ISUZU TROOPER 1998 Service Repair Manual

Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1621 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 19

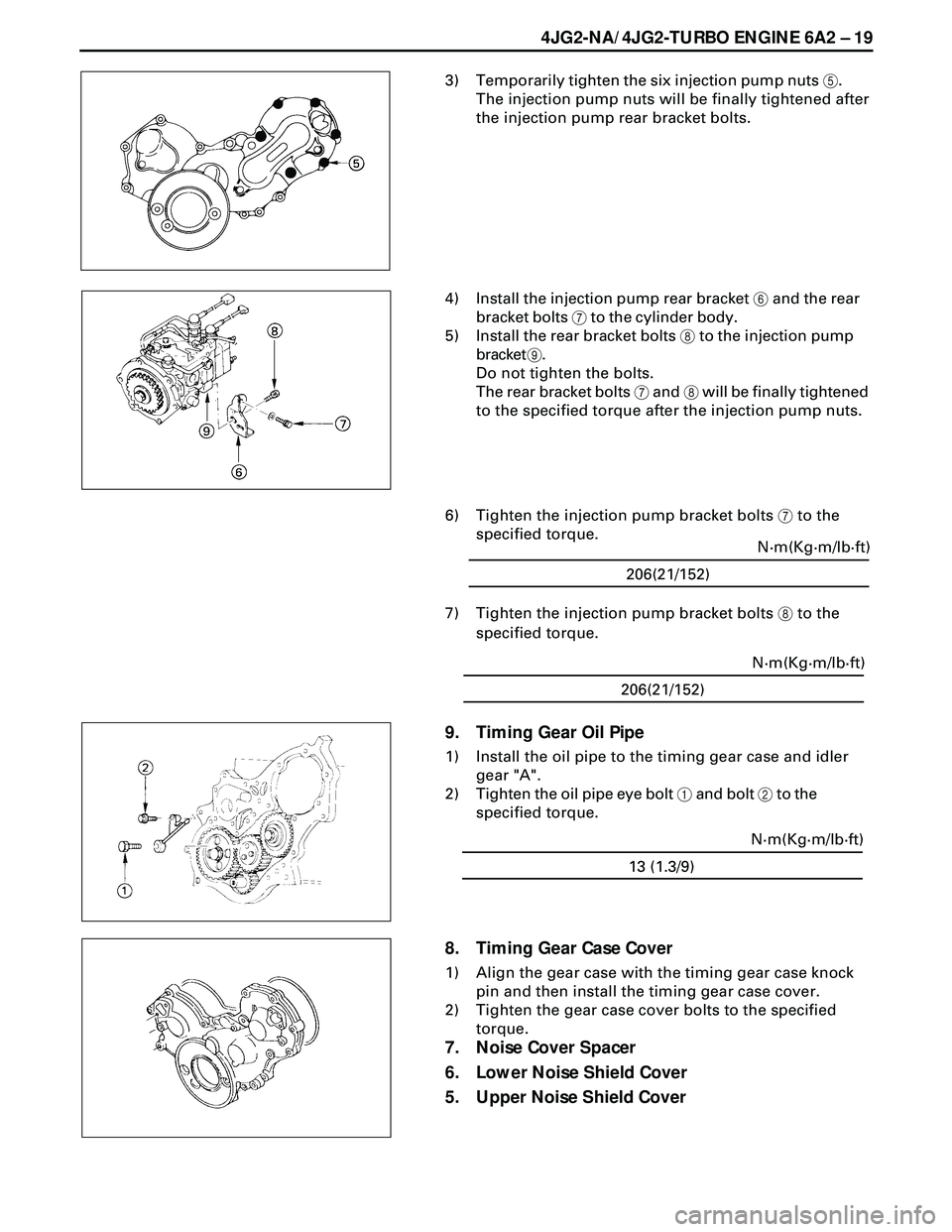

3) Temporarily tighten the six injection pump nuts 5.

The injection pump nuts will be finally tightened after

the injection pump rear bracket bolts.

4) Install the injection pump rear bracket 6 and the rear

bracket bolts 7 to the cylinder body.

5) Install the rear bracket bolts 8 to the injection pump

bracket 9.

Do not tighten the bolts.

The rear bracket bolts 7 and 8 will be finally tightened

to the specified torque after the injection pump nuts.

6) Tighten the injection pump bracket bolts 7 to the

specified torque.

7) Tighten the injection pump bracket bolts 8 to the

specified torque.

9. Timing Gear Oil Pipe

1) Install the oil pipe to the timing gear case and idler

gear "A".

2) Tighten the oil pipe eye bolt 1 and bolt 2 to the

specified torque.

8. Timing Gear Case Cover

1) Align the gear case with the timing gear case knock

pin and then install the timing gear case cover.

2) Tighten the gear case cover bolts to the specified

torque.

7. Noise Cover Spacer

6. Lower Noise Shield Cover

5. Upper Noise Shield Cover

206(21/152)N·m(Kg·m/lb·ft)

206(21/152)N·m(Kg·m/lb·ft)

13 (1.3/9)N·m(Kg·m/lb·ft)

Page 1622 of 3573

6A2 Ð 20 4JG2-NA/4JG2-TURBO ENGINE

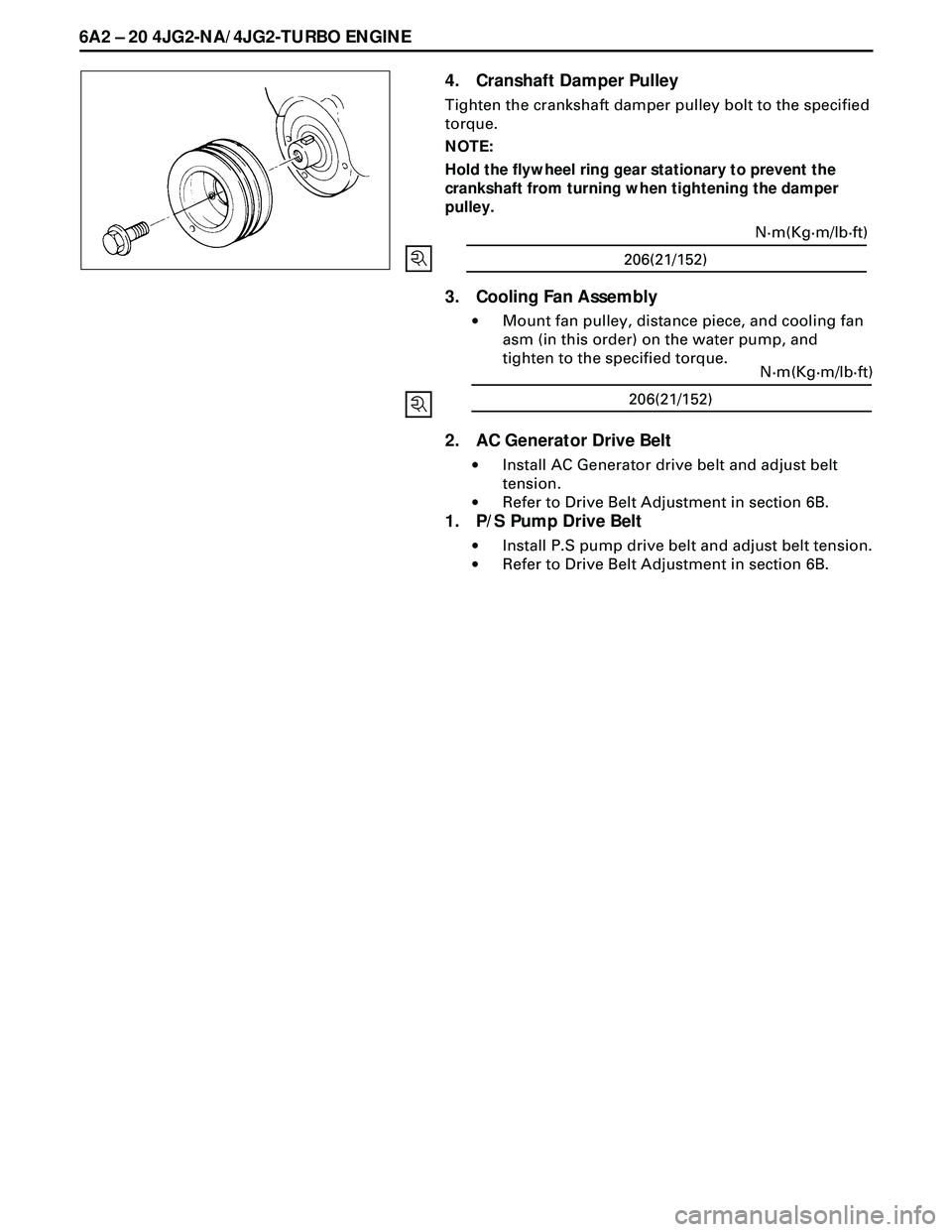

4. Cranshaft Damper Pulley

Tighten the crankshaft damper pulley bolt to the specified

torque.

NOTE:

Hold the flywheel ring gear stationary to prevent the

crankshaft from turning when tightening the damper

pulley.

3. Cooling Fan Assembly

·Mount fan pulley, distance piece, and cooling fan

asm (in this order) on the water pump, and

tighten to the specified torque.

2. AC Generator Drive Belt

·Install AC Generator drive belt and adjust belt

tension.

·Refer to Drive Belt Adjustment in section 6B.

1. P/S Pump Drive Belt

·Install P.S pump drive belt and adjust belt tension.

·Refer to Drive Belt Adjustment in section 6B.

206(21/152)N·m(Kg·m/lb·ft)

206(21/152)N·m(Kg·m/lb·ft)

Page 1623 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 21

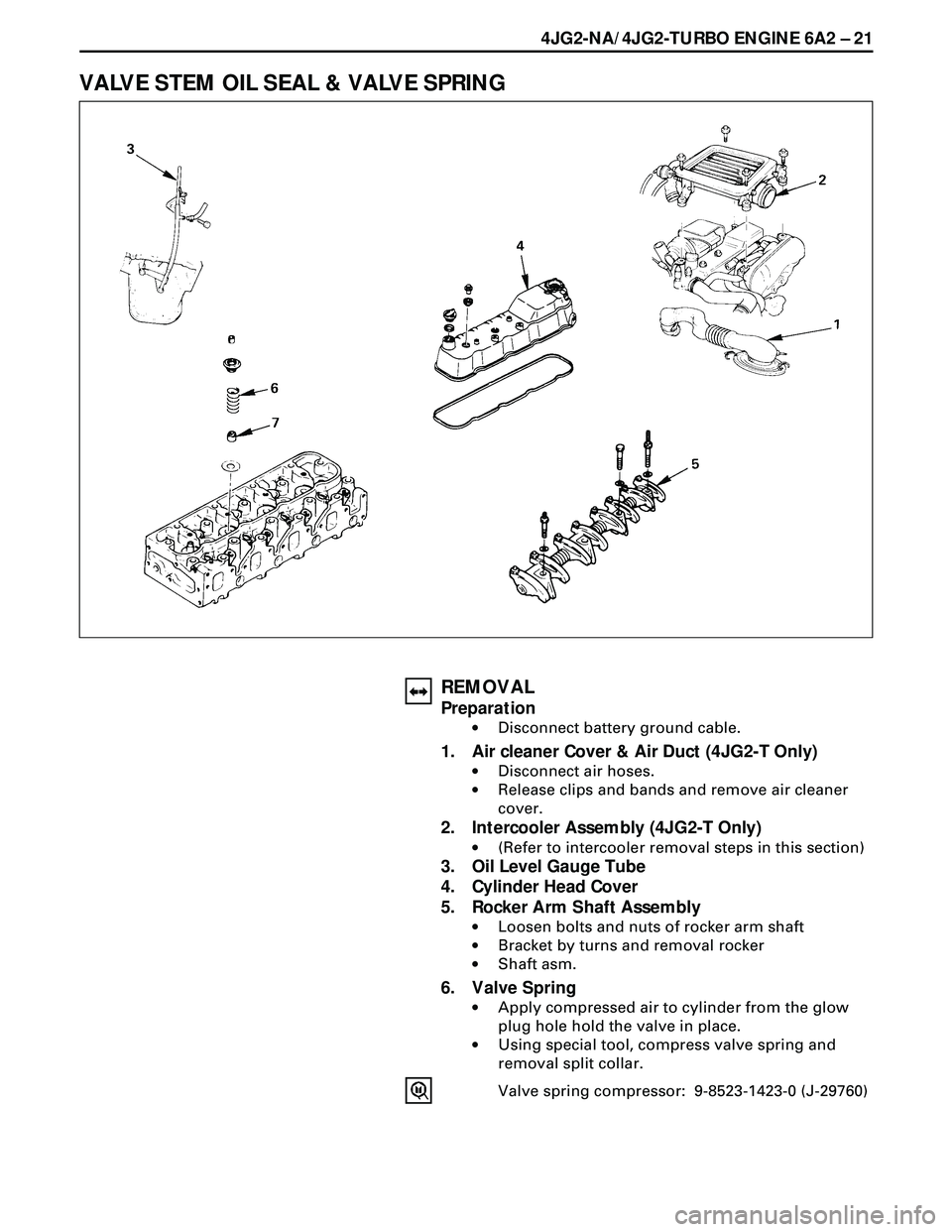

VALVE STEM OIL SEAL & VALVE SPRING

REMOVAL

Preparation

·Disconnect battery ground cable.

1. Air cleaner Cover & Air Duct (4JG2-T Only)

·Disconnect air hoses.

·Release clips and bands and remove air cleaner

cover.

2. Intercooler Assembly (4JG2-T Only)

·(Refer to intercooler removal steps in this section)

3. Oil Level Gauge Tube

4. Cylinder Head Cover

5. Rocker Arm Shaft Assembly

·Loosen bolts and nuts of rocker arm shaft

·Bracket by turns and removal rocker

·Shaft asm.

6. Valve Spring

·Apply compressed air to cylinder from the glow

plug hole hold the valve in place.

·Using special tool, compress valve spring and

removal split collar.

Valve spring compressor: 9-8523-1423-0 (J-29760)

Page 1624 of 3573

6A2 Ð 22 4JG2-NA/4JG2-TURBO ENGINE

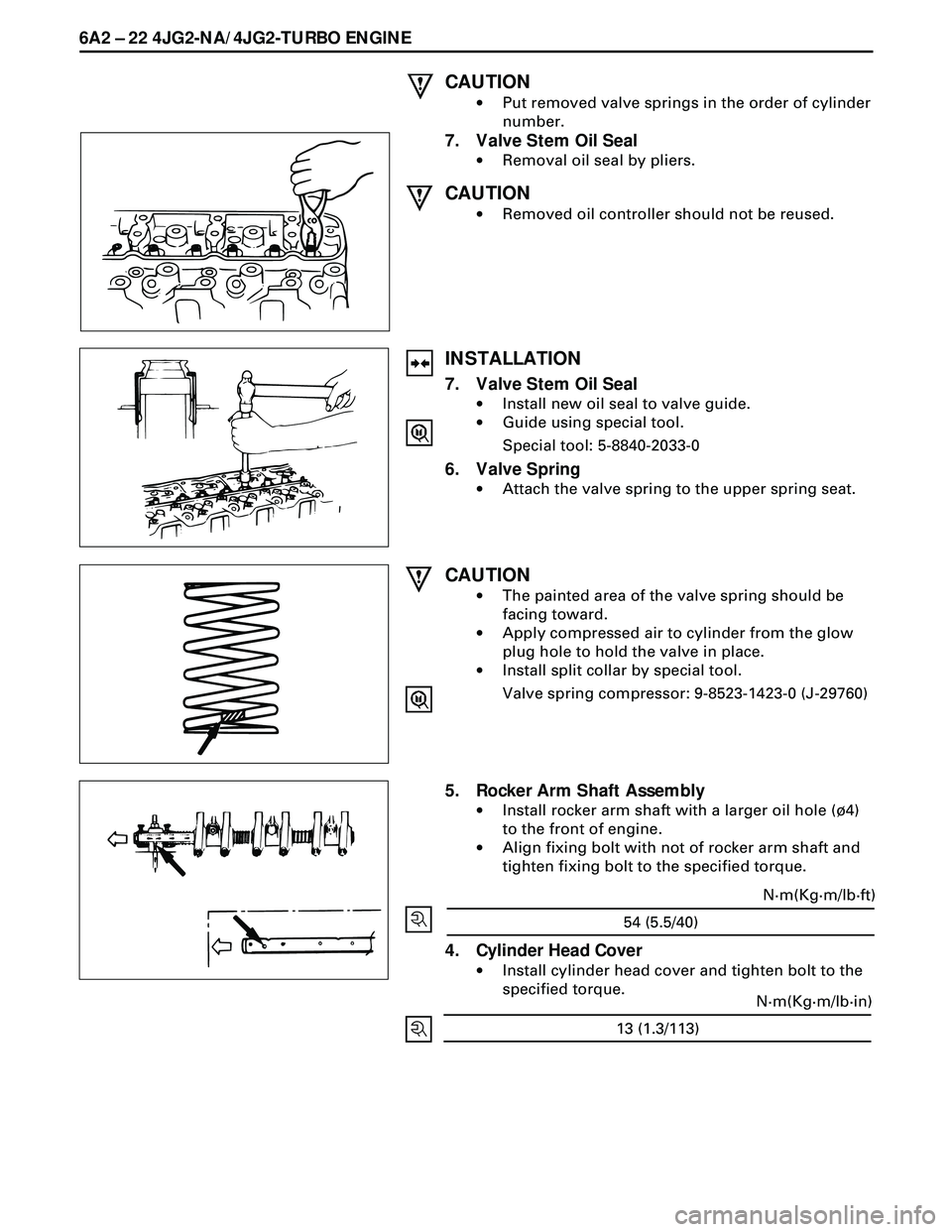

CAUTION

·Put removed valve springs in the order of cylinder

number.

7. Valve Stem Oil Seal

·Removal oil seal by pliers.

CAUTION

·Removed oil controller should not be reused.

CAUTION

·The painted area of the valve spring should be

facing toward.

·Apply compressed air to cylinder from the glow

plug hole to hold the valve in place.

·Install split collar by special tool.

Valve spring compressor: 9-8523-1423-0 (J-29760)

INSTALLATION

7. Valve Stem Oil Seal

·Install new oil seal to valve guide.

·Guide using special tool.

Special tool: 5-8840-2033-0

6. Valve Spring

·Attach the valve spring to the upper spring seat.

5. Rocker Arm Shaft Assembly

·Install rocker arm shaft with a larger oil hole (¿4)

to the front of engine.

·Align fixing bolt with not of rocker arm shaft and

tighten fixing bolt to the specified torque.

54 (5.5/40)

N·m(Kg·m/lb·ft)

4. Cylinder Head Cover

·Install cylinder head cover and tighten bolt to the

specified torque.

13 (1.3/113)

N·m(Kg·m/lb·in)

Page 1625 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 23

2. Intercooler Assembly (4JG2-T Only)

·Refer to intercooler installation steps in this

section.

1. Air Cleaner Cover & Air Duct (4JG2-T Only) 3. Oil Level Gauge Guide Tube

·Tighten guide tube to the specified torque.

19 (1.9/14)

N·m(Kg·m/lb·ft)

Page 1626 of 3573

6A2 Ð 24 4JG2-NA/4JG2-TURBO ENGINE

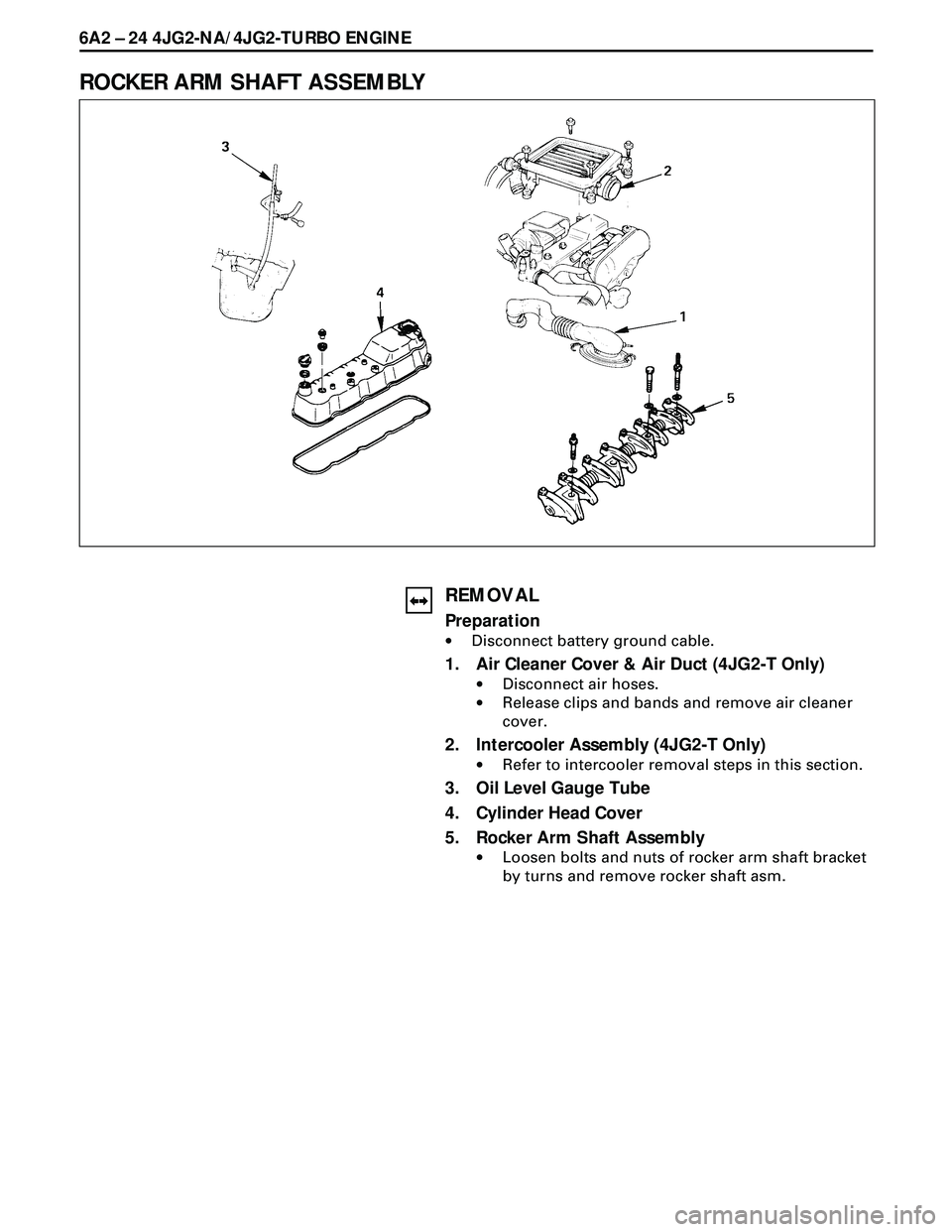

ROCKER ARM SHAFT ASSEMBLY

REMOVAL

Preparation

·Disconnect battery ground cable.

1. Air Cleaner Cover & Air Duct (4JG2-T Only)

·Disconnect air hoses.

·Release clips and bands and remove air cleaner

cover.

2. Intercooler Assembly (4JG2-T Only)

·Refer to intercooler removal steps in this section.

3. Oil Level Gauge Tube

4. Cylinder Head Cover

5. Rocker Arm Shaft Assembly

·Loosen bolts and nuts of rocker arm shaft bracket

by turns and remove rocker shaft asm.

Page 1627 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A2 Ð 25

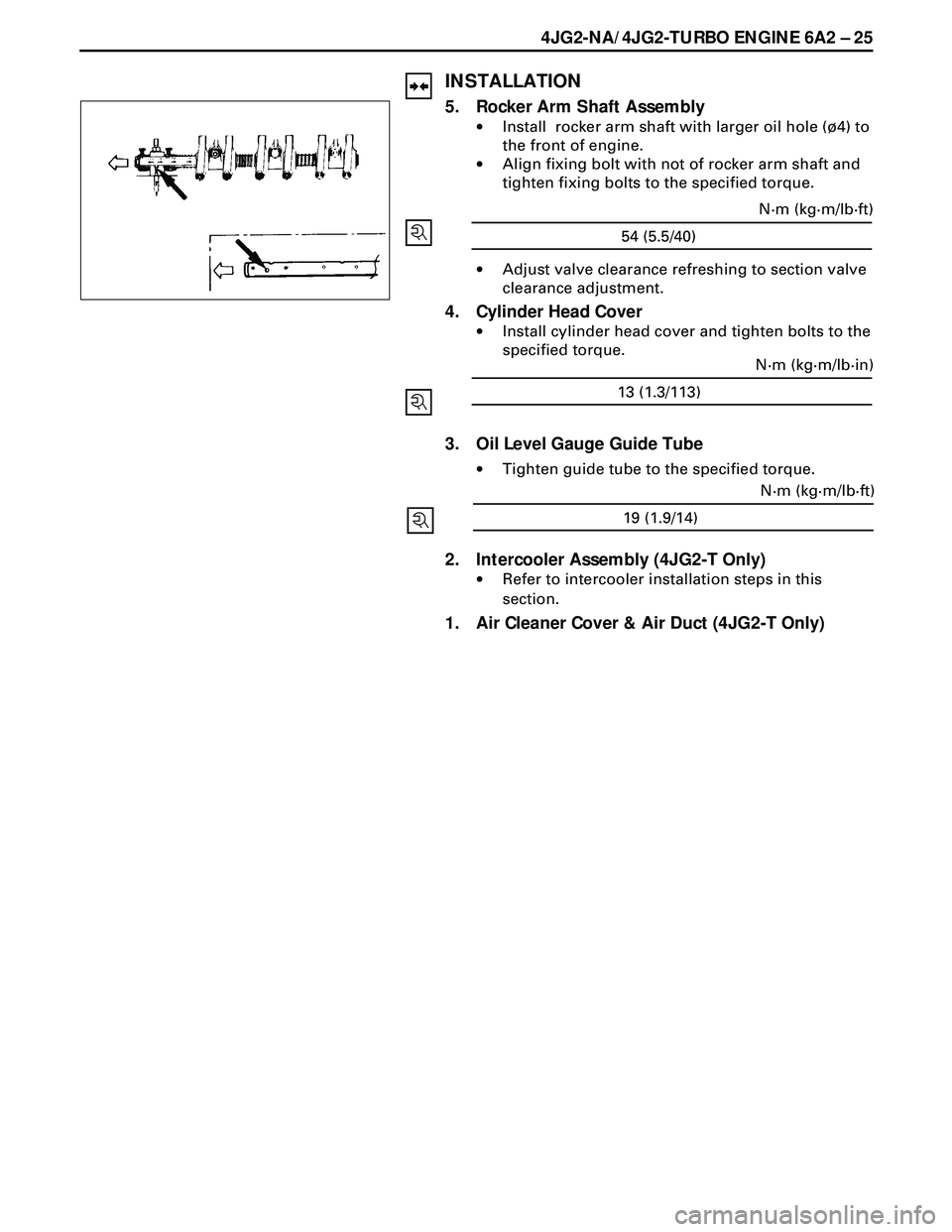

INSTALLATION

5. Rocker Arm Shaft Assembly

·Install rocker arm shaft with larger oil hole (¿4) to

the front of engine.

·Align fixing bolt with not of rocker arm shaft and

tighten fixing bolts to the specified torque.

54 (5.5/40)N·m (kg·m/lb·ft)

·Adjust valve clearance refreshing to section valve

clearance adjustment.

4. Cylinder Head Cover

·Install cylinder head cover and tighten bolts to the

specified torque.

3. Oil Level Gauge Guide Tube

·Tighten guide tube to the specified torque.

2. Intercooler Assembly (4JG2-T Only)

·Refer to intercooler installation steps in this

section.

1. Air Cleaner Cover & Air Duct (4JG2-T Only)

13 (1.3/113)N·m (kg·m/lb·in)

19 (1.9/14)N·m (kg·m/lb·ft)

Page 1628 of 3573

6A2 Ð 26 4JG2-NA/4JG2-TURBO ENGINE

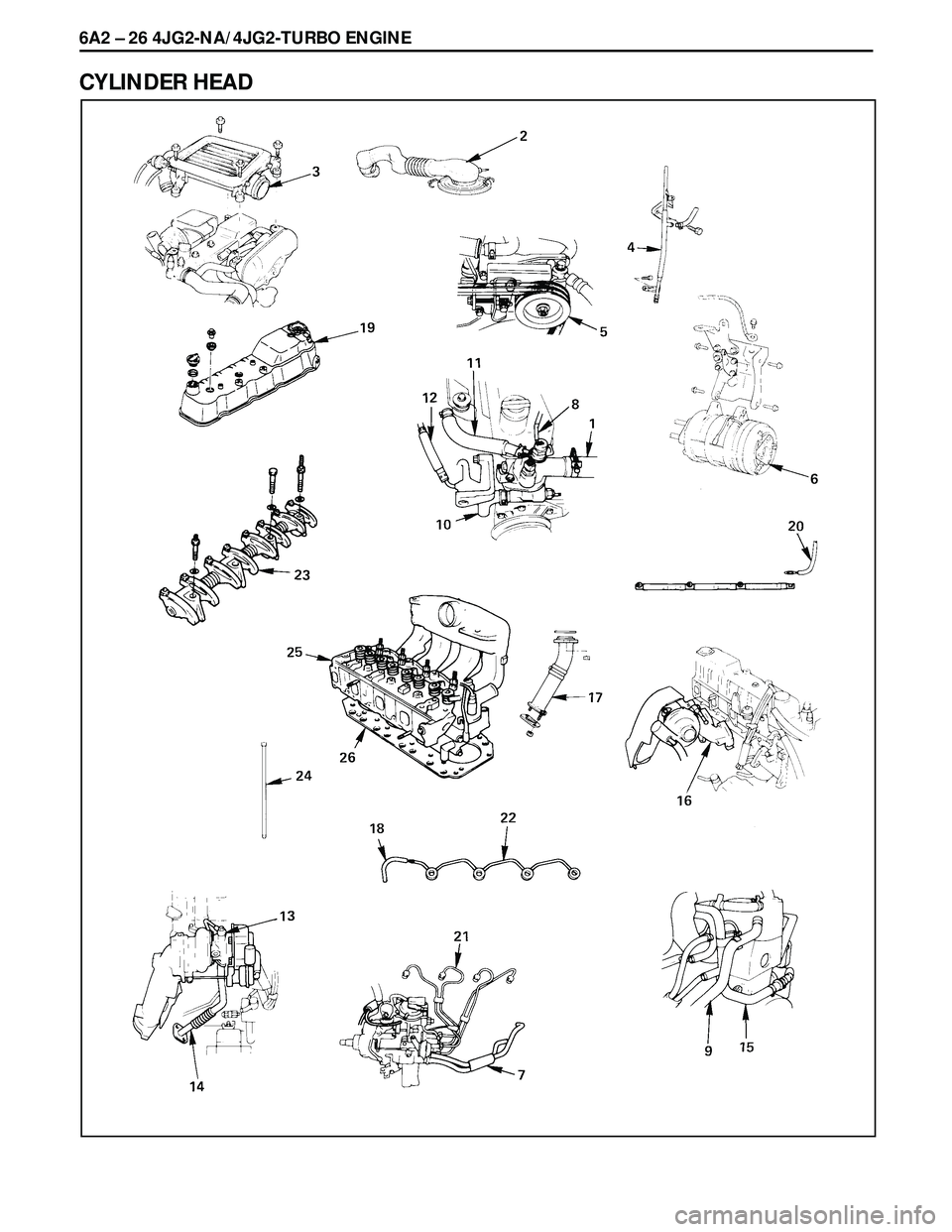

CYLINDER HEAD

Page 1629 of 3573

4JG2-NA/4JG2-TURBO ENGINE 6A 2Ð 27

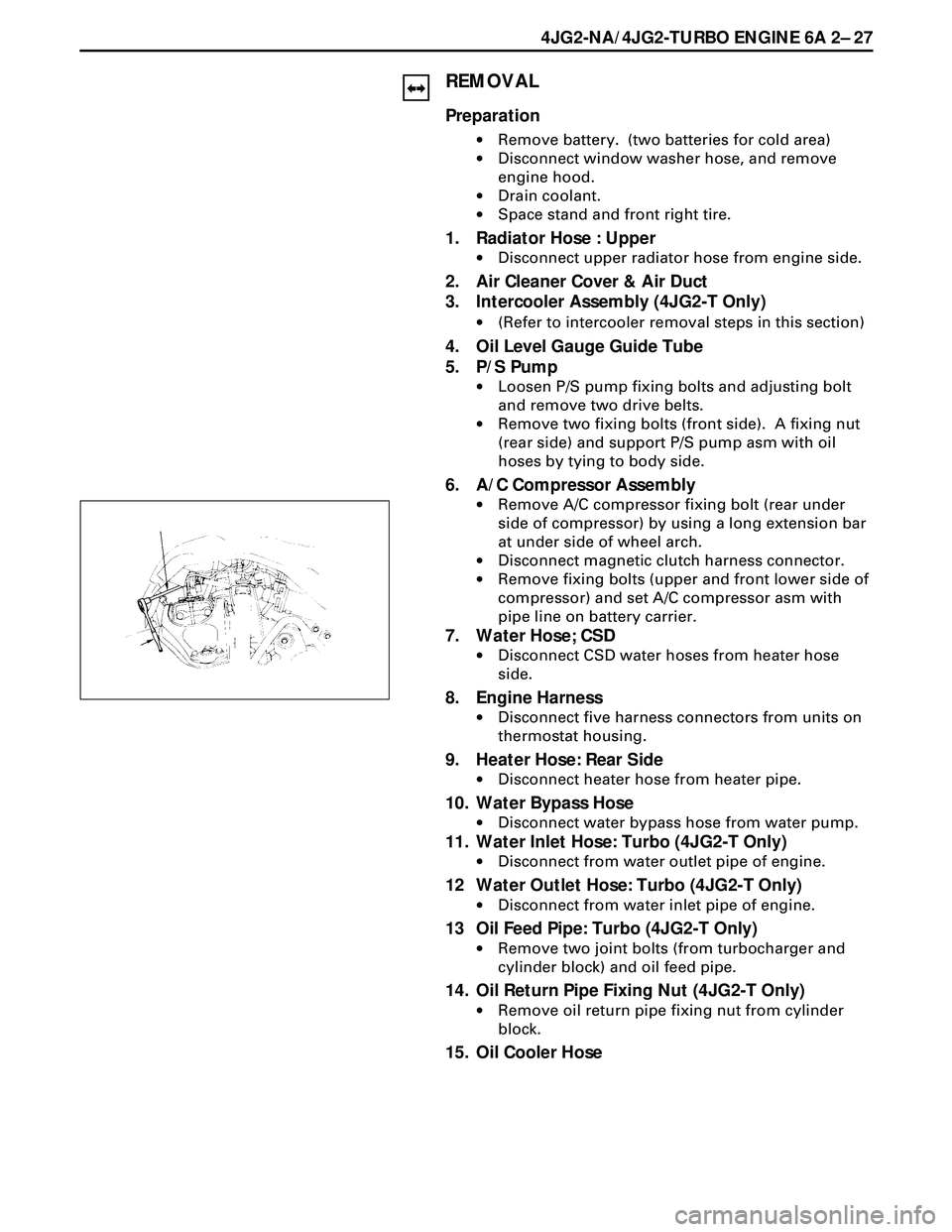

REMOVAL

Preparation

·Remove battery. (two batteries for cold area)

·Disconnect window washer hose, and remove

engine hood.

·Drain coolant.

·Space stand and front right tire.

1. Radiator Hose : Upper

·Disconnect upper radiator hose from engine side.

2. Air Cleaner Cover & Air Duct

3. Intercooler Assembly (4JG2-T Only)

·(Refer to intercooler removal steps in this section)

4. Oil Level Gauge Guide Tube

5. P/S Pump

·Loosen P/S pump fixing bolts and adjusting bolt

and remove two drive belts.

·Remove two fixing bolts (front side). A fixing nut

(rear side) and support P/S pump asm with oil

hoses by tying to body side.

6. A/C Compressor Assembly

·Remove A/C compressor fixing bolt (rear under

side of compressor) by using a long extension bar

at under side of wheel arch.

·Disconnect magnetic clutch harness connector.

·Remove fixing bolts (upper and front lower side of

compressor) and set A/C compressor asm with

pipe line on battery carrier.

7. Water Hose; CSD

·Disconnect CSD water hoses from heater hose

side.

8. Engine Harness

·Disconnect five harness connectors from units on

thermostat housing.

9. Heater Hose: Rear Side

·Disconnect heater hose from heater pipe.

10. Water Bypass Hose

·Disconnect water bypass hose from water pump.

11. Water Inlet Hose: Turbo (4JG2-T Only)

·Disconnect from water outlet pipe of engine.

12 Water Outlet Hose: Turbo (4JG2-T Only)

·Disconnect from water inlet pipe of engine.

13 Oil Feed Pipe: Turbo (4JG2-T Only)

·Remove two joint bolts (from turbocharger and

cylinder block) and oil feed pipe.

14. Oil Return Pipe Fixing Nut (4JG2-T Only)

·Remove oil return pipe fixing nut from cylinder

block.

15. Oil Cooler Hose

Page 1630 of 3573

6A2 Ð 28 4JG2-NA/4JG2-TURBO ENGINE

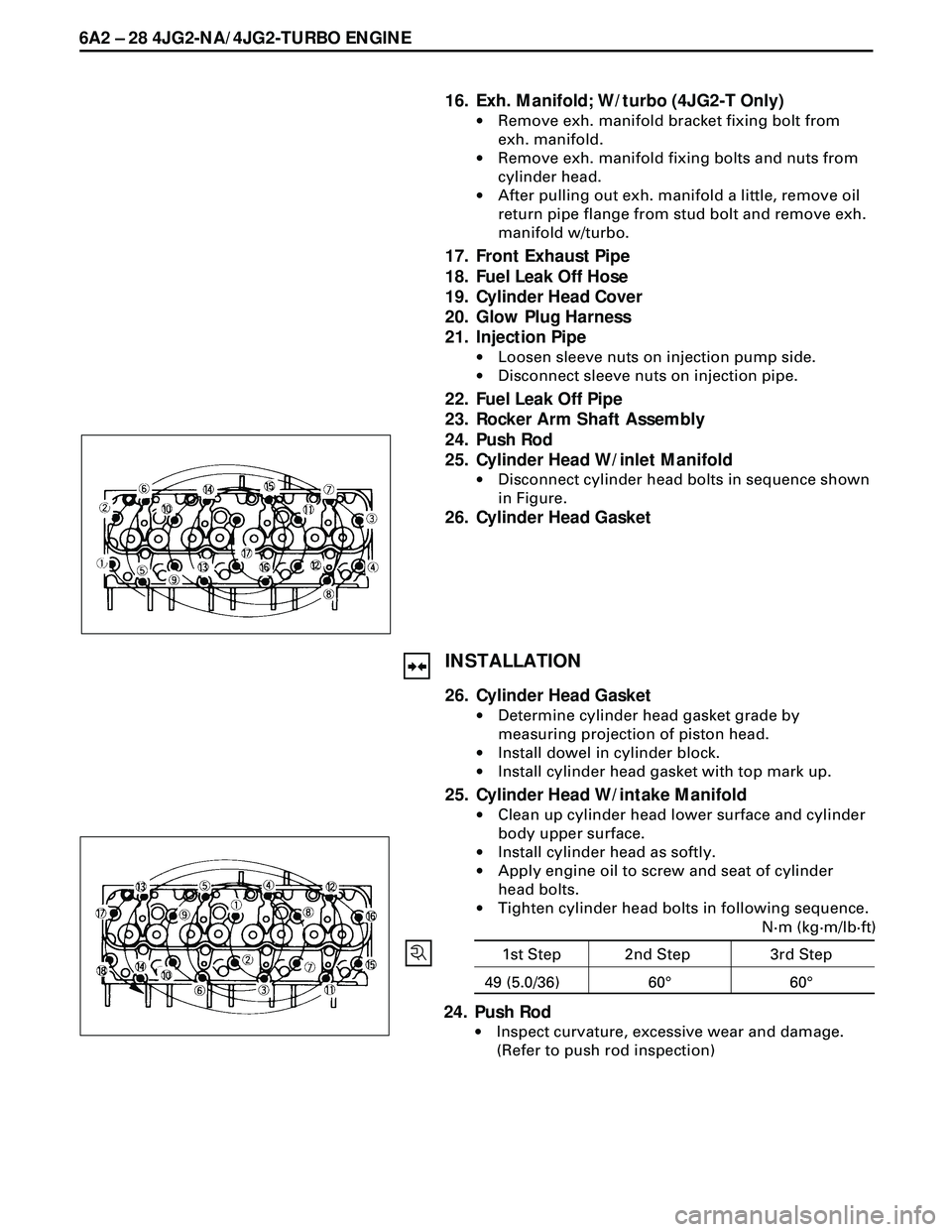

16. Exh. Manifold; W/turbo (4JG2-T Only)

·Remove exh. manifold bracket fixing bolt from

exh. manifold.

·Remove exh. manifold fixing bolts and nuts from

cylinder head.

·After pulling out exh. manifold a little, remove oil

return pipe flange from stud bolt and remove exh.

manifold w/turbo.

17. Front Exhaust Pipe

18. Fuel Leak Off Hose

19. Cylinder Head Cover

20. Glow Plug Harness

21. Injection Pipe

·Loosen sleeve nuts on injection pump side.

·Disconnect sleeve nuts on injection pipe.

22. Fuel Leak Off Pipe

23. Rocker Arm Shaft Assembly

24. Push Rod

25. Cylinder Head W/inlet Manifold

·Disconnect cylinder head bolts in sequence shown

in Figure.

26. Cylinder Head Gasket

INSTALLATION

26. Cylinder Head Gasket

·Determine cylinder head gasket grade by

measuring projection of piston head.

·Install dowel in cylinder block.

·Install cylinder head gasket with top mark up.

25. Cylinder Head W/intake Manifold

·Clean up cylinder head lower surface and cylinder

body upper surface.

·Install cylinder head as softly.

·Apply engine oil to screw and seat of cylinder

head bolts.

·Tighten cylinder head bolts in following sequence.

24. Push Rod

·Inspect curvature, excessive wear and damage.

(Refer to push rod inspection)

1st Step

N·m (kg·m/lb·ft)

49 (5.0/36)

2nd Step

60°3rd Step

60°