ISUZU TROOPER 1998 Service Repair Manual

Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1611 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 9

4. Injection Pipes

·Tighten the sleeve nut to the specified torque

3. Heater and Oil Cooler Pipe Fixing Bolts

·Tighten fixing bolts to the specified torque

2. Oil Level Gauge Tube (4JG2-T only)

1. Inter Cooler (4JG2-T only)

·Refer to ÒInter cooler installationÓsteps in this

section.19 (1.9/14)N·m(Kg·m/lb·ft)

29 (3.0/22)N·m(Kg·m/lb·ft)

Page 1612 of 3573

6A2 Ð 10 4JG2-NA/4JG2-TURBO ENGINE

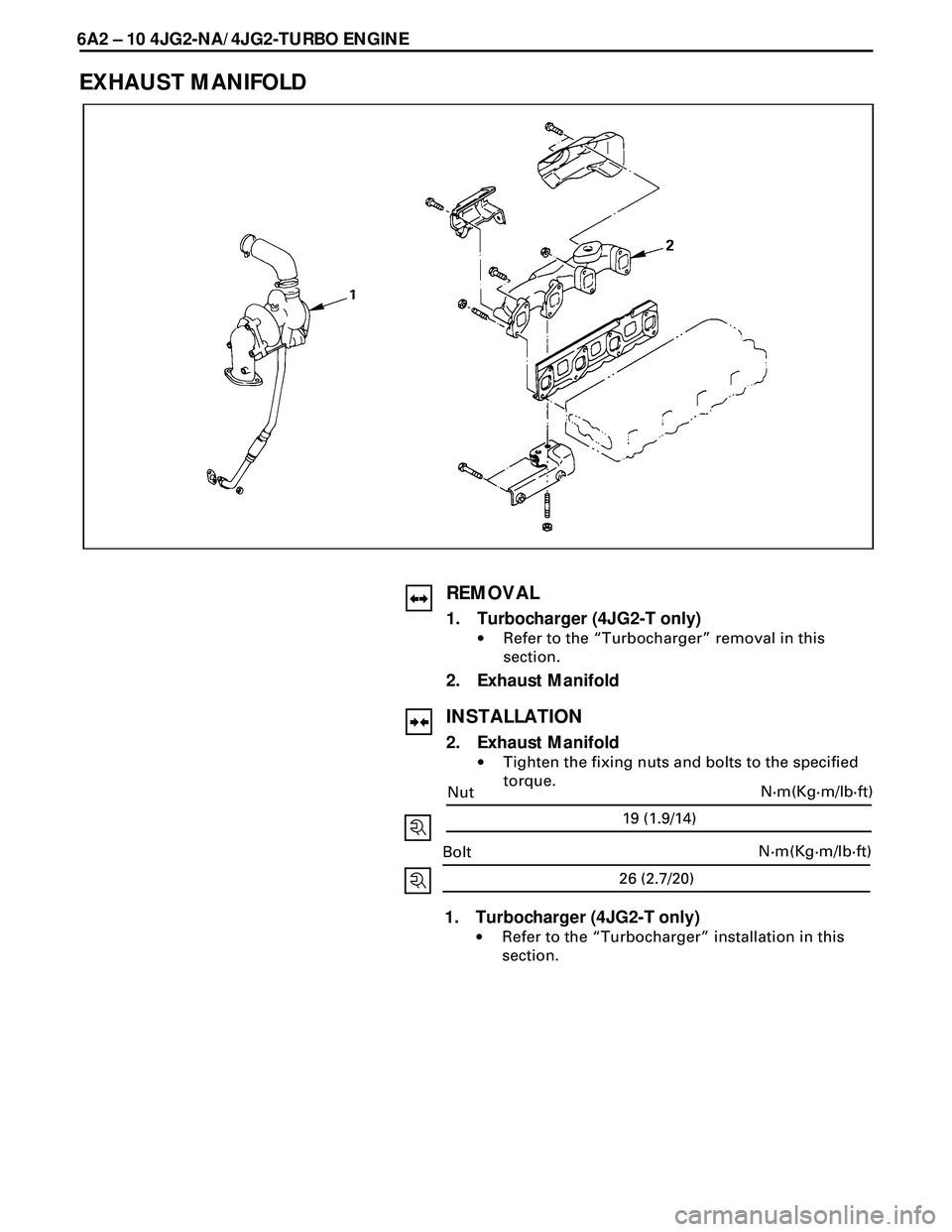

EXHAUST MANIFOLD

REMOVAL

1. Turbocharger (4JG2-T only)

·Refer to the ÒTurbochargerÓ removal in this

section.

2. Exhaust Manifold

INSTALLATION

2. Exhaust Manifold

·Tighten the fixing nuts and bolts to the specified

torque.

1. Turbocharger (4JG2-T only)

·Refer to the ÒTurbochargerÓ installation in this

section.

26 (2.7/20)

N·m(Kg·m/lb·ft)

Bolt

19 (1.9/14)

N·m(Kg·m/lb·ft)

Nut

Page 1613 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 11

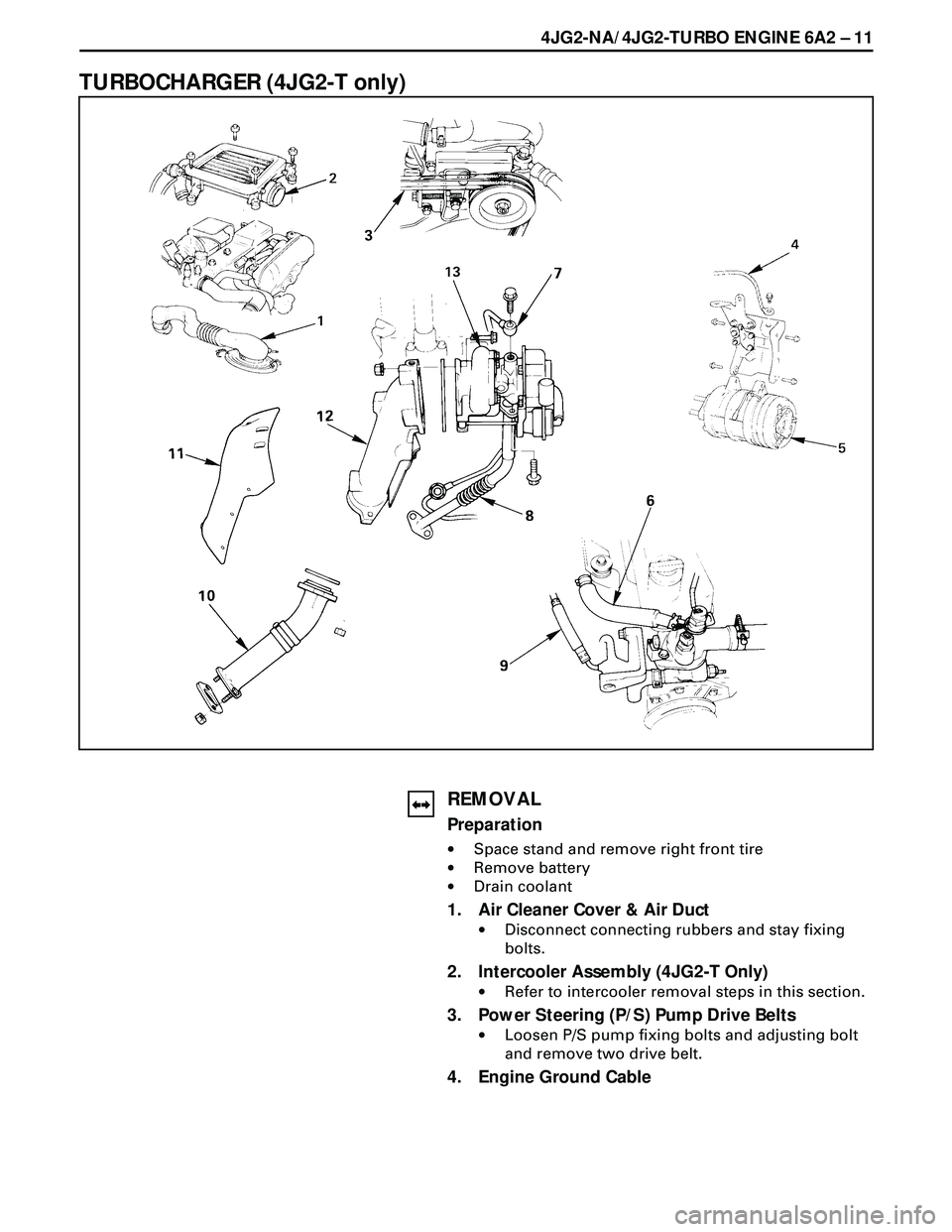

TURBOCHARGER (4JG2-T only)

REMOVAL

Preparation

·Space stand and remove right front tire

·Remove battery

·Drain coolant

1. Air Cleaner Cover & Air Duct

·Disconnect connecting rubbers and stay fixing

bolts.

2. Intercooler Assembly (4JG2-T Only)

·Refer to intercooler removal steps in this section.

3. Power Steering (P/S) Pump Drive Belts

·Loosen P/S pump fixing bolts and adjusting bolt

and remove two drive belt.

4. Engine Ground Cable

Page 1614 of 3573

6A2Ð 12 4JG2-NA/4JG2-TURBO ENGINE

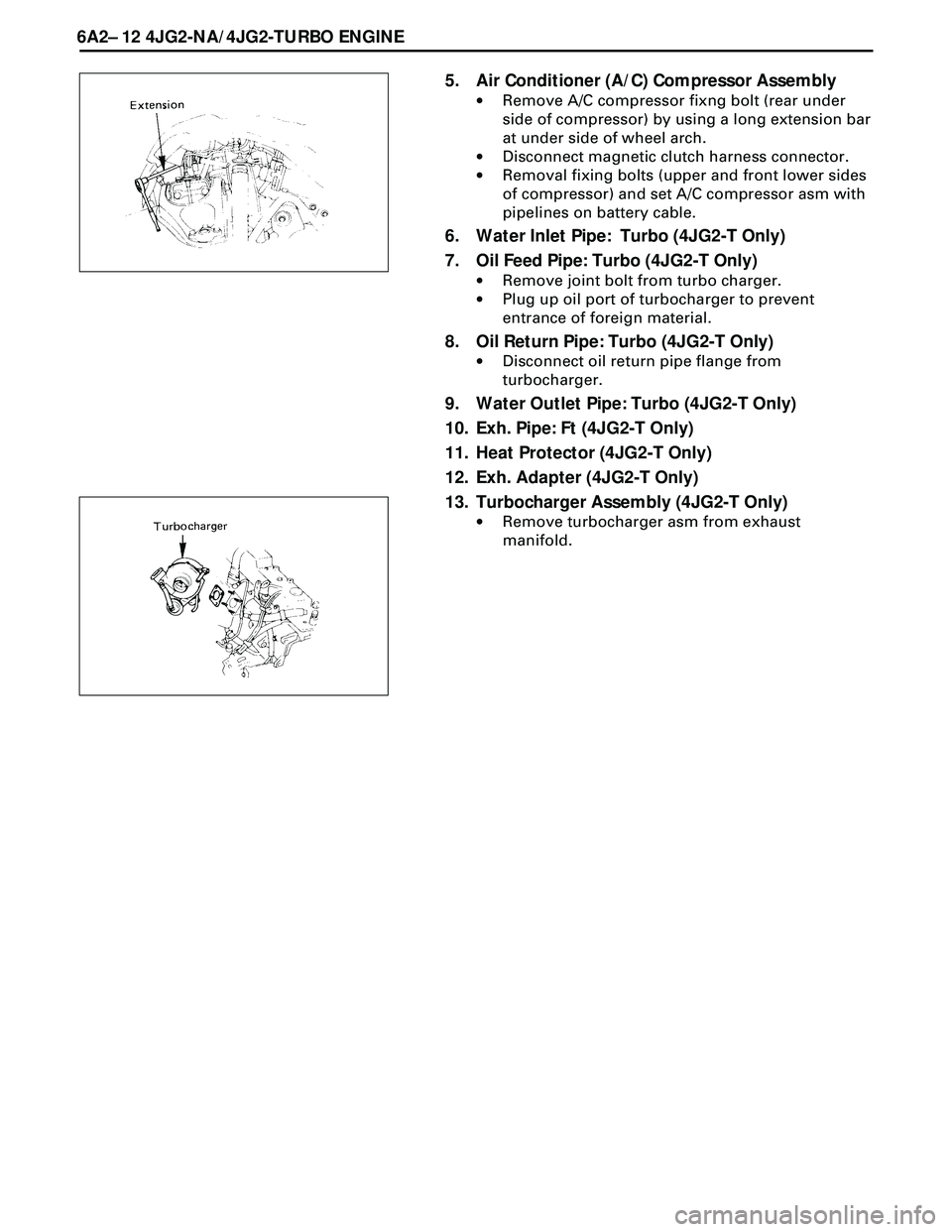

5. Air Conditioner (A/C) Compressor Assembly

·Remove A/C compressor fixng bolt (rear under

side of compressor) by using a long extension bar

at under side of wheel arch.

·Disconnect magnetic clutch harness connector.

·Removal fixing bolts (upper and front lower sides

of compressor) and set A/C compressor asm with

pipelines on battery cable.

6. Water Inlet Pipe: Turbo (4JG2-T Only)

7. Oil Feed Pipe: Turbo (4JG2-T Only)

·Remove joint bolt from turbo charger.

·Plug up oil port of turbocharger to prevent

entrance of foreign material.

8. Oil Return Pipe: Turbo (4JG2-T Only)

·Disconnect oil return pipe flange from

turbocharger.

9. Water Outlet Pipe: Turbo (4JG2-T Only)

10. Exh. Pipe: Ft (4JG2-T Only)

11. Heat Protector (4JG2-T Only)

12. Exh. Adapter (4JG2-T Only)

13. Turbocharger Assembly (4JG2-T Only)

·Remove turbocharger asm from exhaust

manifold.

Page 1615 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 13

26 (2.7/20)N·m(Kg·m/lb·ft)

INSTALLATION

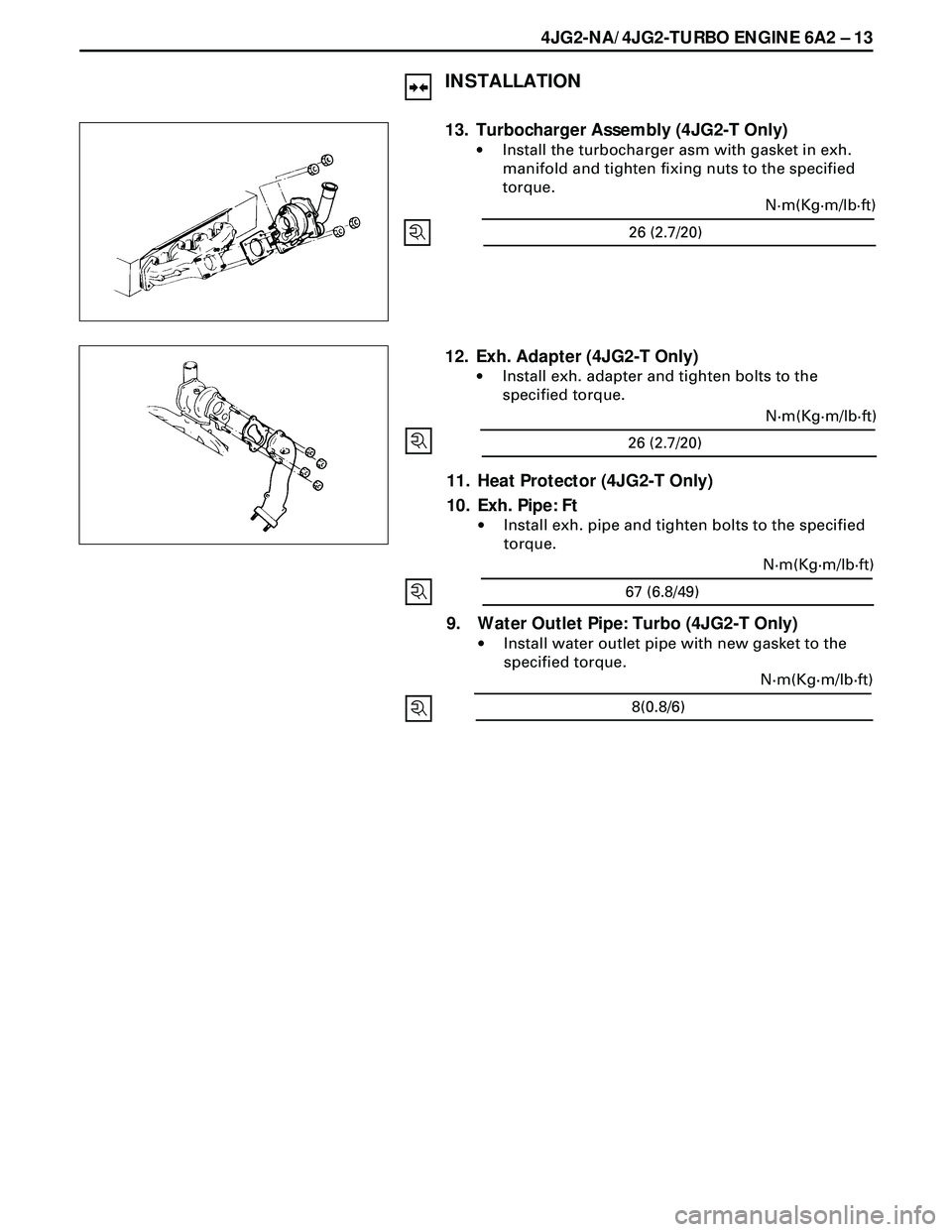

13. Turbocharger Assembly (4JG2-T Only)

·Install the turbocharger asm with gasket in exh.

manifold and tighten fixing nuts to the specified

torque.

12. Exh. Adapter (4JG2-T Only)

·Install exh. adapter and tighten bolts to the

specified torque.

11. Heat Protector (4JG2-T Only)

10. Exh. Pipe: Ft

·Install exh. pipe and tighten bolts to the specified

torque.

9. Water Outlet Pipe: Turbo (4JG2-T Only)

·Install water outlet pipe with new gasket to the

specified torque.

26 (2.7/20)N·m(Kg·m/lb·ft)

67 (6.8/49)N·m(Kg·m/lb·ft)

8(0.8/6)N·m(Kg·m/lb·ft)

Page 1616 of 3573

6A2Ð 14 4JG2-NA/4JG2-TURBO ENGINE

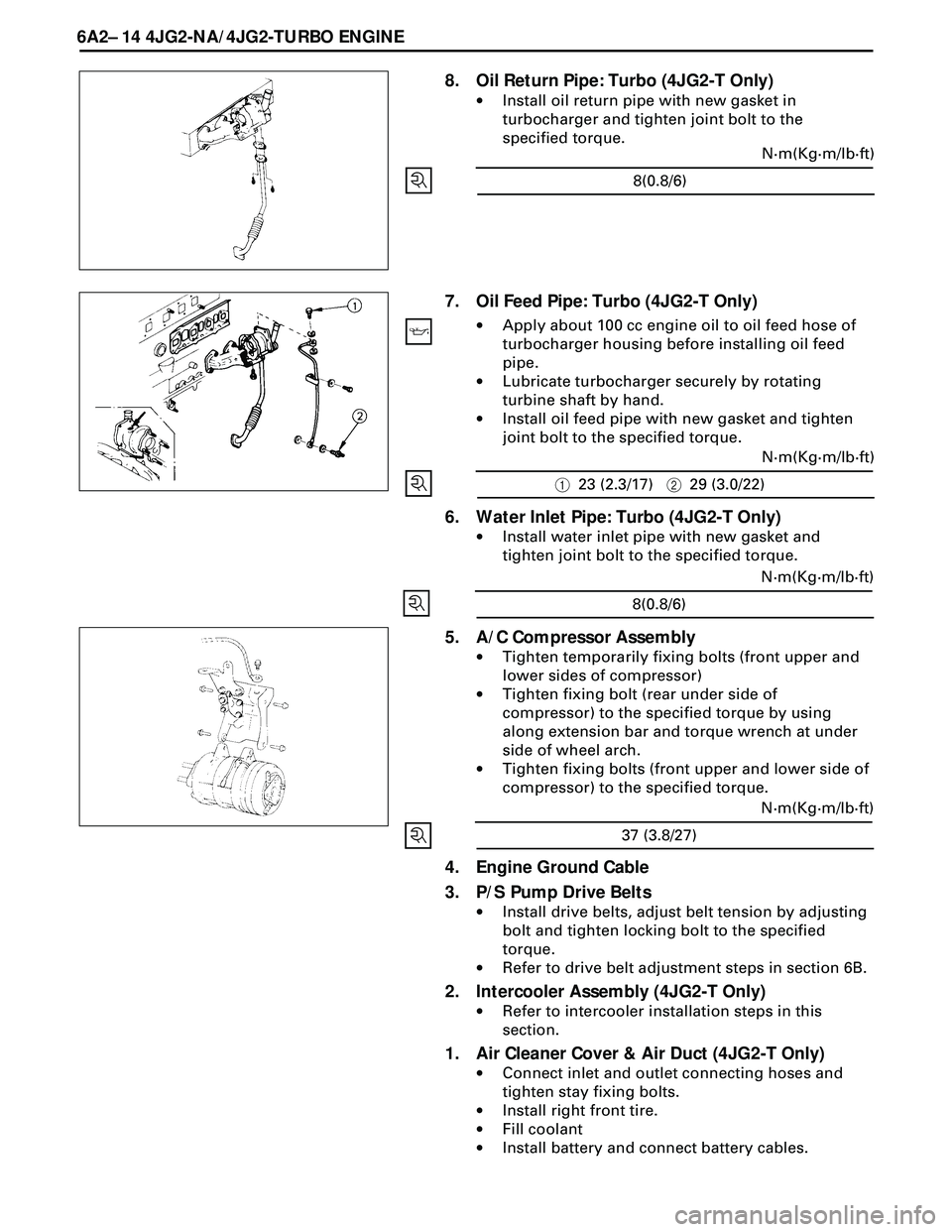

8. Oil Return Pipe: Turbo (4JG2-T Only)

·Install oil return pipe with new gasket in

turbocharger and tighten joint bolt to the

specified torque.

7. Oil Feed Pipe: Turbo (4JG2-T Only)

·Apply about 100 cc engine oil to oil feed hose of

turbocharger housing before installing oil feed

pipe.

·Lubricate turbocharger securely by rotating

turbine shaft by hand.

·Install oil feed pipe with new gasket and tighten

joint bolt to the specified torque.

6. Water Inlet Pipe: Turbo (4JG2-T Only)

·Install water inlet pipe with new gasket and

tighten joint bolt to the specified torque.

4. Engine Ground Cable

3. P/S Pump Drive Belts

·Install drive belts, adjust belt tension by adjusting

bolt and tighten locking bolt to the specified

torque.

·Refer to drive belt adjustment steps in section 6B.

2. Intercooler Assembly (4JG2-T Only)

·Refer to intercooler installation steps in this

section.

1. Air Cleaner Cover & Air Duct (4JG2-T Only)

·Connect inlet and outlet connecting hoses and

tighten stay fixing bolts.

·Install right front tire.

·Fill coolant

·Install battery and connect battery cables.

5. A/C Compressor Assembly

·Tighten temporarily fixing bolts (front upper and

lower sides of compressor)

·Tighten fixing bolt (rear under side of

compressor) to the specified torque by using

along extension bar and torque wrench at under

side of wheel arch.

·Tighten fixing bolts (front upper and lower side of

compressor) to the specified torque.

8(0.8/6)N·m(Kg·m/lb·ft)

123 (2.3/17)229 (3.0/22)N·m(Kg·m/lb·ft)

8(0.8/6)N·m(Kg·m/lb·ft)

37 (3.8/27)N·m(Kg·m/lb·ft)

Page 1617 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 15

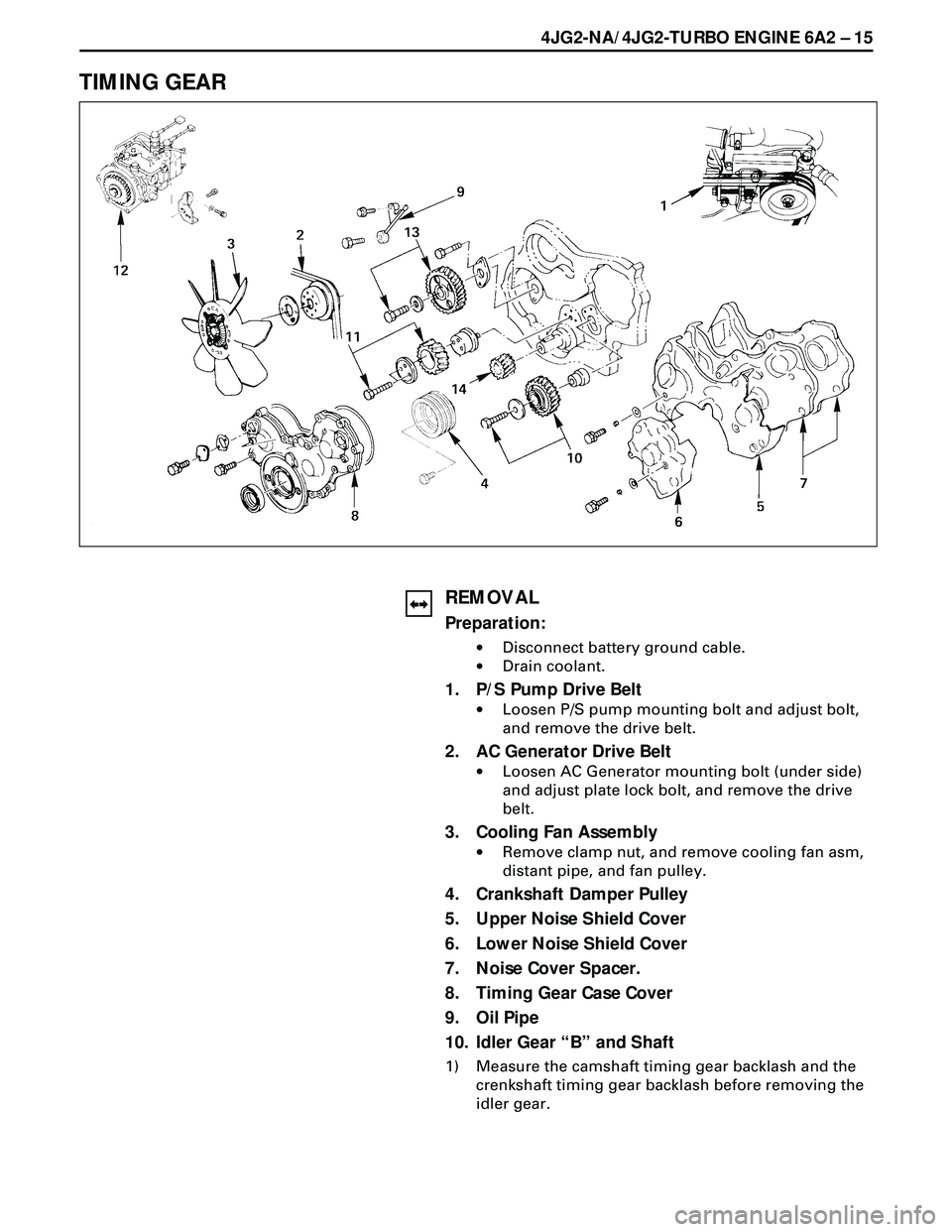

TIMING GEAR

REMOVAL

Preparation:

·Disconnect battery ground cable.

·Drain coolant.

1. P/S Pump Drive Belt

·Loosen P/S pump mounting bolt and adjust bolt,

and remove the drive belt.

2. AC Generator Drive Belt

·Loosen AC Generator mounting bolt (under side)

and adjust plate lock bolt, and remove the drive

belt.

3. Cooling Fan Assembly

·Remove clamp nut, and remove cooling fan asm,

distant pipe, and fan pulley.

4. Crankshaft Damper Pulley

5. Upper Noise Shield Cover

6. Lower Noise Shield Cover

7. Noise Cover Spacer.

8. Timing Gear Case Cover

9. Oil Pipe

10. Idler Gear ÒBÓ and Shaft

1) Measure the camshaft timing gear backlash and the

crenkshaft timing gear backlash before removing the

idler gear.

Page 1618 of 3573

6A2 Ð 16 4JG2-NA/4JG2-TURBO ENGINE

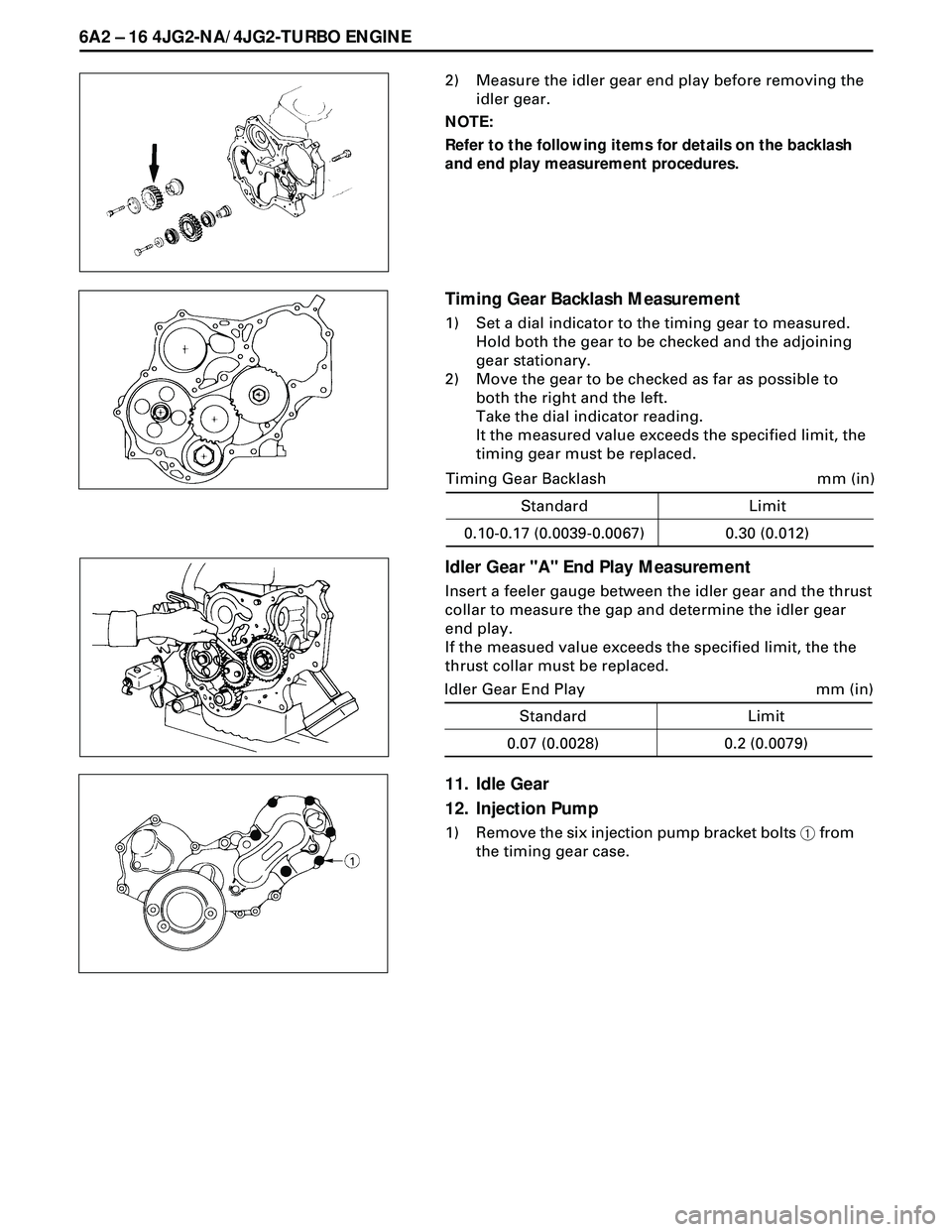

2) Measure the idler gear end play before removing the

idler gear.

NOTE:

Refer to the following items for details on the backlash

and end play measurement procedures.

Timing Gear Backlash Measurement

1) Set a dial indicator to the timing gear to measured.

Hold both the gear to be checked and the adjoining

gear stationary.

2) Move the gear to be checked as far as possible to

both the right and the left.

Take the dial indicator reading.

It the measured value exceeds the specified limit, the

timing gear must be replaced.

Idler Gear "A" End Play Measurement

Insert a feeler gauge between the idler gear and the thrust

collar to measure the gap and determine the idler gear

end play.

If the measued value exceeds the specified limit, the the

thrust collar must be replaced.

Standard

mm (in) Timing Gear Backlash

0.10-0.17 (0.0039-0.0067)Limit

0.30 (0.012)

11. Idle Gear

12. Injection Pump

1) Remove the six injection pump bracket bolts 1 from

the timing gear case.

Standard

mm (in) Idler Gear End Play

0.07 (0.0028)Limit

0.2 (0.0079)

Page 1619 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 17

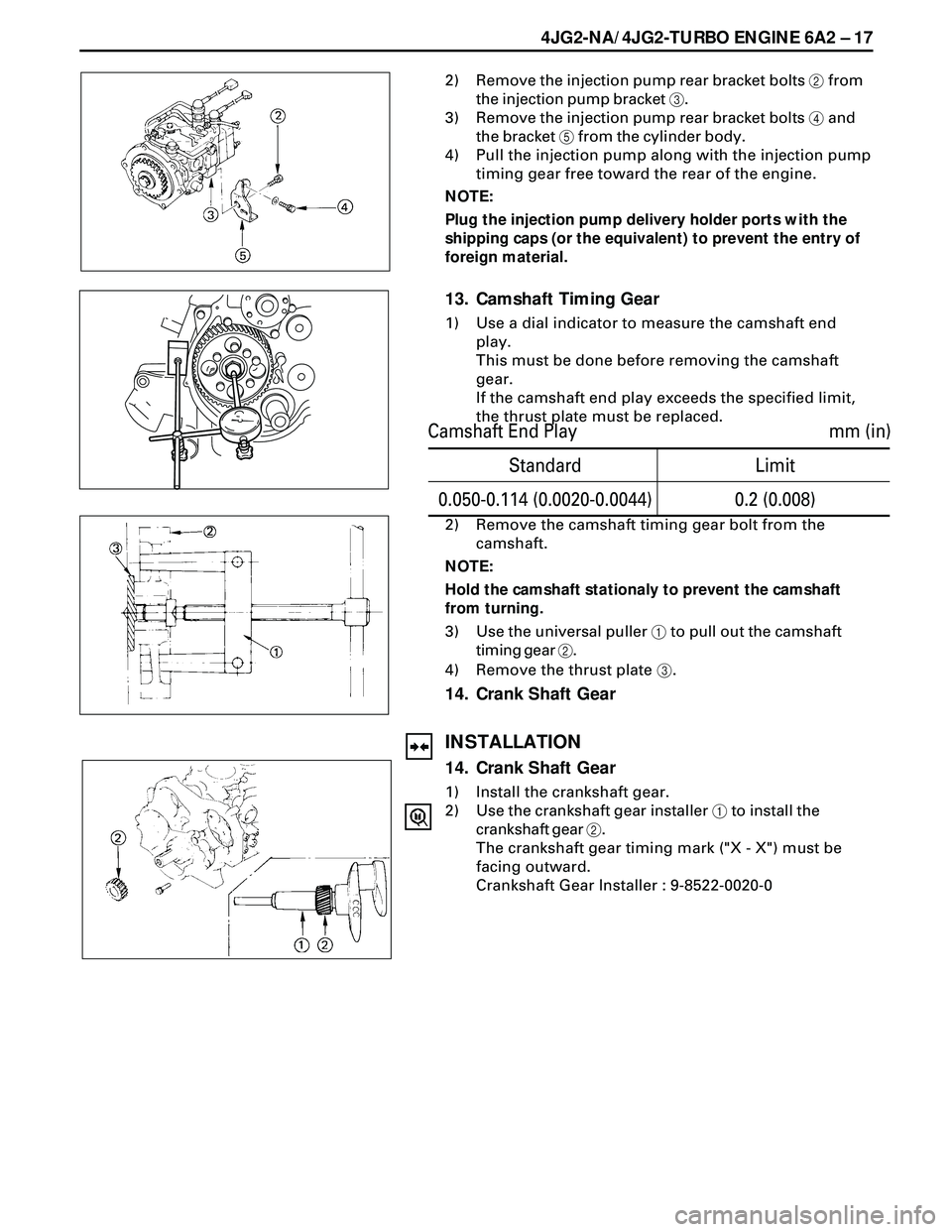

2) Remove the injection pump rear bracket bolts 2 from

the injection pump bracket 3.

3) Remove the injection pump rear bracket bolts 4 and

the bracket 5 from the cylinder body.

4) Pull the injection pump along with the injection pump

timing gear free toward the rear of the engine.

NOTE:

Plug the injection pump delivery holder ports with the

shipping caps (or the equivalent) to prevent the entry of

foreign material.

13. Camshaft Timing Gear

1) Use a dial indicator to measure the camshaft end

play.

This must be done before removing the camshaft

gear.

If the camshaft end play exceeds the specified limit,

the thrust plate must be replaced.

2) Remove the camshaft timing gear bolt from the

camshaft.

NOTE:

Hold the camshaft stationaly to prevent the camshaft

from turning.

3) Use the universal puller 1 to pull out the camshaft

timing gear 2.

4) Remove the thrust plate 3.

14. Crank Shaft Gear

INSTALLATION

14. Crank Shaft Gear

1) Install the crankshaft gear.

2) Use the crankshaft gear installer 1 to install the

crankshaft gear 2.

The crankshaft gear timing mark ("X - X") must be

facing outward.

Crankshaft Gear Installer : 9-8522-0020-0

Standard

mm (in) Camshaft End Play

0.050-0.114 (0.0020-0.0044)Limit

0.2 (0.008)

Page 1620 of 3573

6A2 Ð 18 4JG2-NA/4JG2-TURBO ENGINE

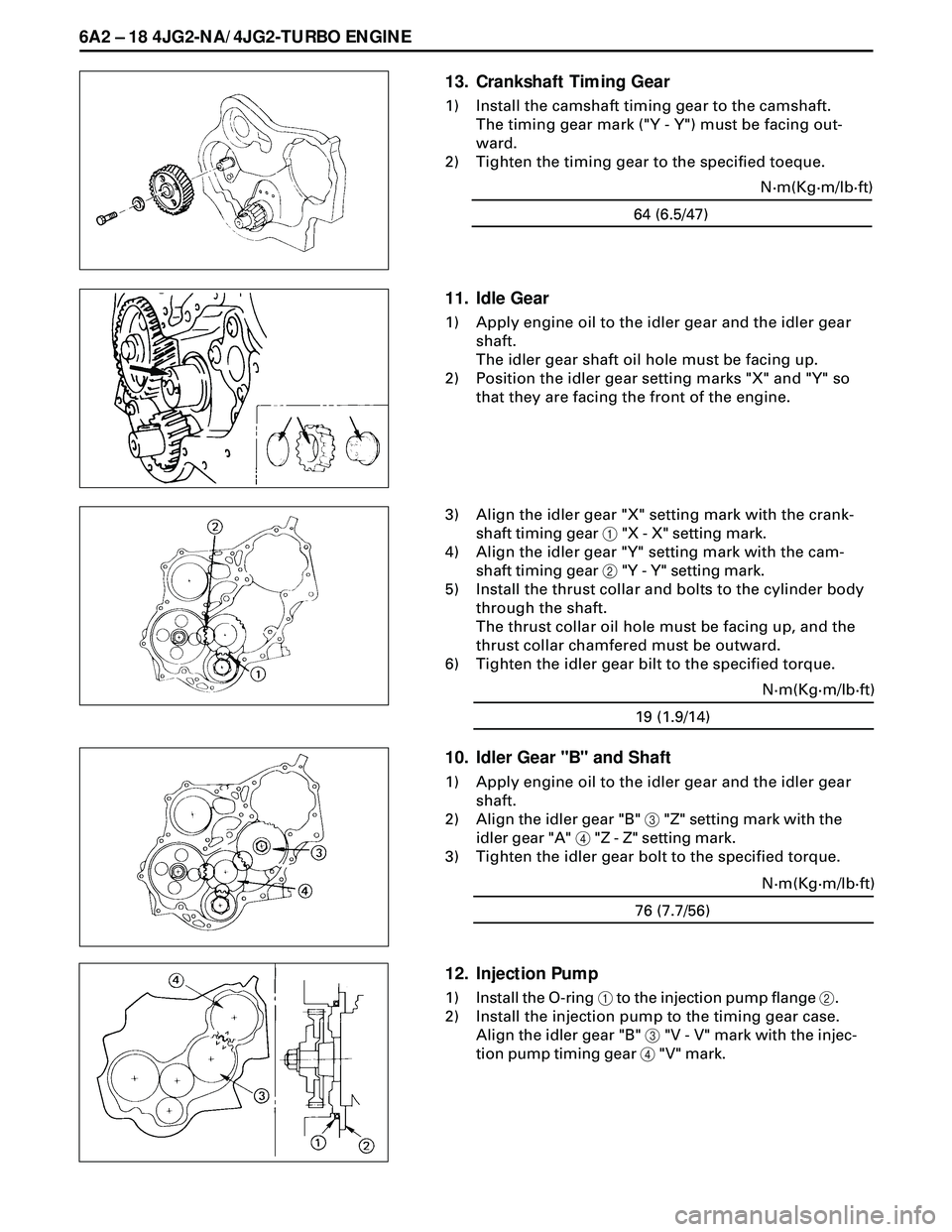

13. Crankshaft Timing Gear

1) Install the camshaft timing gear to the camshaft.

The timing gear mark ("Y - Y") must be facing out-

ward.

2) Tighten the timing gear to the specified toeque.

64 (6.5/47)N·m(Kg·m/lb·ft)

11. Idle Gear

1) Apply engine oil to the idler gear and the idler gear

shaft.

The idler gear shaft oil hole must be facing up.

2) Position the idler gear setting marks "X" and "Y" so

that they are facing the front of the engine.

3) Align the idler gear "X" setting mark with the crank-

shaft timing gear 1 "X - X" setting mark.

4) Align the idler gear "Y" setting mark with the cam-

shaft timing gear 2 "Y - Y" setting mark.

5) Install the thrust collar and bolts to the cylinder body

through the shaft.

The thrust collar oil hole must be facing up, and the

thrust collar chamfered must be outward.

6) Tighten the idler gear bilt to the specified torque.

19 (1.9/14)N·m(Kg·m/lb·ft)

10. Idler Gear "B" and Shaft

1) Apply engine oil to the idler gear and the idler gear

shaft.

2) Align the idler gear "B" 3 "Z" setting mark with the

idler gear "A" 4 "Z - Z" setting mark.

3) Tighten the idler gear bolt to the specified torque.

12. Injection Pump

1) Install the O-ring 1 to the injection pump flange 2.

2) Install the injection pump to the timing gear case.

Align the idler gear "B" 3 "V - V" mark with the injec-

tion pump timing gear 4 "V" mark.

76 (7.7/56)N·m(Kg·m/lb·ft)