Relay JAGUAR X308 1998 2.G Owners Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1719 of 2490

W

ith EM013 disconnected, measure the resistance

between EM013/009 and relay socket pin 1

1

I

s the resistance < 0.5 OHM?

Yes GO to B9

No Inspect connectors EM013, EM051/008, LS003/21,

BT004/009 and BT010/005 for corrosion, damage, bent or

pushed back pins and repair as required. Test the system

for normal operation

B9: CHECK

ECM GROUND CONTINUITY

Page 1720 of 2490

Wi

th EM014 disconnected, measure the resistance

between EM014/010 and ground EM016L.

1

I s

the resistance < 0.5 OHM?

Yes STOP, renew the relay and test the system for normal

operation.

No Inspect harness / connectors EM014, splice EMS37 and

ground EM016L for corrosion, damage, bent or pushed

back pins. Repair as requir ed and test the system for

normal operation.

B10: CHECK FU EL

PUMP CONTINUITY

Page 1723 of 2490

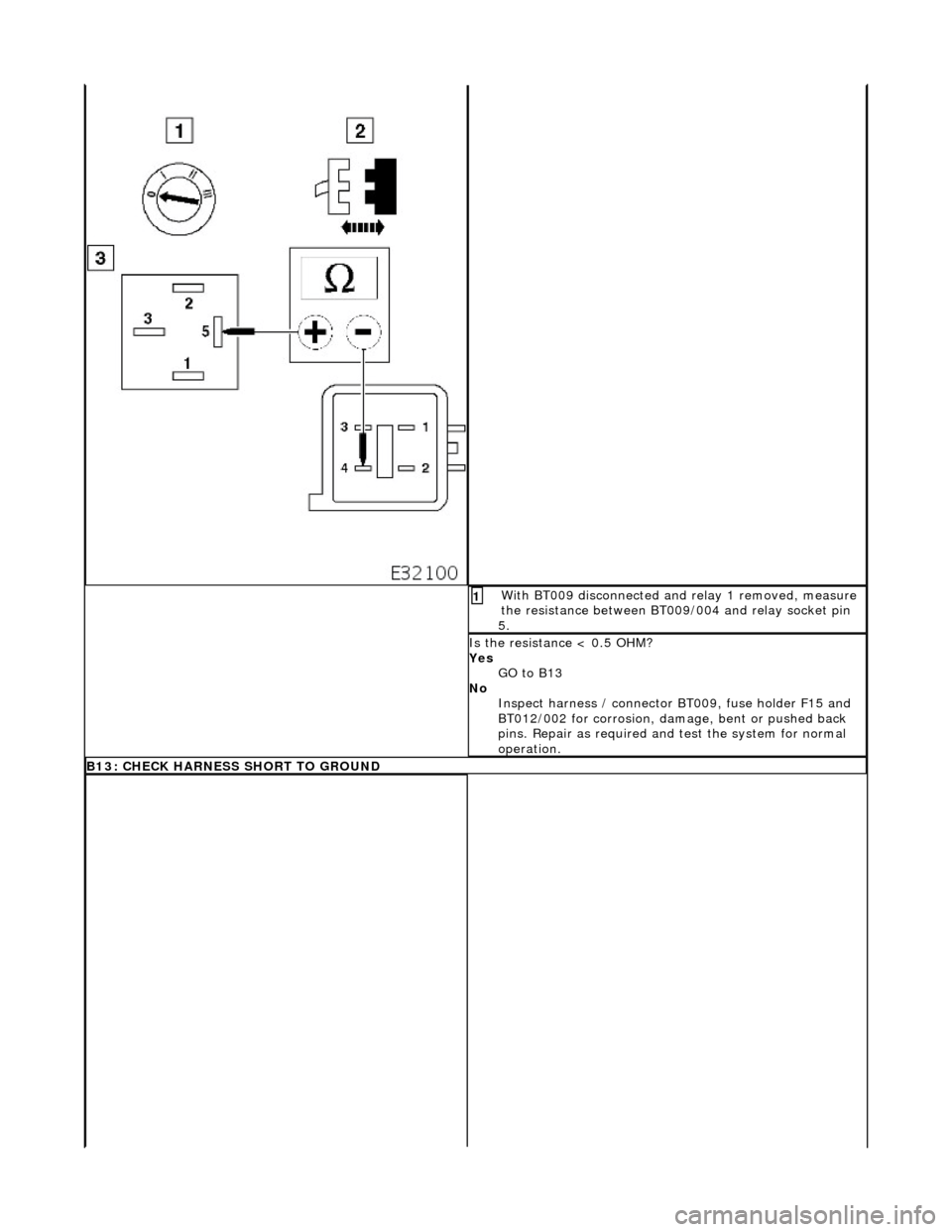

Wi

th BT009 disconnected an

d relay 1 removed, measure

the resistance between BT009/004 and relay socket pin

5.

1

I

s the resistance < 0.5 OHM?

Yes GO to B13

No Inspect harness / connector BT 009, fuse holder F15 and

BT012/002 for corrosion, damage, bent or pushed back

pins. Repair as required and test the system for normal

operation.

B13: CHECK HARNESS SHO

RT TO GROUND

Page 1724 of 2490

Wi

th EM013 and BT009 disconnected, measure the

insulation resistance between EM013/009 and ground

BT020L.

1

I s

the resistance > 10M OHM?

Yes Do not replace relay or reconnect connectors

GO to B14

No Inspect harness / connec tors EM013, EM051/008,

LS003/021, BT004/009 and BT010/005 for corrosion,

damage, bent or pushed back pins. Repair as required

and test the system for normal operation.

B1 4

: CHECK CORE TO CORE INSULATION

Page 1725 of 2490

With

conditions as B13, meas

ure the insulation resistance

between EM013/009 and relay socket pin 5.

1

I

s the resistance > 10M OHM?

Yes GO to B16

No Inspect harness / connec tors EM013, EM051/008,

LS003/021, BT004/009, BT012/002, BT009/004 and

BT010/005 for corrosion, damage, bent or pushed back

pins and repair as required. Test the system for normal

operation

B1

5: CHECK CORE TO CORE INSULATION

Page 1726 of 2490

Pinpoint test C: P0460

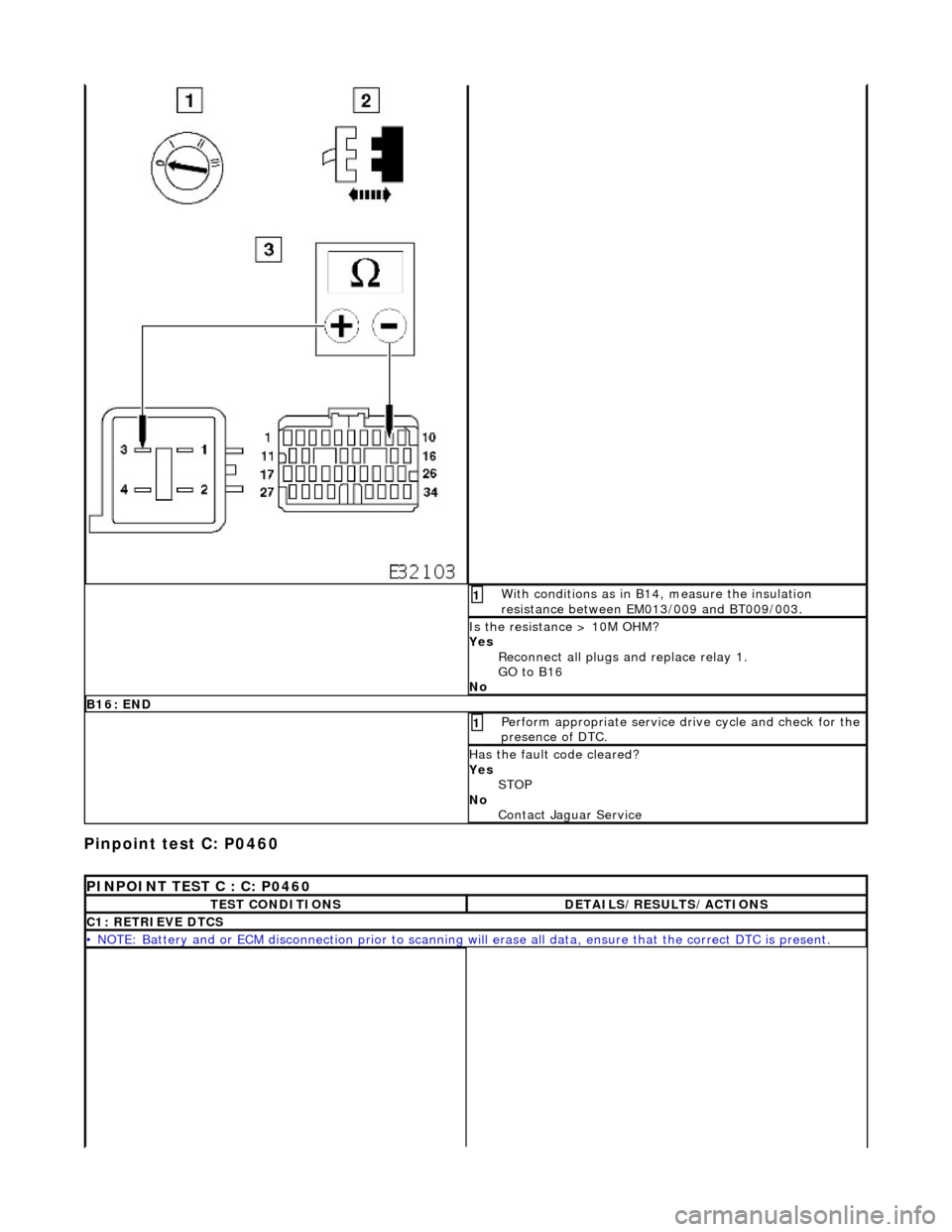

Wi

th conditions as in B14, measure the insulation

resistance between EM013/009 and BT009/003.

1

I s

the resistance > 10M OHM?

Yes Reconnect all plugs and replace relay 1.

GO to B16

No

B 16:

END

Perform

a

ppropriate service drive cycle and check for the

presence of DTC.

1

Has th

e fault code cleared?

Yes STOP

No Contact Jaguar Service

PI

NPOINT TEST C : C: P0460

T

E

ST CONDITIONS

D

E

TAILS/RESULTS/ACTIONS

C1

: RETRIEVE DTC

S

•

NOTE

: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Page 1800 of 2490

Compressor:

Features

Engine mounted, driven by the accessory drive belt. Fixed displacement type. High-pressure relief valve, to avoid system over-pressure. ECM controlled clutch energized via a relay.

Receiver drier:

Vertically mounted on the ri ght-hand side of the engine compartment next to the engine coolant radiator. Fitted with the high-side charge port. Includes a fluorescent tracer dye me chanism to aid leak detection.

ItemPart NumberDescription

1—Compressor assembly

2—Condenser

3—Evaporator and heater matrix (internal)

4—Receiver drier

5—4-level pressure switch

6—Expansion valve (internal)

7—High-side charge port

8—Low-side charge port

9—Suction muffler

10—Discharge hose

11—Discharge pipe

12—Suction hose

13—Suction pipe

14—Liquid line

15—Jumper hose (condenser hose)

Page 1831 of 2490

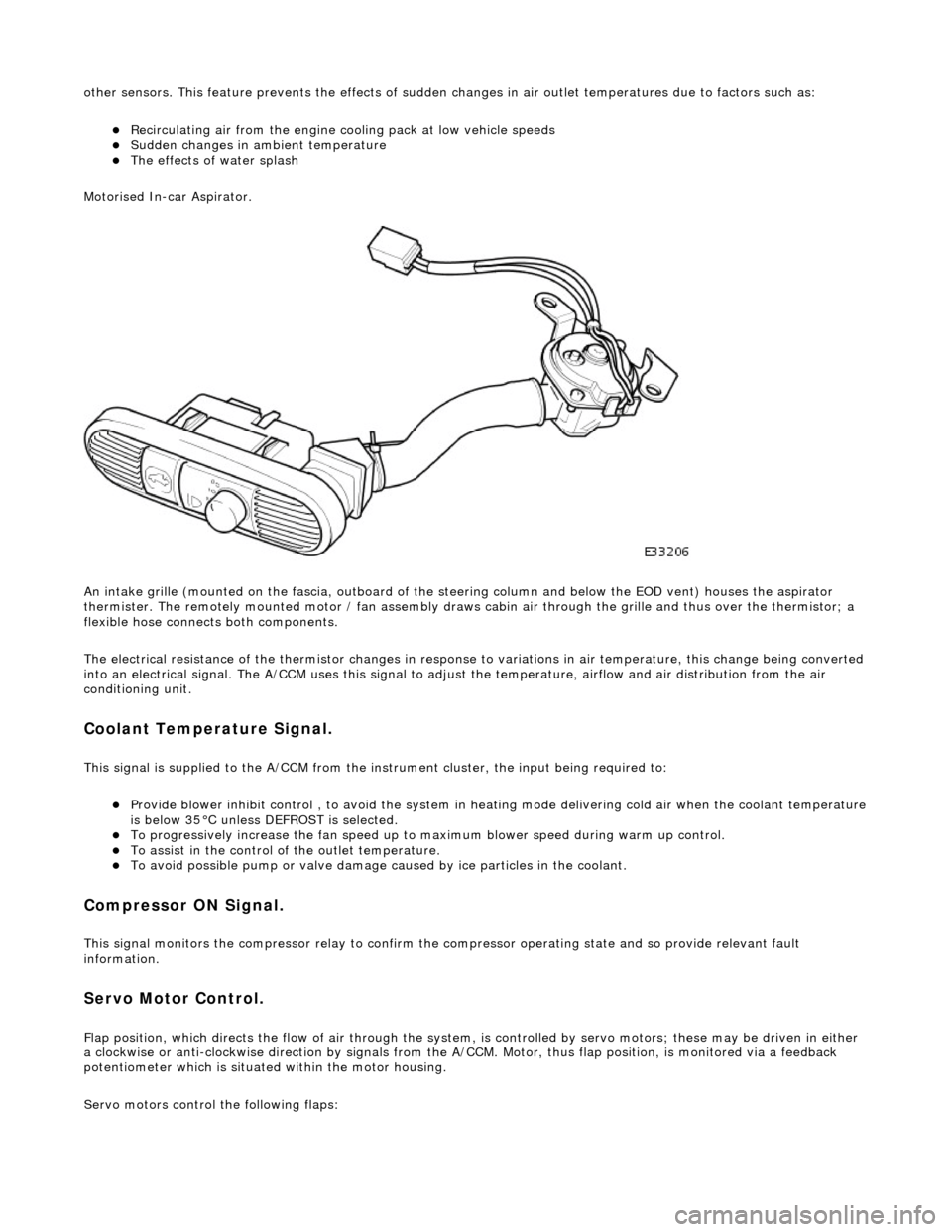

other sensors. This feature prevents the effects of sudden changes in air outlet temperatures due to factors such as:

Recirculating air from the engine cooling pack at low vehicle speeds Sudden changes in ambient temperature The effects of water splash

Motorised In-car Aspirator.

An intake grille (mounted on the fascia , outboard of the steering column and below the EOD vent) houses the aspirator

thermister. The remotely mounted motor / fan assembly draws ca bin air through the grille and thus over the thermistor; a

flexible hose connects both components.

The electrical resistance of the thermistor changes in response to variations in air temperatur e, this change being converted

into an electrical signal. The A/CCM uses this signal to adjust the temperature, airflow and air distribution from the air

conditioning unit.

Coolant Temperature Signal.

This signal is supplied to the A/CCM from the instrument cluster, the input being required to:

Provide blower inhibit control , to avoid the system in heat ing mode delivering cold air when the coolant temperature is below 35°C unless DEFROST is selected. To progressively increase the fan speed up to maximum blower speed during warm up control. To assist in the control of the outlet temperature. To avoid possible pump or valve damage ca used by ice particles in the coolant.

Compressor ON Signal.

This signal monitors the compressor relay to confirm the compressor operating state and so provide relevant fault

information.

Servo Motor Control.

Flap position, which directs the flow of air through the system, is controlled by servo motors; these may be driven in either

a clockwise or anti-clockwise direction by signals from the A/ CCM. Motor, thus flap position, is monitored via a feedback

potentiometer which is situated within the motor housing.

Servo motors control the following flaps:

Page 1833 of 2490

Control Components - Control Components

Diagnosis and Testing

Connector Pin Identity Chart for AC001

Connector Pin Identity Chart for AC002

Pin NumberCircuitCircuit Function

001Compressor ON signal

002Coolant valve

003RH Blower motor relay

004Heated windshield relays (where fitted)

005Heated door mirror relay

006Defrost servomotor (positive)

007Center vent servomotor (positive)

008LH air intake servomotor fre sh / recirculation (positive)

009RH air intake servomotor fresh / recirculation (positive)

010Not used

011Not used

012Foot servomotor (positive)

013Cool air bypass servomotor (positive)

014Not used

015Not used

016LH Blower motor relay

017Coolant pump motor relay

018Heated backlight relay

019Defrost servomotor (negative)

020Center vent servomotor (negative)

021LH air intake servomotor fresh / recirculation (negative)

022RH air intake servomotor fresh / recirculation (negative)

023Not used

024Not used

025Foot servomotor (negative)

026Cool air bypass servomotor (negative)

Page 1835 of 2490

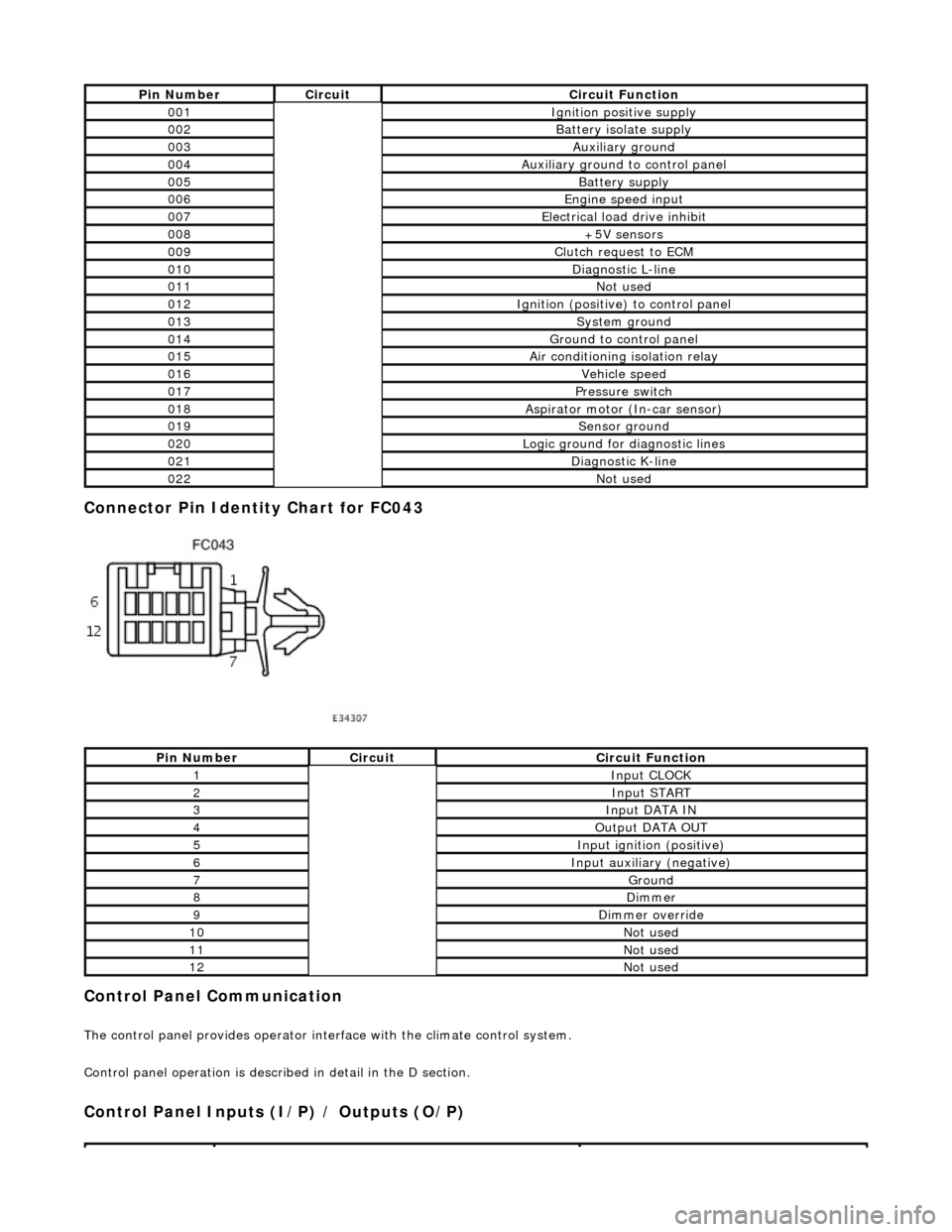

Connector Pin Identity Chart for FC043

Control Panel Communication

The control panel provides operator interface with the climate control system.

Control panel operation is described in detail in the D section.

Control Panel Inputs (I/P) / Outputs (O/P)

Pin NumberCircuitCircuit Function

001Ignition positive supply

002Battery isolate supply

003Auxiliary ground

004Auxiliary ground to control panel

005Battery supply

006Engine speed input

007Electrical load drive inhibit

008+5V sensors

009Clutch request to ECM

010Diagnostic L-line

011Not used

012Ignition (positive) to control panel

013System ground

014Ground to control panel

015Air conditioning isolation relay

016Vehicle speed

017Pressure switch

018Aspirator motor (In-car sensor)

019Sensor ground

020Logic ground for diagnostic lines

021Diagnostic K-line

022Not used

Pin NumberCircuitCircuit Function

1Input CLOCK

2Input START

3Input DATA IN

4Output DATA OUT

5Input ignition (positive)

6Input auxiliary (negative)

7Ground

8Dimmer

9Dimmer override

10Not used

11Not used

12Not used