ISUZU TROOPER 1998 Service Repair Manual

Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1651 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 49

3. Cooling Fan Assembly

┬ĘRemove cooling fan asm fixing nuts, cooling fan

asm, fan pulley and center.

4. Radiator Assembly

┬ĘRemove bracket and radiator asm.

5. Air Cleaner Cover & Air Duct

6. Intercooler Assembly (4JG2 -T only)

┬Ę(Refer to Intercooler removal steps in this section)

7. P/S Pump Drive Belts

┬ĘLoosen P/S pump fixing bolts and adjusting bolt

and remove two drive belts.

8. P/S Pump Assembly

┬ĘRemove two fixing bolts (front side), a fixing nut

(rear side) and support P/S pump asm with oil

hoses by tying to body side.

9. Engine Ground Cable

┬ĘDisconnect ground cable from A/C compressor

bracket.

10. AC Generator Harness

┬ĘDisconnect B terminal and harness connector

from AC generator.

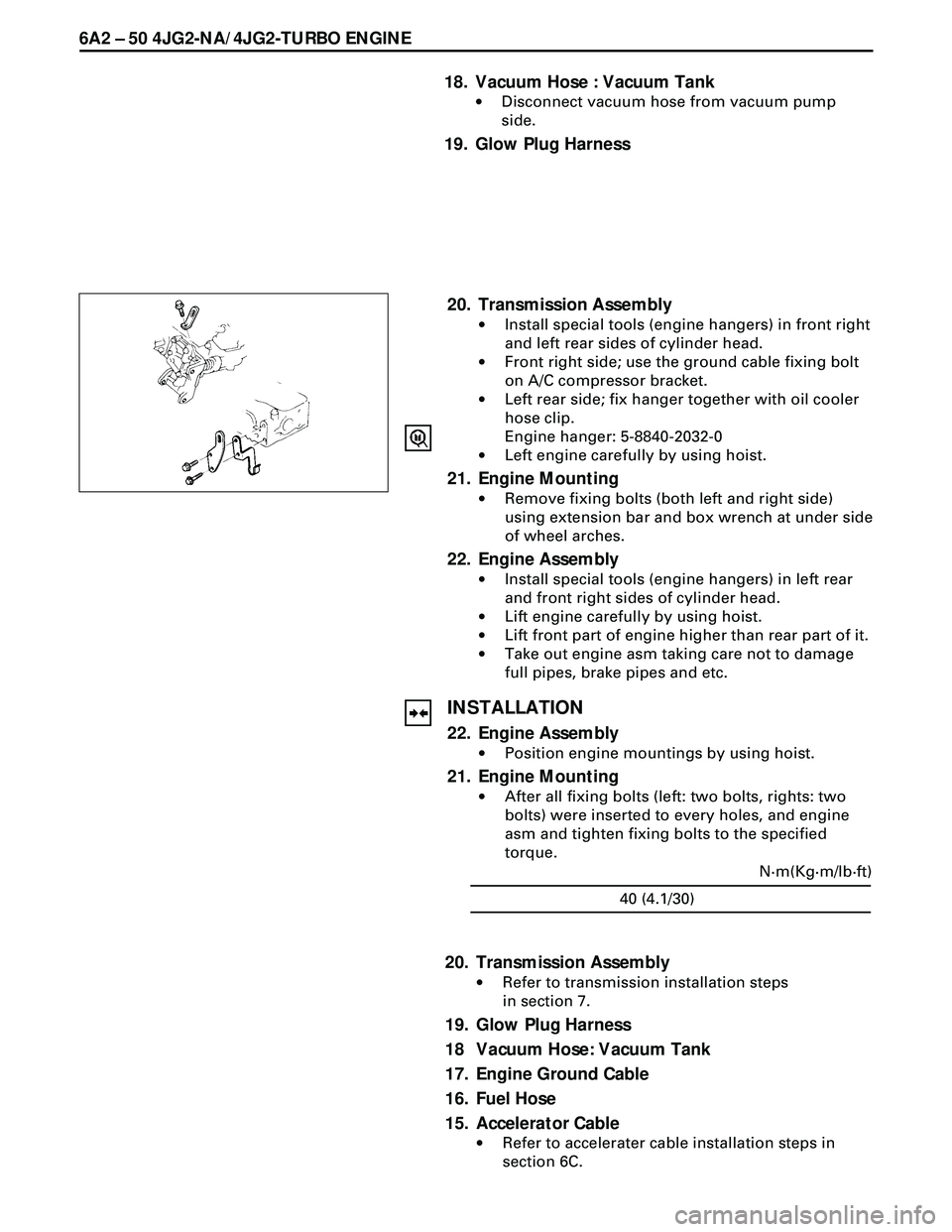

11. A/C Compressor Assembly

┬ĘRemove A/C compressor fixing bolt (rear under

side of compressor) by using a long extension bar

at under side of wheel arch.

┬ĘDisconnect magnetic clutch harness connector.

┬ĘRemove fixing bolts (upper and front lower side

of compressor) and set A/C compressor asm with

pipe lines on battery carrier.

12. Vacuum Hose: Vacuum Pump

┬ĘDisconnect vacuum hose from vacuum pump.

13. Starter Harness

┬ĘDisconnect B terminal and put cable harness close

to chassis side.

┬ĘDisconnect S terminal connector.

14. Engine Harness.

┬ĘDisconnect engine harness close to engine side.

15. Accelerater Cable

┬ĘLoosen locking nut at bracket and disconnect

accelerater cable from injection pump control

lever.

16. Fuel Hoses

┬ĘDisconnect fuel hoses from injection pump side

and take care not to spill fuel and enter dust.

17. Engine Ground Cable

┬ĘDisconnect ground cable from left rear side of

timing gear case.

Page 1652 of 3573

6A2 Ð 50 4JG2-NA/4JG2-TURBO ENGINE

18. Vacuum Hose : Vacuum Tank

┬ĘDisconnect vacuum hose from vacuum pump

side.

19. Glow Plug Harness

20. Transmission Assembly

┬ĘInstall special tools (engine hangers) in front right

and left rear sides of cylinder head.

┬ĘFront right side; use the ground cable fixing bolt

on A/C compressor bracket.

┬ĘLeft rear side; fix hanger together with oil cooler

hose clip.

Engine hanger: 5-8840-2032-0

┬ĘLeft engine carefully by using hoist.

21. Engine Mounting

┬ĘRemove fixing bolts (both left and right side)

using extension bar and box wrench at under side

of wheel arches.

22. Engine Assembly

┬ĘInstall special tools (engine hangers) in left rear

and front right sides of cylinder head.

┬ĘLift engine carefully by using hoist.

┬ĘLift front part of engine higher than rear part of it.

┬ĘTake out engine asm taking care not to damage

full pipes, brake pipes and etc.

INSTALLATION

22. Engine Assembly

┬ĘPosition engine mountings by using hoist.

21. Engine Mounting

┬ĘAfter all fixing bolts (left: two bolts, rights: two

bolts) were inserted to every holes, and engine

asm and tighten fixing bolts to the specified

torque.

40 (4.1/30)N┬Ęm(Kg┬Ęm/lb┬Ęft)

20. Transmission Assembly

┬ĘRefer to transmission installation steps

in section 7.

19. Glow Plug Harness

18 Vacuum Hose: Vacuum Tank

17. Engine Ground Cable

16. Fuel Hose

15. Accelerator Cable

┬ĘRefer to accelerater cable installation steps in

section 6C.

Page 1653 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 51

14. Engine Harness.

13. Starter Harness

12. Vacuum Hose: Vacuum Pump

11. A/C Compressor Assembly

┬ĘTighten temporarily fixing bolts (upper and front

lower sides of compressor).

┬ĘTighten fixing bolt (rear under side of

compressor) to the specified torque by using

along extension bar and torque wrench at under

side of wheel arch.

┬ĘTighten fixing bolts (front upper and lower sides

of compressor) to the specified torque.

40 (4.1/30)N┬Ęm(Kg┬Ęm/lb┬Ęft)

Page 1654 of 3573

6A2 Ð 52 4JG2-NA/4JG2-TURBO ENGINE

6. Intercooler Assembly (4JG2-T Only)

┬ĘRefer to intercooler installation steps in this

section.

5. Air Cleaner Cover & Duct

4. Radiator Assembly

┬ĘInstall cushion rubber in under left and right part

of radiator and position radiator.

┬ĘFix radiator by bracket.

3. Cooling Fan Assembly

┬ĘInstall cooling fan asm and tighten fixing bolts to

the specified torque.

2. Fan Shroud

1. Radiator Hose

┬ĘConnect upper and lower hose to engine side.

┬ĘPour coolant in to radiator.

┬ĘInstall battery.

┬ĘConnect window washer hose.

10. A.C. Generator Harness

9. Engine Ground Cable

┬ĘAttached ground cable to A/C compressor bracket.

8. P/S Pump Assembly

┬ĘInstall P/S pump asm in engine and tighten

temporarily fixing nut.

7. P/S Pump Drive Belt

┬ĘInstall drive belts adjust belt tension by adjusting

bolt and tighten locking bolt to the specified

torque.

┬ĘRefer to ├ÆDrive Belt Adjustment├ō in section 6B.

8 (0.8/69)N┬Ęm(Kg┬Ęm/lb┬Ęin)

40 (4.1/30)N┬Ęm(Kg┬Ęm/lb┬Ęft)

Page 1655 of 3573

ENGINE COOLING 6B Ð 1

SECTION 6B

ENGINE COOLING

CONTENTS

PAGE

General Description ..................................................................................................................... 6B- 1

On-Vehicle Service ....................................................................................................................... 6B- 5

Water Pump ............................................................................................................................. 6B- 5

Thermostat ............................................................................................................................... 6B- 7

Radiator .................................................................................................................................... 6B- 9

Drive Belt Adjustment ............................................................................................................ 6B-15

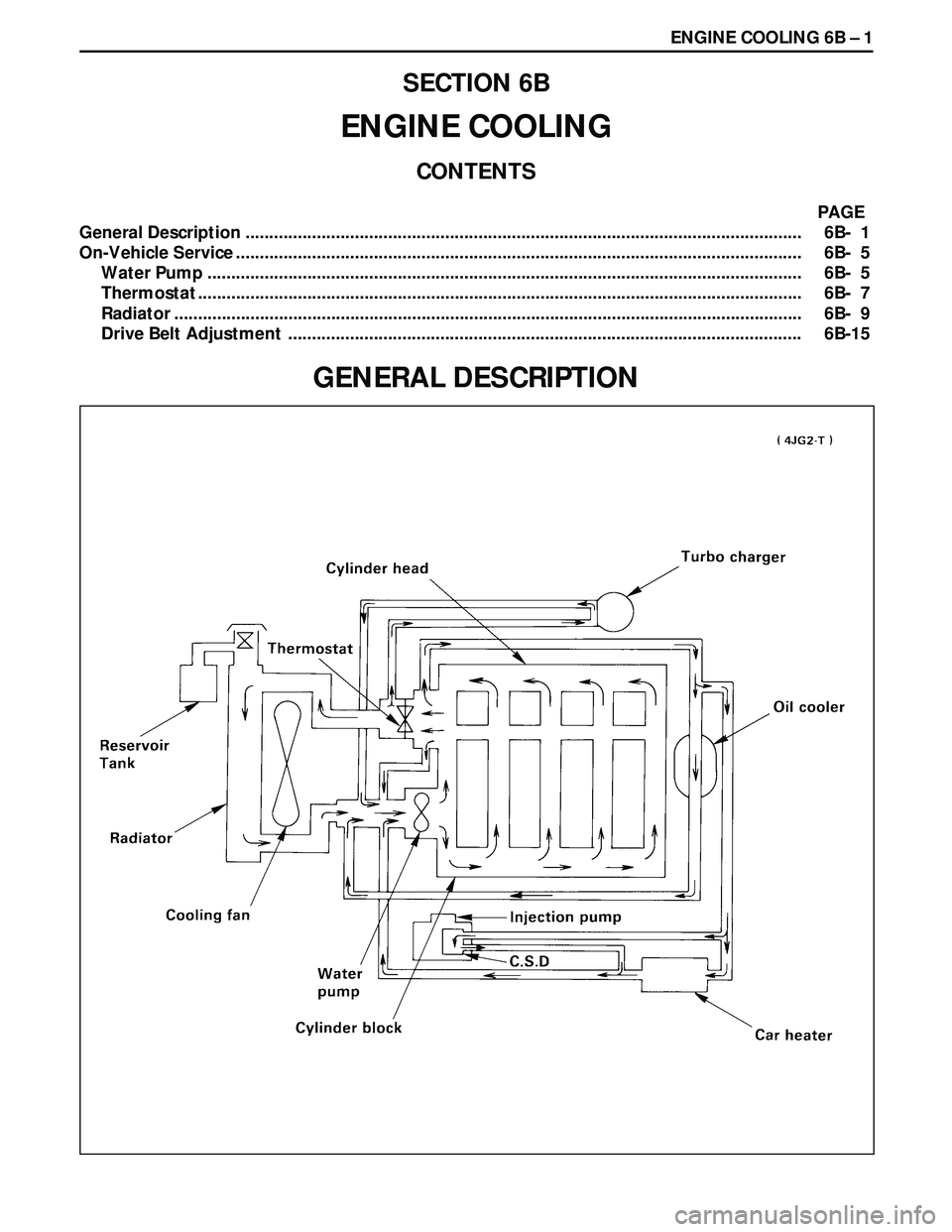

GENERAL DESCRIPTION

Page 1656 of 3573

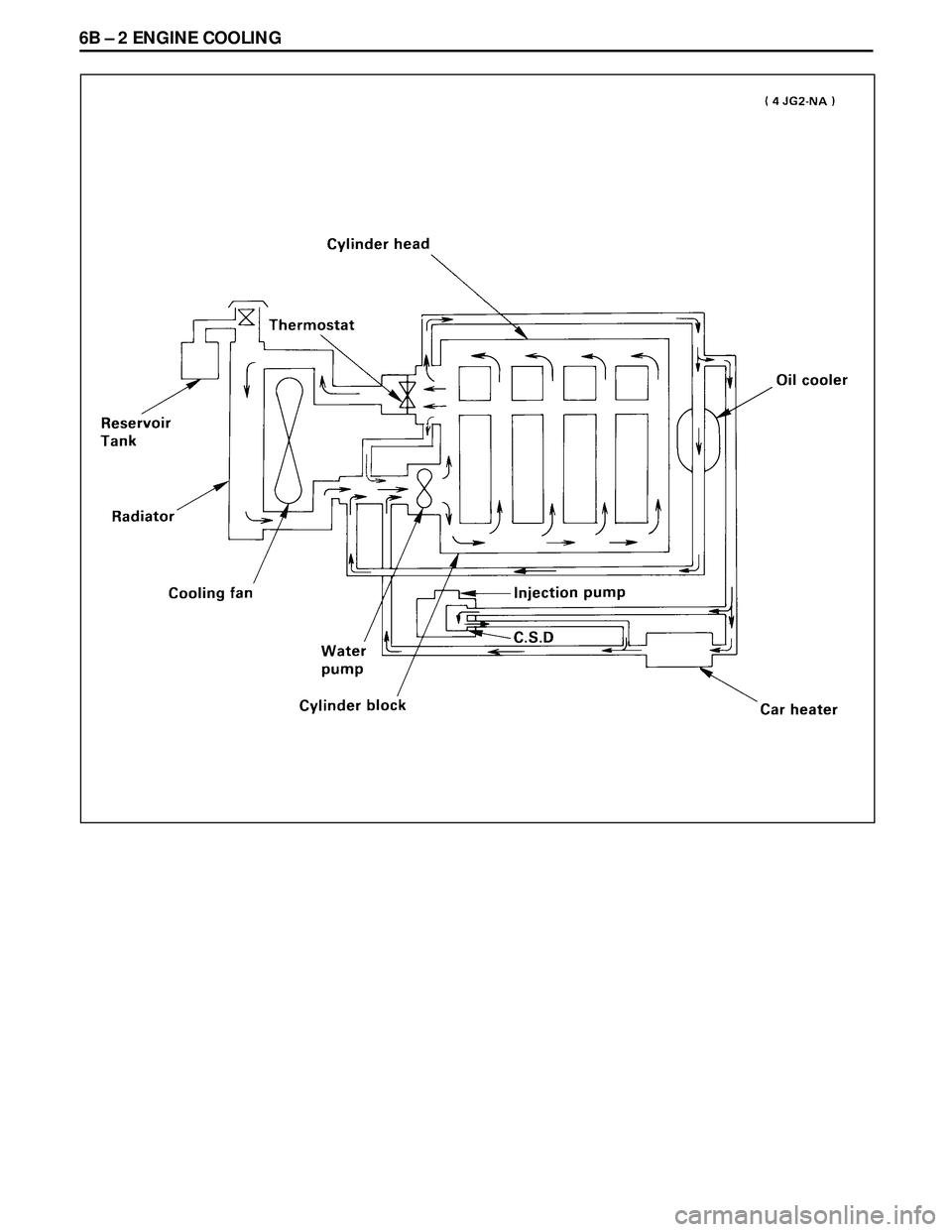

6B Ð 2 ENGINE COOLING

Page 1657 of 3573

ENGINE COOLING 6B Ð 3

The cooling system is a pressurized coolant forced

circulation type which consists of water pump, thermostat

cooling fan, radiator and other components. The

circulating coolant cools the lubricating oil in the oil filter

and turbocharger.

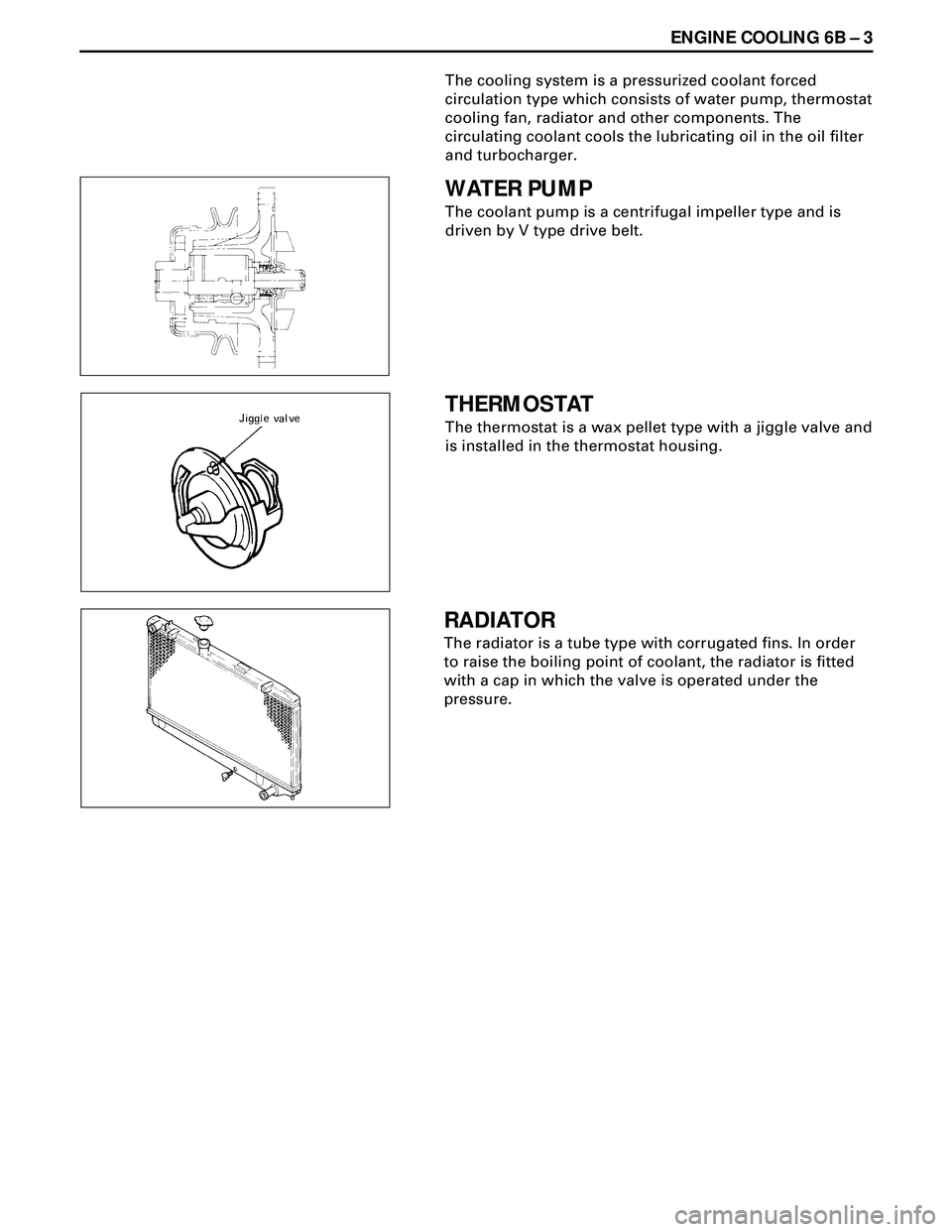

WATER PUMP

The coolant pump is a centrifugal impeller type and is

driven by V type drive belt.

THERMOSTAT

The thermostat is a wax pellet type with a jiggle valve and

is installed in the thermostat housing.

RADIATOR

The radiator is a tube type with corrugated fins. In order

to raise the boiling point of coolant, the radiator is fitted

with a cap in which the valve is operated under the

pressure.

Page 1658 of 3573

6B Ð 4 ENGINE COOLING

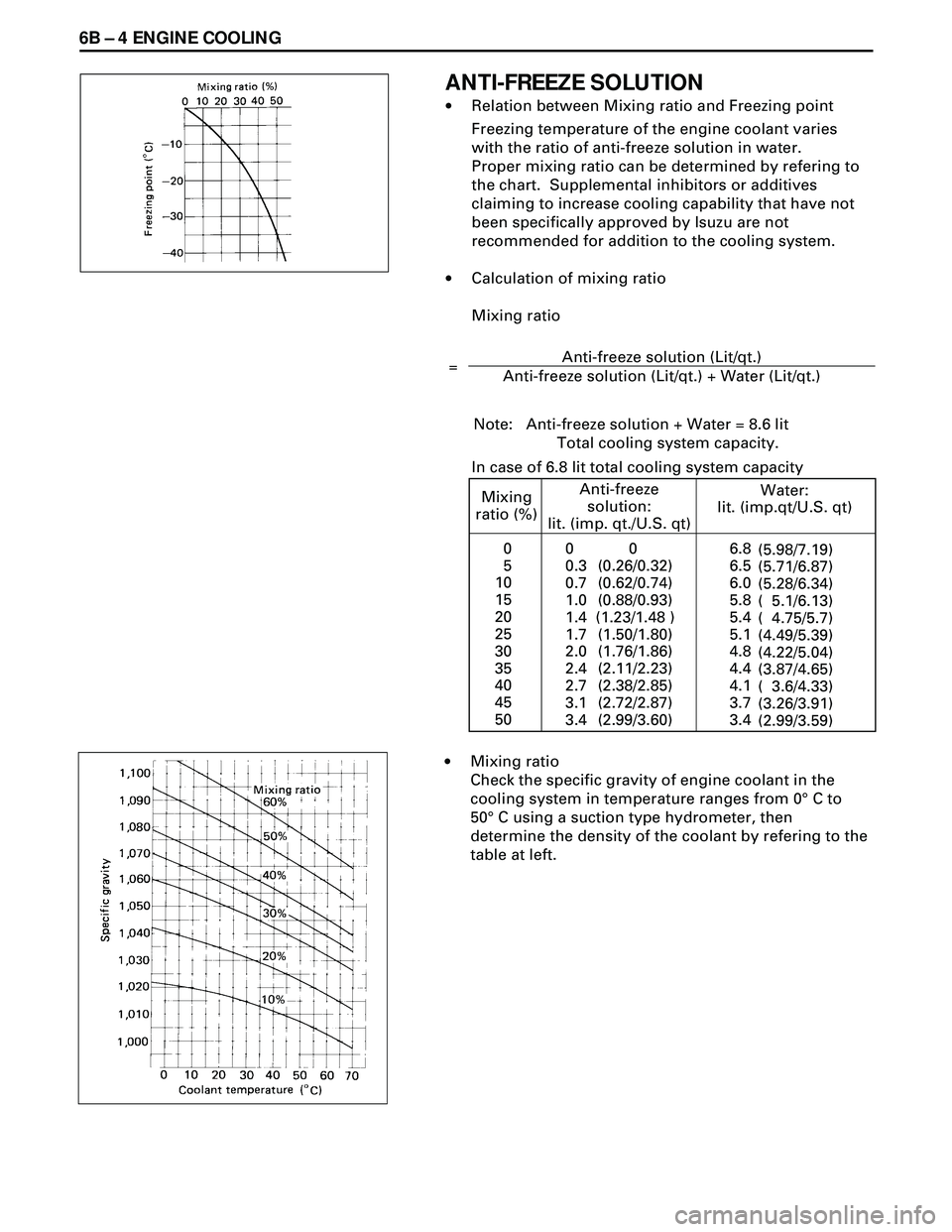

ANTI-FREEZE SOLUTION

┬ĘRelation between Mixing ratio and Freezing point

Freezing temperature of the engine coolant varies

with the ratio of anti-freeze solution in water.

Proper mixing ratio can be determined by refering to

the chart. Supplemental inhibitors or additives

claiming to increase cooling capability that have not

been specifically approved by Isuzu are not

recommended for addition to the cooling system.

┬ĘCalculation of mixing ratio

Mixing ratio

Note: Anti-freeze solution + Water = 8.6 lit

Total cooling system capacity.

=Anti-freeze solution (Lit/qt.)

Anti-freeze solution (Lit/

qt.) + Water (Lit/qt.)

In case of 6.8 lit total cooling system capacity

Mixing

ratio (%)Anti-freeze

solution:

lit. (imp. qt./U.S. qt)Water:

lit. (imp.qt/U.S. qt)

0

5

10

15

20

25

30

35

40

45

500

0.3

0.7

1.0

1.4

1.7

2.0

2.4

2.7

3.1

3.40

(0.26/0.32)

(0.62/0.74)

(0.88/0.93)

(1.23/1.48 )

(1.50/1.80)

(1.76/1.86)

(2.11/2.23)

(2.38/2.85)

(2.72/2.87)

(2.99/3.60)6.8

6.5

6.0

5.8

5.4

5.1

4.8

4.4

4.1

3.7

3.4

(5.98/7.19)

(5.71/6.87)

(5.28/6.34)

( 5.1/6.13)

( 4.75/5.7)

(4.49/5.39)

(4.22/5.04)

(3.87/4.65)

( 3.6/4.33)

(3.26/3.91)

(2.99/3.59)

┬ĘMixing ratio

Check the specific gravity of engine coolant in the

cooling system in temperature ranges from 0┬Ī C to

50┬Ī C using a suction type hydrometer, then

determine the density of the coolant by refering to the

table at left.

Page 1659 of 3573

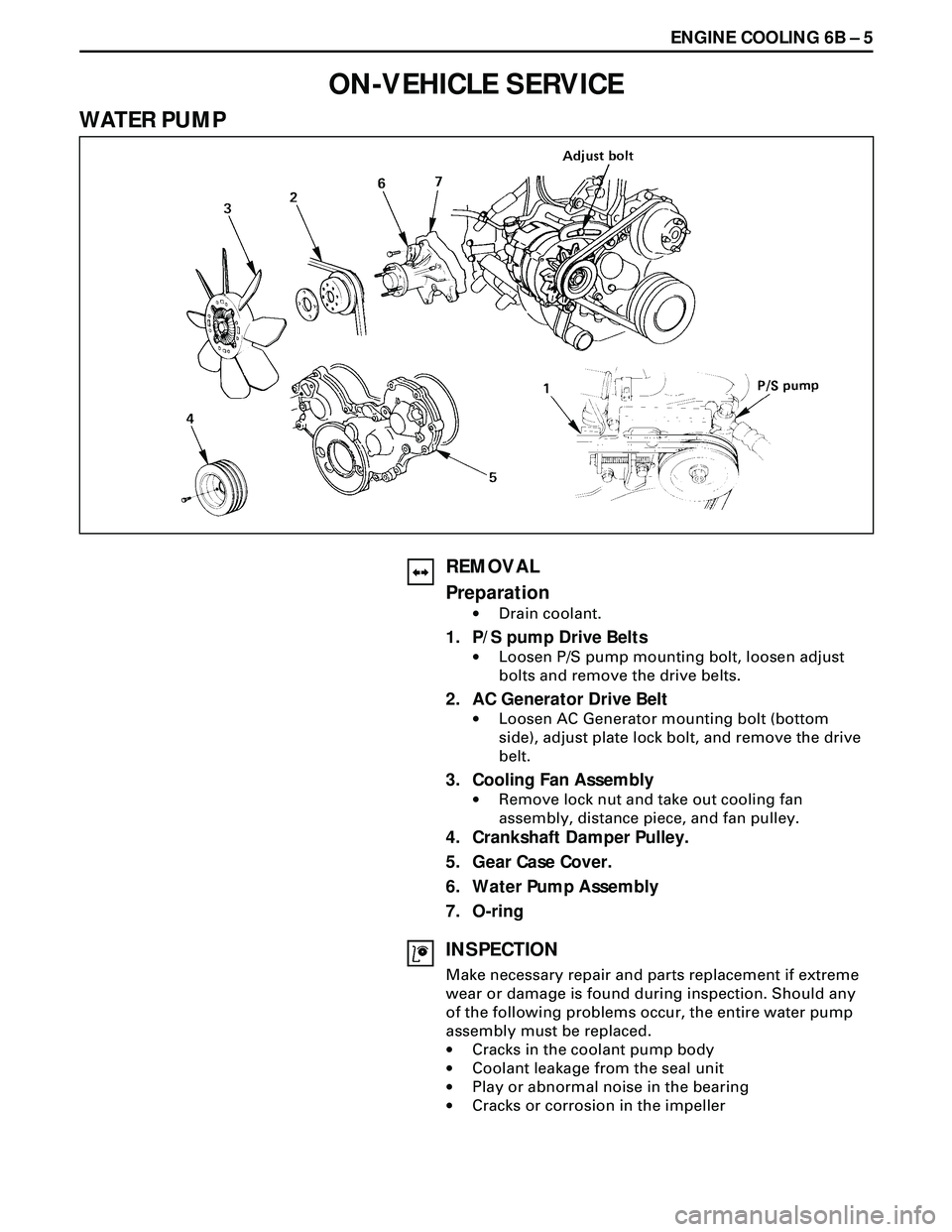

ENGINE COOLING 6B Ð 5

ON-VEHICLE SERVICE

WATER PUMP

REMOVAL

Preparation

┬ĘDrain coolant.

1. P/S pump Drive Belts

┬ĘLoosen P/S pump mounting bolt, loosen adjust

bolts and remove the drive belts.

2. AC Generator Drive Belt

┬ĘLoosen AC Generator mounting bolt (bottom

side), adjust plate lock bolt, and remove the drive

belt.

3. Cooling Fan Assembly

┬ĘRemove lock nut and take out cooling fan

assembly, distance piece, and fan pulley.

4. Crankshaft Damper Pulley.

5. Gear Case Cover.

6. Water Pump Assembly

7. O-ring

INSPECTION

Make necessary repair and parts replacement if extreme

wear or damage is found during inspection. Should any

of the following problems occur, the entire water pump

assembly must be replaced.

┬ĘCracks in the coolant pump body

┬ĘCoolant leakage from the seal unit

┬ĘPlay or abnormal noise in the bearing

┬ĘCracks or corrosion in the impeller

Page 1660 of 3573

6B Ð 6 ENGINE COOLING

INSTALLATION

7. O-ring

┬ĘSet O-ring in water pump body groove.

6. Water Pump Assembly

┬ĘInstall water pump assembly, and tighten to

specified torque.

20(2.0/14)N┬Ęm (Kg┬Ęm/lb.ft)

5. Gear Case Cover

┬ĘInstall gear case cover, and tighten to specified

torque.

8(0.8/69)N┬Ęm (Kg┬Ęm/lb┬Ęin)

4. Crankshaft Damper Pulley

┬ĘInstall crankshaft damper pulley, and tighten to

specified torque.

3. Cooling Fan Assembly

┬ĘInstall fan pulley, distance piece, and cooling fan

assembly in this order on water pump, and tighten

to specified torque.

19(1.9/14)N┬Ęm (Kg┬Ęm/lb┬Ęft)

2. AC Generator Drive Belt

┬ĘInstall AC Generator drive belt and adjust belt

tension.

┬Ę(Refer to Drive Belt Adjustment in this Section).

1. P/S Pump Drive Belts

┬ĘInstall P/S pump drive belts and adjust belt

tension.

┬Ę(Refer to Drive Belt Adjustment in this Section).8(0.8/69)N┬Ęm (Kg┬Ęm/lb┬Ęin)