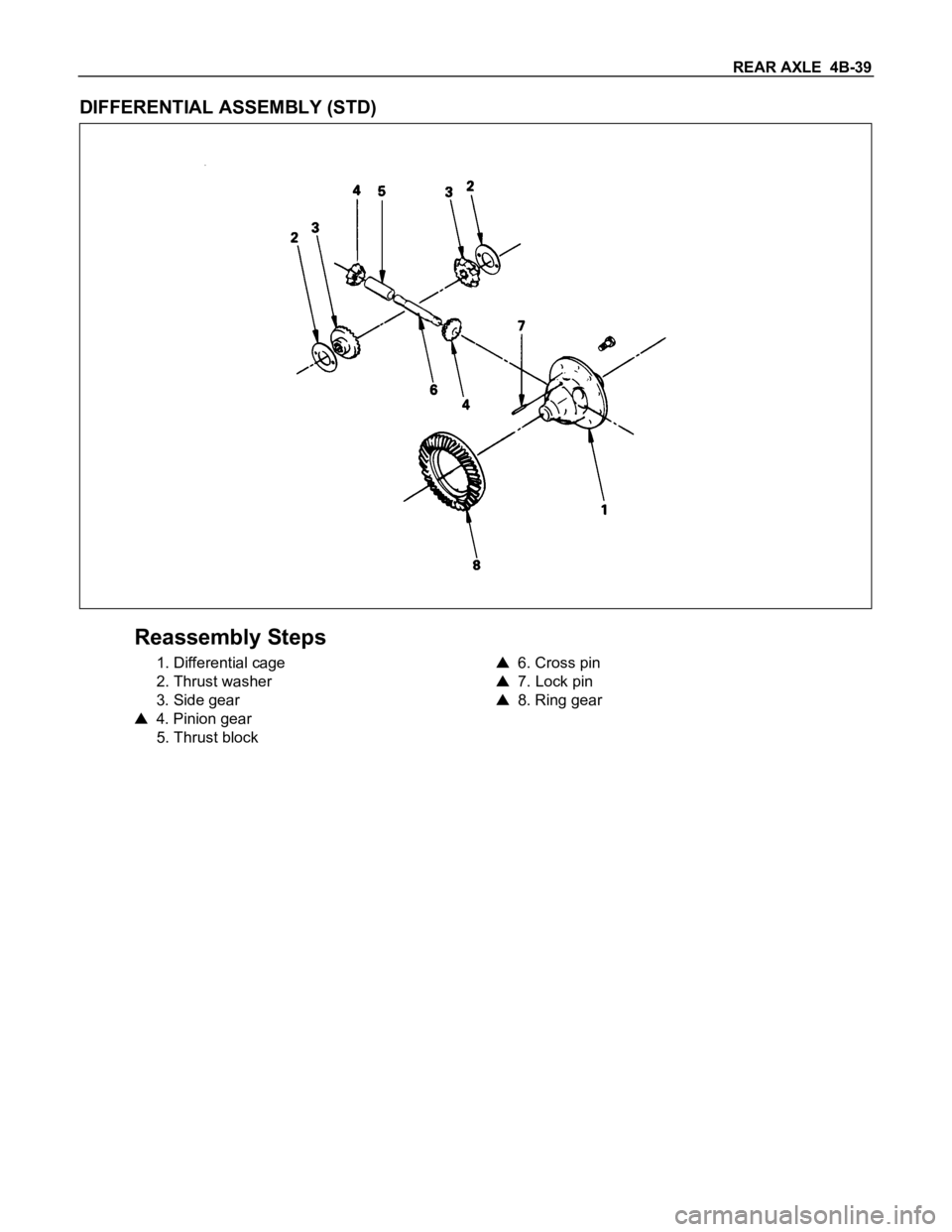

REAR AXLE 4B-39

DIFFERENTIAL ASSEMBLY (STD)

Reassembly Steps

1. Differential cage

2. Thrust washer

3. Side gear

4. Pinion gear

5. Thrust block

6. Cross pin

7. Lock pin

8. Ring gear

Page 36 of 1600

4B-40 REAR AXLE

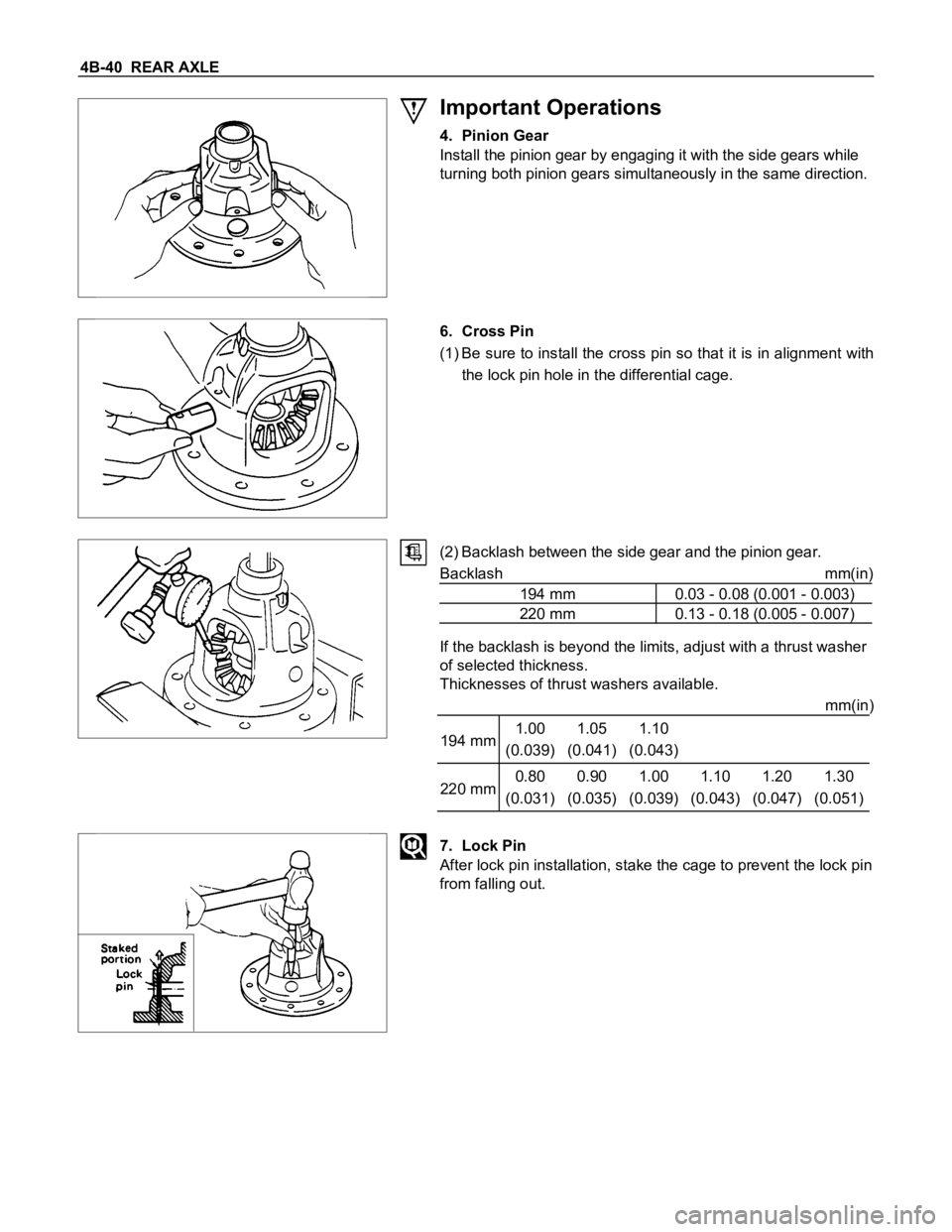

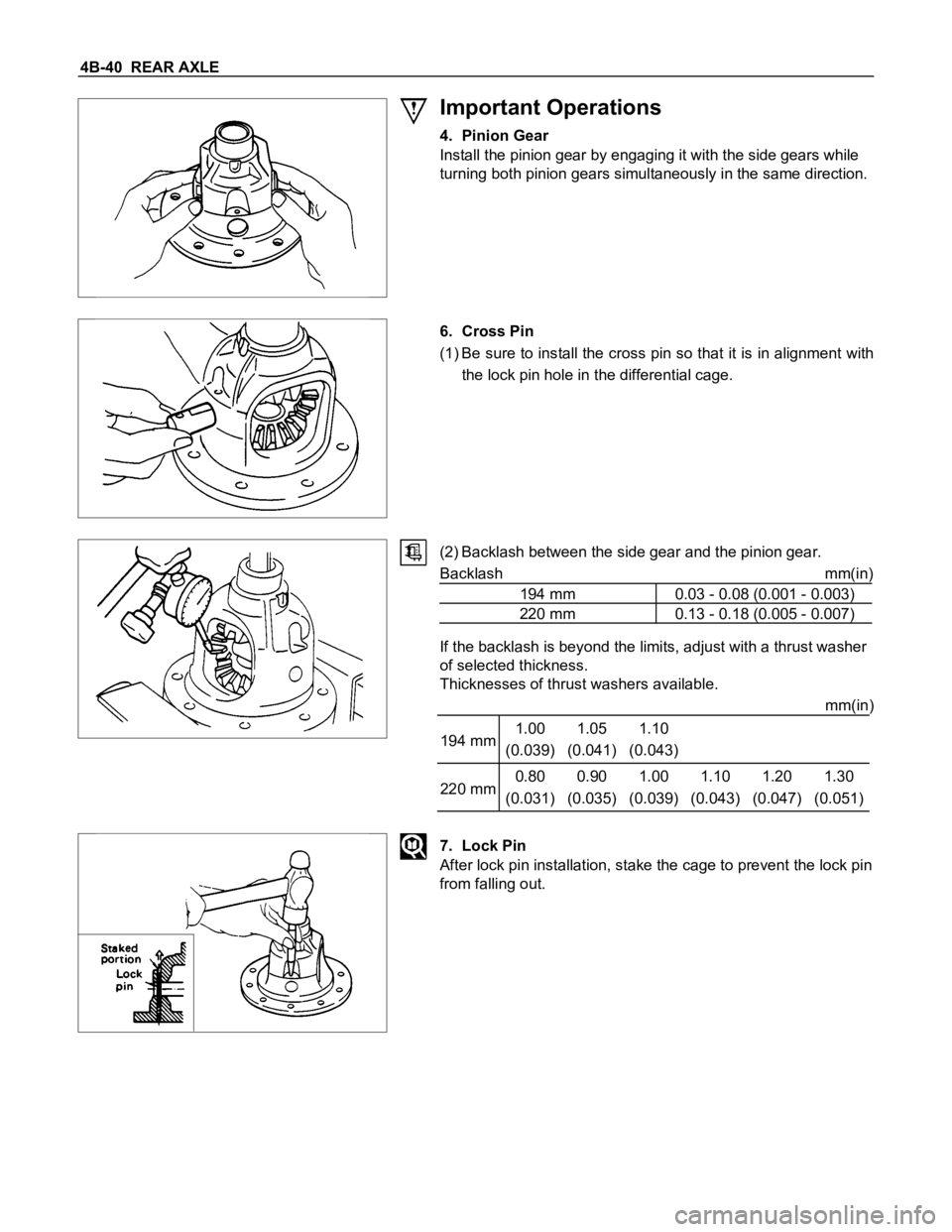

Important Operations

4. Pinion Gear

Install the pinion gear by engaging it with the side gears while

turning both pinion gears simultaneously in the same direction.

6. Cross Pin

(1) Be sure to install the cross pin so that it is in alignment with

the lock pin hole in the differential cage.

(2) Backlash between the side gear and the pinion gear.

Backlash mm(in)

194 mm 0.03 - 0.08 (0.001 - 0.003)

220 mm 0.13 - 0.18 (0.005 - 0.007)

If the backlash is beyond the limits, adjust with a thrust washer

of selected thickness.

Thicknesses of thrust washers available.

mm(in)

194 mm1.00

(0.039)1.05

(0.041)1.10

(0.043)

220 mm0.80

(0.031)0.90

(0.035)1.00

(0.039)1.10

(0.043)1.20

(0.047)1.30

(0.051)

7. Lock Pin

After lock pin installation, stake the cage to prevent the lock pin

from falling out.

Page 37 of 1600

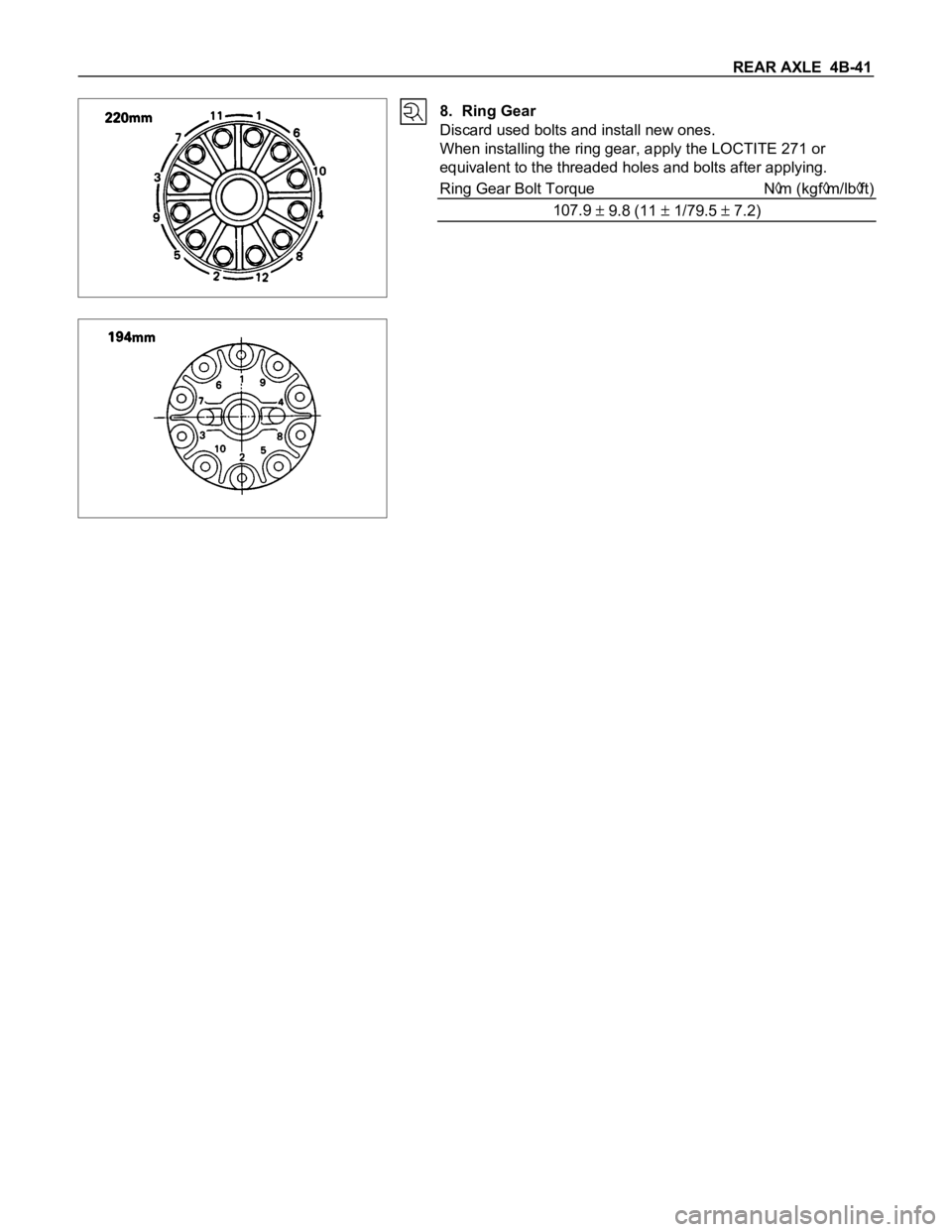

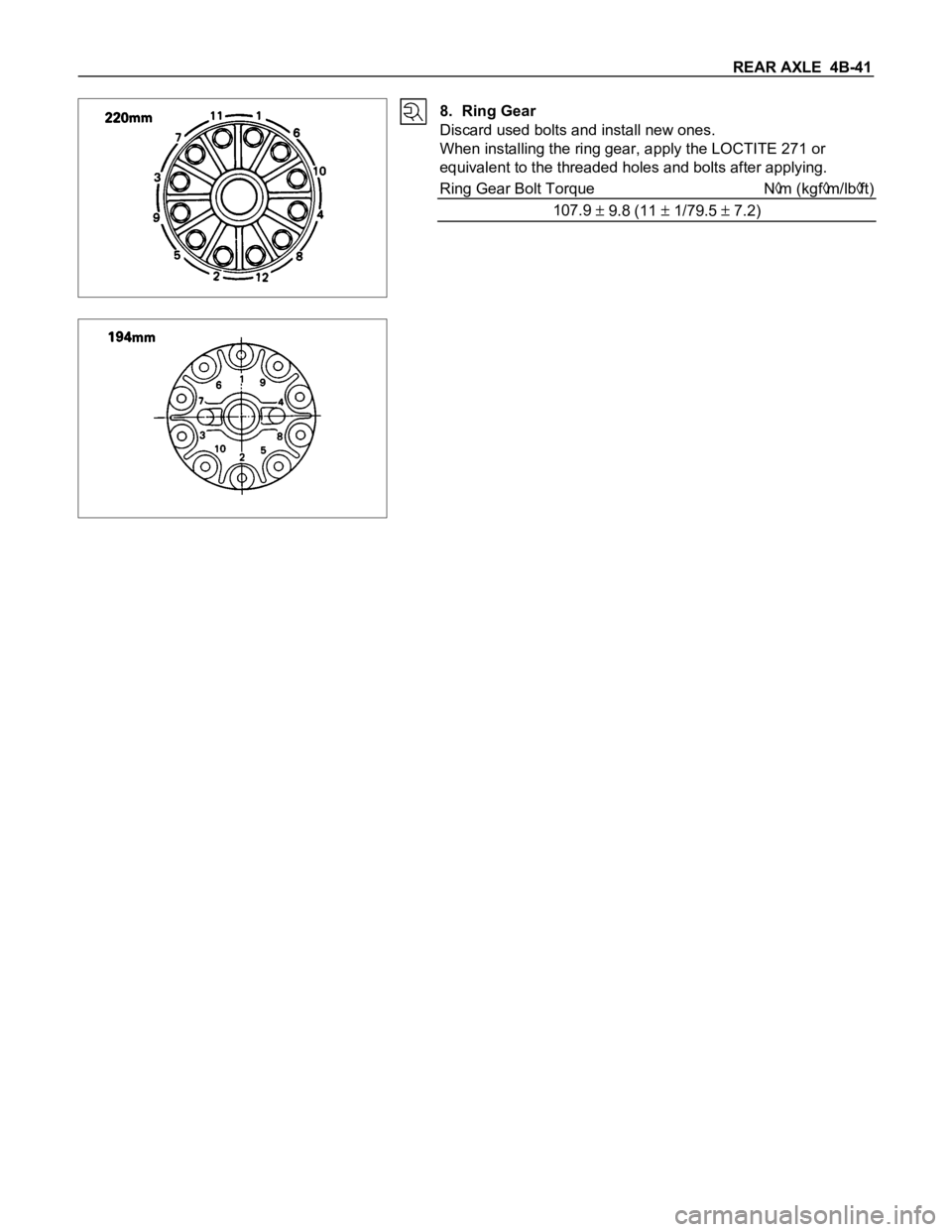

REAR AXLE 4B-41

8. Ring Gear

Discard used bolts and install new ones.

When installing the ring gear, apply the LOCTITE 271 or

equivalent to the threaded holes and bolts after applying.

Ring Gear Bolt Torque N

m (kgfm/lbft)

107.9

9.8 (11 1/79.5 7.2)

Page 38 of 1600

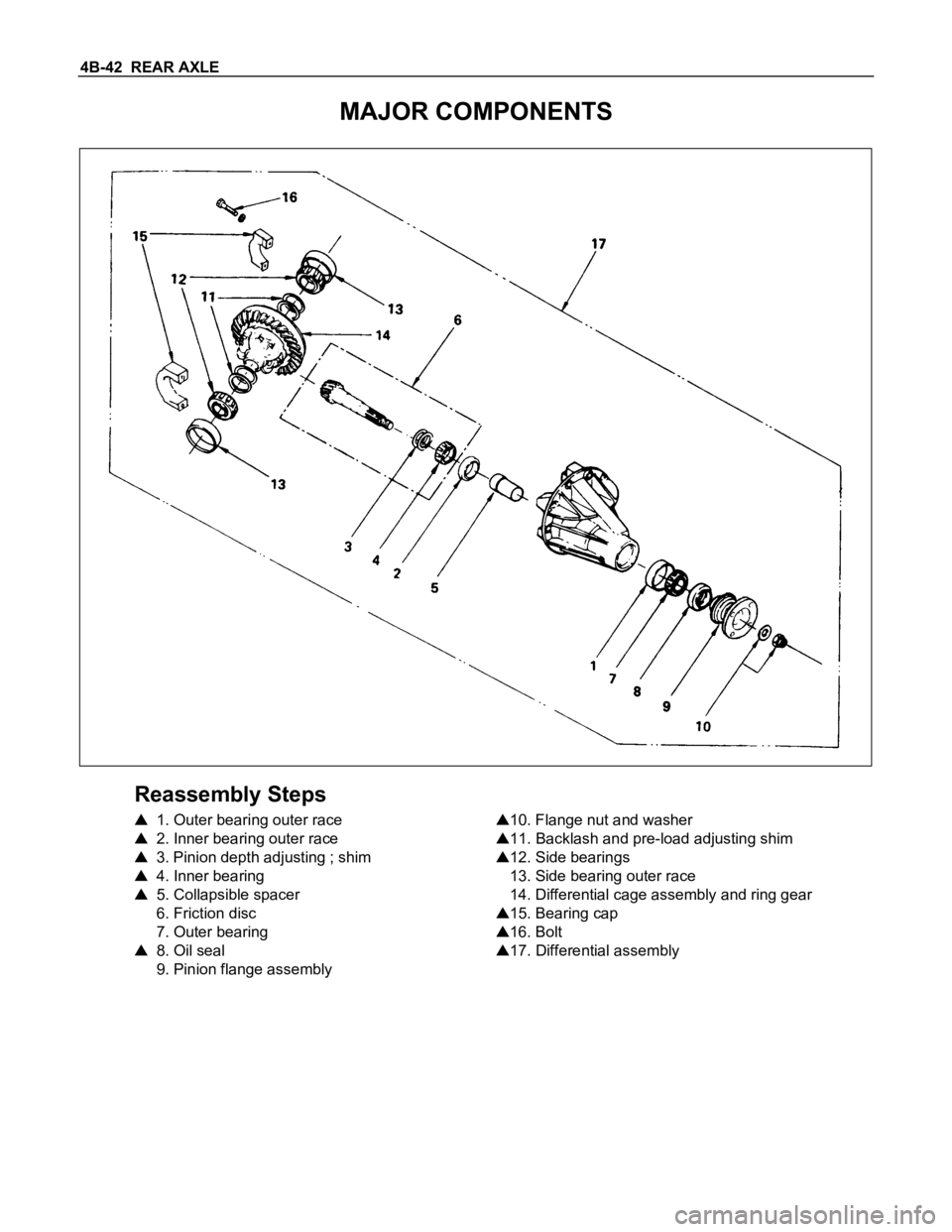

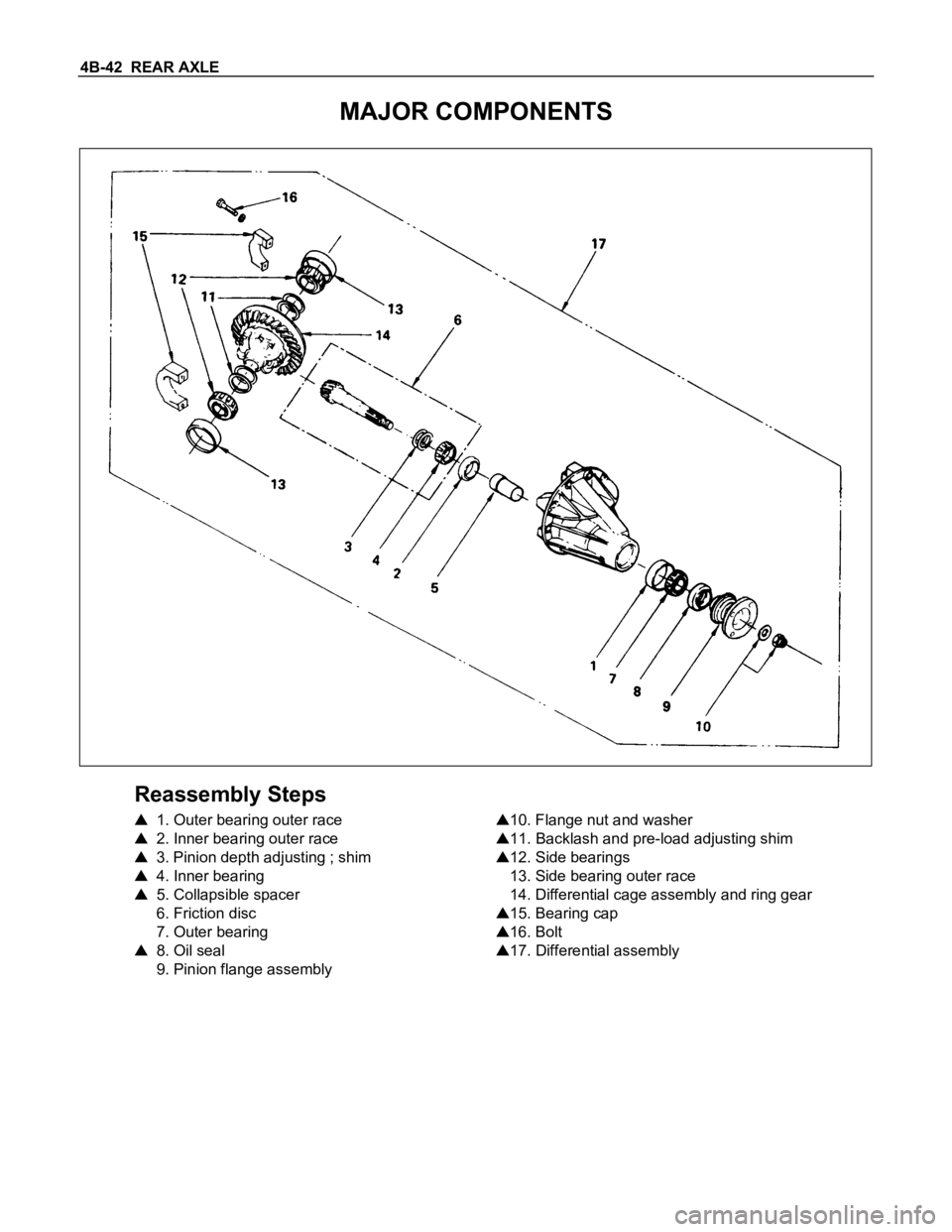

4B-42 REAR AXLE

MAJOR COMPONENTS

Reassembly Steps

1. Outer bearing outer race

2. Inner bearing outer race

3. Pinion depth adjusting ; shim

4. Inner bearing

5. Collapsible spacer

6. Friction disc

7. Outer bearing

8. Oil seal

9. Pinion flange assembly

10. Flange nut and washer

11. Backlash and pre-load adjusting shim

12. Side bearings

13. Side bearing outer race

14. Differential cage assembly and ring gear

15. Bearing cap

16. Bolt

17. Differential assembly

Page 39 of 1600

REAR AXLE 4B-43

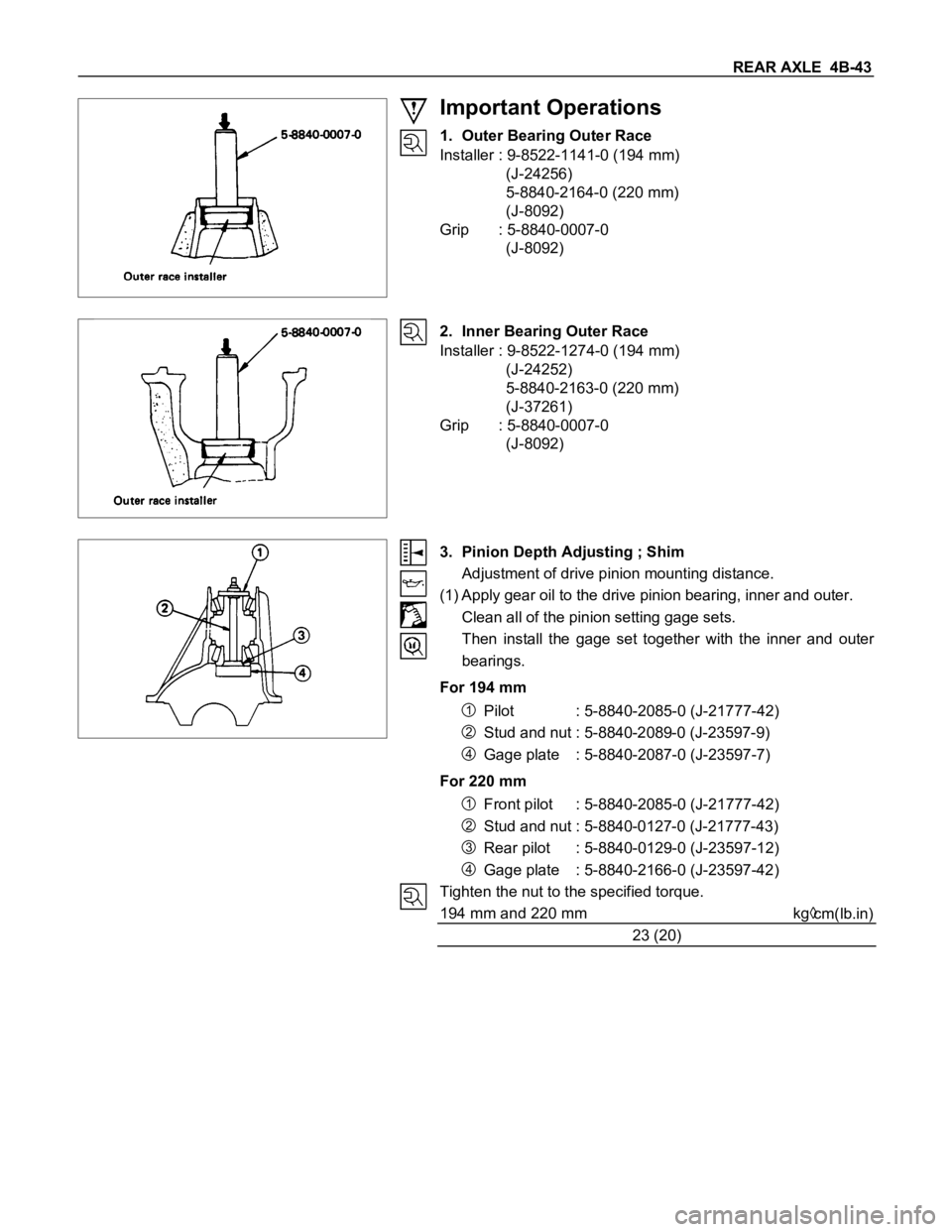

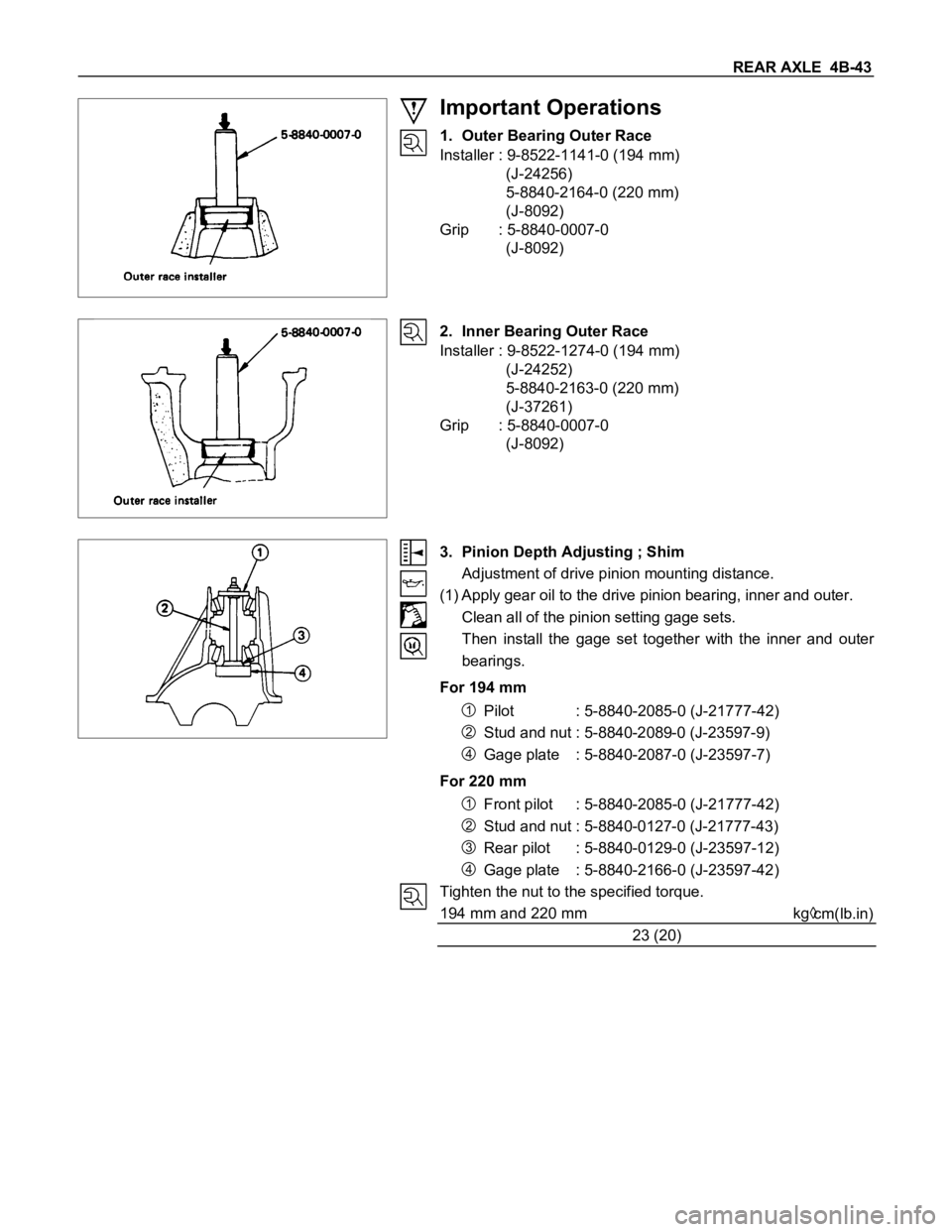

Important Operations

1. Outer Bearing Outer Race

Installer : 9-8522-1141-0 (194 mm)

(J-24256)

5-8840-2164-0 (220 mm)

(J-8092)

Grip : 5-8840-0007-0

(J-8092)

2. Inner Bearing Outer Race

Installer : 9-8522-1274-0 (194 mm)

(J-24252)

5-8840-2163-0 (220 mm)

(J-37261)

Grip : 5-8840-0007-0

(J-8092)

3. Pinion Depth Adjusting ; Shim

Adjustment of drive pinion mounting distance.

(1) Apply gear oil to the drive pinion bearing, inner and outer.

Clean all of the pinion setting gage sets.

Then install the gage set together with the inner and outer

bearings.

For 194 mm

1Pilot : 5-8840-2085-0 (J-21777-42)

2Stud and nut : 5-8840-2089-0 (J-23597-9)

4Gage plate : 5-8840-2087-0 (J-23597-7)

For 220 mm

1Front pilot : 5-8840-2085-0 (J-21777-42)

2Stud and nut : 5-8840-0127-0 (J-21777-43)

3Rear pilot : 5-8840-0129-0 (J-23597-12)

4Gage plate : 5-8840-2166-0 (J-23597-42)

Tighten the nut to the specified torque.

194 mm and 220 mm kg

cm(lb.in)

23 (20)

Page 40 of 1600

4B-44 REAR AXLE

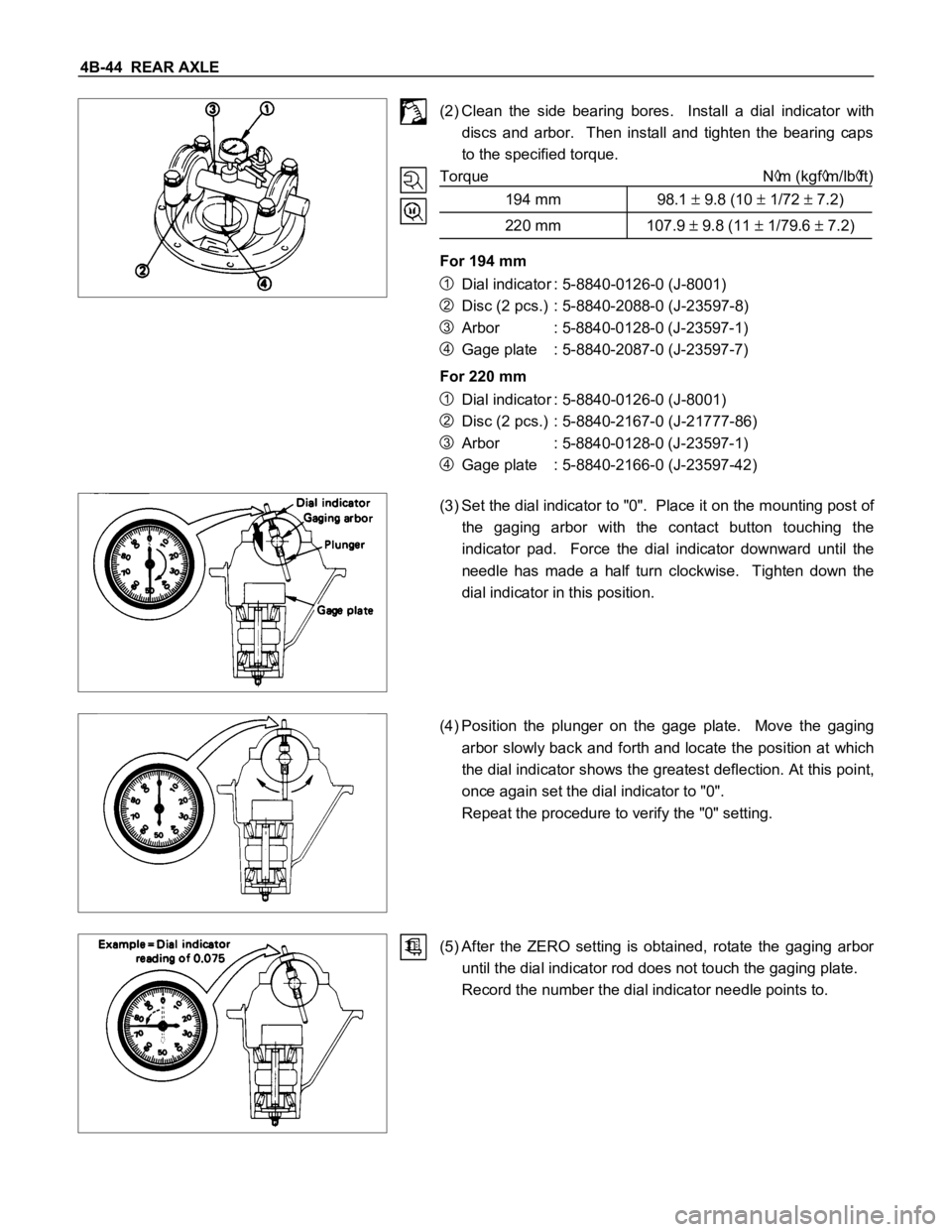

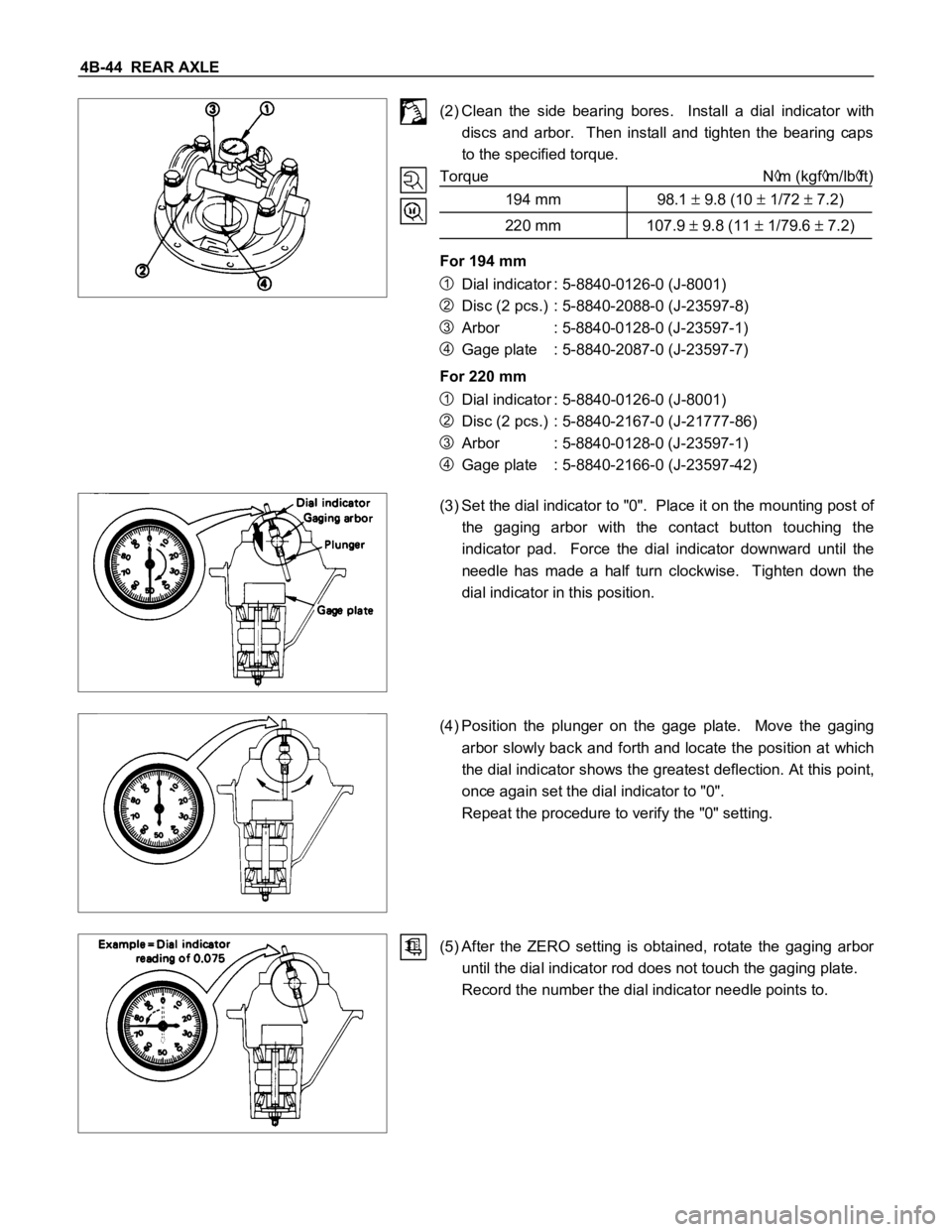

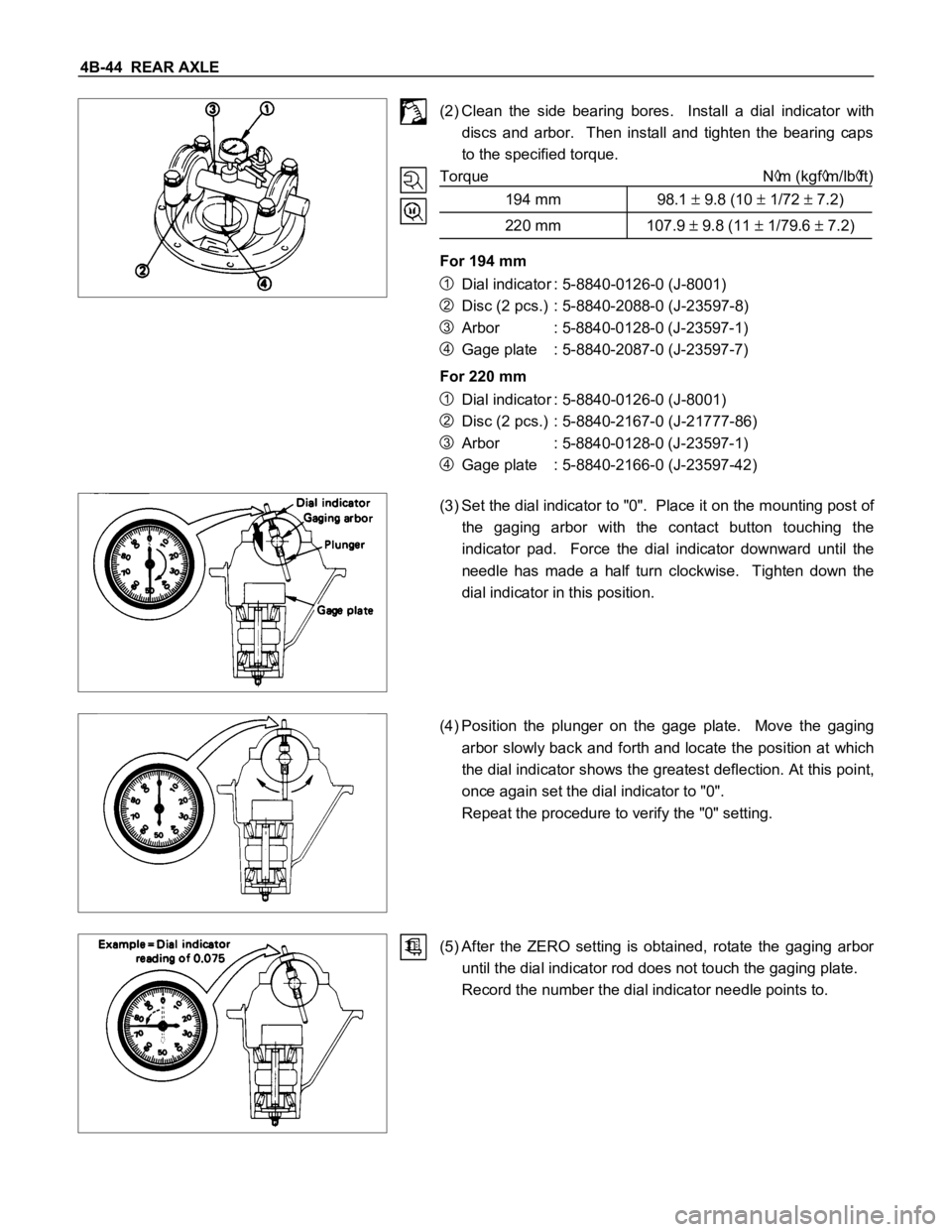

(2) Clean the side bearing bores. Install a dial indicator with

discs and arbor. Then install and tighten the bearing caps

to the specified torque.

Torque N

m (kgfm/lbft)

194 mm 98.1

9.8 (10 1/72 7.2)

220 mm 107.9 9.8 (11 1/79.6 7.2)

For 194 mm

1Dial indicator : 5-8840-0126-0 (J-8001)

2Disc (2 pcs.) : 5-8840-2088-0 (J-23597-8)

3Arbor : 5-8840-0128-0 (J-23597-1)

4Gage plate : 5-8840-2087-0 (J-23597-7)

For 220 mm

1Dial indicator : 5-8840-0126-0 (J-8001)

2Disc (2 pcs.) : 5-8840-2167-0 (J-21777-86)

3Arbor : 5-8840-0128-0 (J-23597-1)

4Gage plate : 5-8840-2166-0 (J-23597-42)

(3) Set the dial indicator to "0". Place it on the mounting post of

the gaging arbor with the contact button touching the

indicator pad. Force the dial indicator downward until the

needle has made a half turn clockwise. Tighten down the

dial indicator in this position.

(4) Position the plunger on the gage plate. Move the gaging

arbor slowly back and forth and locate the position at which

the dial indicator shows the greatest deflection. At this point,

once again set the dial indicator to "0".

Repeat the procedure to verify the "0" setting.

(5) After the ZERO setting is obtained, rotate the gaging arbor

until the dial indicator rod does not touch the gaging plate.

Record the number the dial indicator needle points to.

Trending: remote control, drain bolt, check engine light, clock setting, transmission oil, tire type, wheel alignment