differential ISUZU TFS SERIES 1997 User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1997, Model line: TFS SERIES, Model: ISUZU TFS SERIES 1997Pages: 1600, PDF Size: 40.98 MB

Page 22 of 1600

4B-26 REAR AXLE

Important Operations

Prepare a side gear holder (An axle shaft must be used) as

shown in the left figure, clamp it with a stock vice, and set a

differential.

1. Bolt

Apply a setting mark to the differential cage cover and

differential cage a remove the bolt using the press.

W hen the differential cage is pressed down with the press,

loosen the four bolts fixing the differential cage evenly and

remove them, and then disconnect the differential cage.

Page 23 of 1600

REAR AXLE 4B-27

INSPECTION AND REPAIR

Make all necessary adjustments, repairs, and part replacements if wear, damage, or other problems are discovered

during inspection.

Gear

Bearing

Differential box

Drive pinion

Visual Check

Inspect the following parts for wear, damage or other abnormal

conditions.

Clearance between pinion gear and cross pin:

194 mm and 220 mm mm(in)

Standard Limit

0.06 - 0.12

(0.002 - 0.005)0.2 (0.008)

Clearance between side gear and differential cage.

mm(in)

Standard Limit

194 mm0.03 - 0.10

(0.001 - 0.004)0.15 (0.006)

220 mm0.05 - 0.11

(0.002 - 0.004)0.15 (0.006)

Play in splines between the side gear and axle shafts.

mm(in)

Standard Limit

194 mm 0.08 - 0.36 (0.003 - 0.014)

220 mm 0.08 - 0.38 (0.003 - 0.015)0.5 (0.02)

Page 24 of 1600

4B-28 REAR AXLE

Differential cage

Check the ring gear the side gear fitting faces and the cross pin

hole for scores or roughness. Correct as necessary. Slight

scores or roughness may be corrected with an oil stone or fine

sand paper.

Friction disc and plate assembly.

Check the parts for damage or other abnormal conditions.

Check the friction plate for distortion.

Limit mm(in) 0.07 (0.0027)

Check the friction plate for wear.

Limit (A - B) mm(in) 0.1 (0.0039)

Note : A = Non-sliding face thickness

B = Sliding face thickness

Check the friction disc for distortion.

Limit mm(in) 0.07 (0.0027)

Page 28 of 1600

4B-32 REAR AXLE

REASSEMBLY

MINOR COMPONENTS

LIMITED SLIP DIFFERENTIAL (LSD)

Reassembly Steps

1. Friction disc and plate

2. Disc spring

3. Spring plate

4. Sleeve

5. Differential cage

6. Friction disc and plate assembly

7. Side gear8. Friction disc and plate assembly

9. Side gear

10. Pinion gear

11. Pinion washer

12. Thrust block

13. Pinion shaft

14. Spring pin

Page 29 of 1600

REAR AXLE 4B-33

Important Operations

1. Friction disc and plate

Measure the thickness of disc and plate pack (A). mm(in)

Thickness (A) 7

0.1 (0.27 0.004)

If the thickness (A) is beyond the limits, adjust with a friction

disc of selected thickness.

Thickness of friction discs available mm(in)

1.4 (0.055), 1.5 (0.059)

Apply molybdenum disuffide grease to the friction discs and

plates.

3. Spring plate

Install the spring plate with dished side turned side turned to

the differential cage side.

10.Pinion gear

11.Pinion washer

(1) Clamp special tool (side gear holder) into a vise. Set the

LSD assembly.

Holder : 5-8840-2010-0

(J-36563)

(2) Set special tools (side pinion expanders and side pinion

rotator) to the LSD.

Expander : 5-8840-2011-0

(J-36564)

Rotator : 5-8840-2012-0

(J-36565)

Page 30 of 1600

4B-34 REAR AXLE

(3) Set special tool (cage lock bar) through a ring gear fixing

hole to a vice.

Then rotate side pinion expanders with a wrench one half to

one full turn to provide proper clearance to install the pinion

gears.

Bar : 5-8840-2013-0

(J-36566)

(4) Attach the pinion gears and washers in the proper order to

the left and right hand side of the differential cage.

(5) W ith a wrench, turn special tool (pinion rotator) to align the

pinion gear and washer holes with the pinion shaft holes on

the differential cage.

Confirmation of operation

Using the side gear holder, measure the starting of the side

gear.

Starting Torque N

m (kgfm/lbft)

Standard 147-225 (15 - 23/108 - 166)

Side gear holder : 5-8840-2010-0

(J-36563)

Side gear rotor : 5-8840-2012-0

(J-36565)

Page 31 of 1600

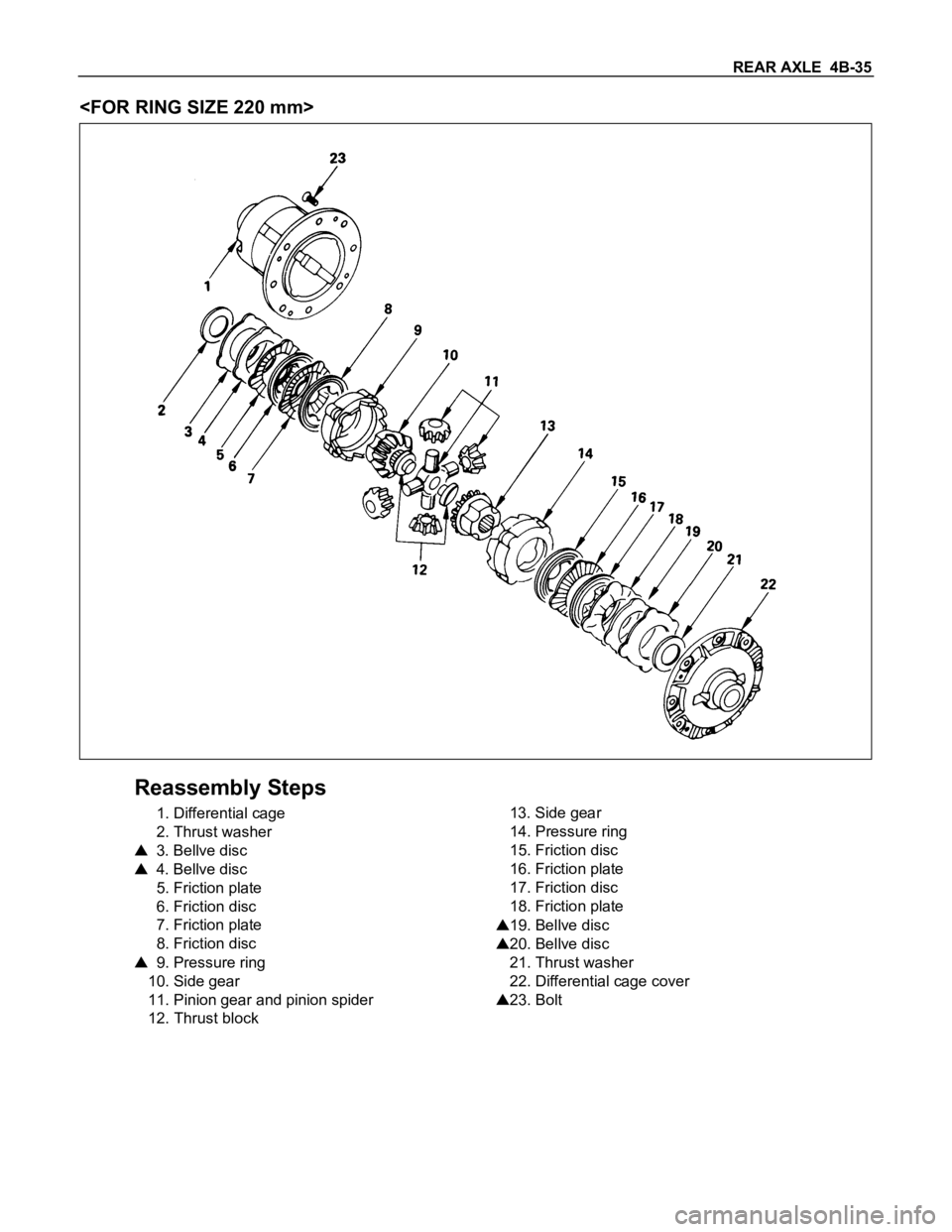

REAR AXLE 4B-35

Reassembly Steps

1. Differential cage

2. Thrust washer

3. Bellve disc

4. Bellve disc

5. Friction plate

6. Friction disc

7. Friction plate

8. Friction disc

9. Pressure ring

10. Side gear

11. Pinion gear and pinion spider

12. Thrust block13. Side gear

14. Pressure ring

15. Friction disc

16. Friction plate

17. Friction disc

18. Friction plate

19. Bellve disc

20. Bellve disc

21. Thrust washer

22. Differential cage cover

23. Bolt

Page 32 of 1600

4B-36 REAR AXLE

Adjustment of Clearance between

Friction Disc and Plate

1) Measuring depth of differential case

mm(in)

Standard (A-B) 80.58 (3.17)

(C) 10.58 (0.41)

2) Measuring overall length of pressure ring, friction disc and

plate assembly

Assembly pinion shaft with pressure ring, then friction

disc and plate.

Measure length between plates at both ends over V-

shape groove. (D)

3) After A, B, C and D dimensions are measured, perform

adjustment with the following procedure.

Measure disc spring :

1.75 mm (0.69 in)

2 pcs (E)

Measure thickness of plate spring

Standard dimension :

1.75 mm (0.069 in)

2 pcs (F)

4) Select a friction disc or plate so that ((A-B+C) - (D+E+F) =

0.06 to 0.20 mm (0.002 to 0.008 in.) and also the difference

in total dimension of friction disc and plate, plate spring and

disc spring (left/right side) does not exceed 0.05 mm (0.002

in.).

Thickness : 1.75, 1.85 mm

Adjusting Backlash of Side Gear in Axial

Direction

1) Measuring depth of differential case

mm(in.)

Standard (F-B) 82.03 (3.23)

(G) 12.03 (0.47)

Page 33 of 1600

REAR AXLE 4B-37

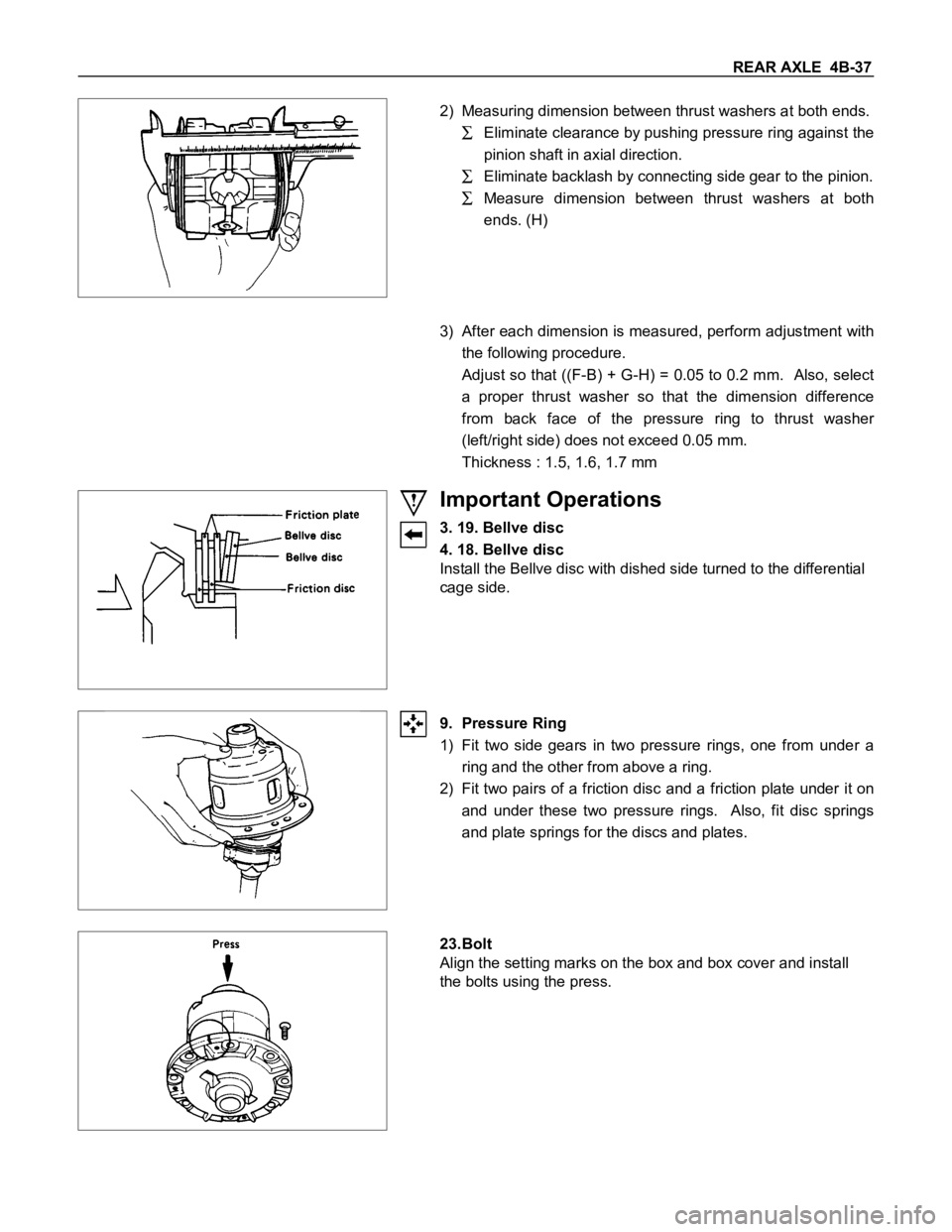

2) Measuring dimension between thrust washers at both ends.

Eliminate clearance by pushing pressure ring against the

pinion shaft in axial direction.

Eliminate backlash by connecting side gear to the pinion.

Measure dimension between thrust washers at both

ends. (H)

3) After each dimension is measured, perform adjustment with

the following procedure.

Adjust so that ((F-B) + G-H) = 0.05 to 0.2 mm. Also, select

a proper thrust washer so that the dimension difference

from back face of the pressure ring to thrust washer

(left/right side) does not exceed 0.05 mm.

Thickness : 1.5, 1.6, 1.7 mm

Important Operations

3. 19. Bellve disc

4. 18. Bellve disc

Install the Bellve disc with dished side turned to the differential

cage side.

9. Pressure Ring

1) Fit two side gears in two pressure rings, one from under a

ring and the other from above a ring.

2) Fit two pairs of a friction disc and a friction plate under it on

and under these two pressure rings. Also, fit disc springs

and plate springs for the discs and plates.

23.Bolt

Align the setting marks on the box and box cover and install

the bolts using the press.

Page 35 of 1600

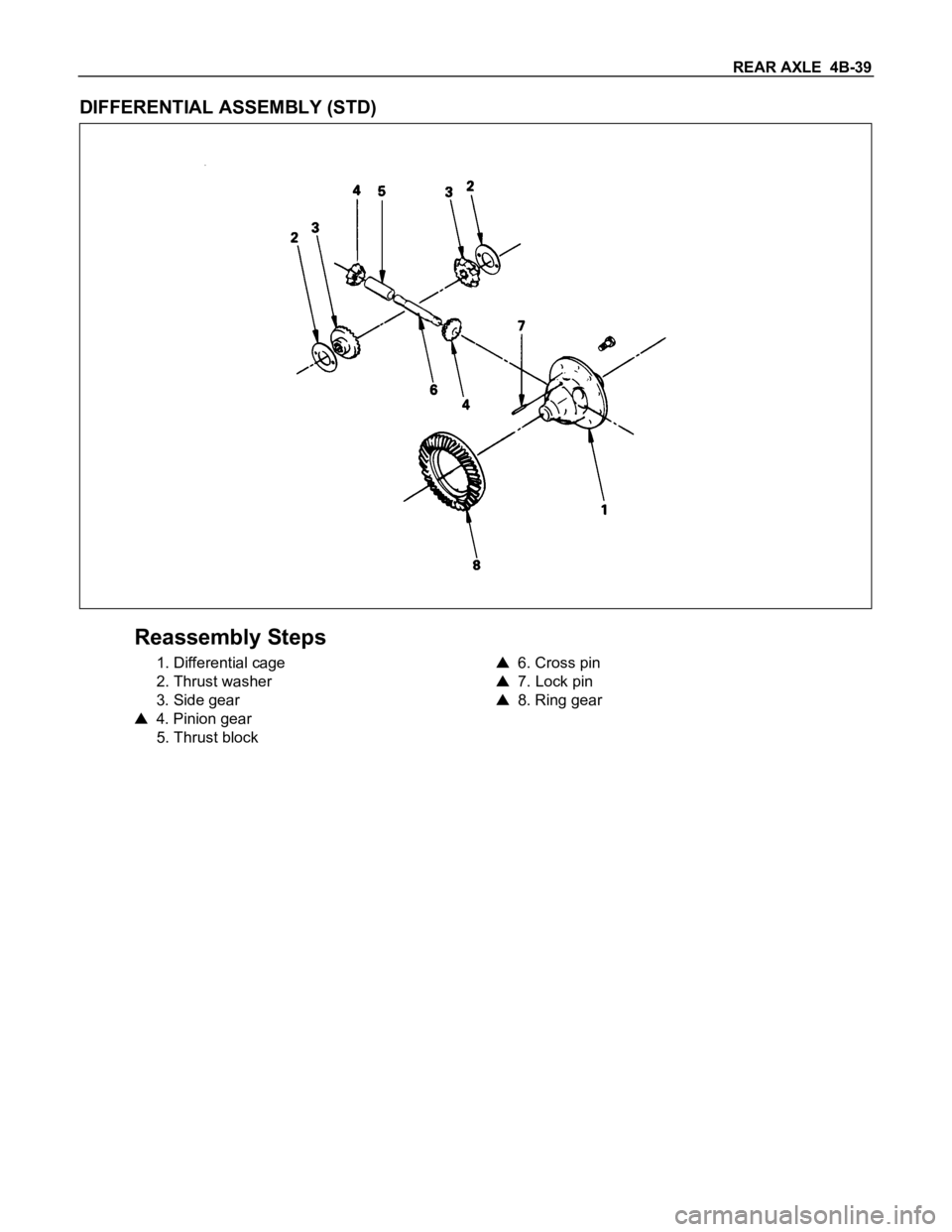

REAR AXLE 4B-39

DIFFERENTIAL ASSEMBLY (STD)

Reassembly Steps

1. Differential cage

2. Thrust washer

3. Side gear

4. Pinion gear

5. Thrust block

6. Cross pin

7. Lock pin

8. Ring gear