torque ISUZU TFS SERIES 1997 User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1997, Model line: TFS SERIES, Model: ISUZU TFS SERIES 1997Pages: 1600, PDF Size: 40.98 MB

Page 40 of 1600

4B-44 REAR AXLE

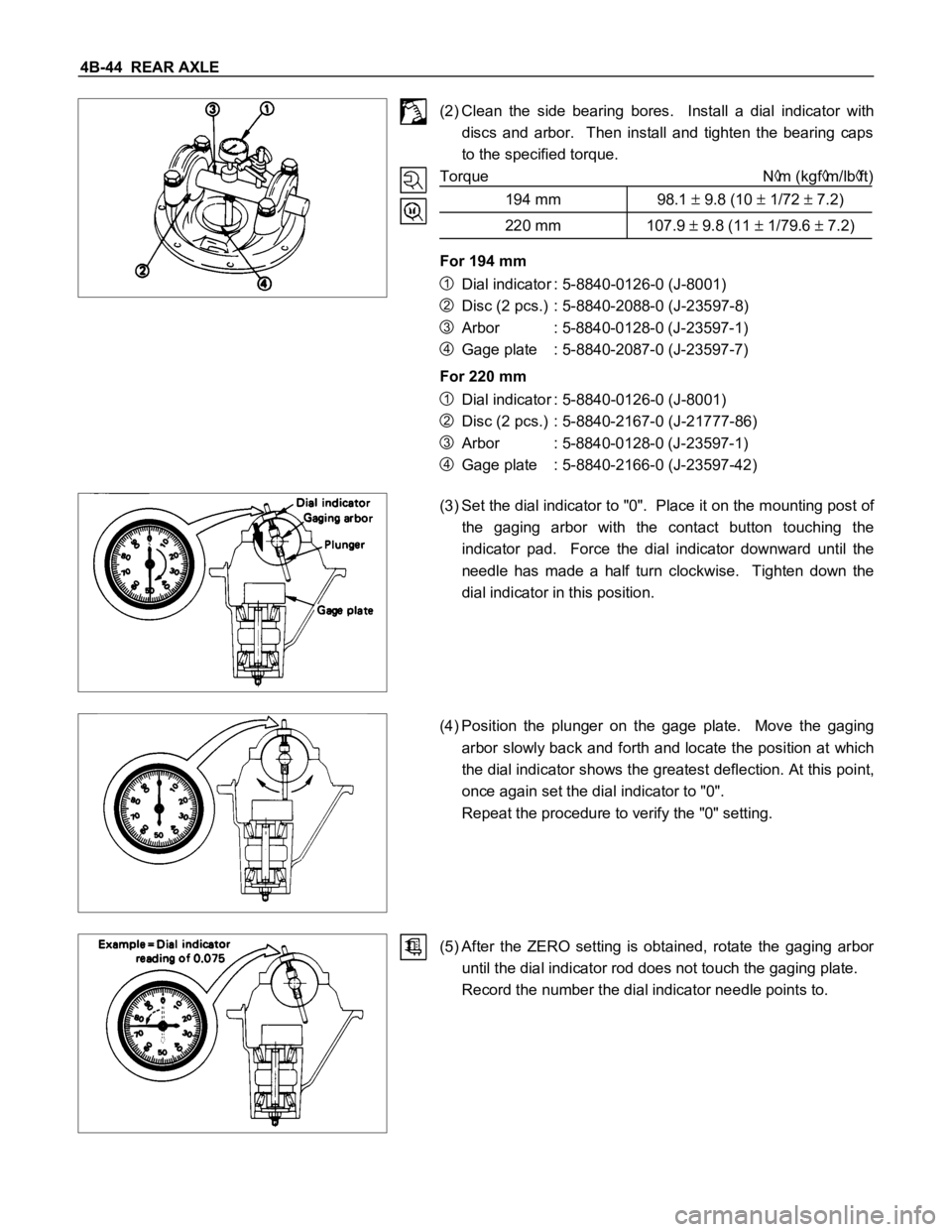

(2) Clean the side bearing bores. Install a dial indicator with

discs and arbor. Then install and tighten the bearing caps

to the specified torque.

Torque N

m (kgfm/lbft)

194 mm 98.1

9.8 (10 1/72 7.2)

220 mm 107.9 9.8 (11 1/79.6 7.2)

For 194 mm

1Dial indicator : 5-8840-0126-0 (J-8001)

2Disc (2 pcs.) : 5-8840-2088-0 (J-23597-8)

3Arbor : 5-8840-0128-0 (J-23597-1)

4Gage plate : 5-8840-2087-0 (J-23597-7)

For 220 mm

1Dial indicator : 5-8840-0126-0 (J-8001)

2Disc (2 pcs.) : 5-8840-2167-0 (J-21777-86)

3Arbor : 5-8840-0128-0 (J-23597-1)

4Gage plate : 5-8840-2166-0 (J-23597-42)

(3) Set the dial indicator to "0". Place it on the mounting post of

the gaging arbor with the contact button touching the

indicator pad. Force the dial indicator downward until the

needle has made a half turn clockwise. Tighten down the

dial indicator in this position.

(4) Position the plunger on the gage plate. Move the gaging

arbor slowly back and forth and locate the position at which

the dial indicator shows the greatest deflection. At this point,

once again set the dial indicator to "0".

Repeat the procedure to verify the "0" setting.

(5) After the ZERO setting is obtained, rotate the gaging arbor

until the dial indicator rod does not touch the gaging plate.

Record the number the dial indicator needle points to.

Page 43 of 1600

REAR AXLE 4B-47

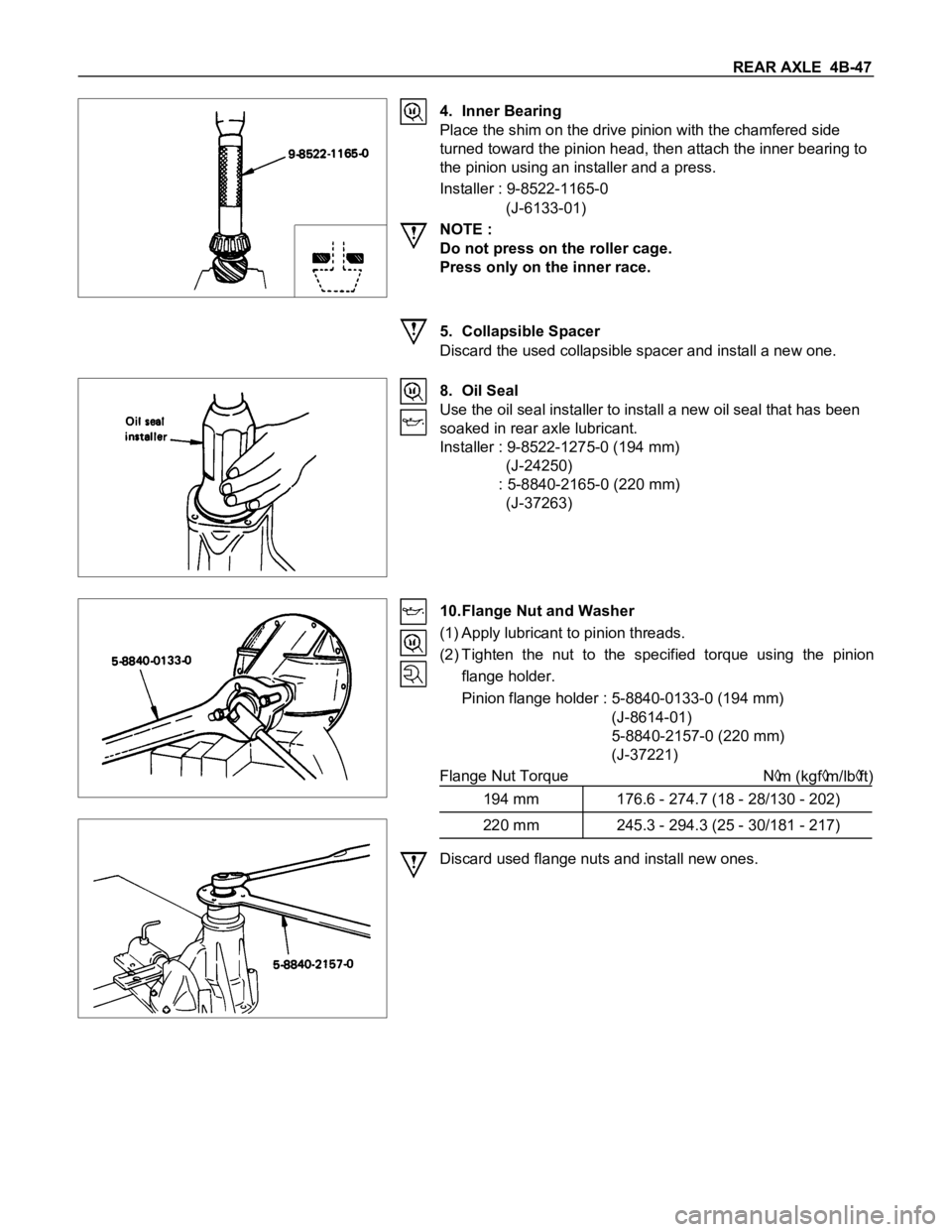

4. Inner Bearing

Place the shim on the drive pinion with the chamfered side

turned toward the pinion head, then attach the inner bearing to

the pinion using an installer and a press.

Installer : 9-8522-1165-0

(J-6133-01)

NOTE :

Do not press on the roller cage.

Press only on the inner race.

5. Collapsible Spacer

Discard the used collapsible spacer and install a new one.

8. Oil Seal

Use the oil seal installer to install a new oil seal that has been

soaked in rear axle lubricant.

Installer : 9-8522-1275-0 (194 mm)

(J-24250)

: 5-8840-2165-0 (220 mm)

(J-37263)

10.Flange Nut and Washer

(1) Apply lubricant to pinion threads.

(2) Tighten the nut to the specified torque using the pinion

flange holder.

Pinion flange holder : 5-8840-0133-0 (194 mm)

(J-8614-01)

5-8840-2157-0 (220 mm)

(J-37221)

Flange Nut Torque N

m (kgfm/lbft)

194 mm 176.6 - 274.7 (18 - 28/130 - 202)

220 mm 245.3 - 294.3 (25 - 30/181 - 217)

Discard used flange nuts and install new ones.

Page 44 of 1600

4B-48 REAR AXLE

(3) Pinion bearing preload.

(a) Measure the bearing preload by using a torque wrench.

Note the scale reading required to rotate the flange.

(b) Continue tightening until the specified starting torque is

obtained.

Pinion Bearing Preload Starting Torque N

m (kgfm/lbft)

194 mm 64 - 113 (6.5 - 11.5/47 - 72)

220 mm 69 - 127 (7 - 13/51 - 94)

11.Backlash and Pre-load Adjusting Shim

(1) Attach the side bearing to the differential assembly without

shims. Support the opposite side using a pilot to prevent

bearing damage.

1Installer : 9-8522-1164-0 (194 mm)

(J-24244)

: 5-8840-2162-0 (220 mm)

(J-37257)

2Drive handle : 5-8840-0007-0

(J-8092)

3Pilot : 9-8521-1743-0

(J-8107-2)

(2) Position the differential cage assembly with the bearing

outer races to the side bearing bores of the carrier.

(3) Using two sets of feeler gauges, insert a feeler stock of

sufficient thickness between each bearing outer race and

the carrier to remove all end play. Make certain the feeler

stock is pushed to the bottom of the bearing bores.

Mount the dial indicator on the carrier so that the indicator

stem is at right angles to a tooth on the ring gear.

Dial indicator : 5-8840-0126-0

(J-8001)

Page 46 of 1600

4B-50 REAR AXLE

16.Bolt

Cap Bolt Torque N

m (kgfm/lbft)

194 mm 98.1

9.8 (10 1/72 7.2)

220 mm 107.9 9.8 (11 1/79.5 7.2)

Measure the amount of run-out of the ring gear at its rear face.

Run-Out mm(in)

Standard Limit

194 mm

220 mm0.02 (0.001) 0.05 (0.002)

Gear Tooth Contact Pattern Check and

Adjustment

Apply a thin coat of prussian blue or equivalent to the faces of

7 - 8 teeth of the ring gear. Check the impression of contact

obtained on the ring gear teeth and make necessary

adjustment as described below if the contact is abnormal.

Page 47 of 1600

REAR AXLE 4B-51

17.Differential Assembly

(1) Clean the faces of the rear axle case and differential carrier

and apply the recommended liquid gasket or its equivalent.

(2) Mount the differential case and the carrier assembly to the

rear axle case and tighten the nuts and bolts.

Torque N

m (kgfm/lbft)

Nut 37.3

3.9 (3.8 0.4/27 2.9)

bolt 24.5 5 (2.5 0.5/18 3.6)

Nut 44 14.7 (4.5 1.5/32.5 10.8)

Bolt 68.5 5 (6.5 0.5/47 3.6)220 mm 194 mm

(3) Install the axle shaft assemblies as instructed earlier in this

section under "Axle Shaft Reassembly".

(4) Fill the axle case with hypoid gear lubricant to just below the

filler hole.

Lubricant Capacity liter (US/UK gal.)

194 mm 1.5 (0.4/0.33)

220 mm 1.8 (0.48/0.4)

Check owners manual for correct type and viscosity of gear

lubricant required.

Page 55 of 1600

REAR AXLE 4B-59

3. OIL LEAKAGE

1) Differential Carrier Leakage

Checkpoint Trouble Cause Countermeasure

Correct the oil levelToo much gear oil NG

Reapply the liquid gasket

and/or tighten the lock nut to

the specified torque

Reapply the liquid gasket

Tighten the bolts to the

specified torque

Replace the oil seal

Ring gear thrust boltLoose lock nut and/or liquid

Liquid gasket seal bed

Loose bolts

Oil sealW orn or defective oil seal

Differential carrier

Clean the air breatherAir breatherClogged air breather

NG NG NG NG NG

OK OK OK

OK

Gear oil level

Page 56 of 1600

4B-60 REAR AXLE

2) Axle Case Leakage

Checkpoint Trouble Cause Countermeasure

Tighten the drain plug and/or

replace the gasket(s)Loose drain plug and/or

defective gasket(s) NG

Reapply the liquid gasket

Tighten the bolts to the

specified torque

Clean the air breather

Liquid gasket seal bad

Loose bolts

Air breatherClogged air breather

Differential carrier

Replace the axle caseAxle caseCracked axle case

NG NG NG NG

OK OK

OK

Oil filler and drain plug

Page 70 of 1600

FRONT WHEEL DRIVE 4C1-7

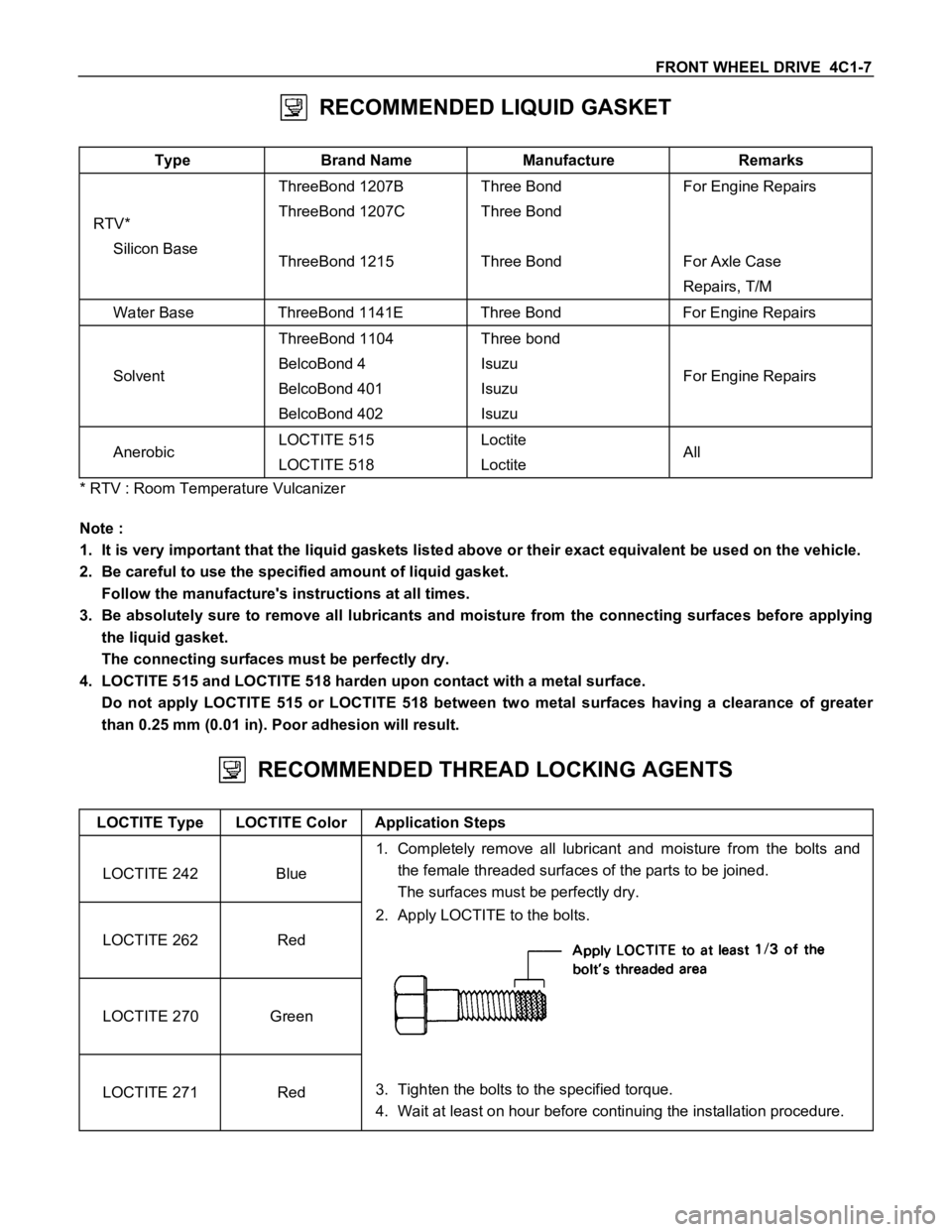

RECOMMENDED LIQUID GASKET

Type Brand Name Manufacture Remarks

RTV*

Silicon BaseThreeBond 1207B

ThreeBond 1207C

ThreeBond 1215Three Bond

Three Bond

Three BondFor Engine Repairs

For Axle Case

Repairs, T/M

Water Base ThreeBond 1141E Three Bond For Engine Repairs

SolventThreeBond 1104

BelcoBond 4

BelcoBond 401

BelcoBond 402Three bond

Isuzu

Isuzu

IsuzuFor Engine Repairs

AnerobicLOCTITE 515

LOCTITE 518Loctite

LoctiteAll

* RTV : Room Temperature Vulcanizer

Note :

1. It is very important that the liquid gaskets listed above or their exact equivalent be used on the vehicle.

2. Be careful to use the specified amount of liquid gasket.

Follow the manufacture's instructions at all times.

3. Be absolutely sure to remove all lubricants and moisture from the connecting surfaces before applying

the liquid gasket.

The connecting surfaces must be perfectly dry.

4. LOCTITE 515 and LOCTITE 518 harden upon contact with a metal surface.

Do not apply LOCTITE 515 or LOCTITE 518 between two metal surfaces having a clearance of greater

than 0.25 mm (0.01 in). Poor adhesion will result.

RECOMMENDED THREAD LOCKING AGENTS

LOCTITE Type LOCTITE Color Application Steps

LOCTITE 242 Blue1. Completely remove all lubricant and moisture from the bolts and

the female threaded surfaces of the parts to be joined.

The surfaces must be perfectly dry.

LOCTITE 262 Red2. Apply LOCTITE to the bolts.

LOCTITE 270 Green

LOCTITE 271 Red3. Tighten the bolts to the specified torque.

4. Wait at least on hour before continuing the installation procedure.

Page 77 of 1600

4C1-14 FRONT WHEEL DRIVE

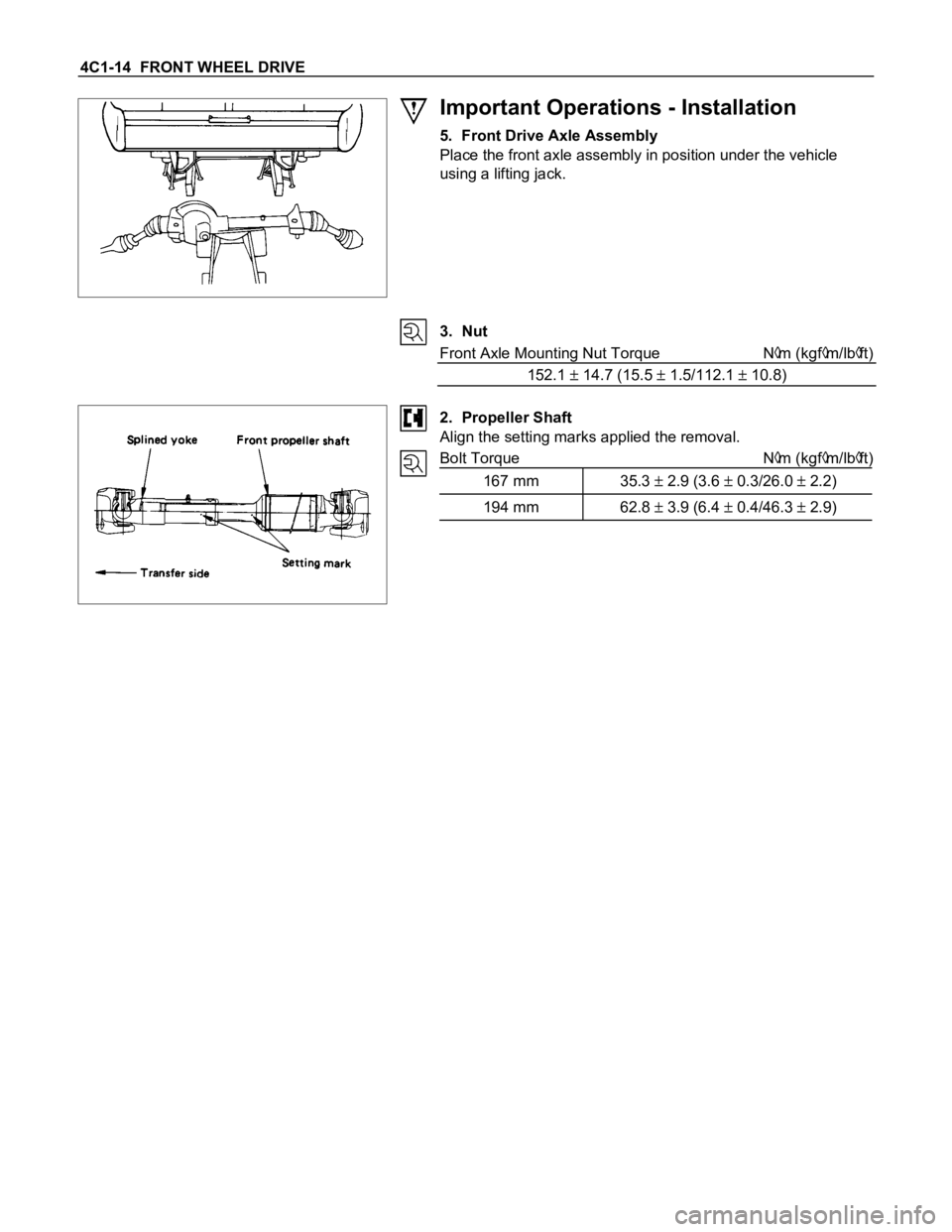

Important Operations - Installation

5. Front Drive Axle Assembly

Place the front axle assembly in position under the vehicle

using a lifting jack.

3. Nut

Front Axle Mounting Nut Torque N

m (kgfm/lbft)

152.1

14.7 (15.5 1.5/112.1 10.8)

2. Propeller Shaft

Align the setting marks applied the removal.

Bolt Torque N

m (kgfm/lbft)

167 mm 35.3

2.9 (3.6 0.3/26.0 2.2)

194 mm 62.8 3.9 (6.4 0.4/46.3 2.9)

Page 83 of 1600

4C1-20 FRONT WHEEL DRIVE

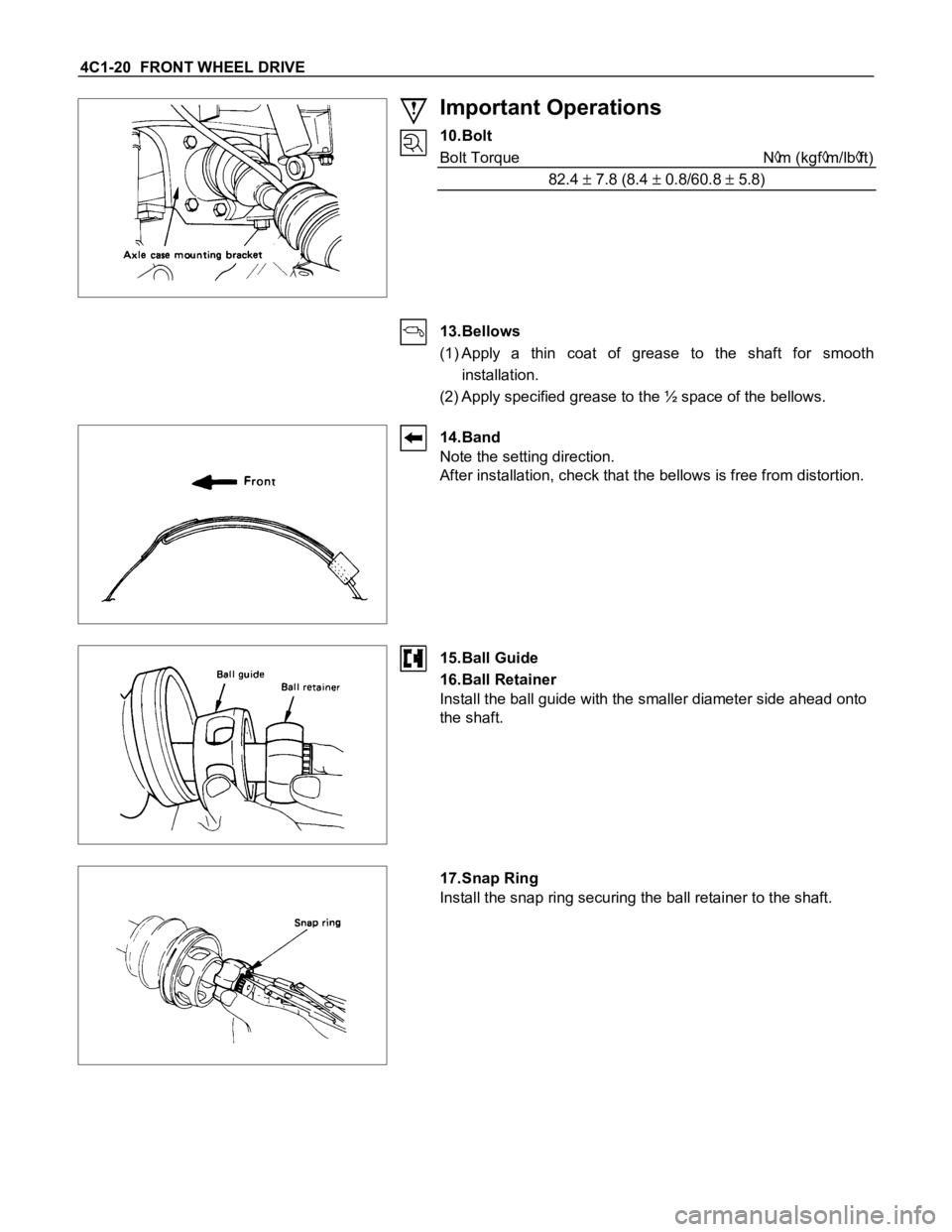

Important Operations

10.Bolt

Bolt Torque N

m (kgfm/lbft)

82.4

7.8 (8.4 0.8/60.8 5.8)

13.Bellows

(1) Apply a thin coat of grease to the shaft for smooth

installation.

(2) Apply specified grease to the ½ space of the bellows.

14.Band

Note the setting direction.

After installation, check that the bellows is free from distortion.

15.Ball Guide

16.Ball Retainer

Install the ball guide with the smaller diameter side ahead onto

the shaft.

17.Snap Ring

Install the snap ring securing the ball retainer to the shaft.