manifold JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1764 of 2490

Clima

te Control System - General Inform

ation - Manifold Gauge Set Connection

Ge

neral Procedures

Mani

fol

d.

Low Side Pressure Gauge.

High Side Pressure Gauge.

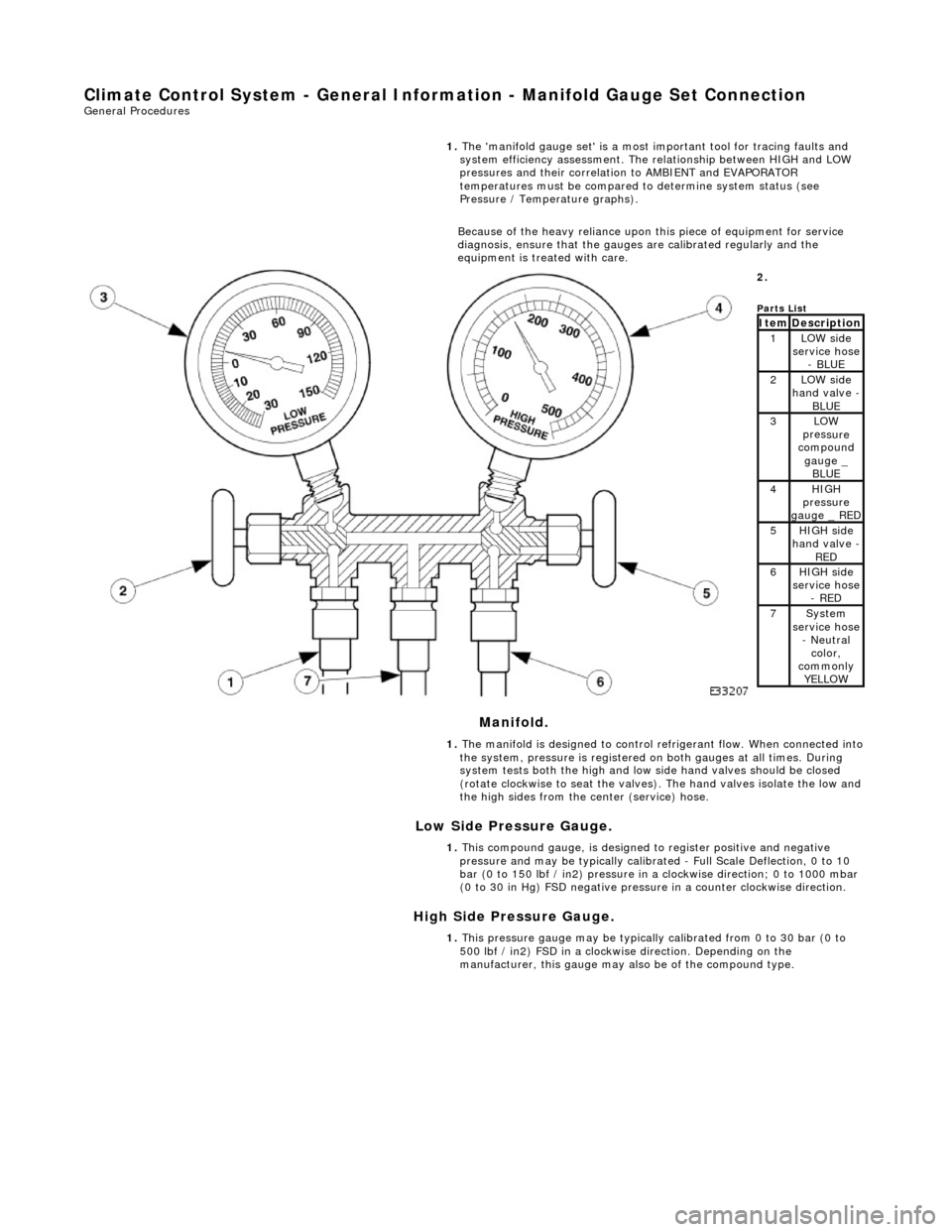

1.

The 'ma

nifold gauge set' is a most important tool for tracing faults and

system efficiency assessment. The relationship between HIGH and LOW

pressures and their correlation to AMBIENT and EVAPORATOR

temperatures must be compared to determine system status (see

Pressure / Temperature graphs).

Because of the heavy reliance upon this piece of equipment for service

diagnosis, ensure that the gauges are calibrated regularly and the

equipment is treated with care.

2.

Parts

List

ItemDescri

ption1LOW side

serv

ice hose

- BLUE

2LOW side

ha

nd valve -

BL

UE3LOW

pres

sure

compound

gauge _ BLUE

4HI GH

pressure

gauge _ RED

5HI GH

side

hand valve -

RED6HI GH

side

service hose

- RED

7Sys t

em

service hose

- Neutral color,

commonly YELLOW

1. The manifold is designed to control refrigerant flow. When connected into

the system, pressure is registered on both gauges at all times. During

system tests both the high and low side hand valves should be closed

(rotate clockwise to seat the valves). The hand valves isolate the low and

the high sides from the center (service) hose.

1. This compound gauge, is designed to register positive and negative

pressure and may be typically calibrate d - Full Scale Deflection, 0 to 10

bar (0 to 150 lbf / in2) pressure in a clockwise direction; 0 to 1000 mbar

(0 to 30 in Hg) FSD negative pressu re in a counter clockwise direction.

1. This pressure gauge may be typically calibrated from 0 to 30 bar (0 to

500 lbf / in2) FSD in a clockwise direction. Depending on the

manufacturer, this gauge may also be of the compound type.

Page 2242 of 2490

Instrument Panel and Console - Instrument Panel

Removal and Installation

Removal

1. Turn ignition switch to position II.

2. Motor driver and front passenger seats rearward.

3. Position steering wheel in stra ight ahead position and fully

lower and extend steering column.

4. Turn ignition switch to position O.

5. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

6. Remove 'J' gate finish er. Refer to 76.25.24.

7. Remove 'J' gate finisher retain ing panel. Refer to 76.25.26.

8. Remove centre console veneer panel. Refer to 76.47.26.

9. Disconnect and remove radio.

10. Remove centre console switch module. Refer to 86.80.32.

11. Remove centre console. Refer to 76.25.01.

12. Slacken and remove centre cons ole vent duct rear securing

screw and withdraw duct assemb ly from air conditioning unit

manifold.

13. WARNING: BEFORE ANY AIRBAG/SRS SERVICE IS

PERFORMED, AT LEAST ONE MINUTE MUST ELAPSE AFTER

DISCONNECTION OF THE BATTERY CABLE, TO ALLOW

DISSIPATION OF BACK-UP POWER SUPPLY ENERGY.

Remove driver airbag. Refer to 76.73.39.

14. Remove steering wheel. Refer to Section 211-04.

15. Remove steering column lo wer cowl. Refer to 76.46.03.

16. Remove steering column u pper cowl. Refer to 76.46.02.

17. Remove driver side unders cuttle. Refer to 76.46.11.

18. Remove combined windshield wiper/washer switch and

audible warning speaker assembly. Refer to 86.65.42.

19. Remove glovebox. Refer to 76.52.03.

20. Remove 'A' post lower trim pads. refer to 76.13.30.

21. Carefully withdraw driver stowage bin trim, remove bin

securing screw and remove bin from facia.

Page 2306 of 2490

Wipers and Washers - Wipers and Washers

Description and Operation

Windshield Wiper

The single wiper system is driven via a sh ort linkage, by an electric motor installed in (external on later models) a moulded

plastic weatherproof housing o ff the plenum wet area. The motor and housing are secured to the BIW bulkhead by three

bolts at the top and three screws (two on later models) with locking clips at the bottom. The complete assembly is handed

for left or right hand drive installation.

The windshield wiper is operated via the RH control column stalk switch. Operating modes are normal, high speed, flick wipe

and six settings of intermittent operation with delays ranging from 2 to 20 seconds.

Windshield Washer

The windshield washer is of wiper arm mounted running jet configuration. The je t assembly comprises two conventional

nozzles plus four nozzles of silicone rubbe r 'duckbill' design. If the system is initially operated at low ambient temperatures ,

the 'duckbill' nozzles permit an y frozen residual washer fluid to be ejected un der pump pressure. The washer jet feed tube

supplied assembled to the wiper ar m, fits at its lower end onto a central connector on the pl enum cover. Washer fluid is

conveyed by a rubber tube, from the washer pump to the jet assembly via a manifold on the underside of the plenum cover.

The windshield washer pump is installed on the rear face of the washer fluid reservoir. The 6.3 liter washer reservoir is

installed on the RH side of th e vehicle in a cavity formed by the front bu mper, the front wheel arch liner and the brake