torque ISUZU TFS SERIES 1997 Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1997, Model line: TFS SERIES, Model: ISUZU TFS SERIES 1997Pages: 1600, PDF Size: 40.98 MB

Page 535 of 1600

10-38 CAB

REMOVAL AND INSTALLATION

BUCKET SEAT BENCH SEAT

Removal Steps

1. Adjust cover

2. Bolt

3. Seat assembly

4. Adjuster

Installation Steps

4. Adjuster

3. Seat assembly

2. Bolt

1. Adjust cover

Important Operation - Installation

2. Bolt

Torque N

m(kgfm/lbft)

39.2

9.8 (4 1 / 28.9 7.2)

Page 536 of 1600

CAB 10-39

FRONT AND REAR SEAT BELT

REMOVAL AND INSTALLATION

1

Removal Steps

1. Trim

2. Seat belt and retractor

Installation Steps

2. Seat belt and retractor

1. Trim

Important Operation - Installation

2. Seat Belt and Retractor

Bolt Torque N

m(kgfm/lbft)

39.2

9.8 (4 1 / 28.9 7.2)

Page 537 of 1600

10-40 CAB

JUMP SEAT

REMOVAL AND INSTALLATION

Removal Steps

1. Head rest and back trim cover

2. Hinge cover, center

3. Bolt

4. Jump seat assembly

Installation Steps

4. Jump seat assembly

3. Bolt

2. Hinge cover ; center

1. Head rest and back trim cover

Important Operation - Installation

3. Bolt

Torque N

m(kgfm/lbft)

19.6

5 (2 0.5 / 14.5 3.6)

Page 538 of 1600

CAB 10-41

JUMP SEAT BELT

REMOVAL AND INSTALLATION

Removal Steps

1. Hinge cover

2. Hinge cover ; center

3. Bolt

Installation Steps

3. Bolt

2. Hinge cover ; center

1. Hinge cover

Important Operation - Installation

3. Bolt

Torque N

m(kgfm/lbft)

39.2

9.8 (4 1 / 28.9 7.2)

Page 541 of 1600

CLUTCH 7C-1

SECTION 7C

CLUTCH

TABLE OF CONTENTS

PAGE

Main Data and Specifications ...................................<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[ 7C- 2

General Description......................................................................................................... 7C-3

Torque Specification ...........................................<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011[ 7C-8

Servicing<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011001100110011[...... 7C- 13

Clut<0046004b0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011[<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011001100110011[........ 7C- 15

Removal and Installation .......................................<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[ 7C- 15

Inspection and Repair................................................................................................. 7C- 20

Clutch Control .................................................................................................................. 7C- 27

Removal and Installation .......................................<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[ 7C- 27

Master Cylinder (Except 6VD1 Engine) .......................................................................... 7C- 30

Disassembly <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011[ 7C-30

Inspection and Repair................................................................................................. 7C- 31

Reassembly <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011[ 7C-32

Master Cylinder (6VD1 LHD Model) ................................................................................ 7C- 33

Disassembly and Reassembly ................................................................................... 7C- 33

Slave Cylinder (Except 6VD1 Engine) ............................................................................ 7C- 35

Disassembly <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011[ 7C-35

Inspection and Repair................................................................................................. 7C- 36

Reassembly <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011001100110011[ 7C-36

Hydraulic Damper Cylinder (Except 6VD1 Engine) ....................................................... 7C- 40

Inspection and Repair................................................................................................. 7C- 40

Troubleshooting .............................................................................................................. 7

C- 41

Special Service Tool ........................................................................................................ 7C-50

INDEX

Page 548 of 1600

7C-8 CLUTCH

TORQUE SPECIFICATION

STANDARD BOLTS

The torque values given in the following table should be applied where a particular torque is not specified.

N

m (kgfm/lbft)

Strength 4.8/4T 7T 8.8 9.8/9T

ClassRefined Non-Refined

Bolt Identifi-

cation

Bolt

Diameter

Pitch (mm)

-

M6 1.0 6 (0.6 / 52 lb.in) 7 (0.7 / 61 lb.in) 8 (0.8 / 69 lb.in) -

M8 1.25 13 (1.3 / 113 lb.in) 17 (1.7 / 12) 20 (2.0 / 14) 24 (2.4 / 17)

M10 1.25 27 (2.8 / 20) 37 (3.8 / 27) 42 (4.3 / 31) 50 (5.1 / 37)

M12 1.25 61 (6.3 / 45) 76 (7.8 / 56) 87 (8.9 / 64) 95 (9.7 / 70)

M14 1.5 96 (9.8 / 71) 116 (11.8 / 85) 133 (13.6 / 98) 142 (14.5 / 105)

M16 1.5 130 (13.3 / 96) 170 (17.3 / 125) 193 (19.7 / 143) 200 (20.4 / 148)

M18 1.5 188 (19.2 / 139) 244 (24.9 / 180) 278 (28.3 / 205) 287 (29.3 / 212)

M20 1.5 258 (26.3 / 190) 337 (34.4 / 249) 385 (39.3 / 284) 396 (40.4 / 292)

M22 1.5 332 (33.9 / 245) 453 (46.3 / 335) 517 (52.7 / 381) 530 (54.1 / 391)

M24 2.0 449 (45.8 / 331) 570 (58.2 / 421) 651 (66.3 / 480) 692 (70.6 / 511)

* M10 1.5 26 (2.7 / 20) 36 (3.7 / 27) 41 (4.2 / 30) 48 (4.9 / 35)

* M12 1.75 57 (5.8 / 42) 71 (7.2 / 52) 80 (8.2 / 59) 89 (9.1 / 66)

* M14 2.0 89 (9.1 / 66) 110 (11.2 / 81) 125 (12.7 / 92) 133 (13.6 / 98)

* M16 2.0 124 (12.7 / 92) 162 (16.5 / 119) 185 (18.9 / 137) 191 (19.5 / 141)

Flange BoltM6 1.0 7 (0.7 / 61 lb.in) 8 (0.8 / 69 lb.in) 9 (0.9 / 78 lb.in) -

M8 1.25 15 (1.5 / 11) 19 (1.9 / 14) 22 (2.2 / 16) 26 (2.7 / 20)

M10 1.25 31 (3.2 / 23) 41 (4.2 / 30) 47 (4.8 / 35) 56 (5.7 / 41)

M12 1.25 69 (7.0 / 51) 85 (8.7 / 63) 97 (9.9 / 72) 106 (10.8 / 78)

M14 1.5 104 (10.6 / 77) 126 (12.8 / 93) 144 (14.6 / 106) 154 (15.7 / 114)

M16 1.5 145 (14.8 / 127) 188 (19.2 / 139) 214 (21.8 / 158) 221 (22.5 / 163)

M18 1.5 - - - -

M20 1.5 - - - -

M22 1.5 - - - -

M24 2.0 - - - -

* M10 1.5 30 (3.1 / 22) 40 (4.1 / 30) 46 (4.7 / 34) 54 (5.5 / 40)

* M12 1.75 64 (6.5 / 47) 78 (8.0 / 58) 89 (9.1 / 66) 99 (10.1 / 73)

* M14 2.0 97 (9.9 / 72) 119 (12.1 / 88) 135 (13.8 / 99.7) 144 (14.7 / 107)

* M16 2.0 137 (14.0 / 101) 178 (18.2 / 132) 203 (20.7 / 132) 210 (21.5 / 155)

The asterisk * indicates that the bolts are used for female-threaded parts that are made of soft materials such as

casting, etc.

FLARE NUTS

Pipe diameter mm (in) Torque Nm (kgfm / lbft) Pipe diameter mm (in) Torque Nm (kgfm / lbft)

4.76 (0.187) 16 (1.6 / 12) 10.00 (0.394) 54 (5.5 / 40)

6.35 (0.250) 26 (2.7 / 20) 12.00 (0.472) 88 (9.0 / 65)

8.00 (0.315) 44 (4.5 / 33) 15.00 (0.591) 106 (10.8 / 78)

Standard Hex.

Head Bolt

Page 557 of 1600

CLUTCH 7C-17

6VD15. Shift Fork (6VD1)

(1) Remove the snap pin.

(2) Remove the shift fork pin and shift fork from the fulcrum

bridge.

6VD17. Fulcrum Bridge (6VD1)

(1) Remove the fulcrum bridge bolts.

(2) Remove the fulcrum bridge from the transmission case.

Important Operations - Installation

Follow the removal procedure in reverse order to perform the

installation procedure.

Pay careful attention to the important points during the

installation procedure.

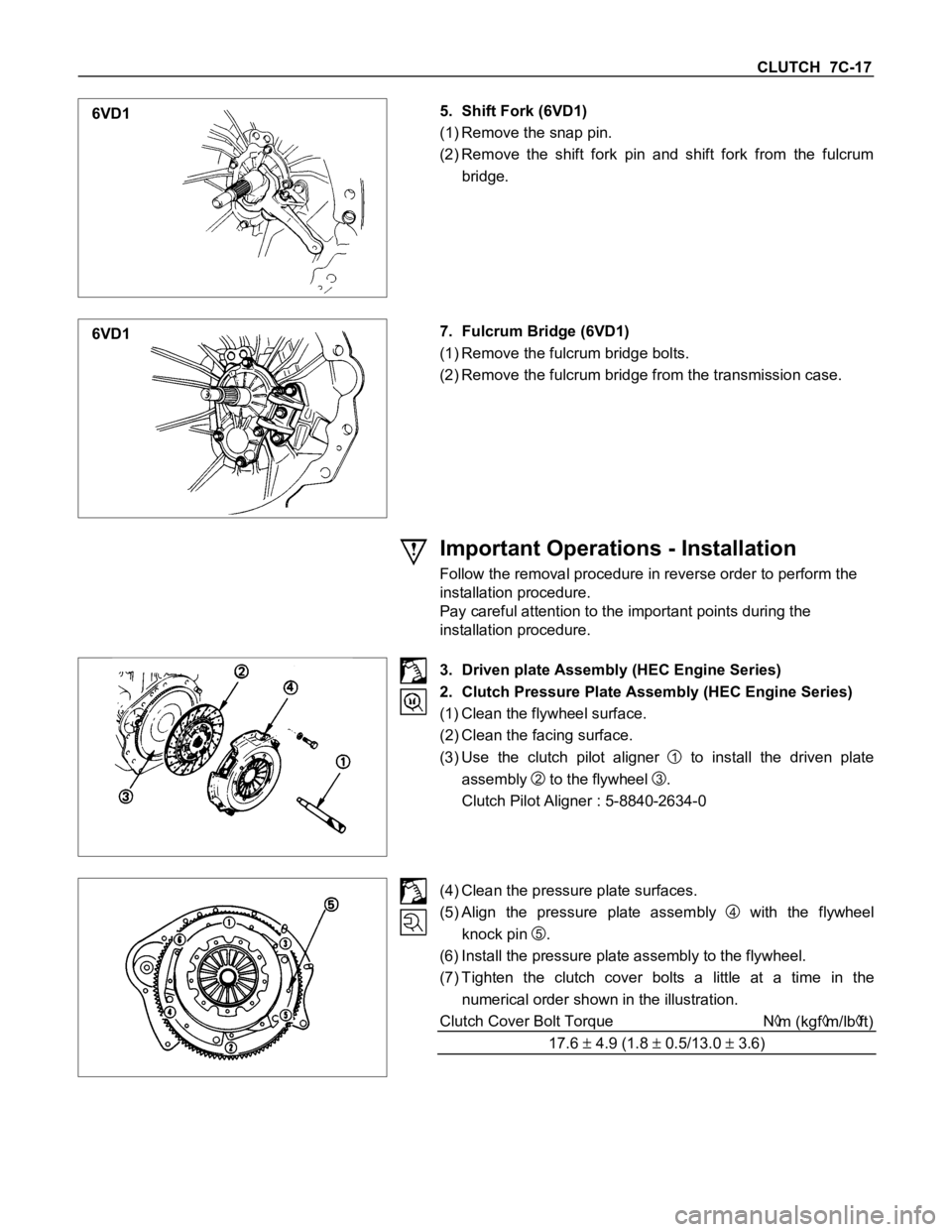

3. Driven plate Assembly (HEC Engine Series)

2. Clutch Pressure Plate Assembly (HEC Engine Series)

(1) Clean the flywheel surface.

(2) Clean the facing surface.

(3) Use the clutch pilot aligner

1 to install the driven plate

assembly

2 to the flywheel

3.

Clutch Pilot Aligner : 5-8840-2634-0

(4) Clean the pressure plate surfaces.

(5) Align the pressure plate assembly

4 with the flywheel

knock pin

5.

(6) Install the pressure plate assembly to the flywheel.

(7) Tighten the clutch cover bolts a little at a time in the

numerical order shown in the illustration.

Clutch Cover Bolt Torque N

m (kgfm/lbft)

17.6

4.9 (1.8 0.5/13.0 3.6)

Page 558 of 1600

7C-18 CLUTCH

8. Remove the clutch pilot aligner.

Note:

Do not strike the clutch pilot aligner with a hammer to

remove it.

6VD17. Fulcrum Bridge (6VD1)

(1) Install the fulcrum bridge to the transmission case.

(2) Tighten three fulcrum bridge bolts to the specified torque.

Fulcrum Bridge Bolt Torque N

m (kgm/lbft)

39 (3.9/28)

6VD15. Shift Fork (6VD1)

(1) Apply molybdenum disulfide contained type grease to the

pin hole inner circumferences and thrust surfaces.

(2) Attach the shift fork to the fulcrum bridge and insert the pin

from below of the fulcrum bridge.

(3) Install the washer and snap pin.

6VD14. Release Bearing (6VD1)

(1) Apply molybdenum disulfide contained type grease to the

areas shown in illustration.

Page 559 of 1600

CLUTCH 7C-19

6VD1(2) Install the release bearing in the proper direction.

3. Driven Plate Assembly (Except HEC Engine Series)

Use the pilot aligner to install the driven plate assembly.

Pilot aligner: 5-8525-3001-0 (J-24547)

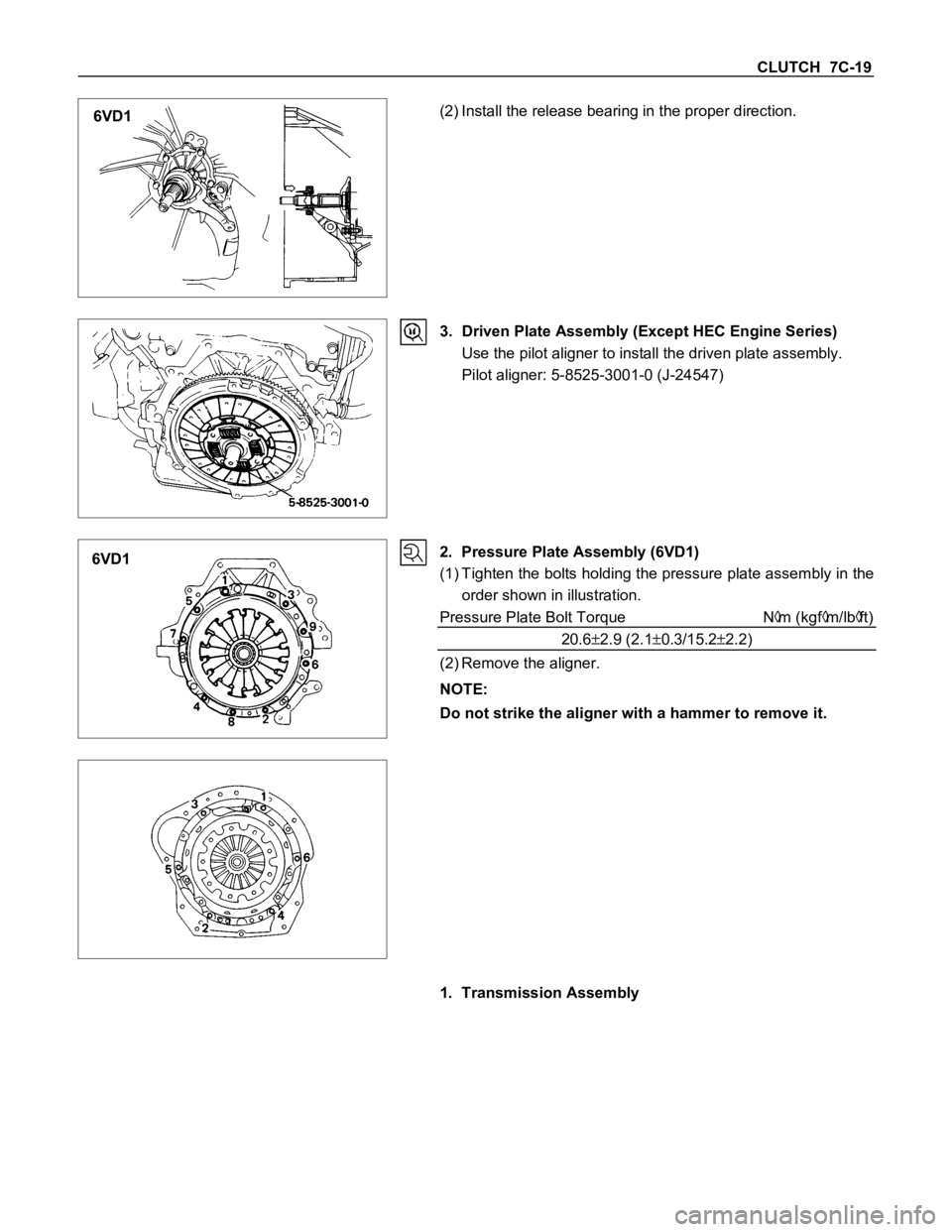

6VD12. Pressure Plate Assembly (6VD1)

(1) Tighten the bolts holding the pressure plate assembly in the

order shown in illustration.

Pressure Plate Bolt Torque N

m (kgfm/lbft)

20.6

2.9 (2.10.3/15.22.2)

(2) Remove the aligner.

NOTE:

Do not strike the aligner with a hammer to remove it.

1. Transmission Assembly