service ISUZU TROOPER 1998 Service Owner's Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 54 of 3573

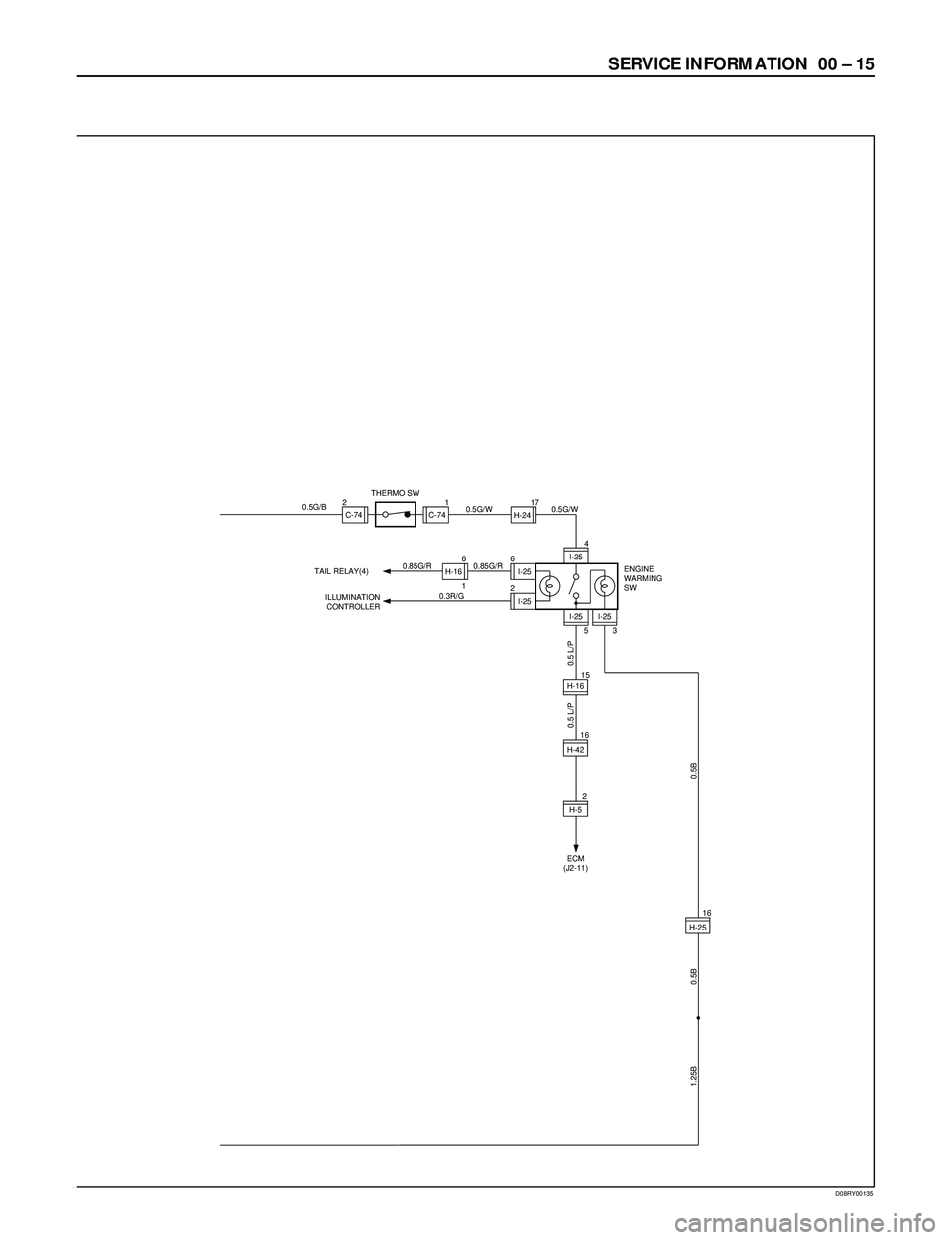

SERVICE INFORMATION 00 Ð 15

D08RY00135

ECM

(J2-11)

0.5 L/P

I-25

I-25

3

I-25 2

I-25 6

I-25

5

4

1H-166

0.3R/G0.85G/R 0.85G/R

ILLUMINATION

CONTROLLER TAIL RELAY(4)

ENGINE

WARMING

SW

1.25B 0.5B

C-74C-741 2THERMO SWH-2417

0.5G/W 0.5G/W

0.5 L/P

0.5G/B

H-2516

H-4216

H-52

0.5B

H-1615

Page 55 of 3573

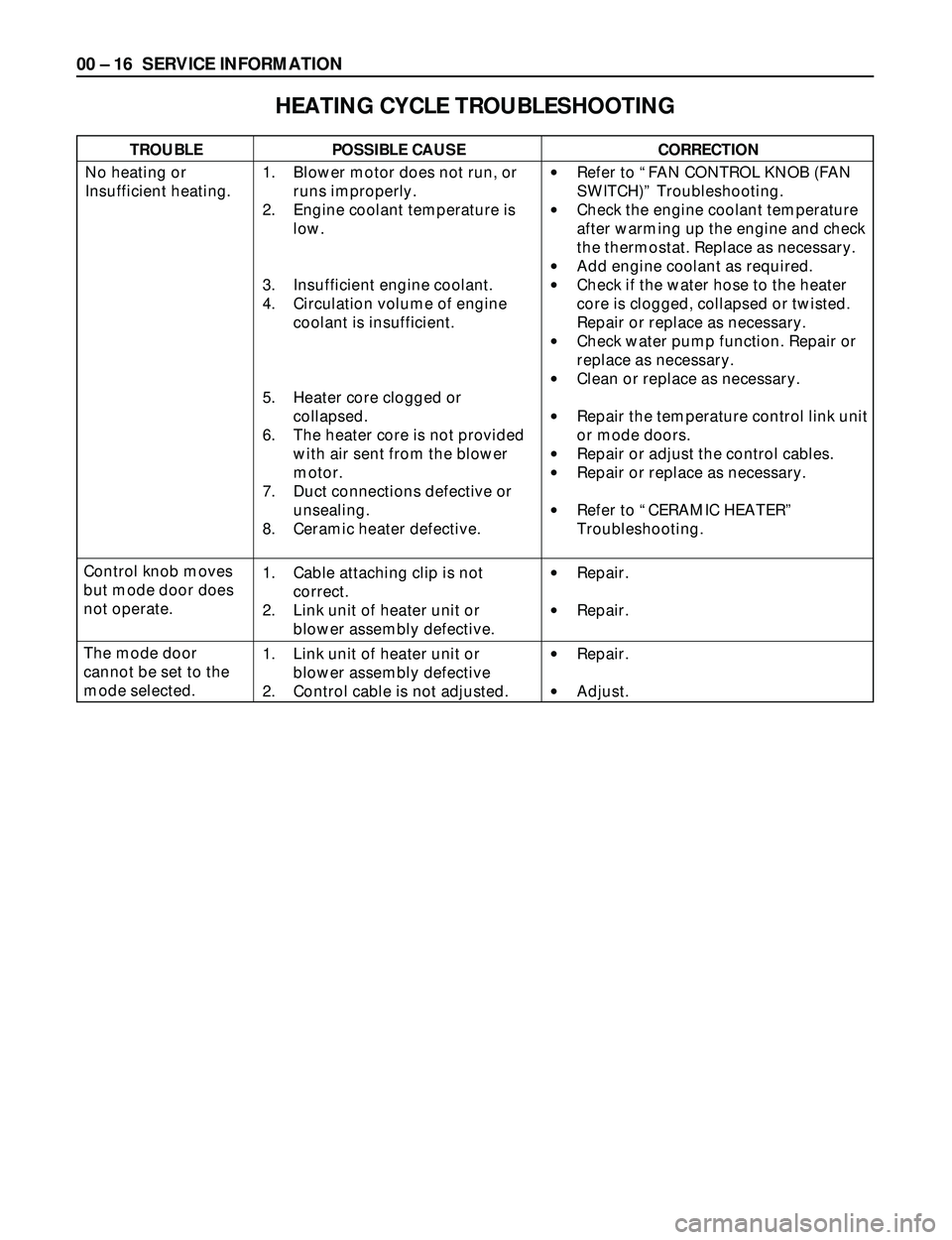

00 Ð 16 SERVICE INFORMATION

TROUBLE POSSIBLE CAUSE CORRECTION

HEATING CYCLE TROUBLESHOOTING

No heating or

Insufficient heating.·Refer to ÒFAN CONTROL KNOB (FAN

SWITCH)Ó Troubleshooting.

·Check the engine coolant temperature

after warming up the engine and check

the thermostat. Replace as necessary.

·Add engine coolant as required.

·Check if the water hose to the heater

core is clogged, collapsed or twisted.

Repair or replace as necessary.

·Check water pump function. Repair or

replace as necessary.

·Clean or replace as necessary.

·Repair the temperature control link unit

or mode doors.

·Repair or adjust the control cables.

·Repair or replace as necessary.

·Refer to ÒCERAMIC HEATERÓ

Troubleshooting.

·Repair.

·Repair.

·Repair.

·Adjust. 1. Blower motor does not run, or

runs improperly.

2. Engine coolant temperature is

low.

3. Insufficient engine coolant.

4. Circulation volume of engine

coolant is insufficient.

5. Heater core clogged or

collapsed.

6. The heater core is not provided

with air sent from the blower

motor.

7. Duct connections defective or

unsealing.

8. Ceramic heater defective.

1. Cable attaching clip is not

correct.

2. Link unit of heater unit or

blower assembly defective.

1. Link unit of heater unit or

blower assembly defective

2. Control cable is not adjusted. Control knob moves

but mode door does

not operate.

The mode door

cannot be set to the

mode selected.

Page 56 of 3573

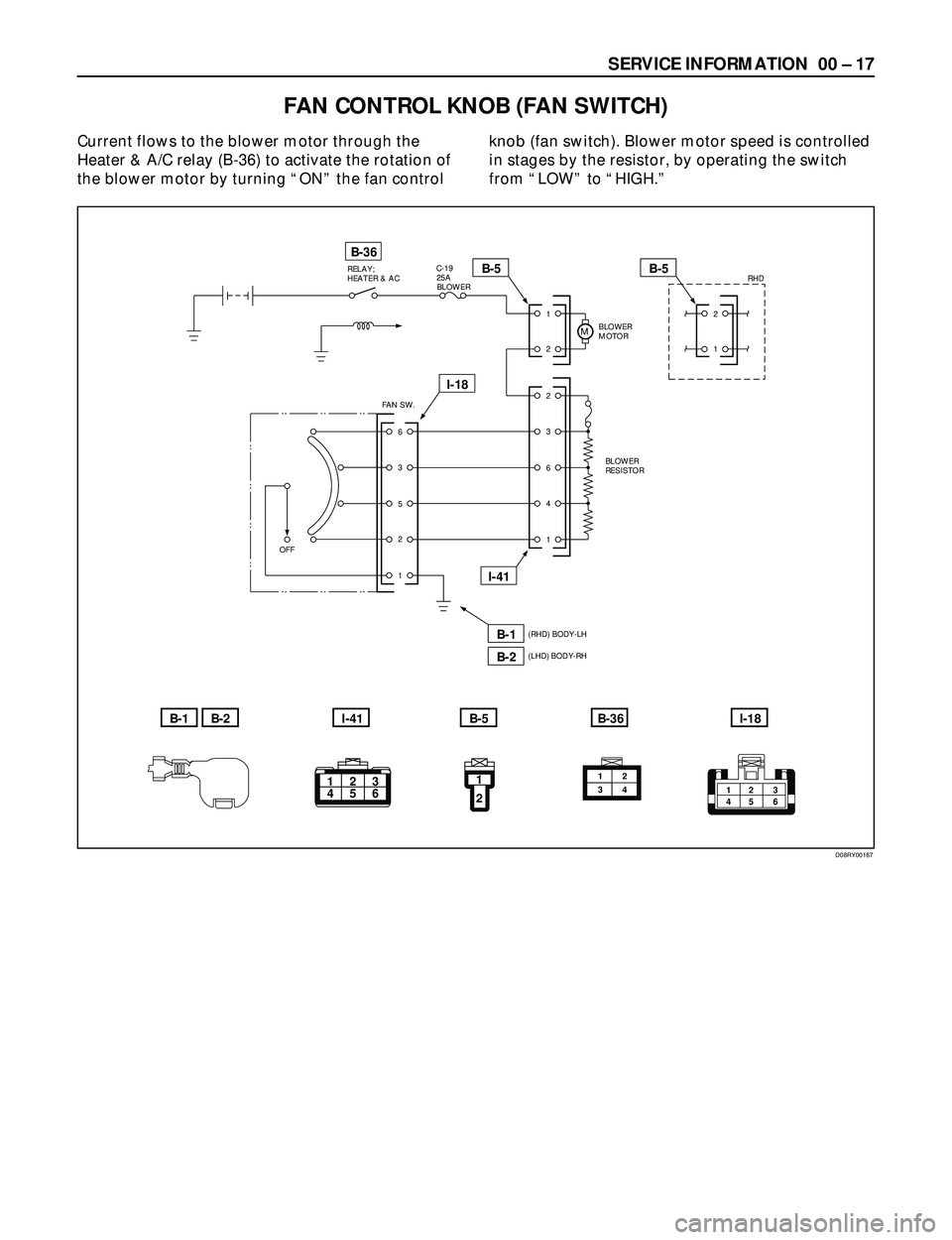

SERVICE INFORMATION 00 Ð 17

FAN CONTROL KNOB (FAN SWITCH)

Current flows to the blower motor through the

Heater & A/C relay (B-36) to activate the rotation of

the blower motor by turning ÒONÓ the fan controlknob (fan switch). Blower motor speed is controlled

in stages by the resistor, by operating the switch

from ÒLOWÓ to ÒHIGH.Ó

12

34

B-36B-1B-2

1234561

2123

45 6

I-41B-5I-18

1

2

B-36RELAY;

HEATER & ACC-19

25A

BLOWER

2

3

6

4

1

6

3

5

2

1

MBLOWER

MOTOR2

1

RHD

OFF

B-5B-5

I-18

BLOWER

RESISTOR FAN SW.

I-41

B-1

B-2(LHD) BODY-RH (RHD) BODY-LH

D08RY00167

Page 57 of 3573

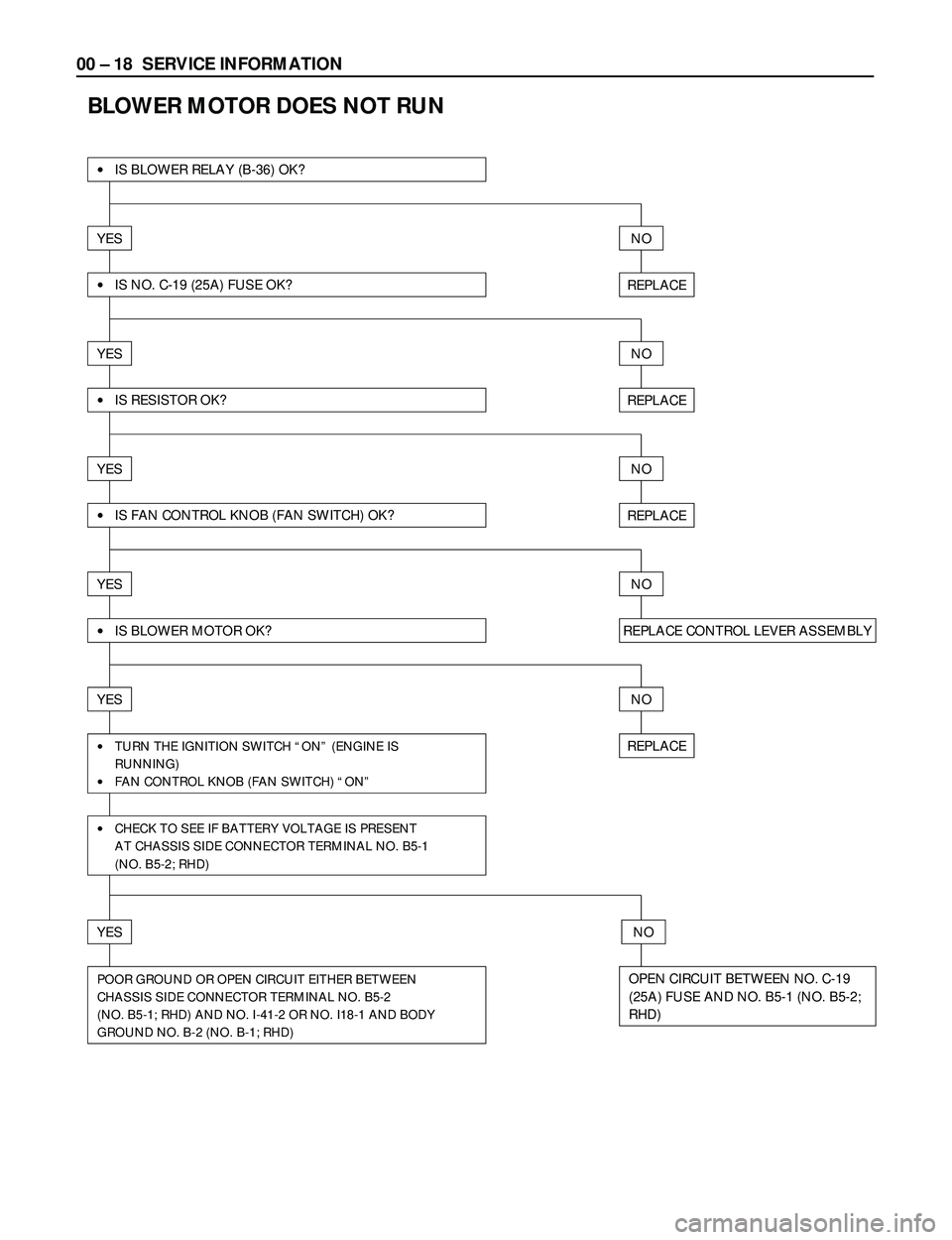

00 Ð 18 SERVICE INFORMATION

BLOWER MOTOR DOES NOT RUN

·IS NO. C-19 (25A) FUSE OK?

·IS BLOWER RELAY (B-36) OK?

YESNO

REPLACE

NO

REPLACE

NO

REPLACE

NO

REPLACE CONTROL LEVER ASSEMBLY

NO

REPLACE

NO

OPEN CIRCUIT BETWEEN NO. C-19

(25A) FUSE AND NO. B5-1 (NO. B5-2;

RHD)

YES

·IS RESISTOR OK?

YES

·IS FAN CONTROL KNOB (FAN SWITCH) OK?

YES

·IS BLOWER MOTOR OK?

YES

·TURN THE IGNITION SWITCH ÒONÓ (ENGINE IS

RUNNING)

·FAN CONTROL KNOB (FAN SWITCH) ÒONÓ

·CHECK TO SEE IF BATTERY VOLTAGE IS PRESENT

AT CHASSIS SIDE CONNECTOR TERMINAL NO. B5-1

(NO. B5-2; RHD)

YES

POOR GROUND OR OPEN CIRCUIT EITHER BETWEEN

CHASSIS SIDE CONNECTOR TERMINAL NO. B5-2

(NO. B5-1; RHD) AND NO. I-41-2 OR NO. I18-1 AND BODY

GROUND NO. B-2 (NO. B-1; RHD)

Page 58 of 3573

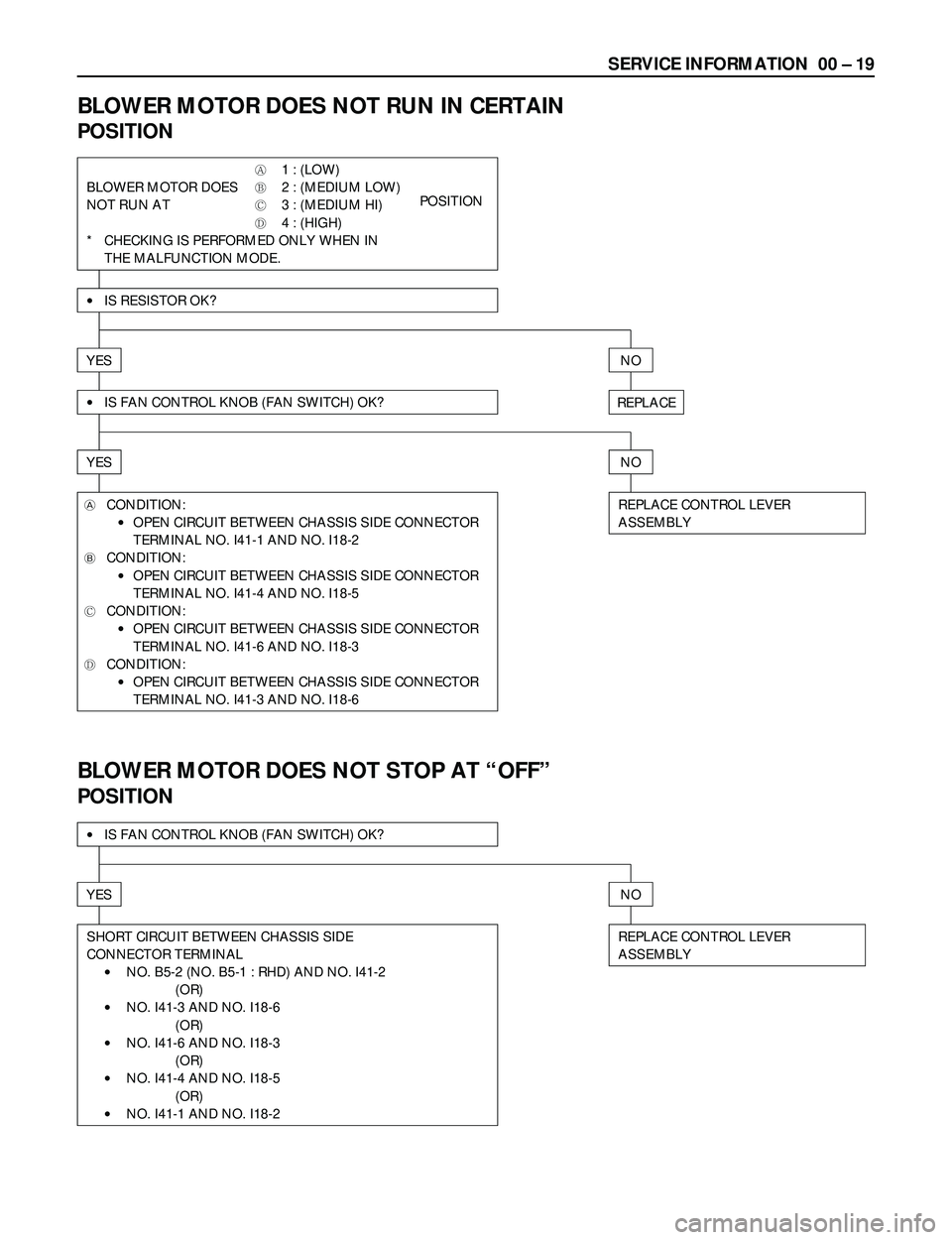

SERVICE INFORMATION 00 Ð 19

BLOWER MOTOR DOES NOT RUN IN CERTAIN

POSITION

A1 : (LOW)

BLOWER MOTOR DOES

B2 : (MEDIUM LOW)

NOT RUN AT

C3 : (MEDIUM HI) POSITION

D4 : (HIGH)

* CHECKING IS PERFORMED ONLY WHEN IN

THE MALFUNCTION MODE.

·IS RESISTOR OK?

YES

·IS FAN CONTROL KNOB (FAN SWITCH) OK?

YES

ACONDITION:

·OPEN CIRCUIT BETWEEN CHASSIS SIDE CONNECTOR

TERMINAL NO. I41-1 AND NO. I18-2

BCONDITION:

·OPEN CIRCUIT BETWEEN CHASSIS SIDE CONNECTOR

TERMINAL NO. I41-4 AND NO. I18-5

CCONDITION:

·OPEN CIRCUIT BETWEEN CHASSIS SIDE CONNECTOR

TERMINAL NO. I41-6 AND NO. I18-3

DCONDITION:

·OPEN CIRCUIT BETWEEN CHASSIS SIDE CONNECTOR

TERMINAL NO. I41-3 AND NO. I18-6

NO

REPLACE

NO

REPLACE CONTROL LEVER

ASSEMBLY

BLOWER MOTOR DOES NOT STOP AT ÒOFFÓ

POSITION

·IS FAN CONTROL KNOB (FAN SWITCH) OK?

YES

SHORT CIRCUIT BETWEEN CHASSIS SIDE

CONNECTOR TERMINAL

·NO. B5-2 (NO. B5-1 : RHD) AND NO. I41-2

(OR)

·NO. I41-3 AND NO. I18-6

(OR)

·NO. I41-6 AND NO. I18-3

(OR)

·NO. I41-4 AND NO. I18-5

(OR)

·NO. I41-1 AND NO. I18-2

NO

REPLACE CONTROL LEVER

ASSEMBLY

Page 59 of 3573

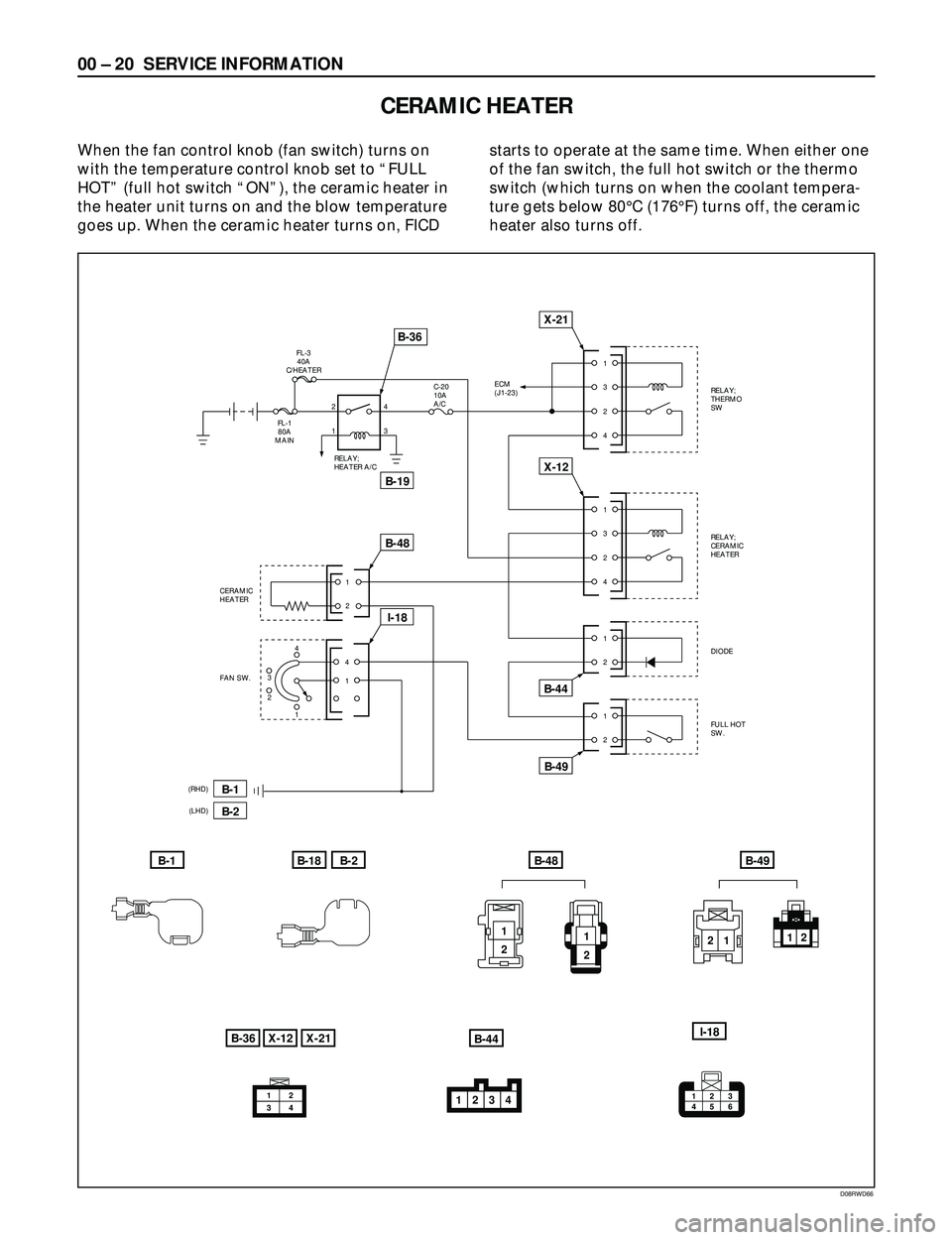

00 Ð 20 SERVICE INFORMATION

CERAMIC HEATER

When the fan control knob (fan switch) turns on

with the temperature control knob set to ÒFULL

HOTÓ (full hot switch ÒONÓ), the ceramic heater in

the heater unit turns on and the blow temperature

goes up. When the ceramic heater turns on, FICDstarts to operate at the same time. When either one

of the fan switch, the full hot switch or the thermo

switch (which turns on when the coolant tempera-

ture gets below 80°C (176°F) turns off, the ceramic

heater also turns off.

FL-3

40A

C/HEATER

RELAY;

HEATER A/CECM

(J1-23)

24

13

C-20

10A

A/C

FL-1

80A

MAIN

B-18B-1

B-36

1

3

X-12

2

4

1

3

X-21

2

4

1

2

1

2

4

13

24

1

1

2CERAMIC

HEATER

FAN SW.

B-19

B-48

I-18

B-44

B-49

RELAY;

THERMO

SW

RELAY;

CERAMIC

HEATER

DIODE

FULL HOT

SW.

B-1

B-48

1

21

22112

B-49

I-18

213

5 4612

34

B-36X-12X-21

1234

B-44

(RHD)

B-2(LHD)

B-2

D08RWD66

Page 60 of 3573

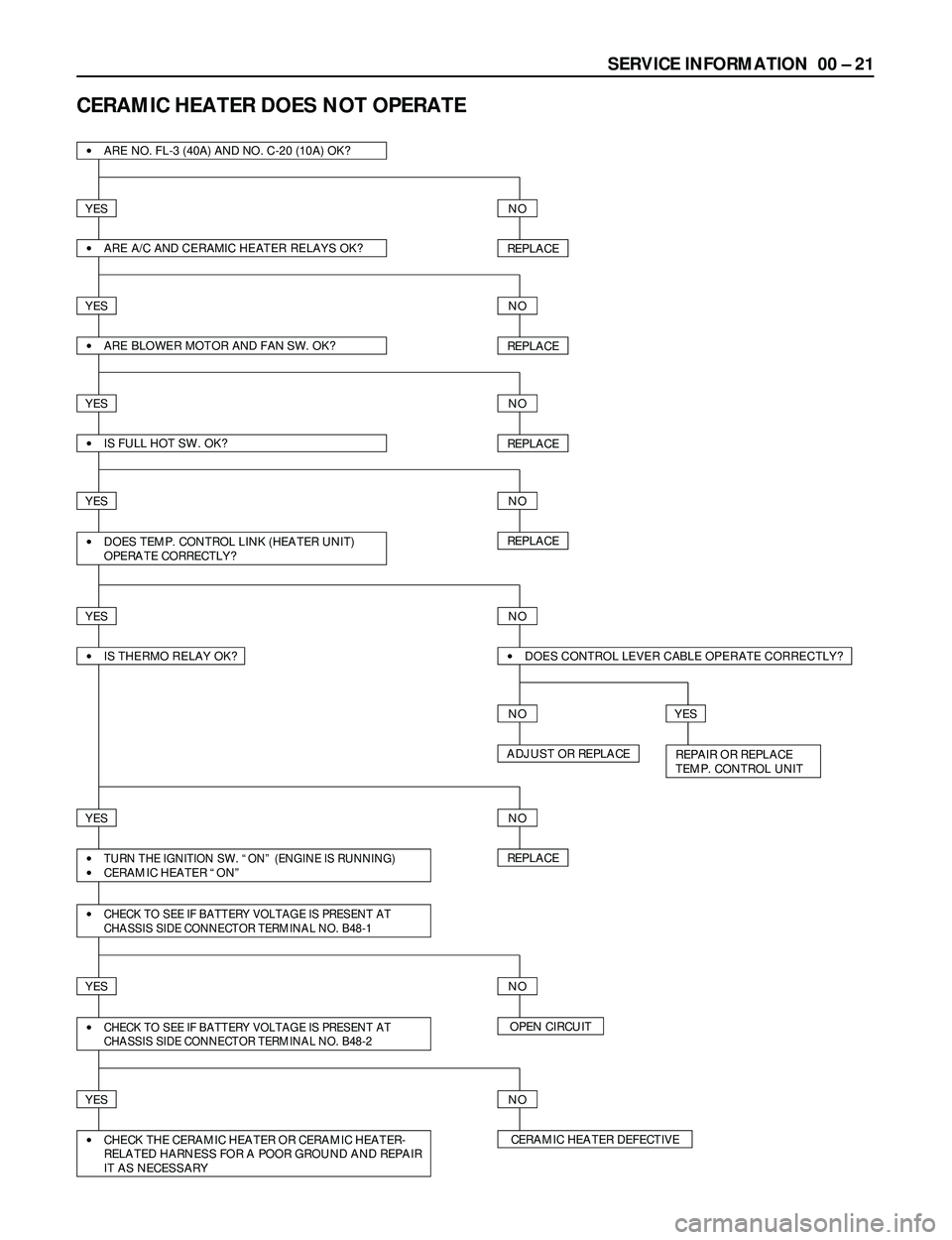

SERVICE INFORMATION 00 Ð 21

CERAMIC HEATER DOES NOT OPERATE

·ARE NO. FL-3 (40A) AND NO. C-20 (10A) OK?

YESNO

REPLACE

REPLACE

REPLACE

REPLACE

·ARE A/C AND CERAMIC HEATER RELAYS OK?

YESNO

·ARE BLOWER MOTOR AND FAN SW. OK?

YESNO

·IS FULL HOT SW. OK?

·DOES TEMP. CONTROL LINK (HEATER UNIT)

OPERATE CORRECTLY?

YESNO

REPLACE·TURN THE IGNITION SW. ÒONÓ (ENGINE IS RUNNING)·CERAMIC HEATER ÒONÓ

·CHECK TO SEE IF BATTERY VOLTAGE IS PRESENT AT

CHASSIS SIDE CONNECTOR TERMINAL NO. B48-1

YESNO

OPEN CIRCUIT·CHECK TO SEE IF BATTERY VOLTAGE IS PRESENT AT

CHASSIS SIDE CONNECTOR TERMINAL NO. B48-2

YESNO

CERAMIC HEATER DEFECTIVE·CHECK THE CERAMIC HEATER OR CERAMIC HEATER-

RELATED HARNESS FOR A POOR GROUND AND REPAIR

IT AS NECESSARY

YESNO

·DOES CONTROL LEVER CABLE OPERATE CORRECTLY?·IS THERMO RELAY OK?

YESNO

NOYES

ADJUST OR REPLACEREPAIR OR REPLACE

TEMP. CONTROL UNIT

Page 61 of 3573

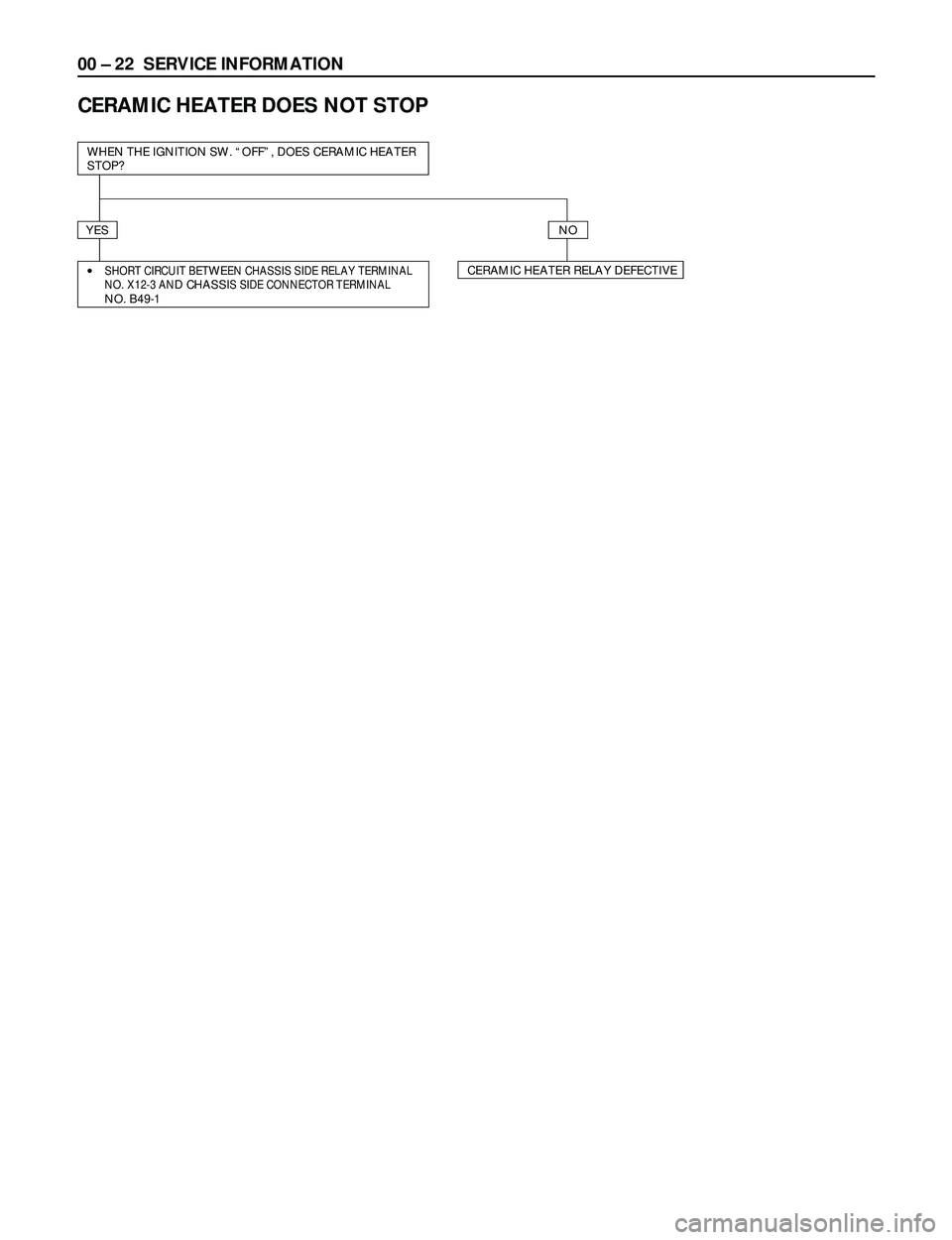

00 Ð 22 SERVICE INFORMATION

CERAMIC HEATER DOES NOT STOP

WHEN THE IGNITION SW. ÒOFFÓ, DOES CERAMIC HEATER

STOP?

YESNO

CERAMIC HEATER RELAY DEFECTIVE·SHORT CIRCUIT BETWEEN CHASSIS SIDE RELAY TERMINAL

NO. X12-3 AND CHASSIS SIDE CONNECTOR TERMINALNO. B49-1

Page 62 of 3573

SERVICE INFORMATION 00 Ð 23

AIR CONDITIONING CYCLE TROUBLESHOOTING

No cooling or insuffi-

cient cooling

Insufficient velocity

of cooling air1. Magnetic clutch does not run

2. Compressor is not rotating properly

·Drive belt loosened or broken

·Magnetic clutch face is not

clean and slips

·Incorrect clearance between

magnetic drive plate and pulley

·Compressor oil leaks from shaft

seal or shell

·Compressor seized

3. Insufficient or excessive charge of

refrigerant

4. Leaks in the refrigerant system

5. Condenser clogged or insufficient

radiation

6. Temperature control link unit of the

heater unit defective

7. Unsteady operation due to foreign

substance in expansion valve

8. Poor operation of electronic thermo-

stat

1. Evaporator clogged or frosted

2. Air leaking from cooling unit or air

duct

3. Blower motor does not rotate prop-

erly·Refer to ÒMAGNETIC CLUTCHÓ

troubleshooting

·Adjust the drive belt to the specified

tension or replace the drive belt

·Clean the magnetic clutch face or

replace

·Adjust the clearance (Refer to

Section 1D ÒCOMPRESSOR OVER-

HAULÓ

·Replace the compressor

·Replace the compressor

·Discharge and recover refrigerant.

Recharge to specified amount.

·Check refrigerant system for leaks

and repair as necessary

Discharge and recover refrigerant.

Recharge to specified amount.

·Clean the condenser or replace as

necessary

·Check radiator or condenser fan

function

·Repair the link unit

·Replace the expansion valve

·Check electronic thermostat and

replace as necessary

·Check evaporator core and replace

or clean the core

·Check evaporator and duct connec-

tion, then repair as necessary

·Refer to Section 00 for ÒFAN

CONTROL KNOB (FAN SWITCH)Ó

troubleshooting

* For the execution of the charging and discharging operation in the table above, refer to the ÒRECOVERY,

RECYCLING, EVACUATING AND CHARGINGÓ in section 1B.

TROUBLEPOSSIBLE CAUSECORRECTION

Page 63 of 3573

00 Ð 24 SERVICE INFORMATION

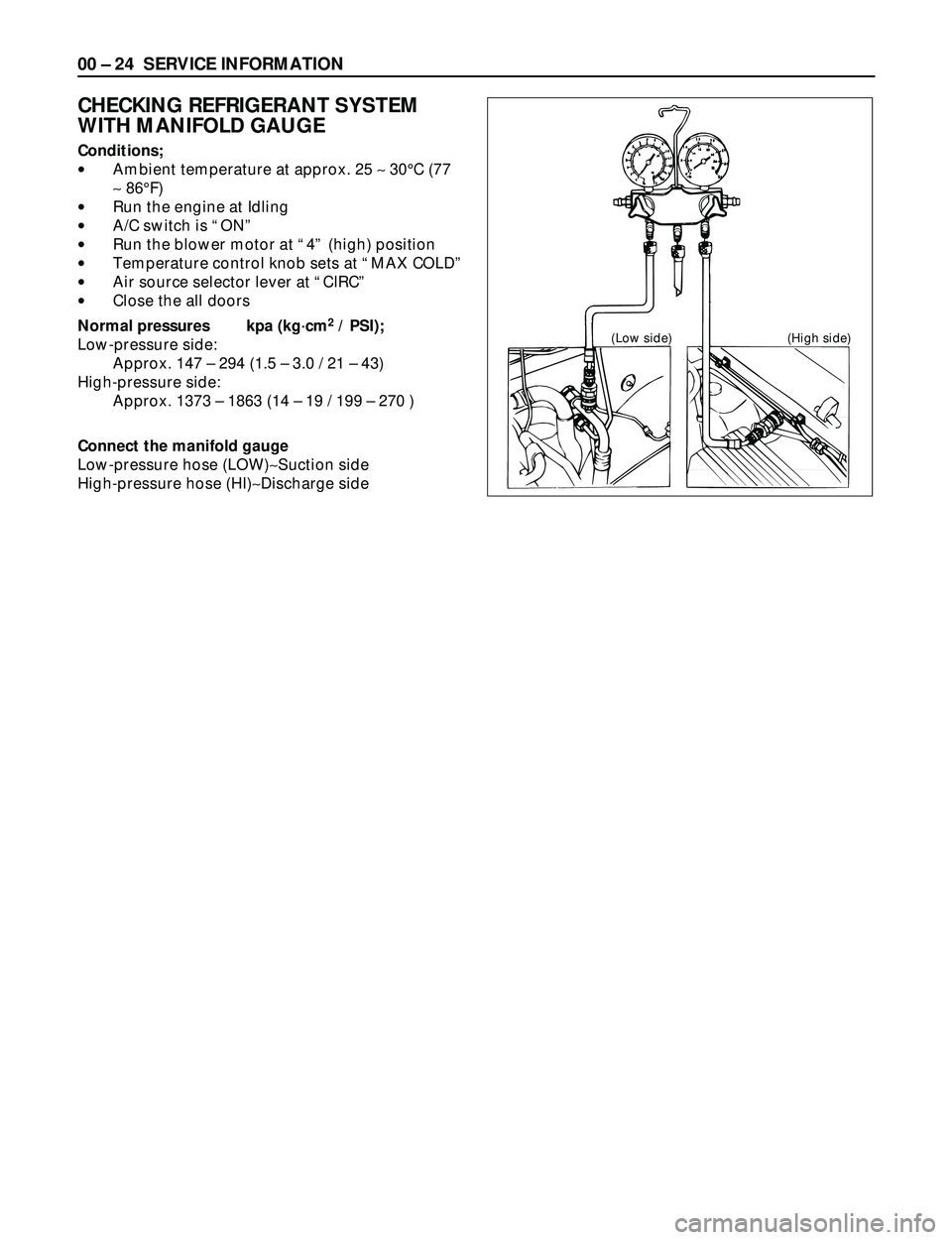

CHECKING REFRIGERANT SYSTEM

WITH MANIFOLD GAUGE

Conditions;

·Ambient temperature at approx. 25 ~30°C (77

~86°F)

·Run the engine at Idling

·A/C switch is ÒONÓ

·Run the blower motor at Ò4Ó (high) position

·Temperature control knob sets at ÒMAX COLDÓ

·Air source selector lever at ÒCIRCÓ

·Close the all doors

Normal pressures kpa (kgácm

2/ PSI);

Low-pressure side:

Approx. 147 Ð 294 (1.5 Ð 3.0 / 21 Ð 43)

High-pressure side:

Approx. 1373 Ð 1863 (14 Ð 19 / 199 Ð 270 )

Connect the manifold gauge

Low-pressure hose (LOW)~Suction side

High-pressure hose (HI)~Discharge side (Low side) (High side)