ISUZU TROOPER 1998 Service Repair Manual

Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 2871 of 3573

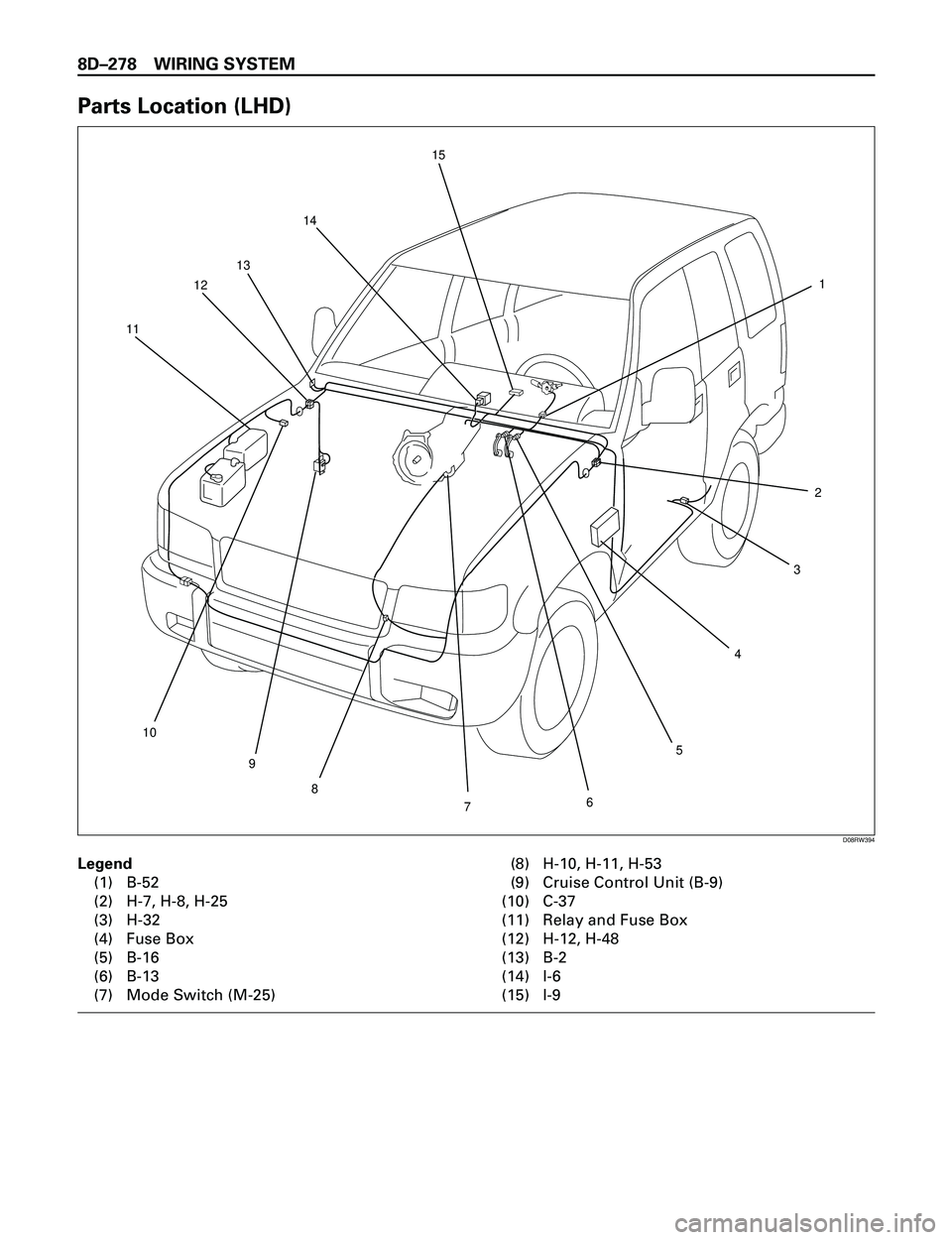

8DÐ278 WIRING SYSTEM

Parts Location (LHD)

Legend

(1) B-52

(2) H-7, H-8, H-25

(3) H-32

(4) Fuse Box

(5) B-16

(6) B-13

(7) Mode Switch (M-25)(8) H-10, H-11, H-53

(9) Cruise Control Unit (B-9)

(10) C-37

(11) Relay and Fuse Box

(12) H-12, H-48

(13) B-2

(14) I-6

(15) I-9

1

2

3

4

5

6

7 8 9 10 1112131415

D08RW394

Page 2872 of 3573

WIRING SYSTEM 8DÐ279

Diagnosis

The cruise control unit uses the cruise main indicator light and diagnoses the failure, when the control unit

detects abnormality on the table below.

PART POSIBLE CAUSE DETECTION PERIOD DTC

Motor system short circuit Energizing motor 1Ð1

Clutch system short circuit Energizing clutch 1Ð2

Actuator Clutch system open circuit Energizing clutch 1Ð2

Mechanical defect Cruise controlling 1Ð3

Close side of motor system open circuit Cruise controlling 1Ð1

CruiseOpen side of motor system continuously energizing While starter sw on 1Ð4

control unit

Clutch output abnormality While starter sw on 1Ð4

VehicleSignal of vehicle speed disconnection Cruise controlling 2Ð1

speed sensor

Signal of vehicle speed abnormality Cruise controlling 2Ð1

SwitchTurning on switch at all times While starter sw on 3Ð1

Turning on switch at the same time. While starter sw on 3Ð1

DTC: Diagnostic Trouble Code

DTC Display Condition

1. While starter switch on and vehicle speed is 0 km/h, the DTC output begins in top priority by cancel switch

turn on and off being repeated three times for 2 sec. while cruise main switch pushing on, and stops the

DTC output whether vehicle speed is more than 10 km/h or the resume switch is turned on.

2. The cruise control unit outputs the DTC(s) in order from small figure of the code.

3. The header of display of DTC(s) is assumed 4 sec., and it is 2 sec. between different kind of codes.

4. The DTC(s) are erased with the starter switch turned off.

DTC Display Format

1. When no DTCs are detected. (The unit : sec.)

2. When two or more DTCs are detected. (The unit ; sec.)

0.25 0.25

Code 1–1 Code 2–2 410.5

11 1 1 1 1 12

Page 2873 of 3573

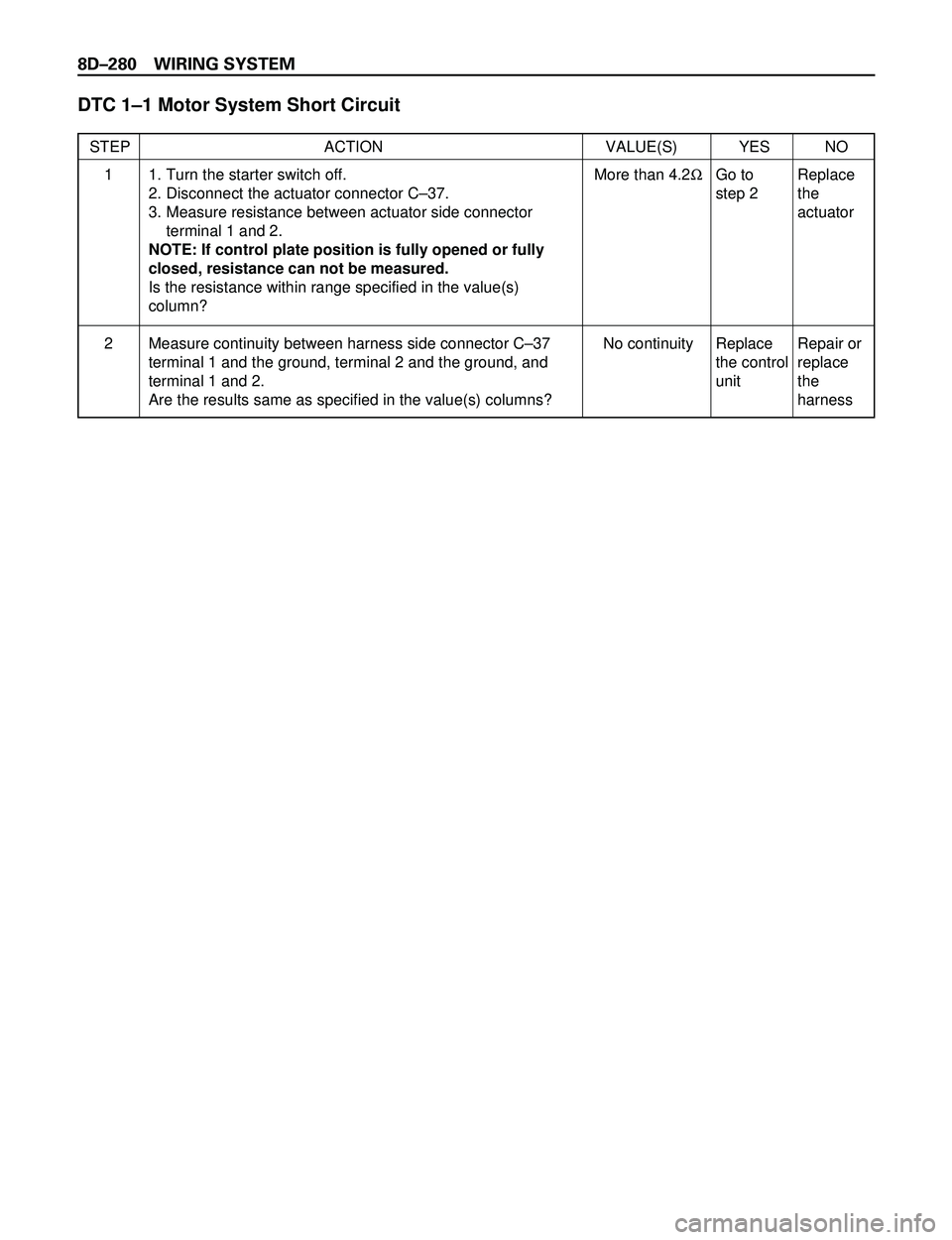

8DÐ280 WIRING SYSTEM

DTC 1Ð1 Motor System Short Circuit

STEP ACTION VALUE(S) YES NO

1. Turn the starter switch off.

2. Disconnect the actuator connector CÐ37.

3. Measure resistance between actuator side connector

terminal 1 and 2.

NOTE: If control plate position is fully opened or fully

closed, resistance can not be measured.

Is the resistance within range specified in the value(s)

column?

Measure continuity between harness side connector CÐ37

terminal 1 and the ground, terminal 2 and the ground, and

terminal 1 and 2.

Are the results same as specified in the value(s) columns?More than 4.2½

No continuityGo to

step 2

Replace

the control

unitReplace

the

actuator

Repair or

replace

the

harness 1

2

Page 2874 of 3573

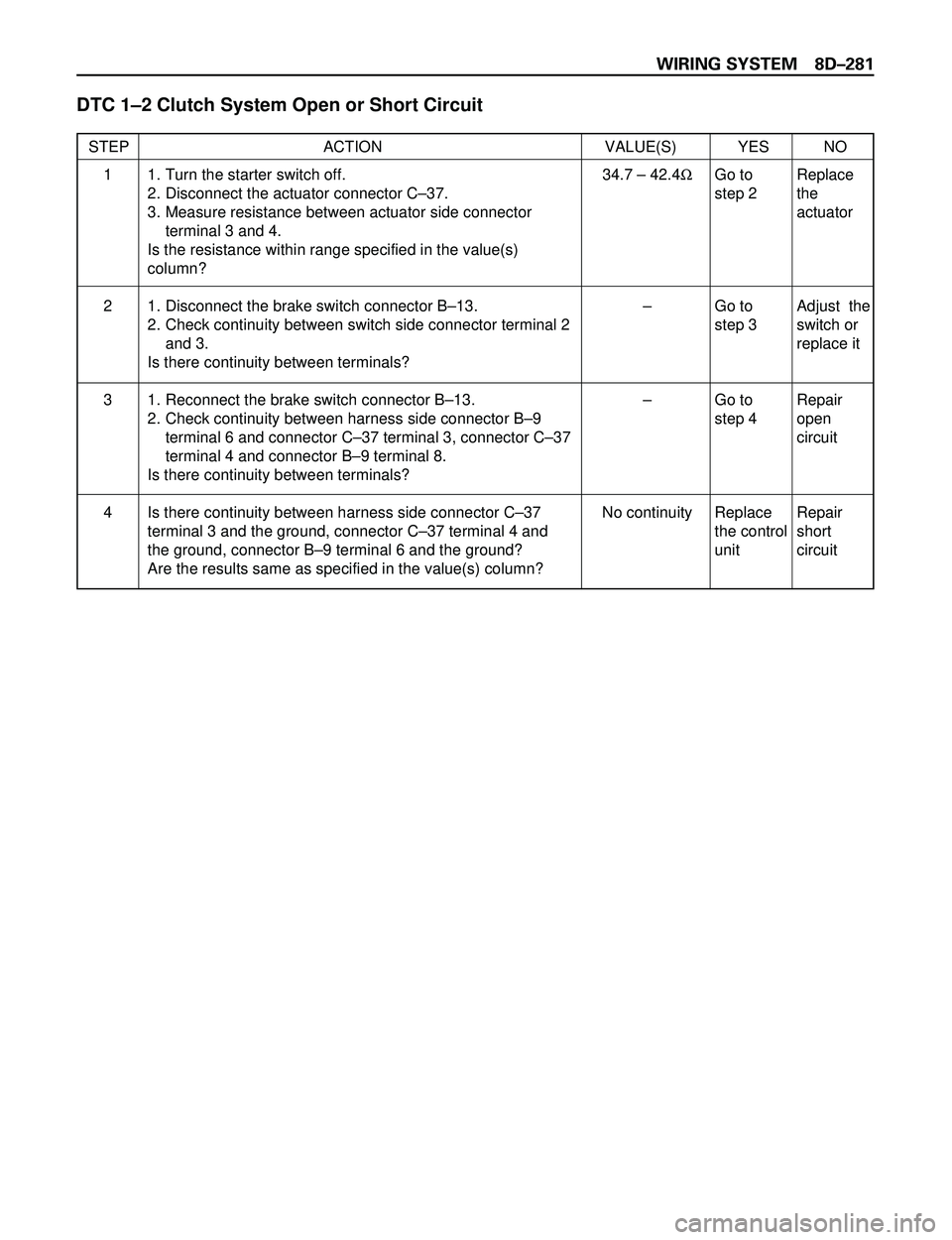

WIRING SYSTEM 8DÐ281

DTC 1Ð2 Clutch System Open or Short Circuit

STEP ACTION VALUE(S) YES NO

1. Turn the starter switch off.

2. Disconnect the actuator connector CÐ37.

3. Measure resistance between actuator side connector

terminal 3 and 4.

Is the resistance within range specified in the value(s)

column?

1. Disconnect the brake switch connector BÐ13.

2. Check continuity between switch side connector terminal 2

and 3.

Is there continuity between terminals?

1. Reconnect the brake switch connector BÐ13.

2. Check continuity between harness side connector BÐ9

terminal 6 and connector CÐ37 terminal 3, connector CÐ37

terminal 4 and connector BÐ9 terminal 8.

Is there continuity between terminals?

Is there continuity between harness side connector CÐ37

terminal 3 and the ground, connector CÐ37 terminal 4 and

the ground, connector BÐ9 terminal 6 and the ground?

Are the results same as specified in the value(s) column?34.7 Ð 42.4½

Ð

Ð

No continuityGo to

step 2

Go to

step 3

Go to

step 4

Replace

the control

unitReplace

the

actuator

Adjust the

switch or

replace it

Repair

open

circuit

Repair

short

circuit 1

2

3

4

Page 2875 of 3573

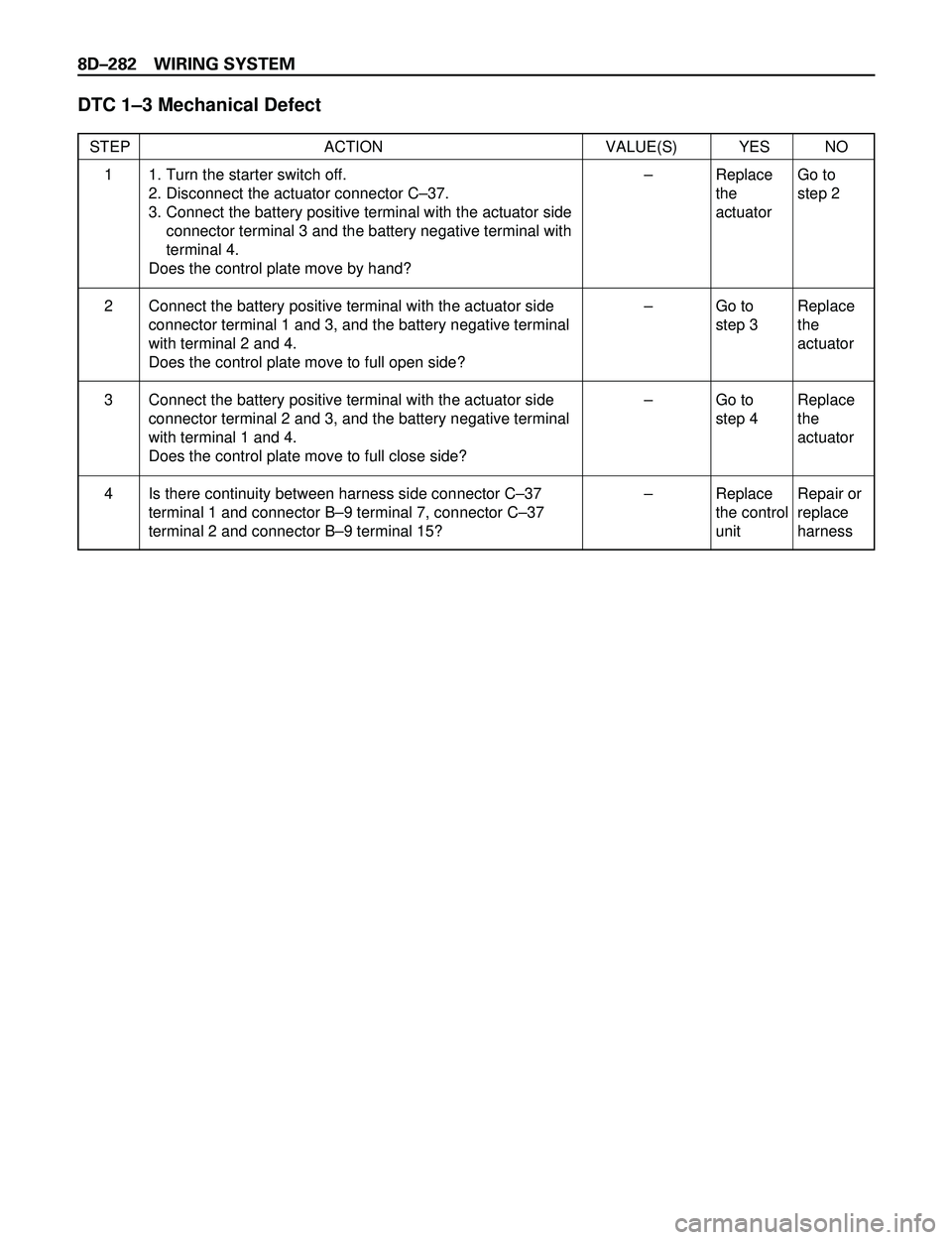

8DÐ282 WIRING SYSTEM

DTC 1Ð3 Mechanical Defect

STEP ACTION VALUE(S) YES NO

1. Turn the starter switch off.

2. Disconnect the actuator connector CÐ37.

3. Connect the battery positive terminal with the actuator side

connector terminal 3 and the battery negative terminal with

terminal 4.

Does the control plate move by hand?

Connect the battery positive terminal with the actuator side

connector terminal 1 and 3, and the battery negative terminal

with terminal 2 and 4.

Does the control plate move to full open side?

Connect the battery positive terminal with the actuator side

connector terminal 2 and 3, and the battery negative terminal

with terminal 1 and 4.

Does the control plate move to full close side?

Is there continuity between harness side connector CÐ37

terminal 1 and connector BÐ9 terminal 7, connector CÐ37

terminal 2 and connector BÐ9 terminal 15?Ð

Ð

Ð

ÐReplace

the

actuator

Go to

step 3

Go to

step 4

Replace

the control

unitGo to

step 2

Replace

the

actuator

Replace

the

actuator

Repair or

replace

harness 1

2

3

4

Page 2876 of 3573

WIRING SYSTEM 8DÐ283

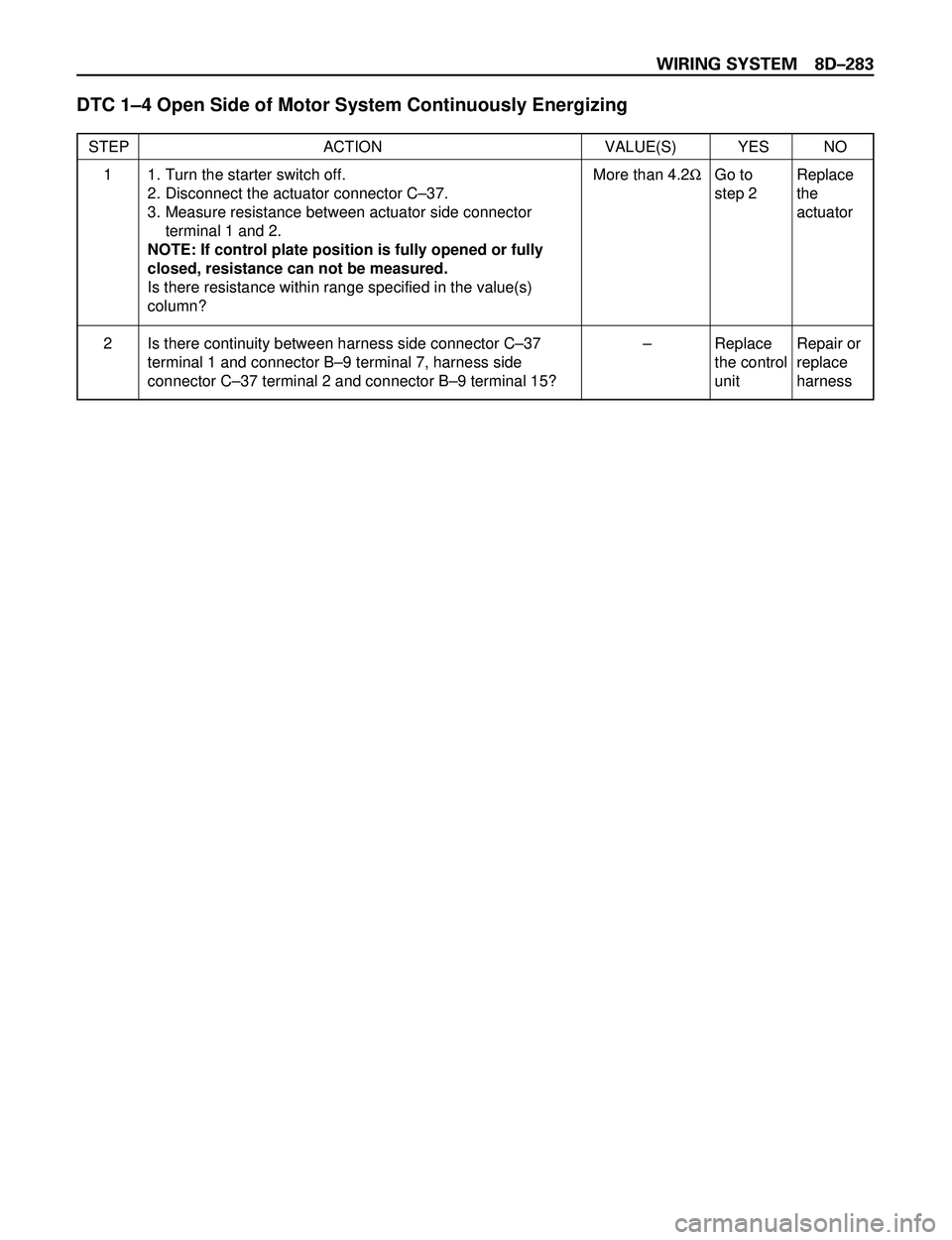

DTC 1Ð4 Open Side of Motor System Continuously Energizing

STEP ACTION VALUE(S) YES NO

1. Turn the starter switch off.

2. Disconnect the actuator connector CÐ37.

3. Measure resistance between actuator side connector

terminal 1 and 2.

NOTE: If control plate position is fully opened or fully

closed, resistance can not be measured.

Is there resistance within range specified in the value(s)

column?

Is there continuity between harness side connector CÐ37

terminal 1 and connector BÐ9 terminal 7, harness side

connector CÐ37 terminal 2 and connector BÐ9 terminal 15?More than 4.2½

ÐGo to

step 2

Replace

the control

unitReplace

the

actuator

Repair or

replace

harness 1

2

Page 2877 of 3573

8DÐ284 WIRING SYSTEM

Anti-lock Brake System (ABS)

General Description

The circuit consists of EHCU (Electronic Hydraulic

Control Unit), wheel speed sensor, GÐsensor,

stoplight switch or brake switch (w/cruise control),

backup light switch, transmission switchÐ1, 2,

indicator light and data link connector.

EHCU controls brake fluid pressure applied to front

and rear wheels to prevent wheels from locking by

using speed sensor and GÐsensor signals.

Based on wheel speed signals from speed sensor,

EHCU activates solenoid valves incorporated into

the control unit to increase, maintain or decrease

brake fluid pressure.

Refer to AntiÐlock Brake System in Brakes section.

Page 2878 of 3573

WIRING SYSTEM 8DÐ285

Circuit Diagram (RHD)-1

2.0

Y/G2.0

W/G 3.0

W/G

0.5

LG FL-6 40A

ABS

F-9 20A

ABS

INDICATOR

LIGHT(METER)

BRAKE

SW STOP

LIGHT

SW

ELECTRONIC

HYDRAULIC

CONTROL UNIT4WD CONTROL

UNIT(19)

14

C-413

C-4

3.0

B/Y3.0

B/Y

0.85

L/W0.5

L/W0.5

L/W

2.0

BC-4 10A

ELEC.IGN.STARTER SW

(IG1)STARTER SW

(IG1)

C-10 10A

METER,GAUGE

I-9

I-10156I-9

2H-26H-1619

H-2718 16

5.0

W

0.85

G/W C-14 15A

STOP,A/T CONT. BATT.(+) BATT.(+)

STOP LIGHT

10

C-430.85

G/W (W/CRUISE CONTROL) 0.85

G/W

0.85

G/Y

0.85

G/Y 0.85

G/Y

0.85

G/Y

B-131B-13

4

B-14H-131B-14

2

G-

SENSOR26

C-4 0.5

L/W

0.5

Y/B

0.5

Y/BB-252B-25

1H-151

8

C-4

6C-39

FENDER-RHH-131C-4

15

16

C-4 0.5

L/Y

0.5

L/Y

0.5

Y

0.5

Y

A

2.0

B(DIESEL)

5C-39

FENDER-RHC-4

15

2.0

BC-85

ENG.ROOM-FRTC-4 GROUND GROUND GROUND BATTERY BATTERY G-SENSOR POWER

SUPPLYSILA BRAKE LIGHT

SWITCH

12

4WDABS

D08RW601

Page 2879 of 3573

8DÐ286 WIRING SYSTEM

Circuit Diagram (RHD 6V*1)-2

0.5

GR0.5

GR

0.5

O/G0.5

O/B0.5

O/W

0.5

O/G0.5

O/B 0.5

L0.5

G 0.5

W 0.5

B/L0.5

R

0.5

W 0.5

B/L

0.5

O 0.5

O/L 0.5

W/L0.5

W

0.5

O 0.5

O/L 0.5

W/L0.5

W0.5

O 0.5

O/L 0.5

W/L0.5

W0.5

O 0.5

O/L 0.5

W/L0.5

W

0.5

R0.5

O/W0.85

G/W 0.5

P

0.5

B/L0.5

B/L

1.25

B/L

1.0

B/L

ELECTRONIC

HYDRAULIC

CONTROL

UNIT

PCM

(A12)(A/T)

SPEED

SENSORC-4

23

C-4

22

8

H-46H-138

6

H-46H-135

7

H-466

C-4

TMM

GND RLS GND RRS GND FLS GND FRS SDL2DIAG

KDIAG

L TMMTFM2 6

C-49

C-4

8

C-39 1

F-32

F-3H-134

14

H-5

FENDER-RH

COMMON

CHAMBER

(W/O T.O.D.)

SPEED

SENSORC-4

3

C-4

2

11

H-46H-1314

12

H-46

6

H-334

H-335

H-332

H-333

H-33

1

F-22

F-2H-1313

C-4

2C-63

E-305C-63

4

C-63

H-423

C-4

7C-63H-429

C-4

12C-63H-421 25 24 17

16

C-63H-79

SPEED

SENSORC-4

21

C-4

20

H-4215

H-4211

H-4214

1

C-132

C-13

SPEED

SENSOR

FRT-RH FRT-LH

RR-RH RR-LHDATA LINK CONNECTORC-4

5

C-4

4

1

C-412

C-41

A

4WD

�$�0�/�5�3�0�-��

UNIT(20)

B

C

C

0.5

P

TFM29C-4T.O.D.

CONTROL UNIT

9H-15

0.5

LG/R

ABS

STATUS27C-4T.O.D.

CONTROL UNIT

20H-15

D08RW786

Page 2880 of 3573

WIRING SYSTEM 8DÐ287

Circuit Diagram (RHD 4J**)-2

0.5

GR

0.5

O/B0.5

O/W

0.5

O/B 0.5

L0.5

G 0.5

W 0.5

B/L0.5

R

0.5

W 0.5

B/L

0.5

O 0.5

O/L 0.5

W/L0.5

W0.5

O 0.5

O/L 0.5

W/L0.5

W0.5

O 0.5

O/L 0.5

W/L0.5

W

0.5

R0.5

O/W0.85

G/W

0.5

B0.5

B

ELECTRONIC

HYDRAULIC

CONTROL

UNIT

SPEED

SENSOR

C-4

23

C-4

22

6

H-334

H-335

H-33 8

H-466

H-467

H-4611

H-4215

H-4214

H-42 6

C-4

TMM

GND RLS GND RRS GND FLS GND FRSDIAG

KDIAG

L

1

F-32

F-3

7

C-16

FENDER-LH

SPEED

SENSORC-4

3

C-4

2

2

H-333

H-33 11

H-4612

H-46 0.5

O 0.5

O/L 0.5

W/L0.5

W

8

H-135

H-134

H-1314

H-1313

H-13

1

F-22

F-2

8

C-39

FENDER-RH

5

C-63

4

C-63C-4

7C-639

C-4

12C-63 24 17

16

C-63H-79

SPEED

SENSORC-4

21

C-4

20

1

C-132

C-13

SPEED

SENSOR

FRT-RH FRT-LH

RR-RH RR-LHDATA LINK CONNECTORC-4

5

C-4

4

1

C-412

C-411

H-42

H-42

A

0.5

P

TFM29C-44WD

�$�0�/�5�3�0�-��

�6�/�*�5(20)

B

C

C

0.5

B

D08RW788