ISUZU TROOPER 1998 Service Repair Manual

Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1631 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A 2Ð 29

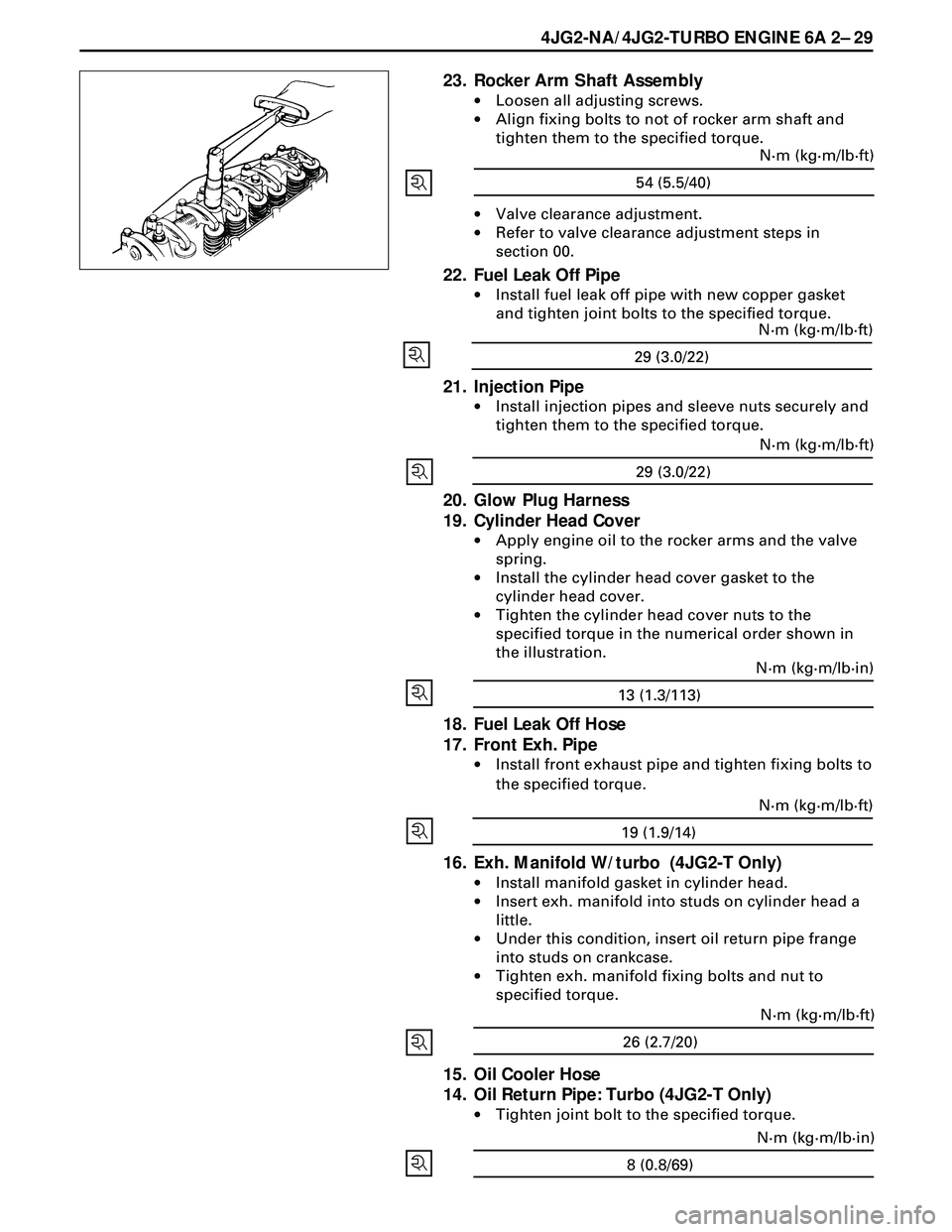

23. Rocker Arm Shaft Assembly

·Loosen all adjusting screws.

·Align fixing bolts to not of rocker arm shaft and

tighten them to the specified torque.

·Valve clearance adjustment.

·Refer to valve clearance adjustment steps in

section 00.

22. Fuel Leak Off Pipe

·Install fuel leak off pipe with new copper gasket

and tighten joint bolts to the specified torque.

54 (5.5/40)N·m (kg·m/lb·ft)

21. Injection Pipe

·Install injection pipes and sleeve nuts securely and

tighten them to the specified torque.

29 (3.0/22)N·m (kg·m/lb·ft)

29 (3.0/22)N·m (kg·m/lb·ft)

20. Glow Plug Harness

19. Cylinder Head Cover

·Apply engine oil to the rocker arms and the valve

spring.

·Install the cylinder head cover gasket to the

cylinder head cover.

·Tighten the cylinder head cover nuts to the

specified torque in the numerical order shown in

the illustration.

18. Fuel Leak Off Hose

17. Front Exh. Pipe

·Install front exhaust pipe and tighten fixing bolts to

the specified torque.

13 (1.3/113)N·m (kg·m/lb·in)

19 (1.9/14)N·m (kg·m/lb·ft)

16. Exh. Manifold W/turbo (4JG2-T Only)

·Install manifold gasket in cylinder head.

·Insert exh. manifold into studs on cylinder head a

little.

·Under this condition, insert oil return pipe frange

into studs on crankcase.

·Tighten exh. manifold fixing bolts and nut to

specified torque.

26 (2.7/20)N·m (kg·m/lb·ft)

15. Oil Cooler Hose

14. Oil Return Pipe: Turbo (4JG2-T Only)

·Tighten joint bolt to the specified torque.

8 (0.8/69)N·m (kg·m/lb·in)

Page 1632 of 3573

6A2 Ð 30 4JG2-NA/4JG2-TURBO ENGINE

13. Oil Feed Pipe: Turbo (4JG2-T Only)

·Tighten joint bolts (cylinder block and turbo

charger side) to the specified torque.

12. Water Outlet Hose: Turbo (4JG2-T Only)

·Connect to water inlet pipe of engine.

11. Water Inlet Hose: Turbo (4JG2-T Only)

·Connect to water outlet pipe.

10. Water Bypass Hose

·Water bypass hose connect to water inlet pipe.

9. Heater Hose

·Connect to heater pipe.

8. Engine Harness

·Connect five harness connecters to units on

thermostat housing.

7. Water Hose: CSD

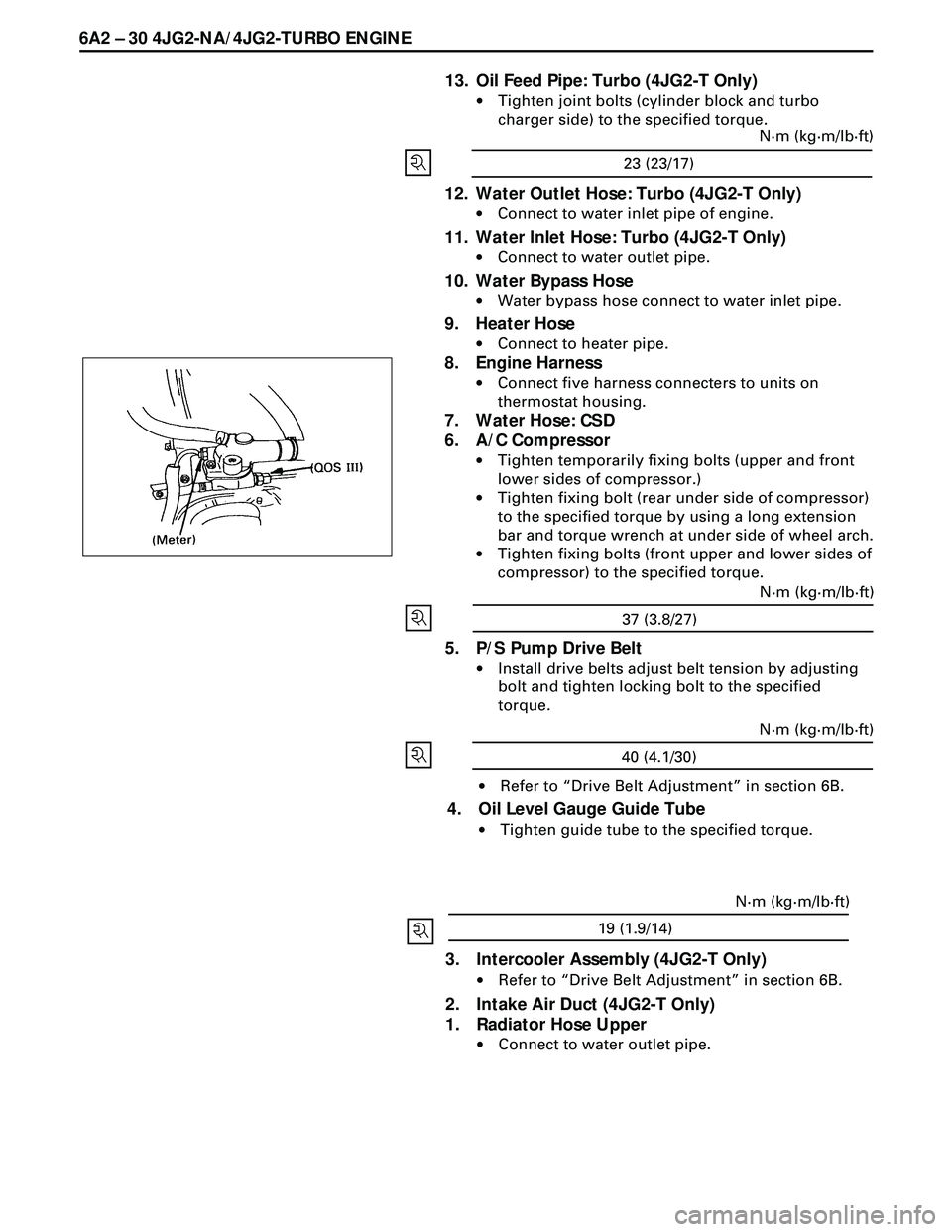

6. A/C Compressor

·Tighten temporarily fixing bolts (upper and front

lower sides of compressor.)

·Tighten fixing bolt (rear under side of compressor)

to the specified torque by using a long extension

bar and torque wrench at under side of wheel arch.

·Tighten fixing bolts (front upper and lower sides of

compressor) to the specified torque.

5. P/S Pump Drive Belt

·Install drive belts adjust belt tension by adjusting

bolt and tighten locking bolt to the specified

torque.

·Refer to ÒDrive Belt AdjustmentÓ in section 6B.

4. Oil Level Gauge Guide Tube

·Tighten guide tube to the specified torque.

23 (23/17)N·m (kg·m/lb·ft)

37 (3.8/27)N·m (kg·m/lb·ft)

40 (4.1/30)N·m (kg·m/lb·ft)

19 (1.9/14)N·m (kg·m/lb·ft)

3. Intercooler Assembly (4JG2-T Only)

·Refer to ÒDrive Belt AdjustmentÓ in section 6B.

2. Intake Air Duct (4JG2-T Only)

1. Radiator Hose Upper

·Connect to water outlet pipe.

Page 1633 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 31

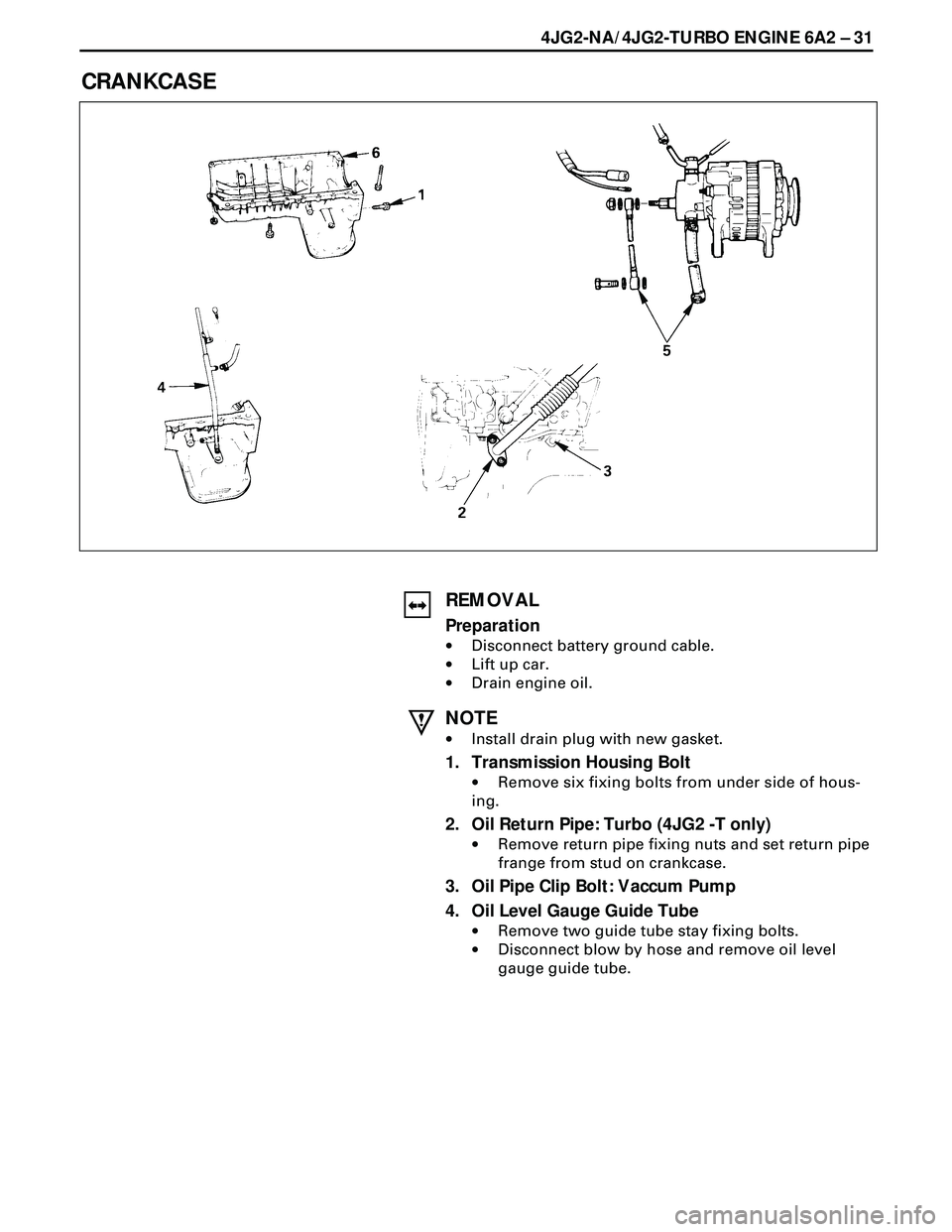

CRANKCASE

REMOVAL

Preparation

·Disconnect battery ground cable.

·Lift up car.

·Drain engine oil.

NOTE

·Install drain plug with new gasket.

1. Transmission Housing Bolt

·Remove six fixing bolts from under side of hous-

ing.

2. Oil Return Pipe: Turbo (4JG2 -T only)

·Remove return pipe fixing nuts and set return pipe

frange from stud on crankcase.

3. Oil Pipe Clip Bolt: Vaccum Pump

4. Oil Level Gauge Guide Tube

·Remove two guide tube stay fixing bolts.

·Disconnect blow by hose and remove oil level

gauge guide tube.

Page 1634 of 3573

6A2 Ð 32 4JG2-NA/4JG2-TURBO ENGINE

5. Vacuum Hose

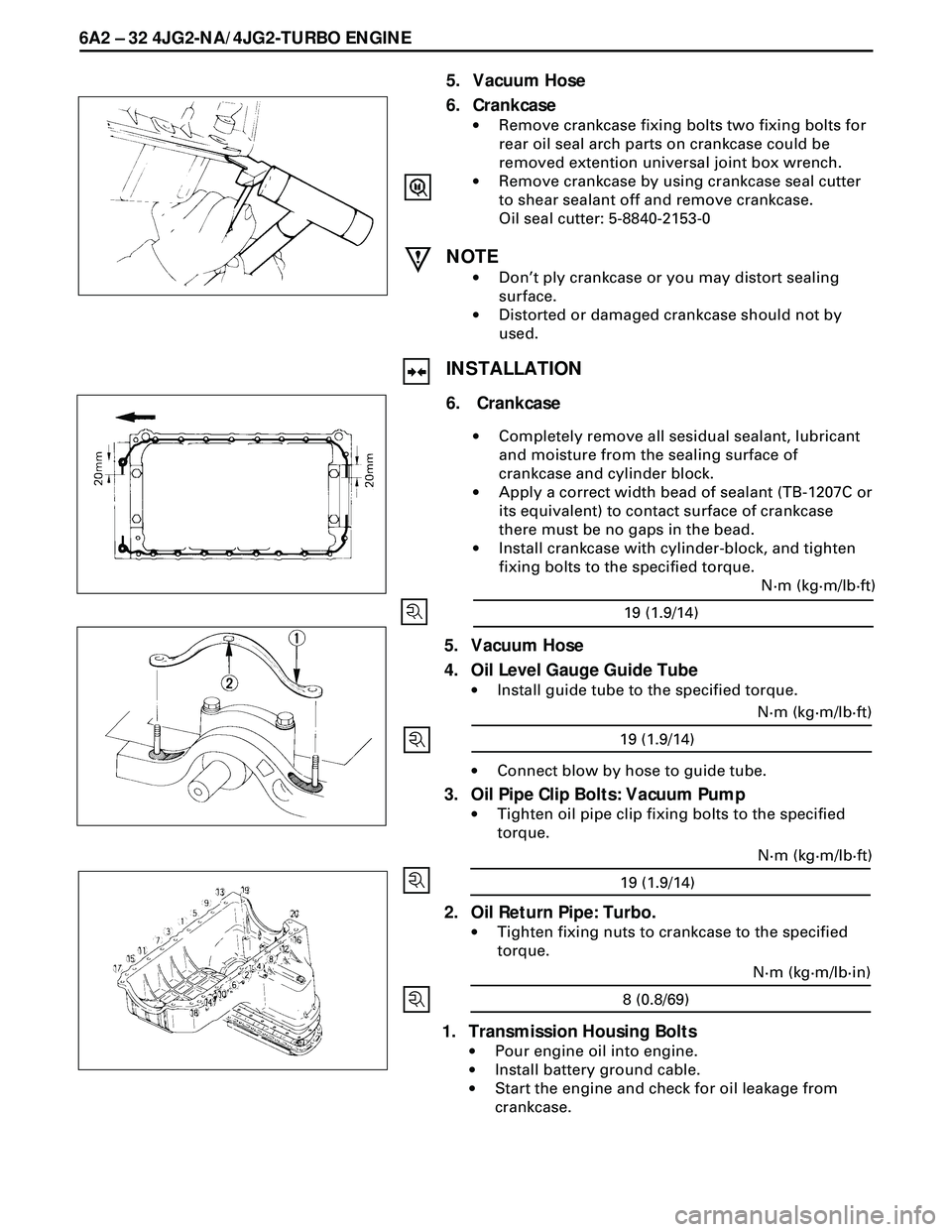

6. Crankcase

·Remove crankcase fixing bolts two fixing bolts for

rear oil seal arch parts on crankcase could be

removed extention universal joint box wrench.

·Remove crankcase by using crankcase seal cutter

to shear sealant off and remove crankcase.

Oil seal cutter: 5-8840-2153-0

NOTE

·DonÕt ply crankcase or you may distort sealing

surface.

·Distorted or damaged crankcase should not by

used.

INSTALLATION

6. Crankcase

·Completely remove all sesidual sealant, lubricant

and moisture from the sealing surface of

crankcase and cylinder block.

·Apply a correct width bead of sealant (TB-1207C or

its equivalent) to contact surface of crankcase

there must be no gaps in the bead.

·Install crankcase with cylinder-block, and tighten

fixing bolts to the specified torque.

5. Vacuum Hose

4. Oil Level Gauge Guide Tube

·Install guide tube to the specified torque.

·Connect blow by hose to guide tube.

3. Oil Pipe Clip Bolts: Vacuum Pump

·Tighten oil pipe clip fixing bolts to the specified

torque.

2. Oil Return Pipe: Turbo.

·Tighten fixing nuts to crankcase to the specified

torque.

1. Transmission Housing Bolts

·Pour engine oil into engine.

·Install battery ground cable.

·Start the engine and check for oil leakage from

crankcase.

19 (1.9/14)N·m (kg·m/lb·ft)

19 (1.9/14)N·m (kg·m/lb·ft)

19 (1.9/14)N·m (kg·m/lb·ft)

8 (0.8/69)N·m (kg·m/lb·in)

Page 1635 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 33

OIL FILTER CARTRIDGE

REMOVAL

·Place a receptacle beneath the oil filter to contain the

drained oil.

·Remove the oil filter cartridge using filter wrench.

Filter wrench: 5-8840-0200-0

INSTALLATION

·Lightly oil the o-ring of oil filter cartridge.

·Turn in the new oil filter cartridge by hand until the

sealing face is fiffted again the o-ring.

·Use the filter wrench to turn in the oil filter and

additional one and 1á1/8 turns.

·Start the engine and check for oil leakage from oil filter.

Page 1636 of 3573

6A2 Ð 34 4JG2-NA/4JG2-TURBO ENGINE

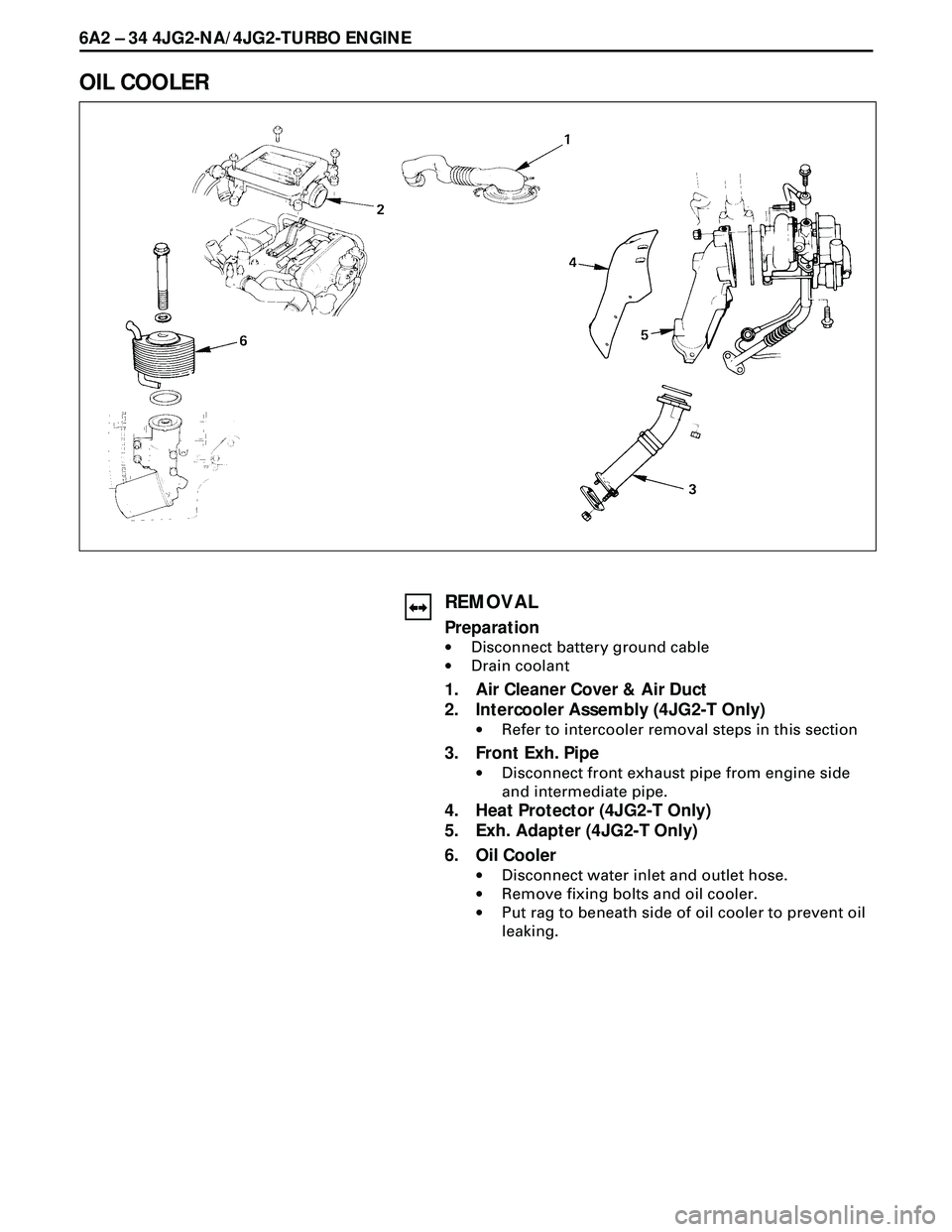

OIL COOLER

REMOVAL

Preparation

·Disconnect battery ground cable

·Drain coolant

1. Air Cleaner Cover & Air Duct

2. Intercooler Assembly (4JG2-T Only)

·Refer to intercooler removal steps in this section

3. Front Exh. Pipe

·Disconnect front exhaust pipe from engine side

and intermediate pipe.

4. Heat Protector (4JG2-T Only)

5. Exh. Adapter (4JG2-T Only)

6. Oil Cooler

·Disconnect water inlet and outlet hose.

·Remove fixing bolts and oil cooler.

·Put rag to beneath side of oil cooler to prevent oil

leaking.

Page 1637 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2Ð 35

INSTALLATION

6. Oil Cooler

·Tighten oil cooler fixing bolt to the specified

torque and connect water hose.

5. Exh. Adapter (4JG2-T Only)

·Install exhaust duct with gasket and tighten fixing

bolts to the specified torque.

26 (2.7/20)N·m(Kg·m/lb·ft)

4. Heat Protector (4JG2-T Only)

3. Front Exh. Pipe

·Install front exhaust pipe and tighten fixing bolts

to the specified torque.

2. Intercooler Assembly (4JG2-T Only)

·Refer to intercooler installation steps in section.

·Pour coolant into radiator.

·Install battery ground cable.

·Start engine and check for oil and water leakage

carefully.

1. Air Cleaner Cover & Air Duct

67 (6.8/49)N·m(Kg·m/lb·ft)

Exh Dust Side

43 (4.4/32)N·m(Kg·m/lb·ft)

Intermediate pipe side 29 (3.0/22)N·m(Kg·m/lb·ft)

Page 1638 of 3573

6A2 Ð 36 4JG2-NA/4JG2-TURBO ENGINE

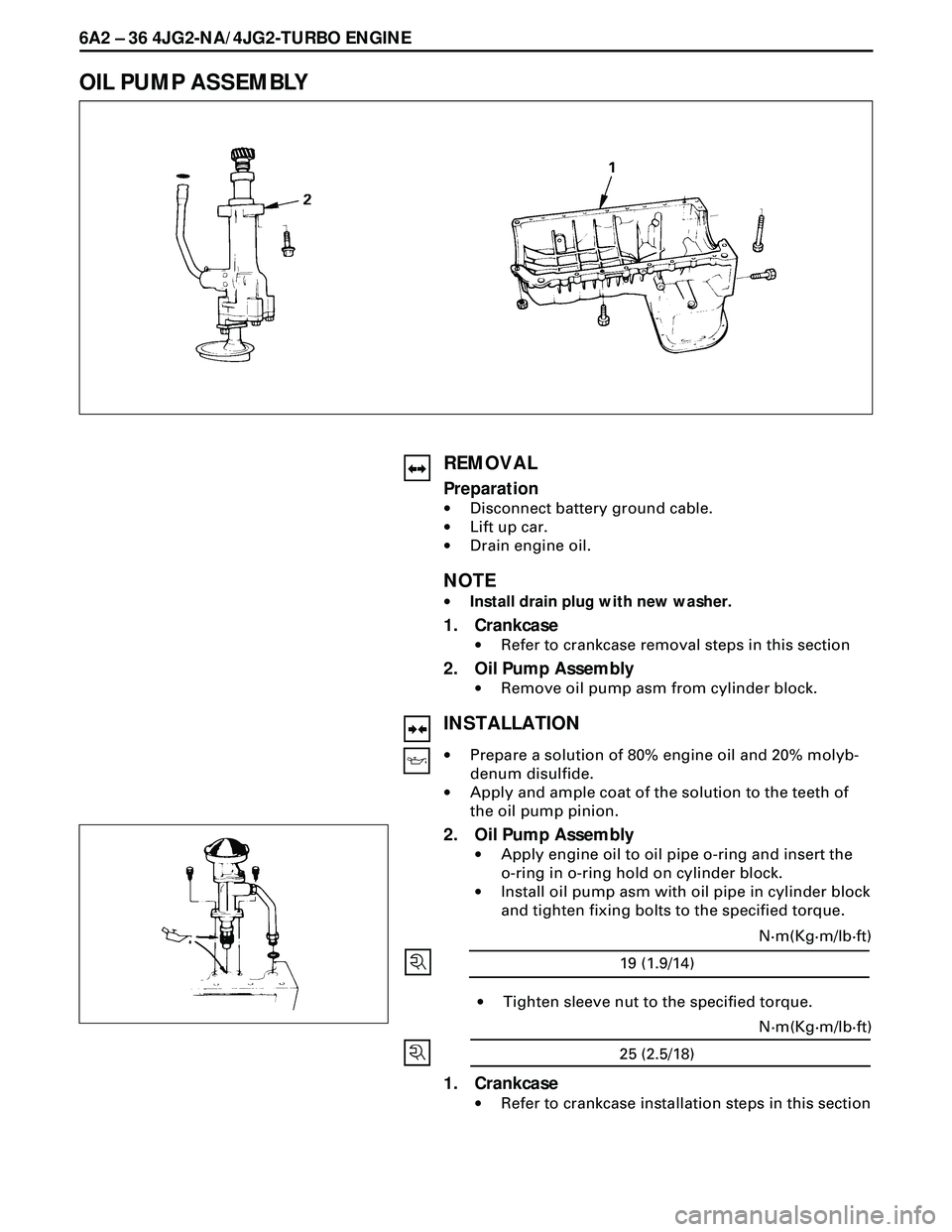

OIL PUMP ASSEMBLY

REMOVAL

Preparation

·Disconnect battery ground cable.

·Lift up car.

·Drain engine oil.

NOTE

·Install drain plug with new washer.

1. Crankcase

·Refer to crankcase removal steps in this section

2. Oil Pump Assembly

·Remove oil pump asm from cylinder block.

INSTALLATION

·Prepare a solution of 80% engine oil and 20% molyb-

denum disulfide.

·Apply and ample coat of the solution to the teeth of

the oil pump pinion.

2. Oil Pump Assembly

·Apply engine oil to oil pipe o-ring and insert the

o-ring in o-ring hold on cylinder block.

·Install oil pump asm with oil pipe in cylinder block

and tighten fixing bolts to the specified torque.

19 (1.9/14)N·m(Kg·m/lb·ft)

·Tighten sleeve nut to the specified torque.

25 (2.5/18)N·m(Kg·m/lb·ft)

1. Crankcase

·Refer to crankcase installation steps in this section

Page 1639 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 37

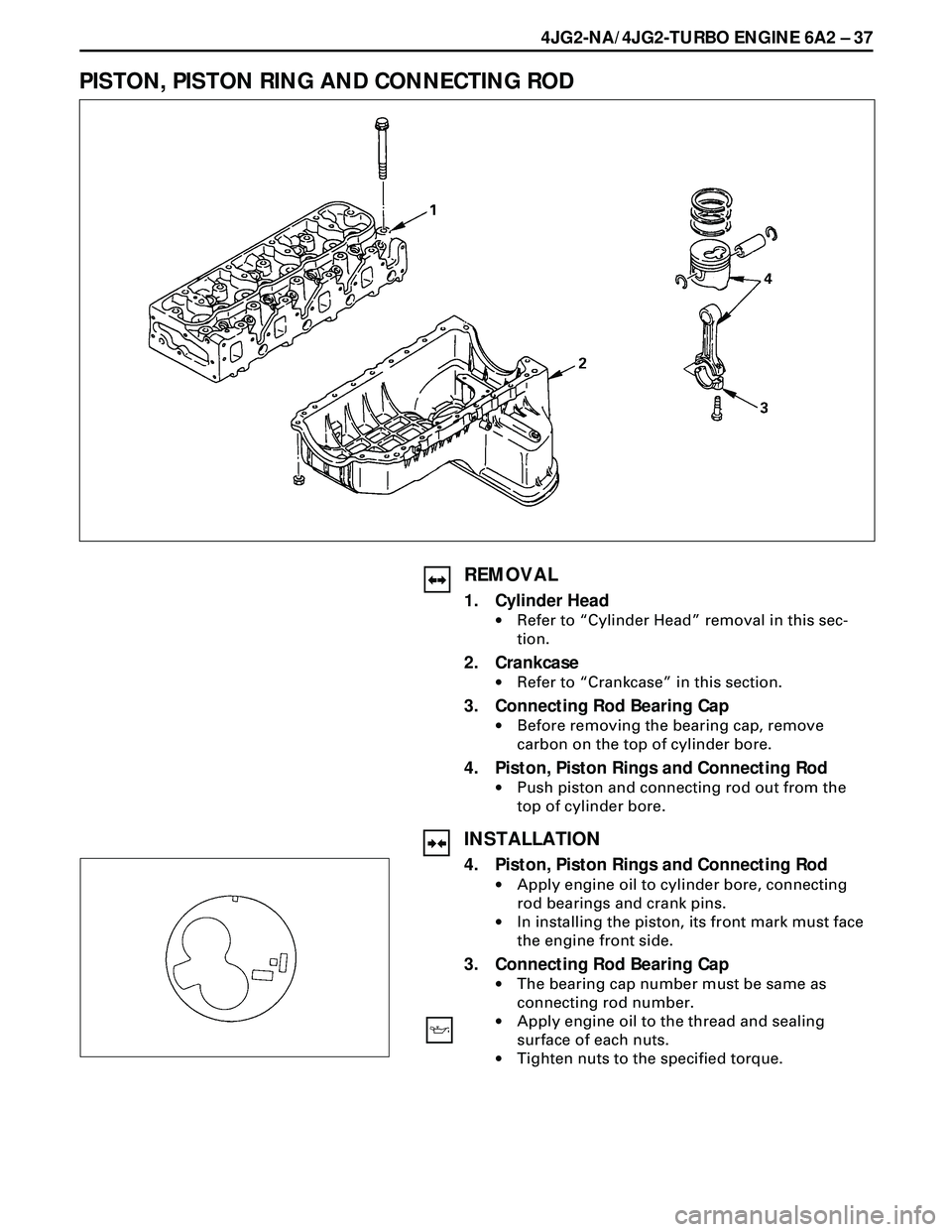

PISTON, PISTON RING AND CONNECTING ROD

REMOVAL

1. Cylinder Head

·Refer to ÒCylinder HeadÓ removal in this sec-

tion.

2. Crankcase

·Refer to ÒCrankcaseÓ in this section.

3. Connecting Rod Bearing Cap

·Before removing the bearing cap, remove

carbon on the top of cylinder bore.

4. Piston, Piston Rings and Connecting Rod

·Push piston and connecting rod out from the

top of cylinder bore.

INSTALLATION

4. Piston, Piston Rings and Connecting Rod

·Apply engine oil to cylinder bore, connecting

rod bearings and crank pins.

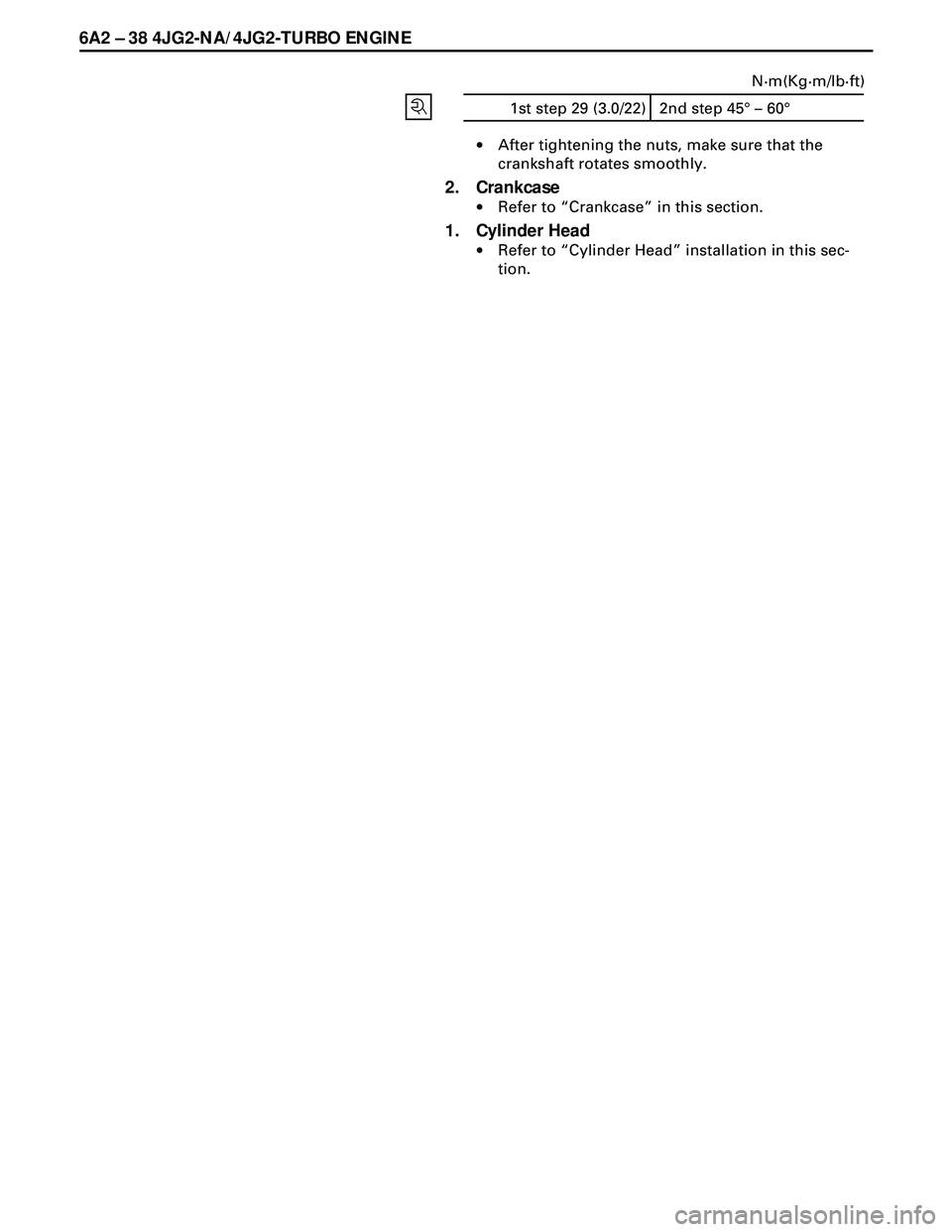

·In installing the piston, its front mark must face

the engine front side.

3. Connecting Rod Bearing Cap

·The bearing cap number must be same as

connecting rod number.

·Apply engine oil to the thread and sealing

surface of each nuts.

·Tighten nuts to the specified torque.

Page 1640 of 3573

6A2 Ð 38 4JG2-NA/4JG2-TURBO ENGINE

·After tightening the nuts, make sure that the

crankshaft rotates smoothly.

2. Crankcase

·Refer to ÒCrankcaseÓ in this section.

1. Cylinder Head

·Refer to ÒCylinder HeadÓ installation in this sec-

tion.

1st step 29 (3.0/22) 2nd step 45° – 60°N·m(Kg·m/lb·ft)